Automatic bending device for metal glasses frame machining

A technology for bending devices and spectacle frames, which can be used in metal processing, metal processing equipment, manufacturing tools, etc., and can solve problems such as inability to bend spectacle frames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

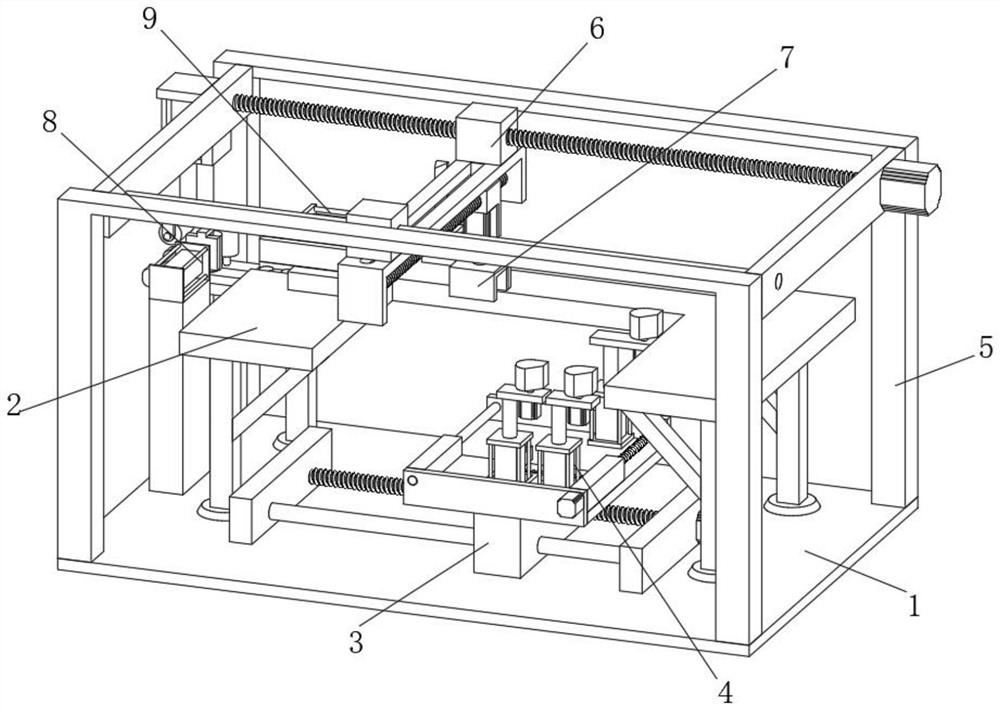

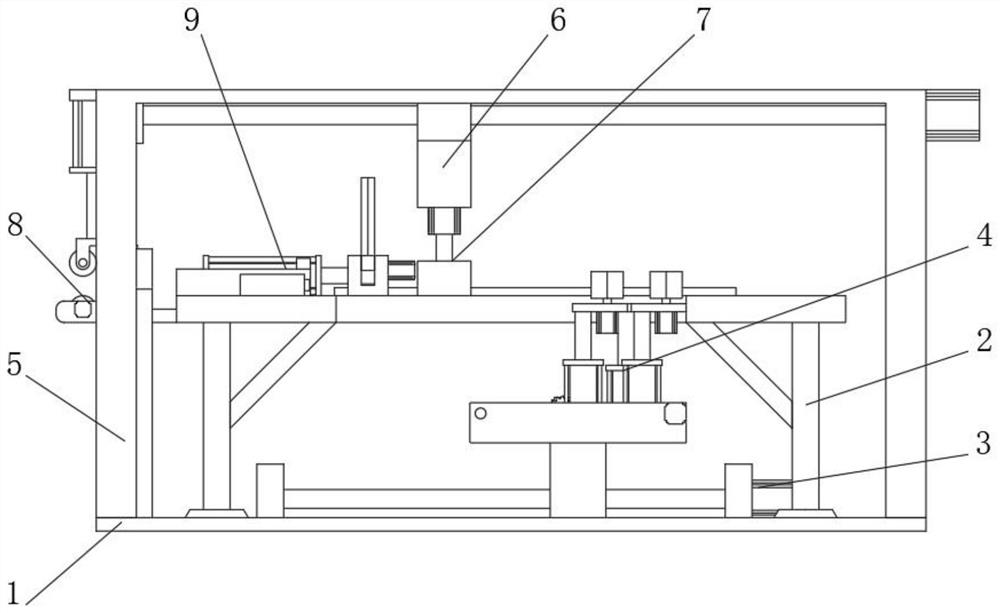

[0039] see figure 1 , Figure 10 , Figure 11 , the present invention provides a technical solution:

[0040] An automatic bending device for processing metal spectacle frames. The device is opened before use, and the metal strip of the spectacle frame is compressed and transmitted through the compression transmission mechanism 8. At the same time, the thickness of the metal strip can be checked by the thickness detection mechanism 10. For detection, when the metal strip is transported to the surface of the workbench 2, the clamp driving mechanism 6 operates to drive the clamp 7 to move laterally on the surface of the workbench 2, so that the metal strip can be inserted into the clamp 7 and clamped by the clamp 7. Clamping the metal strip can pull the metal strip to move laterally on the surface of the workbench 2. At the same time, according to the size of the spectacle frame to be bent, the bending mechanism driving mechanism 3 is turned on, and the driving screw 304 is op...

