Slope protecting method combining multi-hole concrete and grass vines

A porous concrete and concrete technology, which is applied in the field of landscaping engineering, can solve the problems of porous concrete damage, inconsistent grass growth, and large seasonal climate effects, and achieves the effect of good distribution and reduction of empty window periods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A porous concrete slope protection method combined with grass and vines, specifically comprising the following steps:

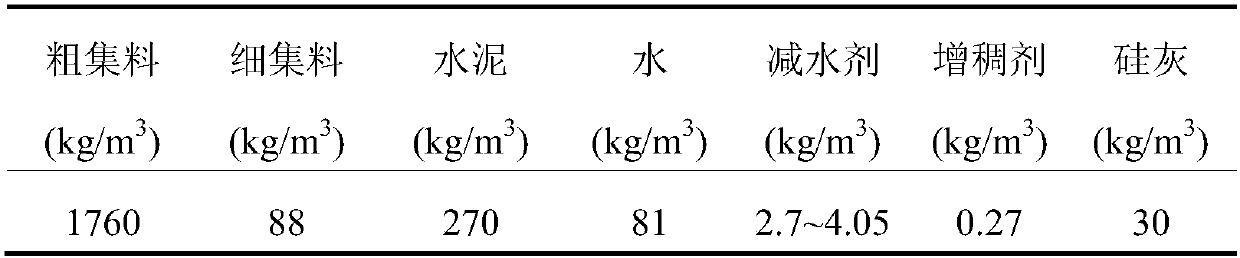

[0025] 1) Add 270 parts of cement and 30 parts of silica fume, a mineral admixture, into the concrete mixer and mix well, then add 64.8 parts of water and 3 parts of water reducing agent and mix for 90 seconds, then put in 1760 parts of coarse aggregate and 88 parts of fine aggregate 16.2 parts of water, 0.27 parts of thickener and mix for 120s;

[0026] 2) Level the soil base of the side slope of the road, and then lay a sand layer of about 5cm; the formwork is made of wooden formwork, processed on site, the upper end is fixed with wooden piles, and the lower end is pushed with heavy stones, and the formwork is reinforced to ensure that it is vibrated during pouring. Not out of shape afterward. When filling the mixture, first fill it to half of the mold, tamp it with a tamping stick, then continue to fill it up and vibrate it, the time is controlled ...

Embodiment 2

[0030] 1) Add 270 parts of cement and 30 parts of silica fume as a mineral admixture into the concrete mixer and mix well, then add 64.8 parts of water and 3.2 parts of water reducing agent and mix for 90 seconds, then put in 1760 parts of coarse aggregate and 88 parts of fine aggregate 16.2 parts of water, 0.27 parts of thickener and mix for 120s;

[0031]2) Level the soil base of the side slope of the road, and then lay a sand layer of about 5cm; the formwork is made of wooden formwork, processed on site, the upper end is fixed with wooden piles, and the lower end is pushed with heavy stones. Not out of shape. When filling the mixture, first fill it to half of the mold, tamp it with a tamping stick, then continue to fill it up and vibrate it, the time is controlled at about 45s, and the test piece after the vibration is scraped and formed with a spatula;

[0032] 3) Curing: Sprinkle water 1-2 times after each construction period after the initial setting, and cover it with ...

Embodiment 3

[0035] 1) Add 270 parts of cement and 30 parts of silica fume, a mineral admixture, into the concrete mixer and mix well, then add 64.8 parts of water and 3.5 parts of water reducer and mix for 90 seconds, then put in 1760 parts of coarse aggregate and 88 parts of fine aggregate 16.2 parts of water, 0.27 parts of thickener and mix for 120s;

[0036] 2) The soil base of the side slope of the level road. If it is a rocky slope, clean up the gravel on the surface of the slope, and chisel the surface to facilitate the combination of concrete and the surface of the slope. Then lay a sand layer of about 5cm; the formwork is made of wooden formwork, processed on site, the upper end is fixed with wooden piles, and the lower end is pushed up with heavy stones, and the formwork is reinforced to ensure that it will not lose its shape after pouring and vibration. When filling the mixture, first fill it to half of the mold, tamp it with a tamping stick, then continue to fill it up and vib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com