A raw material weighing device for hollow brittle production

A raw material weighing and hollowing technology, applied in the direction of measuring devices, weighing, automatic feeding/discharging weighing equipment, etc., can solve the problems of manpower consumption and low efficiency, so as to improve production efficiency, improve accuracy, and meet The effect of using demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

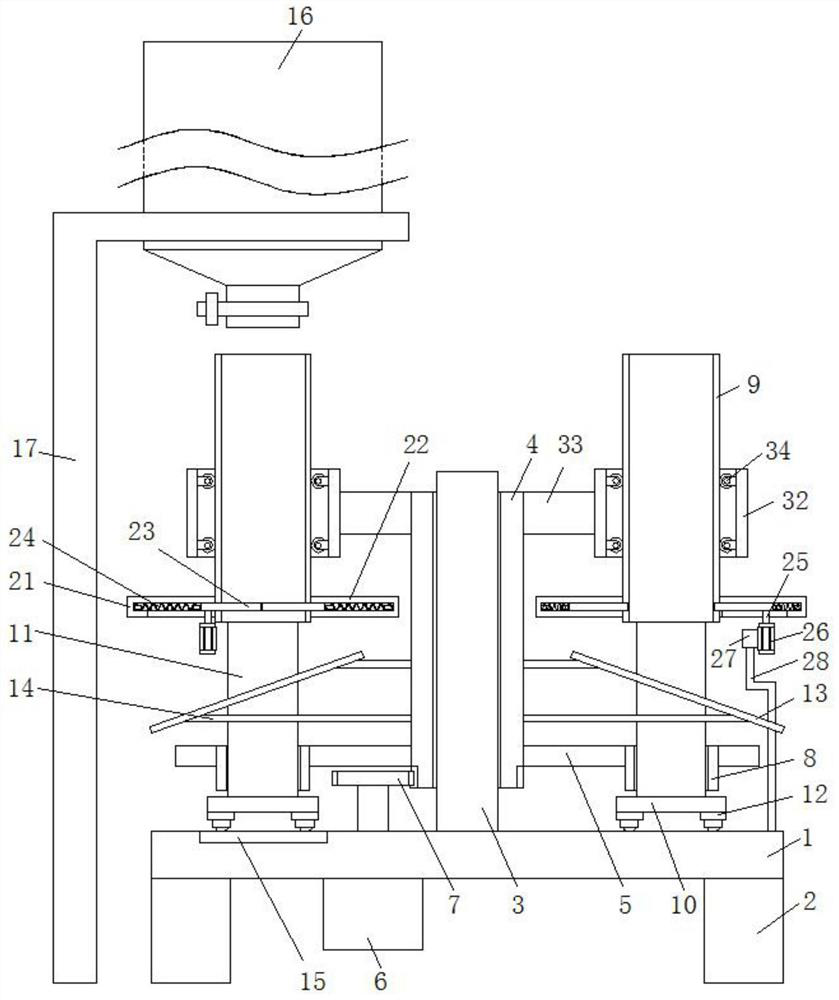

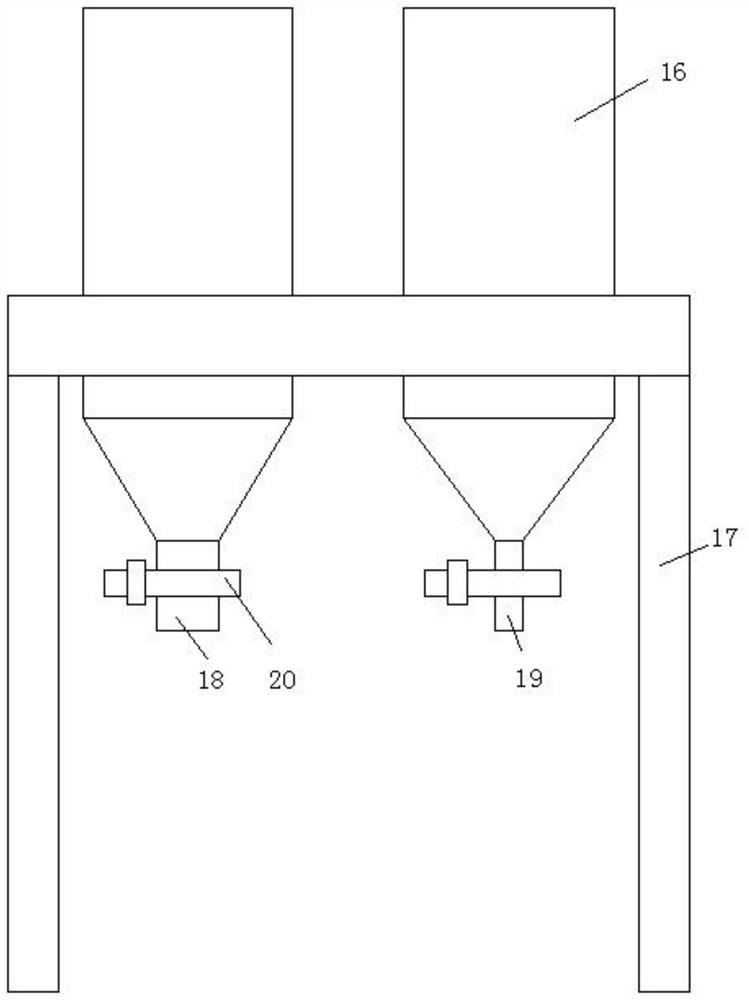

Embodiment 1

[0021] refer to Figure 1-4 , a raw material weighing device for hollow brittle production, comprising a device bottom plate 1, a plurality of feet 2 are arranged on the bottom side of the device bottom plate 1, the device bottom plate 1 is a circular structure, and the middle part of the top side of the device bottom plate 1 is fixedly connected with a middle Axis column 3, the outer rotation sleeve of the central axis column 3 is provided with a drum 4, the outer side of the drum 4 is fixedly connected with a turntable 5, one side of the device bottom plate 1 is fixed with a motor 6 by bolts, and the output shaft of the motor 6 is connected with Drive gear 7, the outside of the bottom end of drum 4 is provided with tooth grooves and meshed with drive gear 7, and the top side of device base plate 1 is provided with three stations, and the three stations are arranged in a regular triangle, and the plate body of turntable 5 is located at three Vertical through-holes are provide...

