Double-movable-frame jig device for automobile checking fixture

A technology of a fixture device and a movable frame, which is applied in the direction of using a mechanical device, a measuring device, a mechanical measuring device, etc., can solve the problems such as the weak adjustment ability of the fixture device, and achieve the effect of improving the adjustment ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

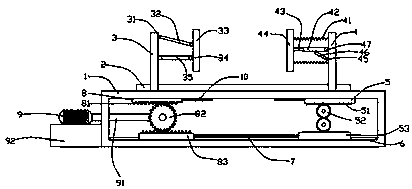

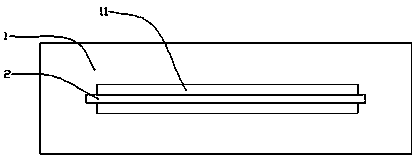

[0025] see Figure 1~2 , in an embodiment of the present invention, a double movable frame fixture device for automobile inspection tools, including a workbench 1, a first slide rail 2, a first movable frame 3, a second movable frame 4, a first fixed plate 8, a second Slide rail 6, linkage rod 7, second fixed plate 5, motor 9 and limit plate 10, described first slide rail 2 is fixed on the top of workbench 1, and described first movable frame 3 and second movable frame 4 Both are slidingly connected with the first slide rail 2, the first movable frame 3 and the second movable frame 4 can move freely on the first slide rail 2, and the first movable frame 3 is provided with a first rotating shaft 31, so The first rotating shaft 31 is rotatably connected to the first clamp 33 through the first connecting rod 32, and the first clamp 33 is rotatably connected to the second connecting rod 35 through the second rotating shaft 34. The other side of the second connecting rod 35 Also r...

Embodiment 2

[0028] The difference between this embodiment of the present invention and Embodiment 1 is that the motor 9 is installed on a placement table 92 , and both the placement table 92 and the motor 9 are located outside the workbench 1 .

[0029] The working principle of the present invention is: the motor 9 drives the first gear 82 to rotate clockwise, and the first gear 82 meshes with the first teeth 81 on the first fixed plate 8 to drive the first movable frame 3 on the first slide rail. 2 to move to the right, and the first gear 82 meshes with the first teeth 81 on the first sliding plate 83 below, driving the first sliding plate 83 to move to the left on the second slide rail 6, through the linkage rod 7 , it can drive the second sliding plate 53 to move leftward on the second slide rail 6, and through the action of the two second gears 52, it can drive the second mobile frame 4 to move leftward, through the first clamp 33 and the second clamp 44 Clamp the vehicle inspection f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com