Patents

Literature

84results about How to "Small output torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

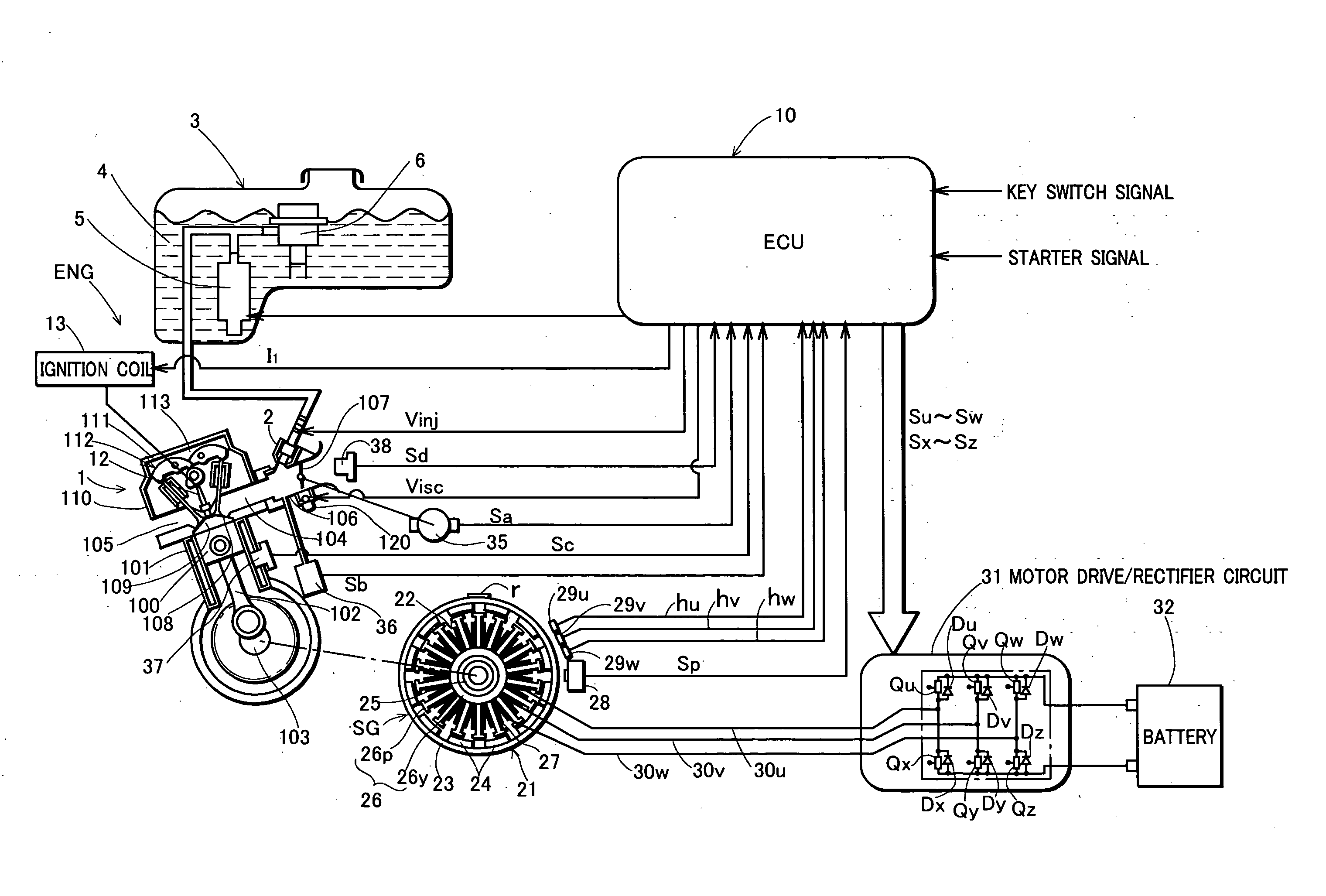

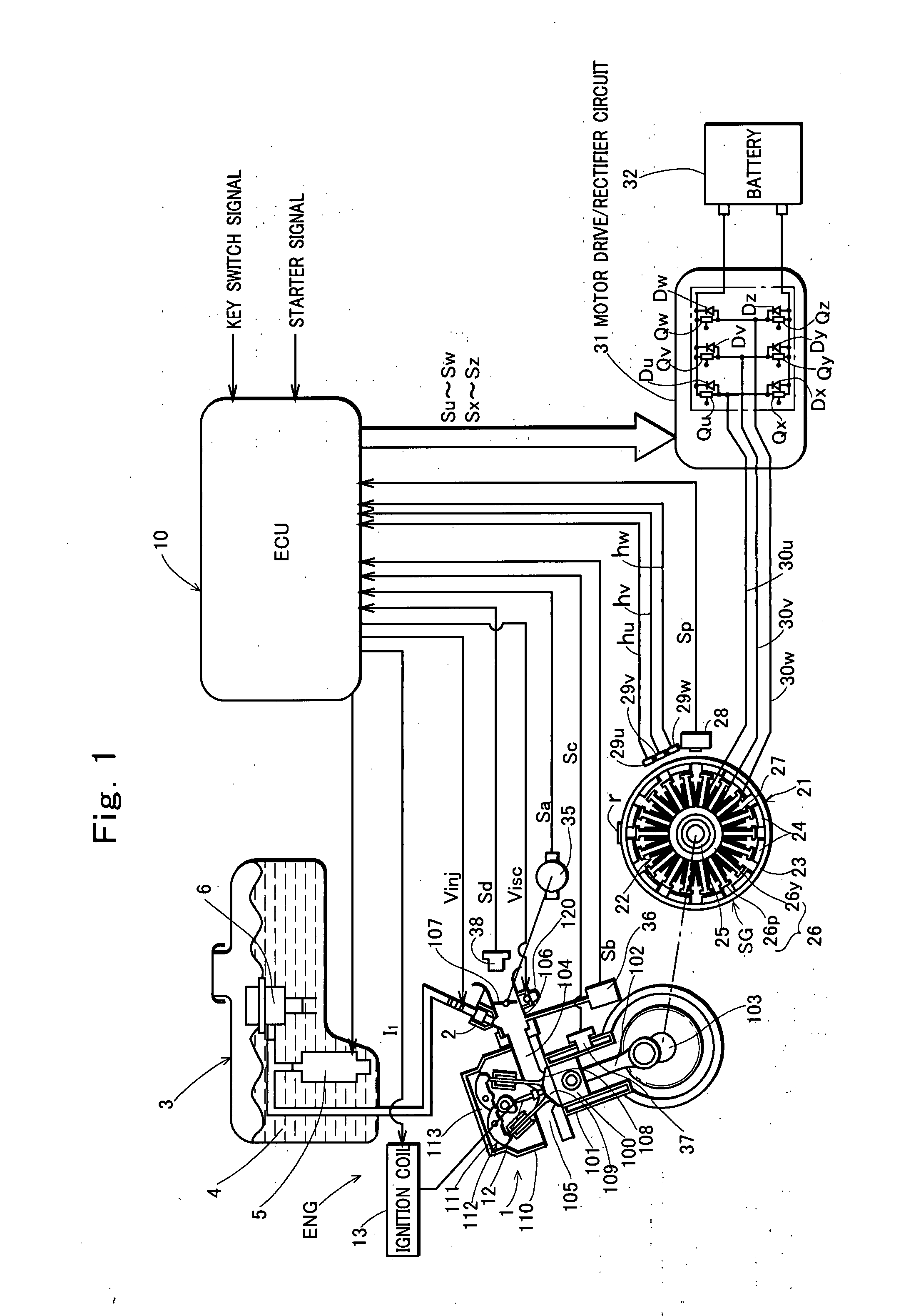

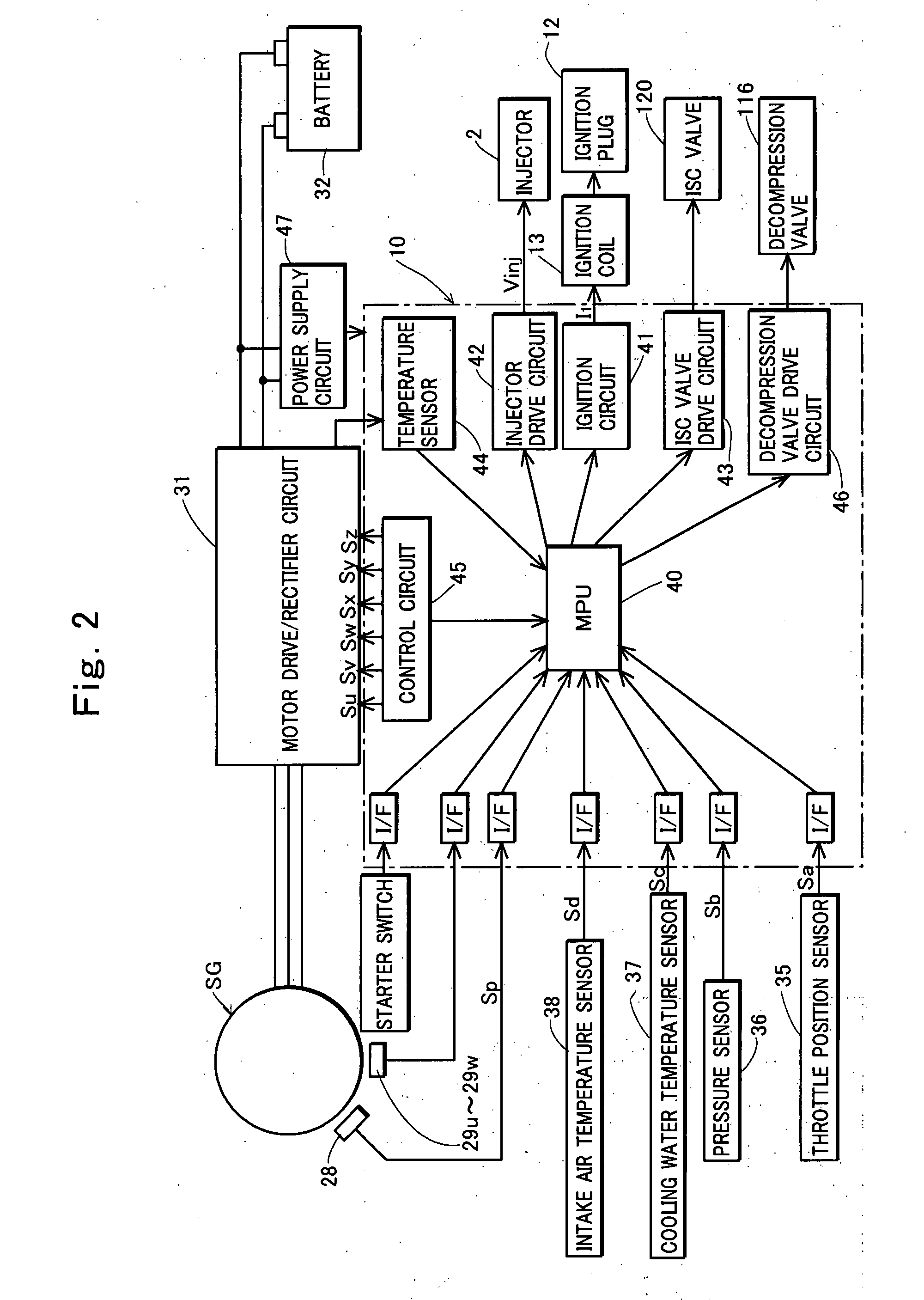

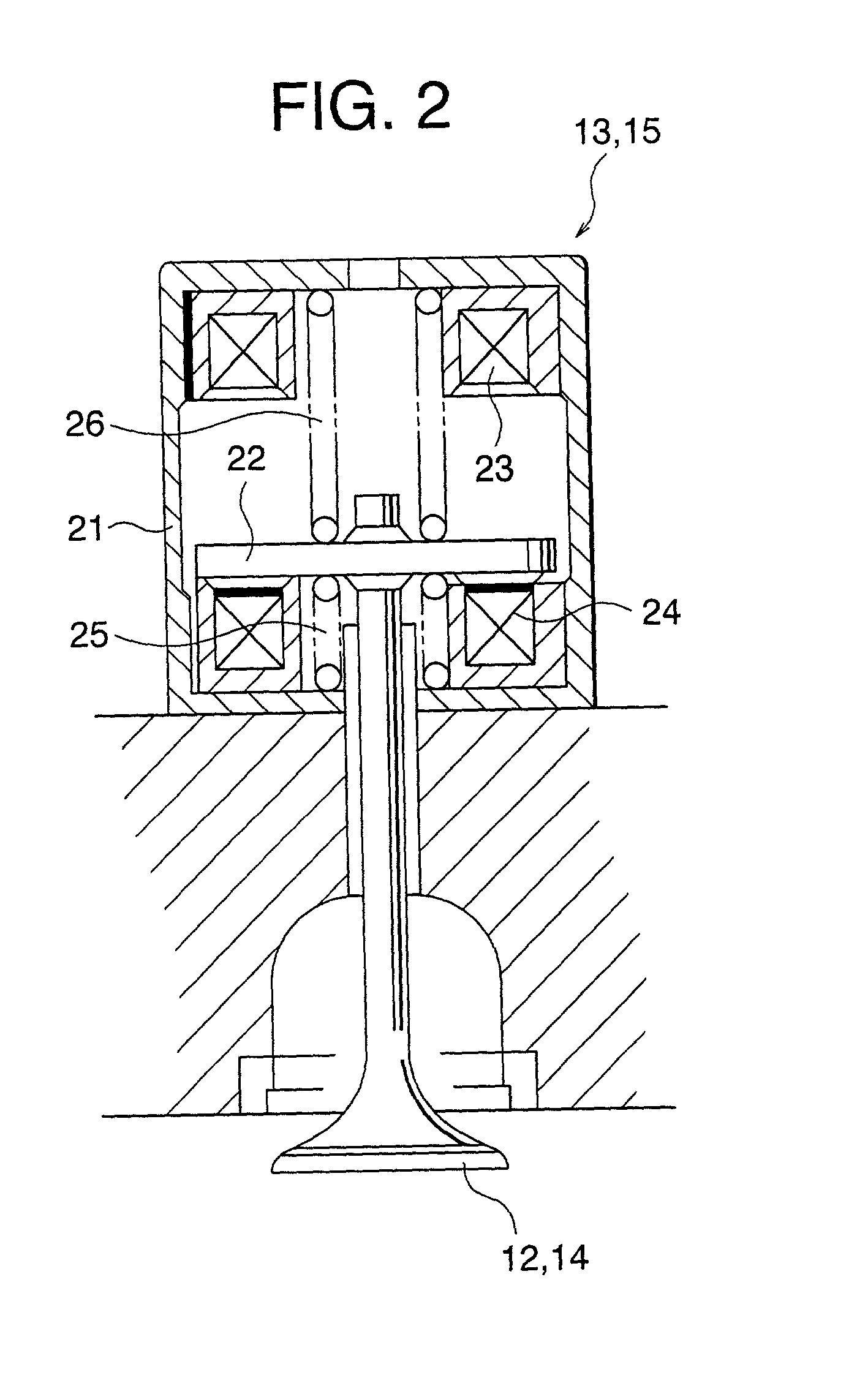

Engine starting device

InactiveUS20070204827A1Startability is improvedImprove performanceElectrical controlElectric ignition installationTop dead centerCrankshaft

An engine starting device which makes fuel injected in preparation for ignition performed in a cylinder of an engine after starting drive of a starter motor in a forward rotational direction so as to start the engine, and makes ignition performed in a suitable ignition position at the time of engine start while the starter motor is driven in a forward rotational direction, the engine starting device being comprised so as to continue driving the starter motor in a direction for starting the engine, even when a crankshaft stops before a piston in a cylinder of the engine reaches a top dead center of a compression stroke.