Embodiment 2

[0044] see Figure 10 , on the basis of Embodiment 1, the present invention provides a technical solution:

[0045] An automatic bending device for processing metal spectacle frames. The device is equipped with a hydraulic cylinder 1 402, a hydraulic cylinder 2 413 and a telescopic rod 3 424 on the base 401, and the hydraulic cylinder 1 402 drives the telescopic rod 1 403 to connect the shaft lifting platform 1 404 slides up and down, so that the height of the bending block 1 406 installed on the lifting platform 1 404 changes, and the operation of the motor 2 405 can drive the bending block 1 406 to rotate on the surface of the lifting platform 1 404 to change direction. Similarly, the hydraulic cylinder 2 413 The height of bending block 2 417 can be changed and motor 4 416 can change the angle of bending block 2 417, hydraulic cylinder 3 423 can change the height of bending block 3 427 and motor 6 426 can change the angle of bending block 1 406, So that when the first bendi...

Embodiment 3

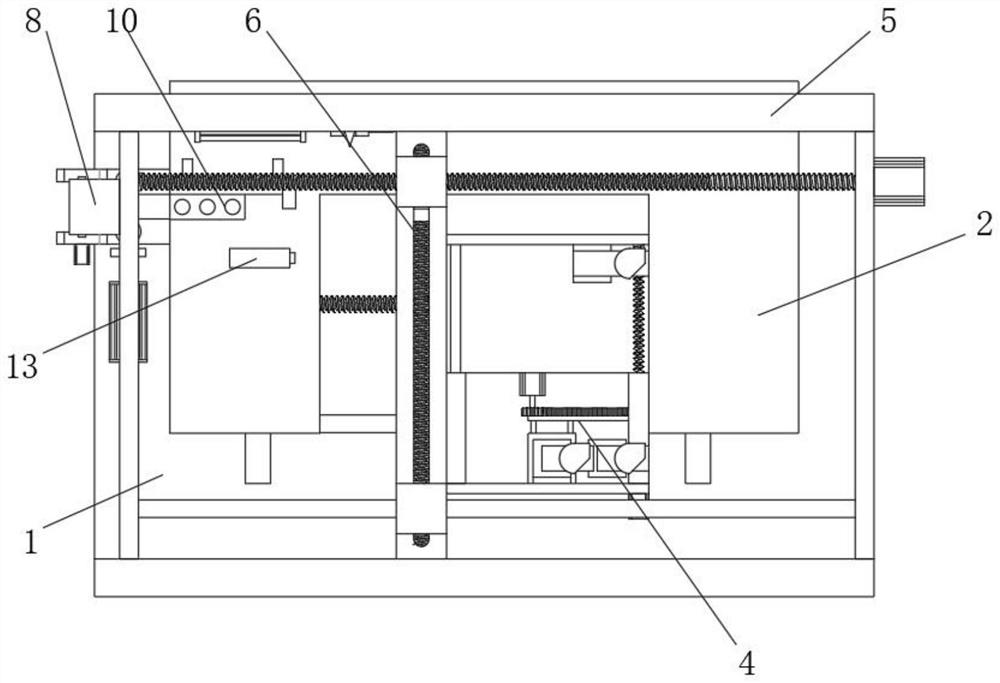

[0047] see figure 1 , Figure 5 , Image 6 , Figure 9 , on the basis of Embodiment 1, the present invention provides a technical solution:

[0048] An automatic bending device for processing metal spectacle frames. When the compression transmission mechanism 8 compresses and transmits the metal strip, one end of the metal strip is first inserted between the lower compression wheel 803 and the upper compression wheel 813, and the Cylinder 6 810 drives telescopic rod 5 811 to connect the mounting block 3 812 to slide down, so that the upper pinch wheel 813 hinged on the mounting block 3 812 slides downward and clamps the metal strip up and down with the lower pinch wheel 803, and then the motor 10. 802 runs and drives the lower pressing wheel 803 to rotate on the two sets of mounting frames 801. Through the cooperation of the mounting frame 801 and the upper pressing wheel 813, the metal strip can be compressed and transmitted to the left pressing wheel 805 and the right pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com