Rotating disc type multi-station numerical control machining platform

A processing platform, multi-station technology, applied in the direction of workbench, comprehensive factory control, manufacturing tools, etc., can solve the problems of difficult to optimize the rational allocation of resources, difficult to harmonize and unify processing time, and difficult to further improve the overall efficiency. The degree of flexible and reasonable configuration is improved, the operation efficiency is improved, and the effect of reducing the empty window period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

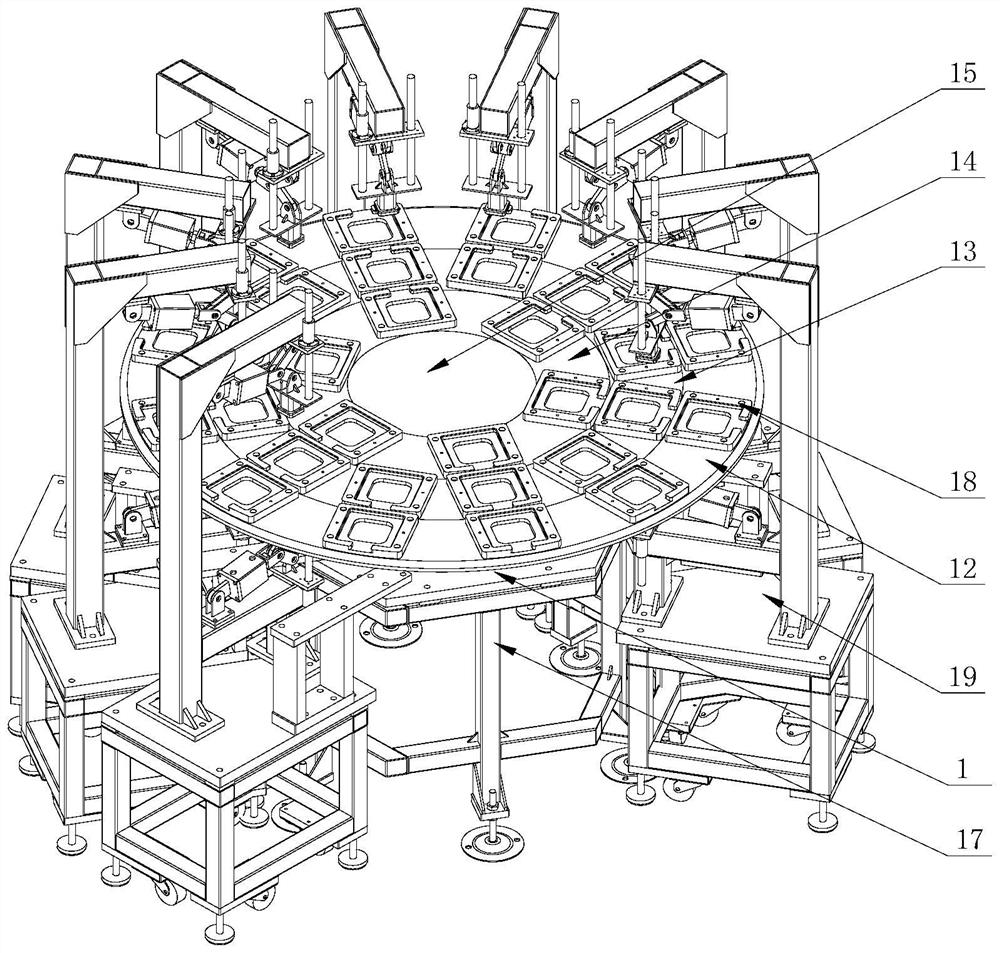

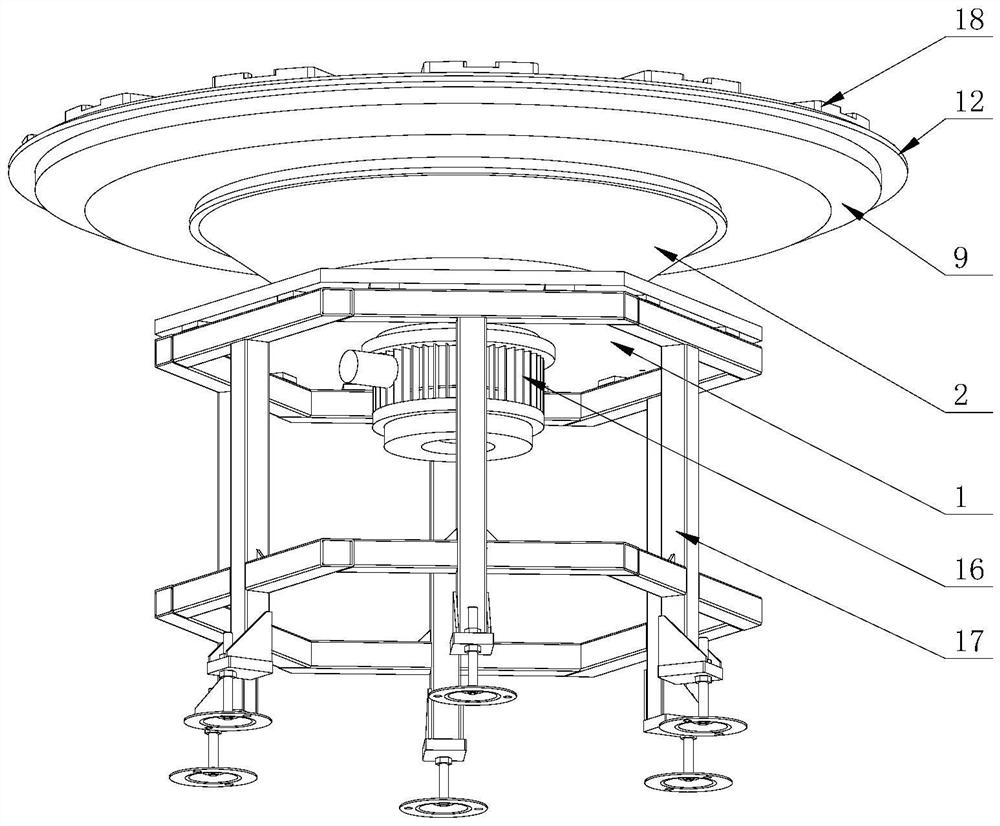

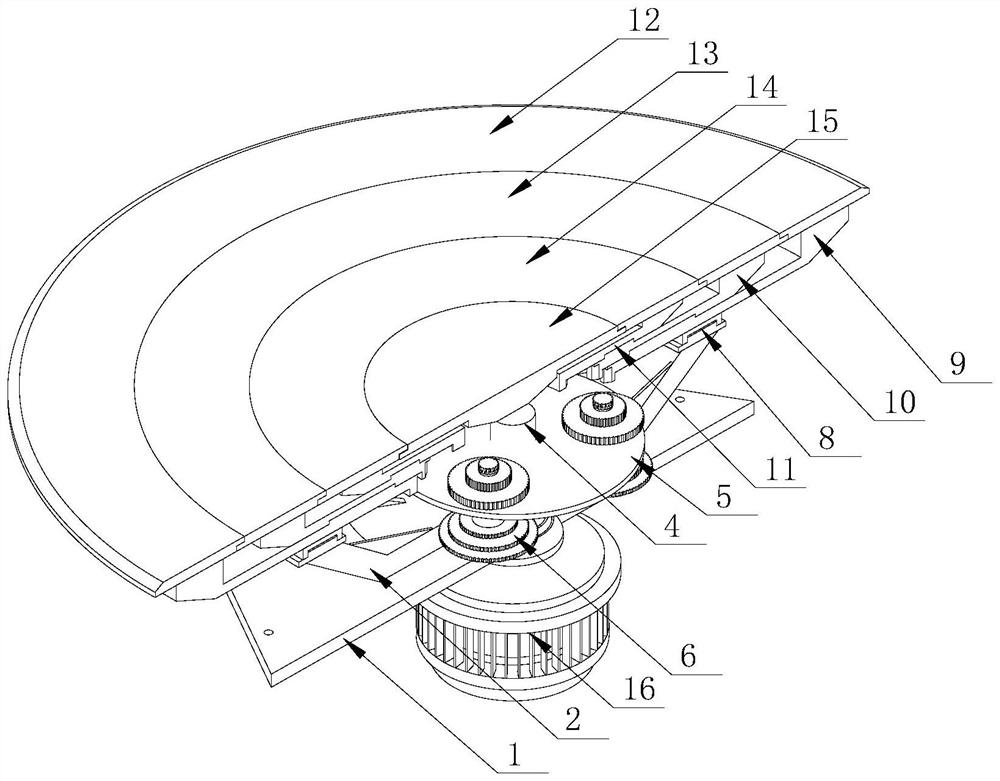

[0035] see Figure 1 to Figure 10 , The present invention provides a technical solution: a turntable multi-station CNC machining platform, comprising a platen 1, a support cylinder 3 is fixedly connected to the upper surface of the platen 1, and a support base 2 is fixedly connected to the surface of the support cylinder 3 , an outer support frame 9, a middle support frame 10 and an inner support frame 11 are arranged above the support base 2, and the upper surfaces of the outer support frame 9, the middle support frame 10 and the inner support frame 11 are respectively fixed with an outer support ring 12, a middle support frame Expander 13 and inner expander 14 .

[0036] The inner walls of the outer support frame 9, the middle support frame 10 and the inner support frame 11 are jointly engaged with several driving mechanisms 6. The surface of the support cylinder 3 is provided with a control mechanism 7 for controlling the driving mechanism 6. A drive shaft 4 which is drive...

Embodiment 2

[0039] It is basically the same as the first embodiment, and further is:

