Precision pressure control system and hydraulic machining method of servo pump control hydraulic machine

A technology of precision pressure and control system, used in hydraulic processing of hydraulic presses, precision pressure control systems, and hydraulic presses. Pressure oscillation, to achieve the effect of timely response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

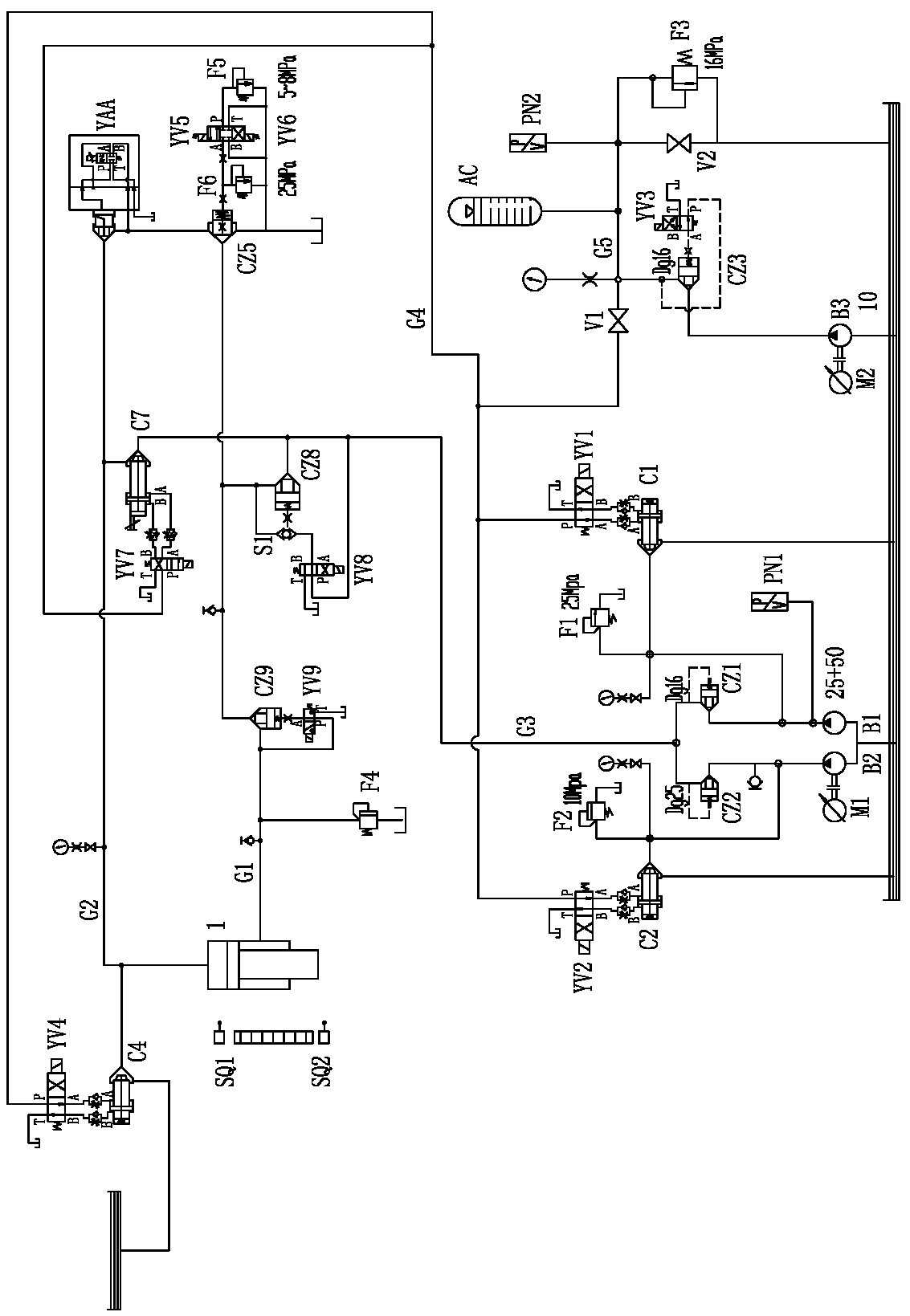

[0023] Such as figure 1 As shown, the precision pressure control system of the servo pump control hydraulic press of the present invention includes a master cylinder 1 installed above the slider, the lower chamber of the master cylinder 1 is connected with the oil passage G1 of the lower chamber of the master cylinder, and the upper chamber of the master cylinder 1 is connected with the master cylinder. The upper cavity of the cylinder is connected to the oil circuit G2, and also includes the medium flow servo pump B1 and the large flow servo pump B2 jointly driven by the servo motor M1. The outlet of the medium flow servo pump B1 is connected with the inlet of the cartridge valve CZ1, and the large flow servo pump The outlet of the pump B2 is connected to the inlet of the second cartridge valve CZ2, the hydraulic control ports of the first cartridge valve CZ1 and the second cartridge valve CZ2 are respectively connected to their respective outlets, and the outlets of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com