Composite bearing for self-tightening drill chuck

A composite bearing and drill chuck technology, applied in the mechanical field, can solve the problems of the drill chuck falling apart and relying on threaded connection, etc., and achieve the effect of simple and compact structure, stable support and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

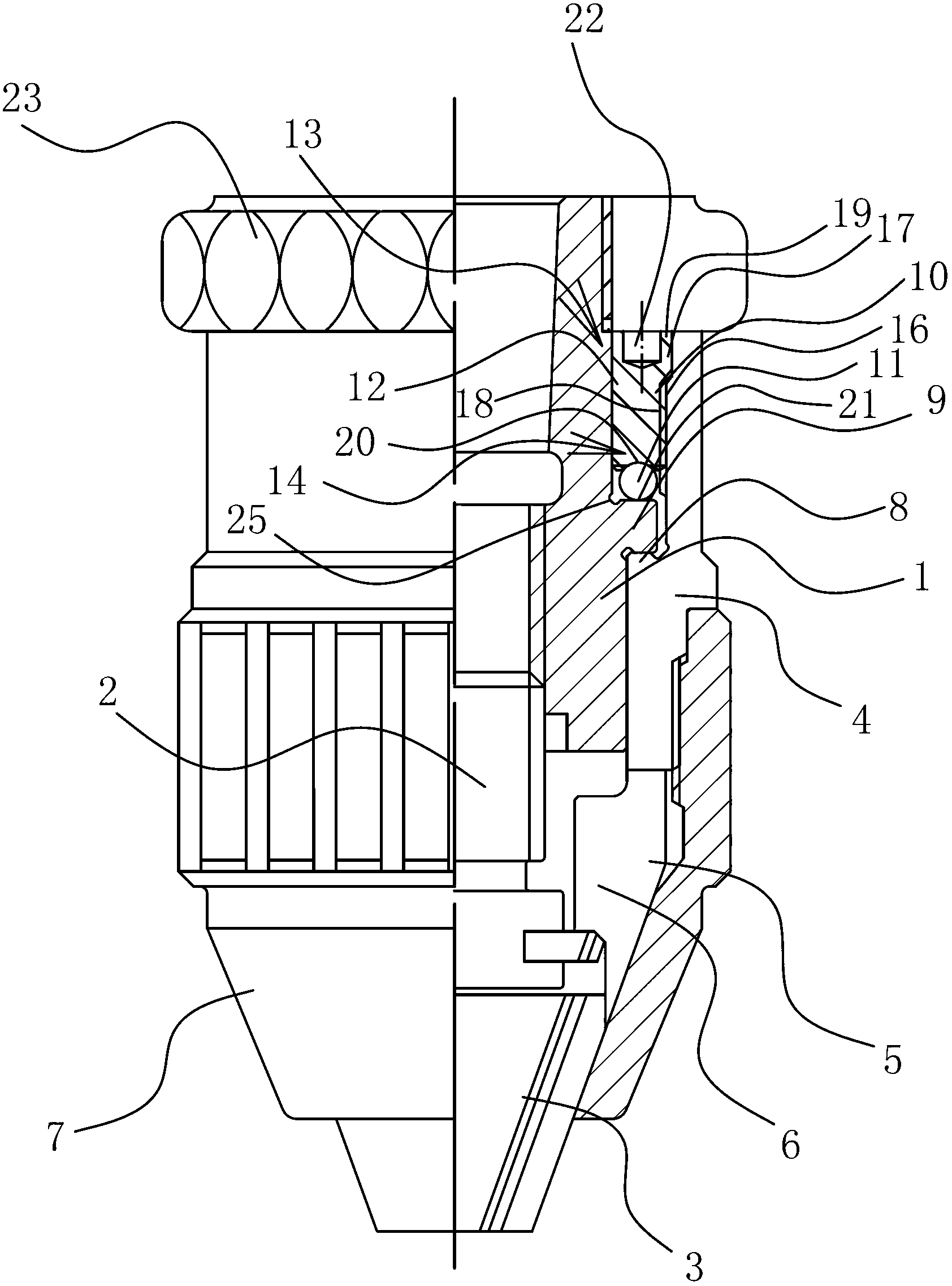

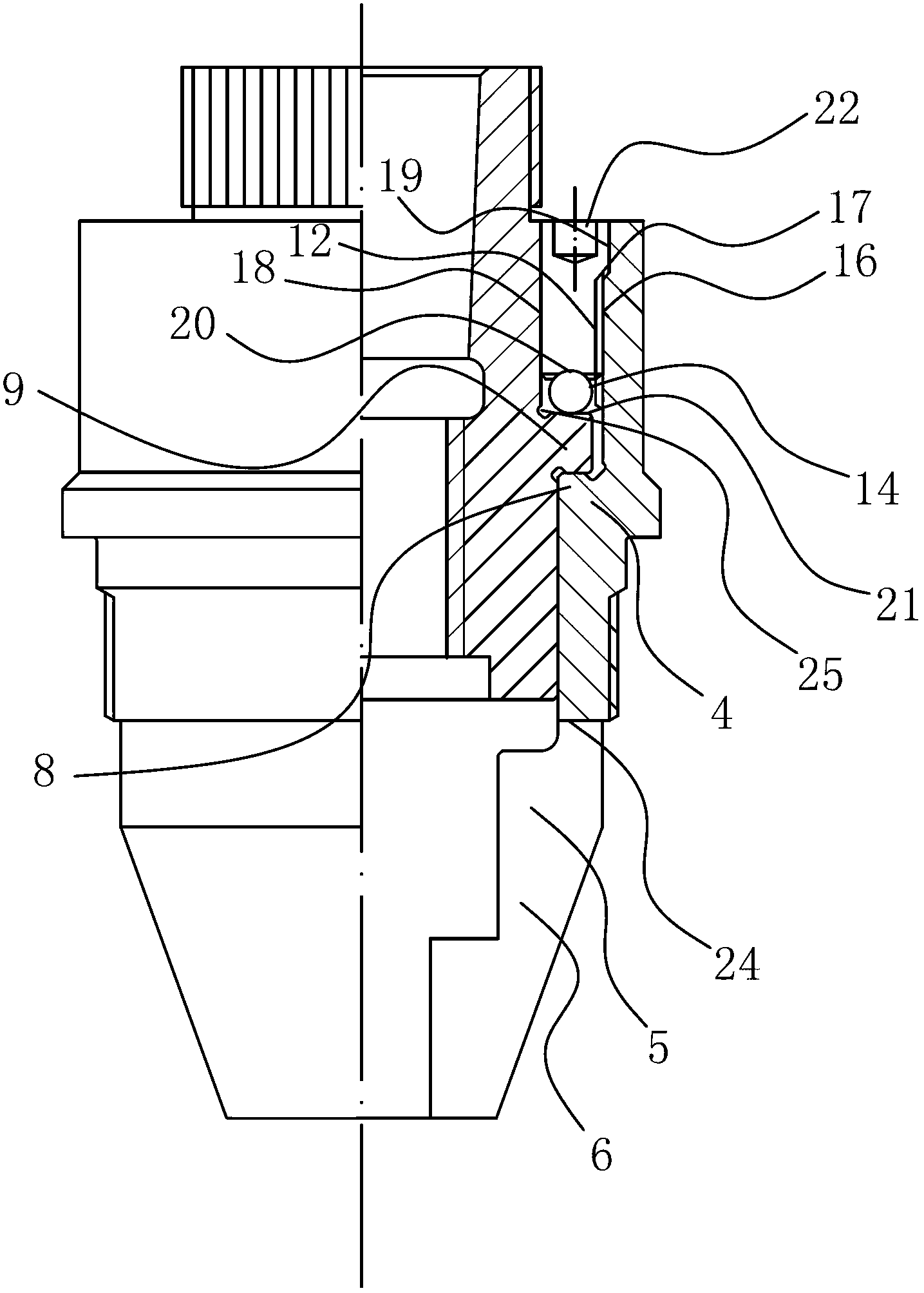

[0019] Such as figure 1 with 2 As shown, the self-tightening drill chuck includes a main body 1, a locking screw 2, a jaw 3, an end cover 7, a shaft seat 10, a ball 11, an elastic sleeve 23, an integrated bearing seat 24 and other components. More specifically, the self-tightening drill chuck includes a cylindrical main body 1, the main body 1 is arranged in a cylindrical one-piece guide seat 24, and the upper part of the one-piece guide seat 24 is a cylindrical whole Type bearing part 4, the lower part is the jaw guide rail part 5 that is conical cylinder. That is, the integral guide seat 24 is divided into two functions: the integral guide portion 4 and the jaw guide rail portion 5 , and the integral guide portion 4 and the jaw guide rail portion 5 are of an integral structure. The composite bearing used for the self-tightening drill chuck is an integral part of the self-tightening drill chuck, including a cylindrical shaft seat 10, which is fixed between the radial direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com