Owner:KOKUSAN DENKI CO LTD

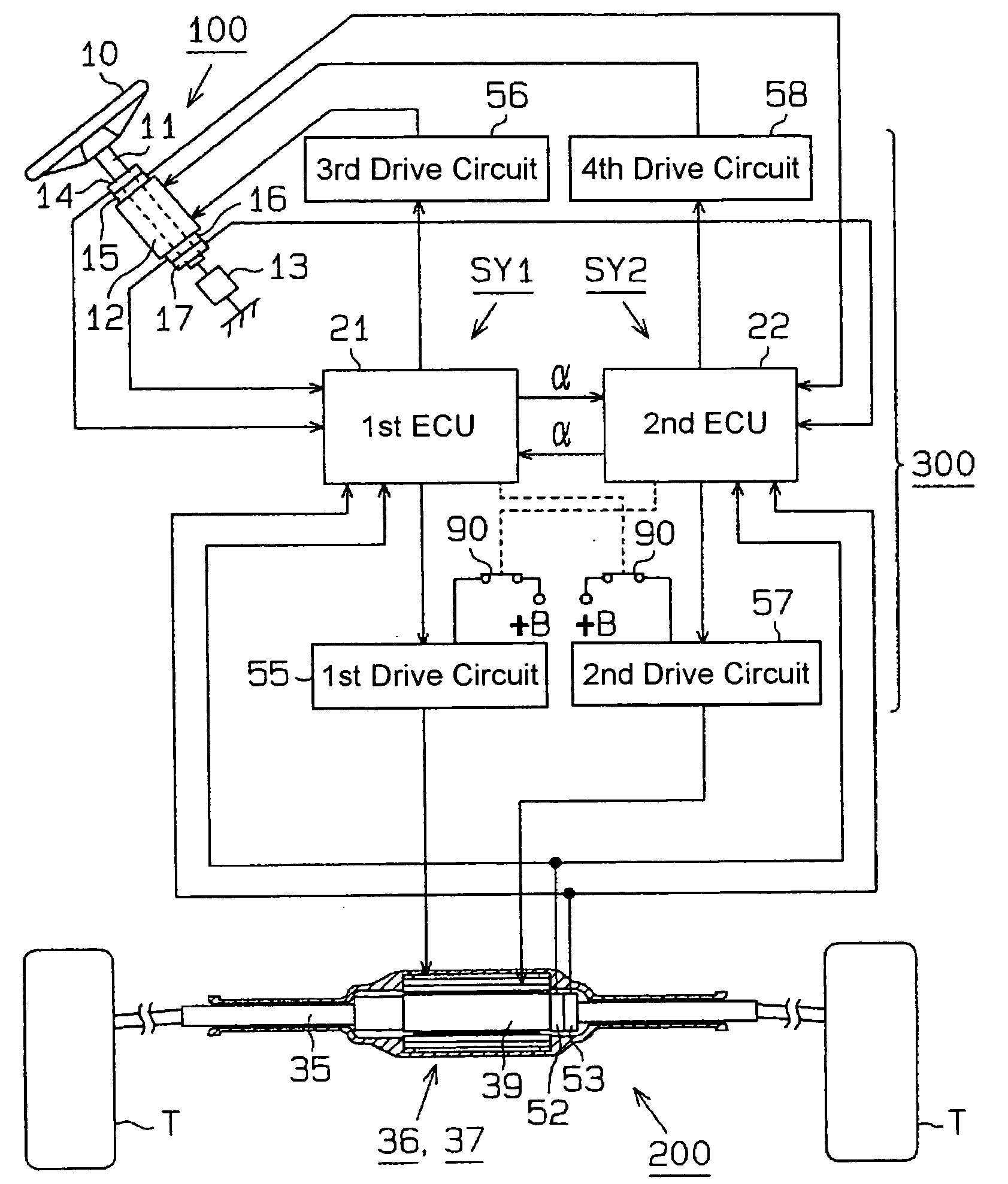

