Electric heating plate

A technology of electric heating and heating plate, applied in the direction of heating element shape, etc., can solve the problems of easy desoldering of conductive electrode coating and conductive terminal, low energy conversion efficiency, and low energy efficiency of electric ceramic furnace, so as to avoid poor contact , Good heat conduction effect, good conduction effect of electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

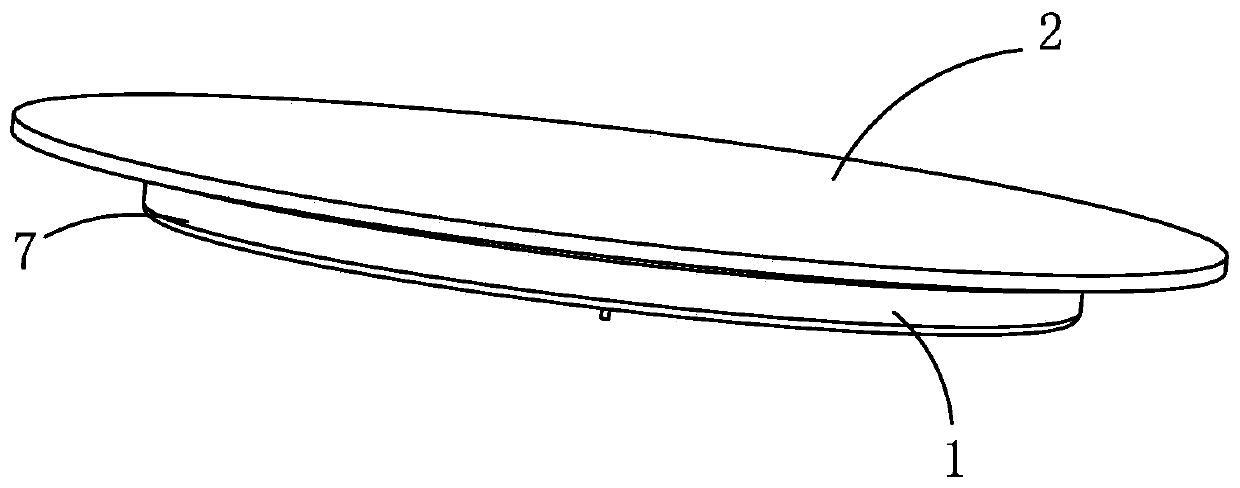

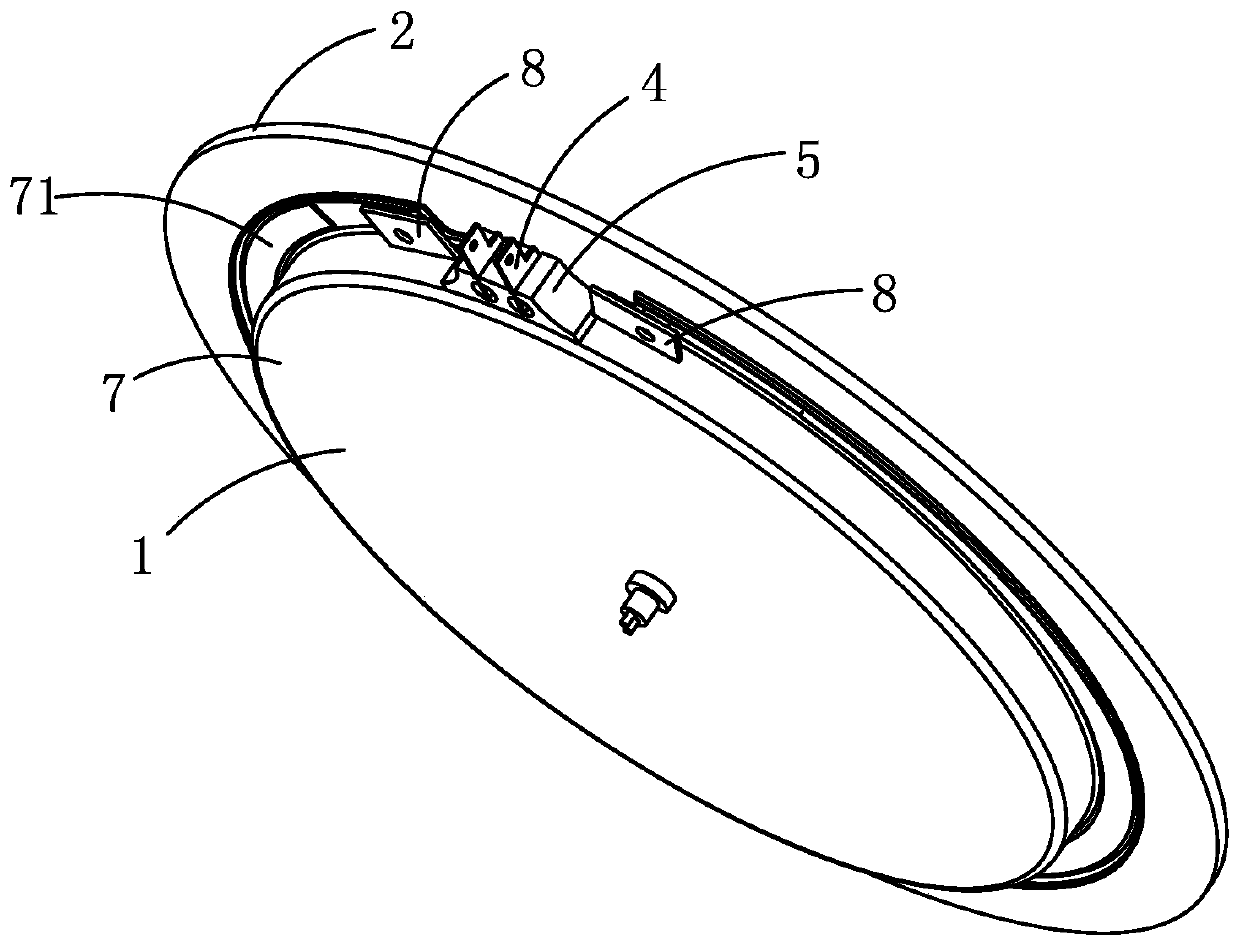

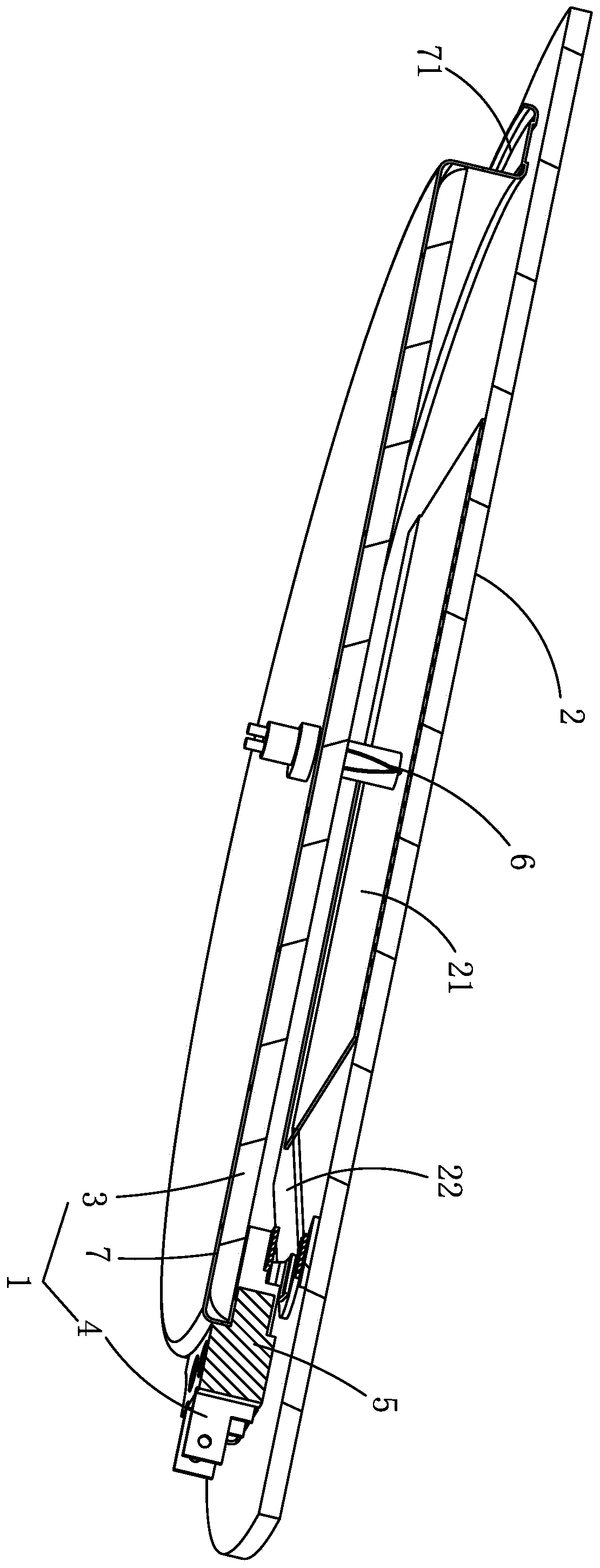

[0036] Example, combined with Figure 1 to Figure 11 As shown, an electric heating plate includes a furnace body 1, a high-temperature heat conduction plate 2, a mounting seat 5, a thermocouple 6 and a controller.

[0037] The furnace body 1 includes a heating disc shell 7, a heat insulating layer 3, and an elastic conductive sheet 4. The upper part of the furnace body 1 is open, and the heat insulating insulating layer 3 is arranged in the heating disc shell 7, and the side wall of the heating disc shell 7 is provided with The gap 11, the mounting base 5 is a ceramic insulating base, the mounting base 5 is fixed on the gap 11, the mounting base 5 has a slot 51, and the bottom of the slot 51 has a socket 52.

[0038] The heating disc shell 7 is provided with a flange 71, and the heating disc shell 7 is bonded to the bottom surface of the high-temperature heat conducting plate 2 through high-temperature silicone glue.

[0039] The high-temperature heat-conducting plate 2 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com