Complete stroke thermal insulating cover for continuous casting conveying roller way

A conveying roller table, the whole process technology, applied in the field of continuous casting, can solve the problems of large temperature drop of billet, waste of energy, increase of unsafe factors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

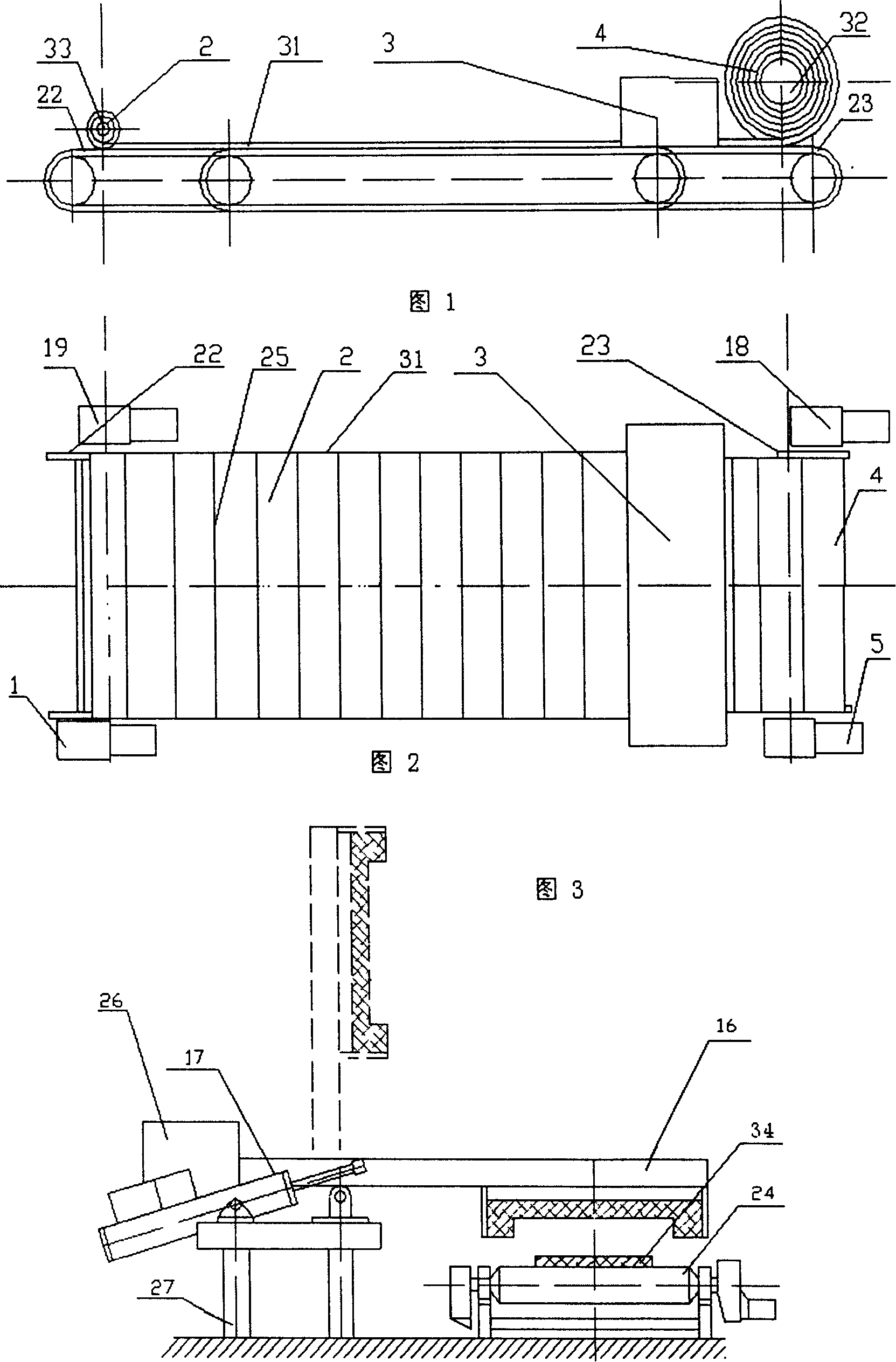

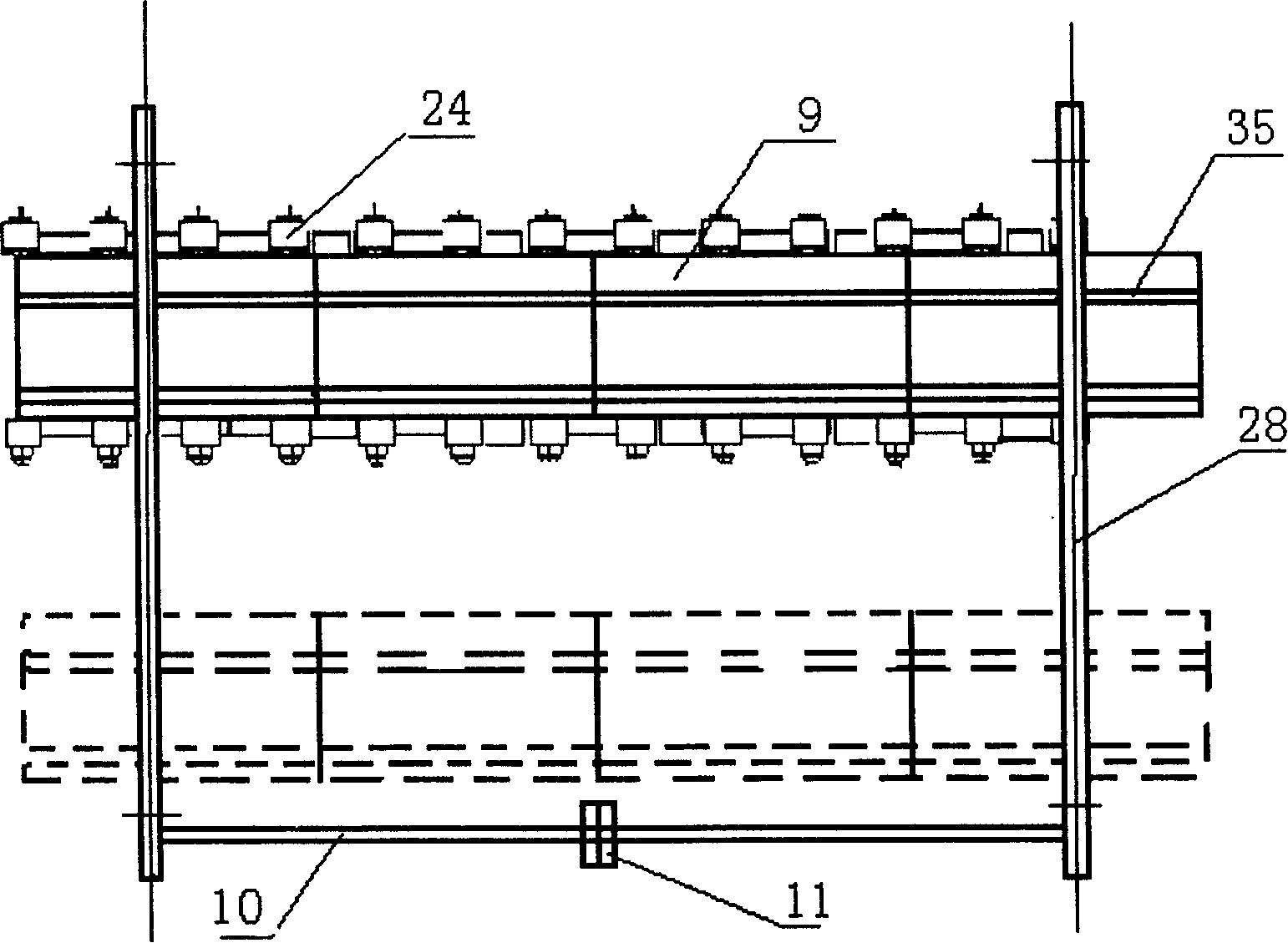

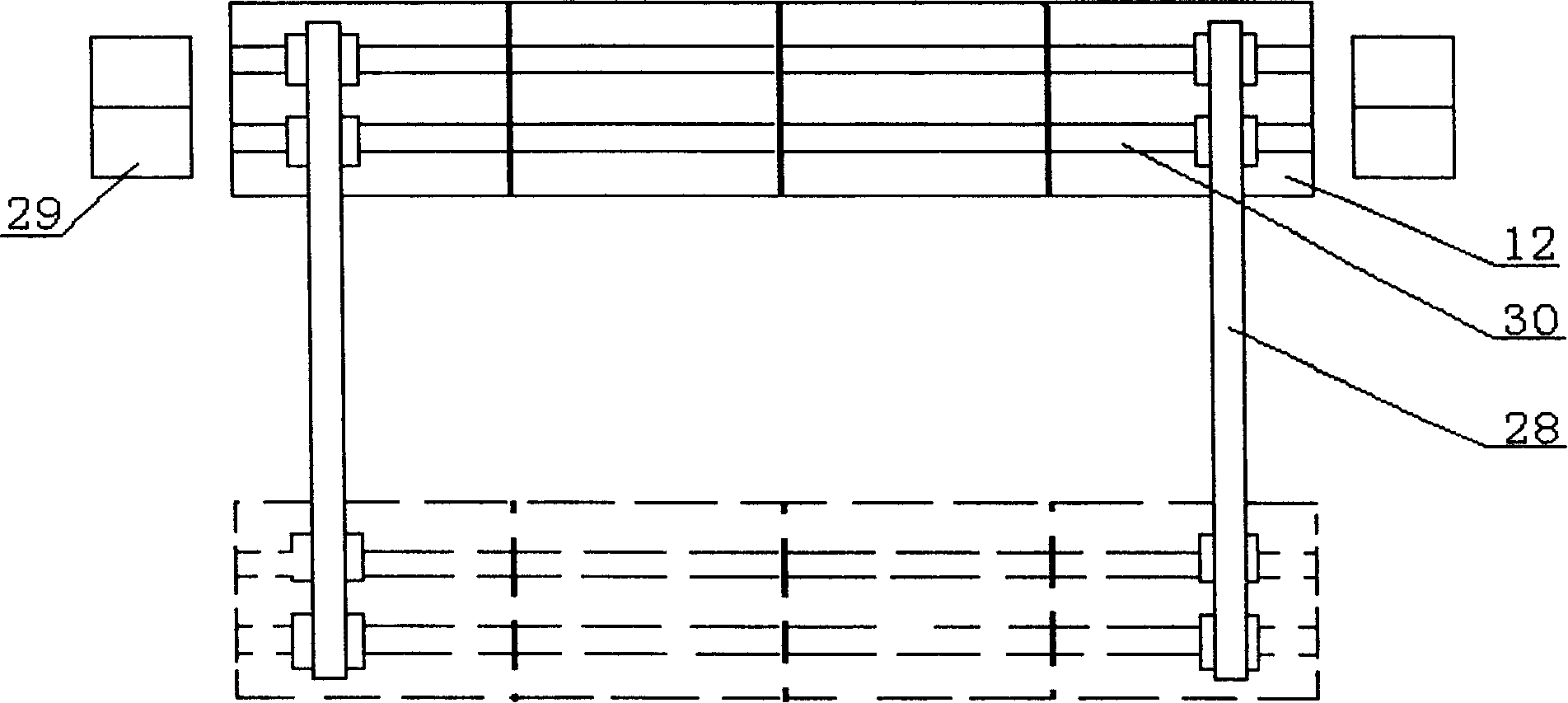

[0017] The present invention will be further described below with reference to the accompanying drawings. According to the characteristics of three different conveying rollers, the whole process heat preservation cover of the present invention designs three corresponding heat preservation covers, including a pull-out heat preservation cover, a tilting heat preservation cover and a translation heat preservation cover. They can be opened, they are independent of each other during the working process, and can act independently, and cooperate with each other during production to form a full-range heat preservation cover system for the continuous casting output roller table.

[0018] The present invention takes two continuous casting machines as an example to provide a two-in-one conveying roller table for casting slabs for a heating furnace of a rolling mill. Two conveying roller tables of the continuous casting machine with the same structure are arranged in parallel, including t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com