Automatic feeding device of high-precision bidirectional hammer type forging press

A technology of automatic feeding and forging presses, applied in forging/pressing/hammer devices, operating devices, metal processing equipment, etc., can solve problems such as burns of operators, loosening and damage of motors and fixing plates, etc., so as to improve the service life and avoid The effect of excessive temperature and safe working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

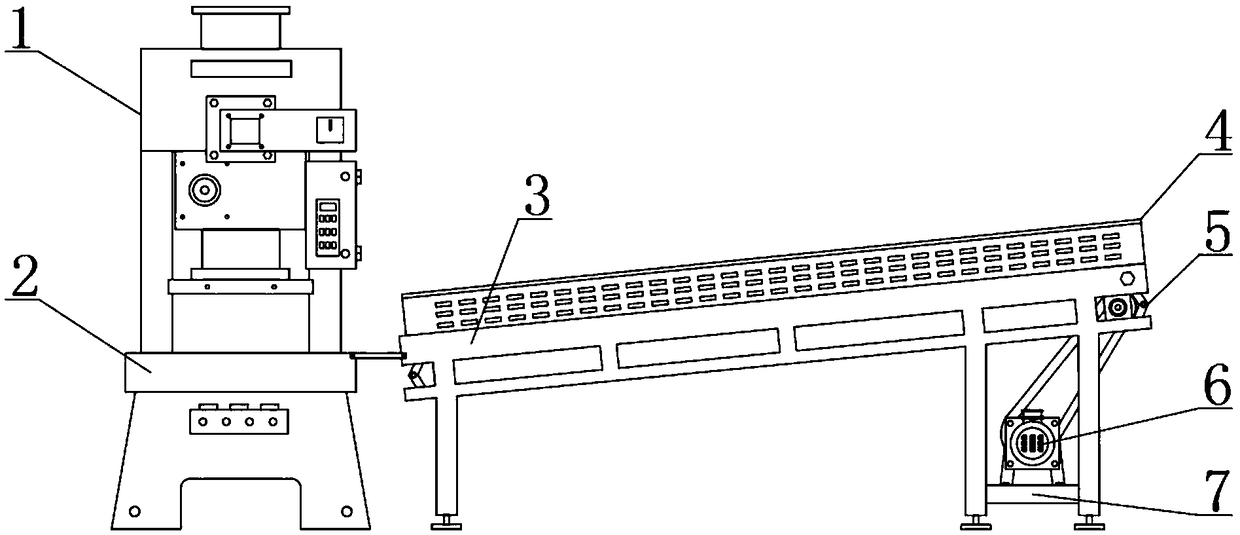

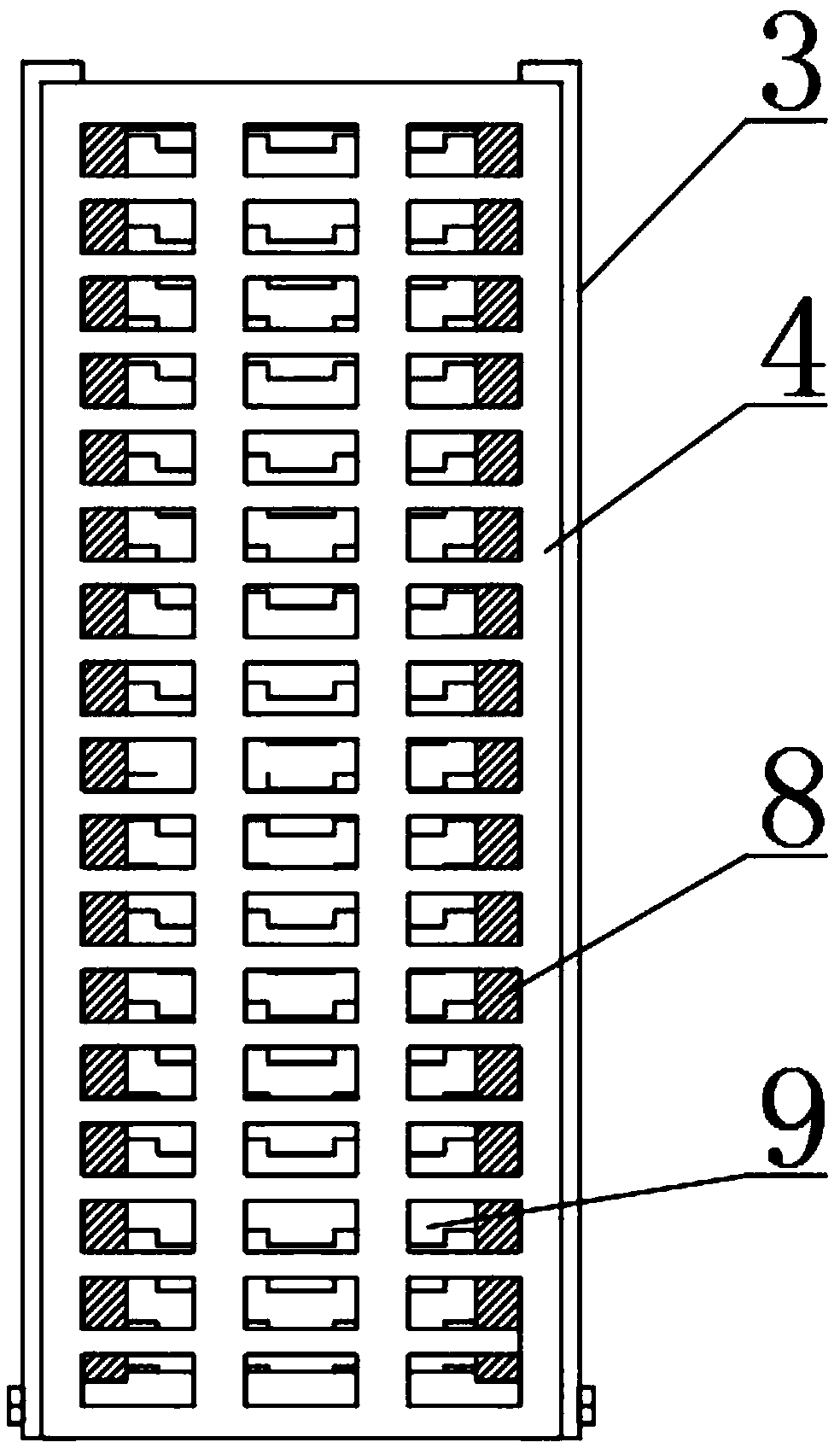

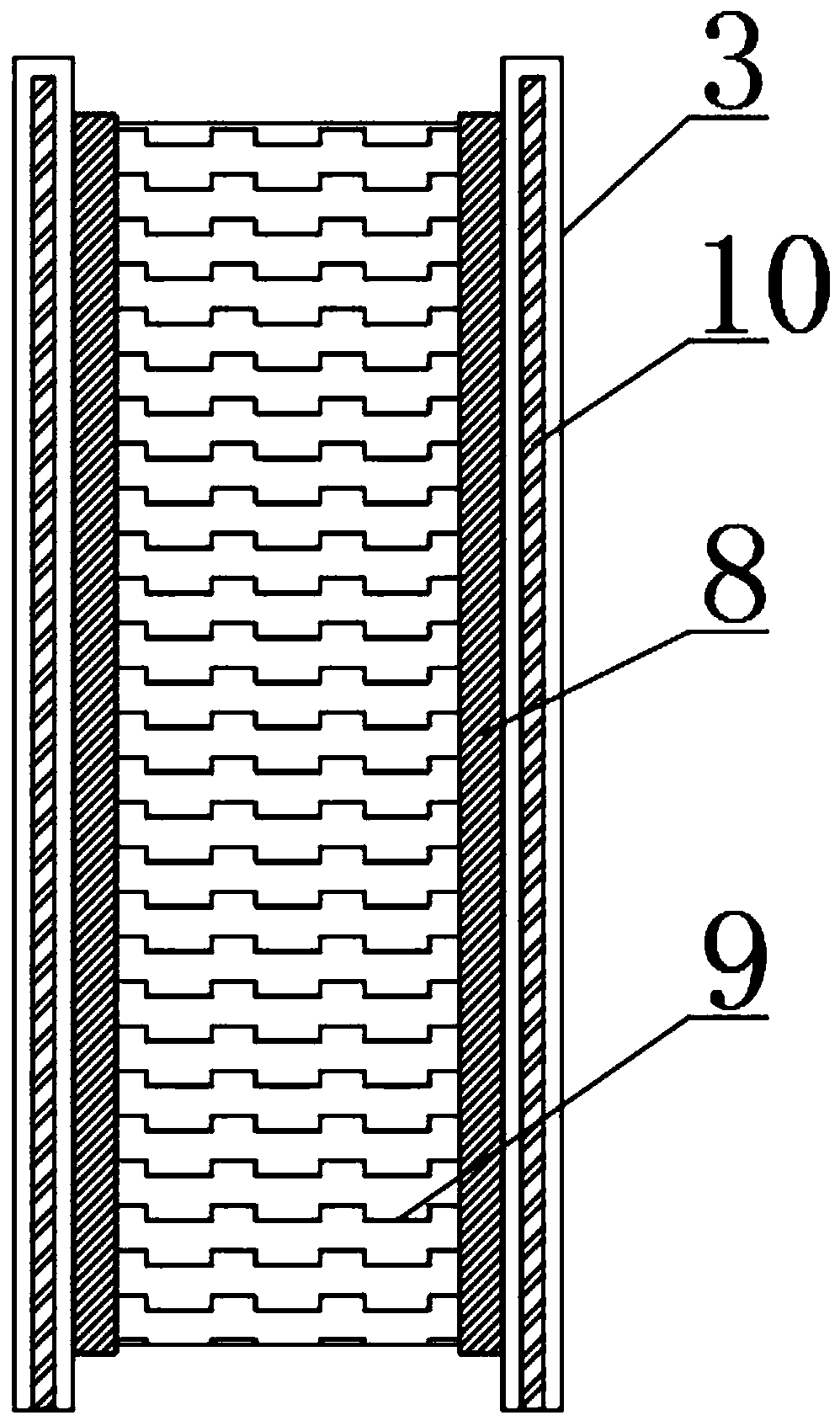

[0030] see Figure 1 to Figure 7 , the present invention provides a technical solution: an automatic feeding device for a high-precision two-way hammer forging press, including a forging press 1, a transmission chain belt 5, a forging panel 2 is provided at the bottom