[0040] When a plurality of CNC stations 19 are in the process of synchronous processing, according to the processing time and complexity of different processes, several CNC stations 19 are allocated in proportion according to the processing steps from time to time. Position 19 performs staggered processing in three rotation intervals. When the CNC station 19 of the next process is processed, switch to another rotation interval for processing. At this time, the outer support ring 12, the middle support ring 13 and the inner support ring 14 The three rotation intervals of the 100°C are independently rotated. If the outer support ring 12 and the inner support ring 14 are being processed, the middle support ring 13 needs to be rotated. At this time, the corresponding electromagnetic ring 75 on the surface of the second control disk 72 is closed, so that it is in the metal position. The ring 74 loses the ads...

Embodiment 3

[0042] It is basically the same as the first embodiment, and further is:

[0043] When performing simple process processing, the outer support ring 12 and the middle support ring 13 are used to cooperate in the two processing rotation intervals. When the driver 16 rotates forward, the corresponding electromagnetic ring 75 on the surface of the third control disk 73 is closed, so that the outer support ring 75 is closed. The support ring 12 starts to rotate. After the station switching is completed, the electromagnetic ring 75 on the surface of the third control panel 73 is turned on. Then when the driver 16 is reversed, the electromagnetic ring 75 corresponding to the top of the second control panel 72 is closed, so that the second control panel 75 is closed. The meshing between the disc 72 and the second transmission gear 65 is completed, so that during the revolving and self-rotating process of the inner cylinder 62, the middle support ring 13 and the outer support ring 12 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com