Device for efficiently obtaining air lift through low-density gas

An air-lift, low-density technology, applied in the field of lift systems, can solve the problems of difficulty in vacuuming the cavity, large air pressure of the cylinder head, and huge friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner will be further described below in conjunction with the accompanying drawings.

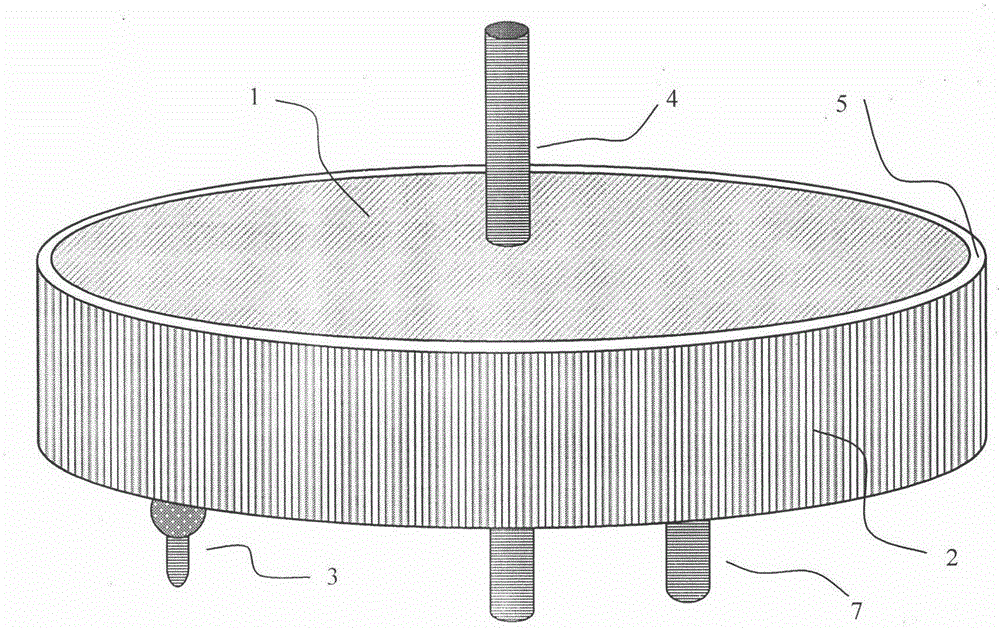

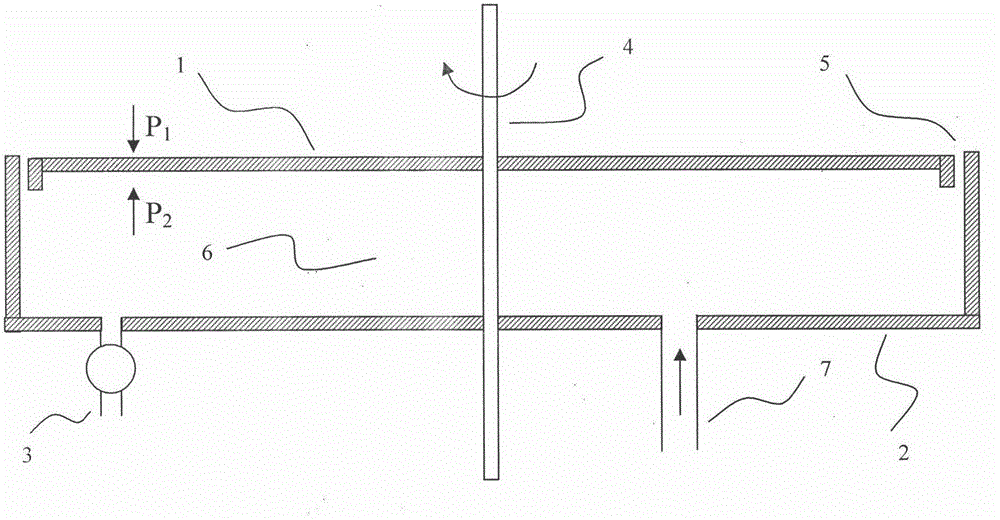

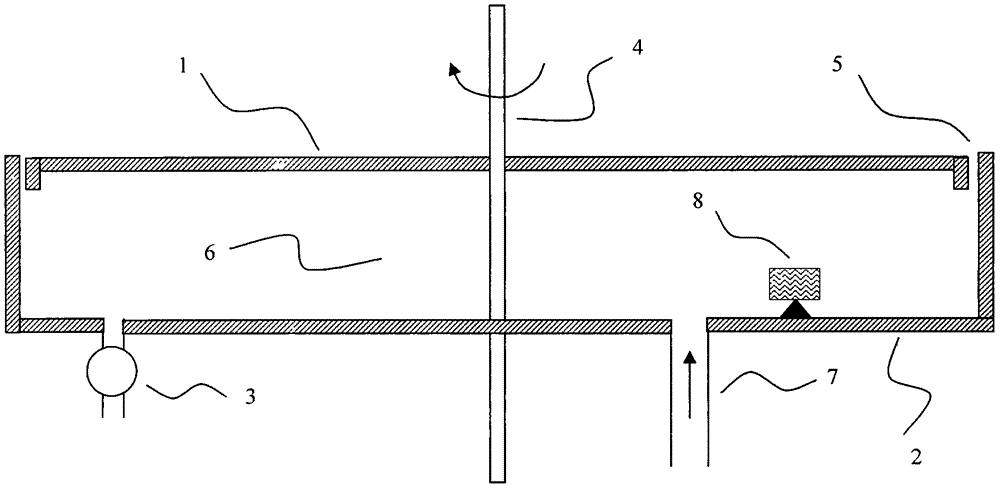

[0030] figure 1 is a perspective view of an embodiment, figure 2 is a cross-sectional view of this embodiment. figure 1 and figure 2 Shown: a device that utilizes low-density gas to efficiently obtain air lift, characterized in that: the device consists of a rotating member (1), a windshield member (2), an air pressure regulator (3), a rotating shaft (4) and Composed of an air intake pipe (7); the rotating member (1) has the shape of a rotating body and is fixedly connected to the rotating shaft (4) at the center; the windshield member (2) is located below the rotating member (1) and keep a small gap (5) with it but does not rotate with the rotating shaft (4); the gap (5) is located at a circular position centered on the rotating shaft (4); the rotating member ( 1) A cavity (6) is formed inside the windshield (2); the air pressure regulator (3) is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com