of the forging press 1, and a forging panel 2 The side is connected with a conveyor 3 through a movable connector, and the interior of the conveyor 3 is provided with a conveying panel 9, and the two sides of the conveying panel 9 are connected with the conveyor 3 through a transmission chain belt 5, and the top of the conveyor 3 is fixed by a bolt. Guard plate 4, and the bottom of both sides of guard plate 4 is provided with integrated slide block 11, and the top of both sides of conveyor 3 is provided with guard plate chute 10, and slide block 11 is in the inside of guard plate chute 10, guard plate Heat dissipation holes are distributed on the surface of the board 4 .

[0031] In order to fix the bottom of th...

Embodiment 2

[0039] see figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 , the present invention provides a technical solution: an automatic feeding device for a high-precision two-way hammer forging press, including a forging press 1, a transmission chain belt 5, a forging panel 2 is provided at the bottom of the forging press 1, and a forging panel 2 The side is connected with a conveyor 3 through a movable connector, and the interior of the conveyor 3 is provided with a conveying panel 9, and the two sides of the conveying panel 9 are connected with the conveyor 3 through a transmission chain belt 5, and the top of the conveyor 3 is fixed by a bolt. Guard plate 4, and the bottom of both sides of guard plate 4 is provided with integrated slide block 11, and the top of both sides of conveyor 3 is provided with guard plate chute 10, and slide block 11 is in the inside of guard plate chute 10, guard plate Heat dissipation holes are distributed on the surface of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com