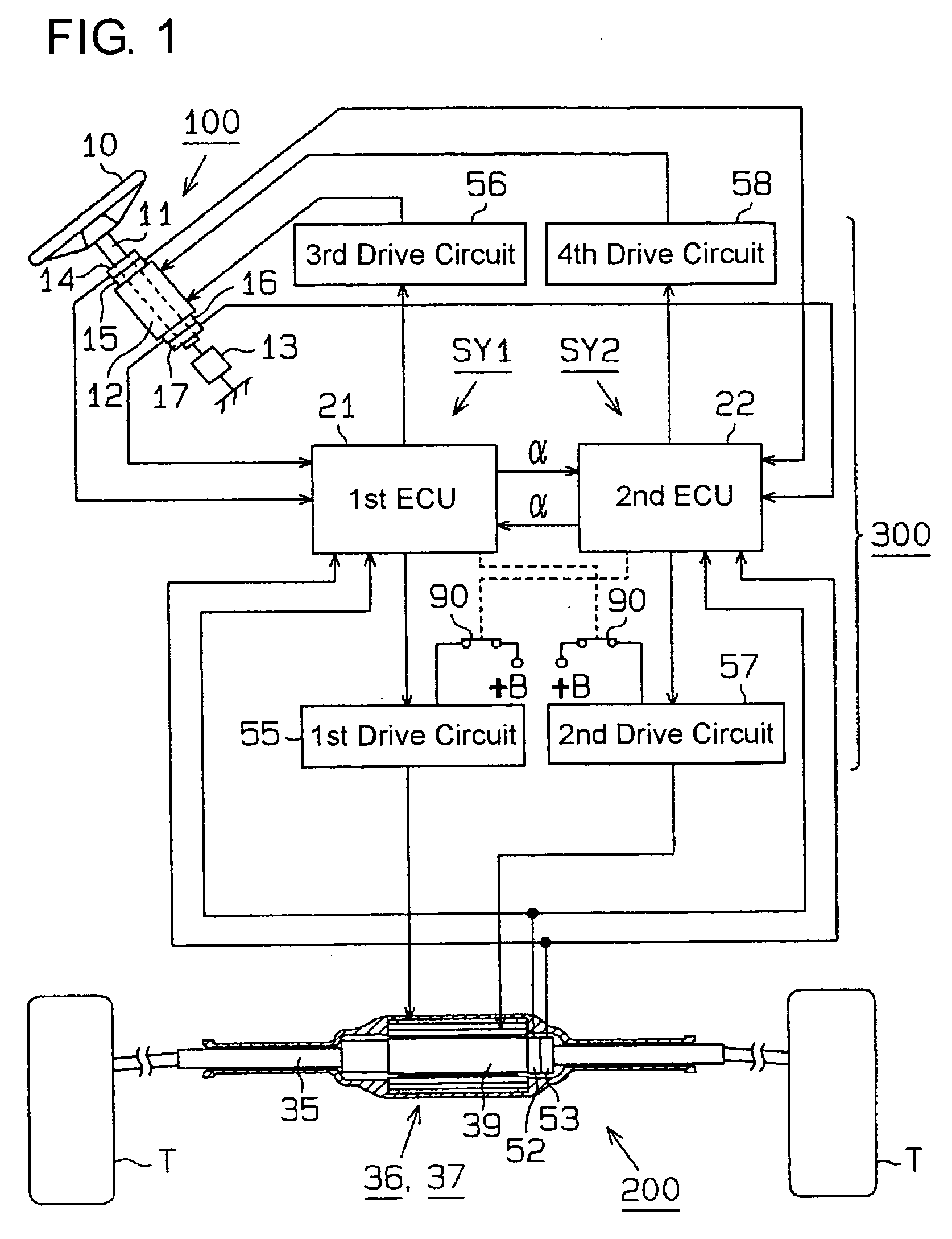