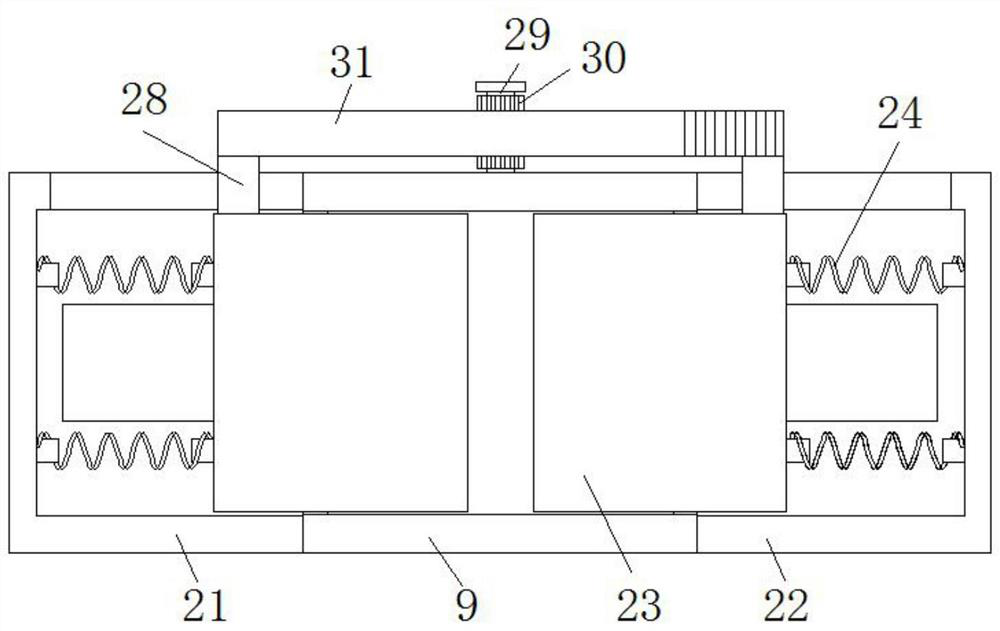

Embodiment 2

[0024] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the side box 1 21 is located on the side of the transfer bin 9 away from the drum 4, and the side box 2 22 is located on the side of the transfer bin 9 close to the drum 4. The cross section of the rotating seat 29 is a T-shaped structure.

[0025] In this embodiment, the movement of the one-side partition 23 is completed through the cooperation of the stressed roller 26 and the track plate 27, and then the two partitions are realized through the cooperation of the second connecting rod 28, the rotating seat 29, the gear cylinder 30 and the tooth plate 31. Simultaneous movement of the plate 23.

Embodiment 3

[0027] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the inclined material guide plate 13 is located on the side where the two supporting side plates 11 are close to each other, and the end of the inclined material guide plate 13 away from the drum 4 is inclined downward.

[0028] In this embodiment, the weighed materials are exported from the transfer bin 9 to the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com