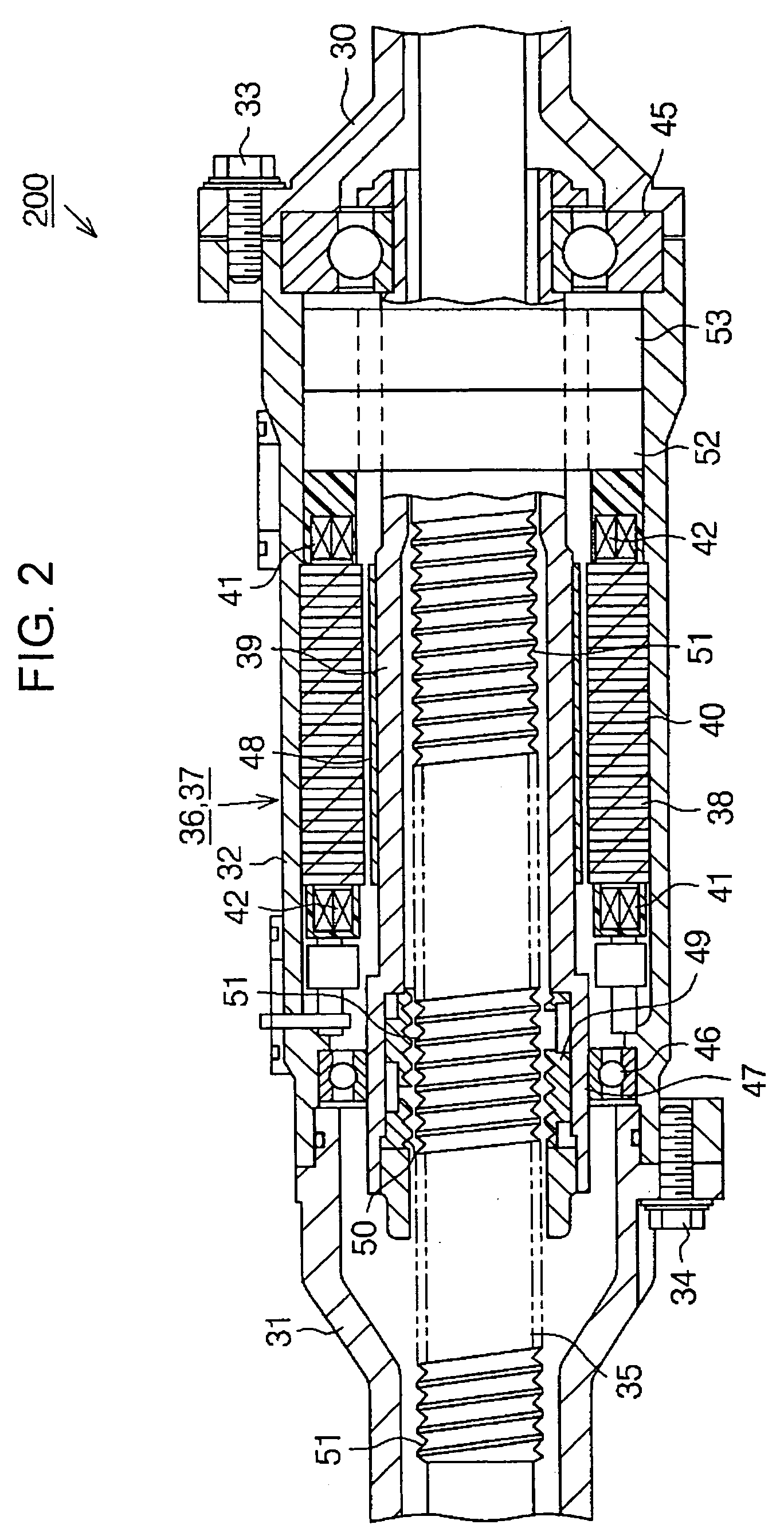

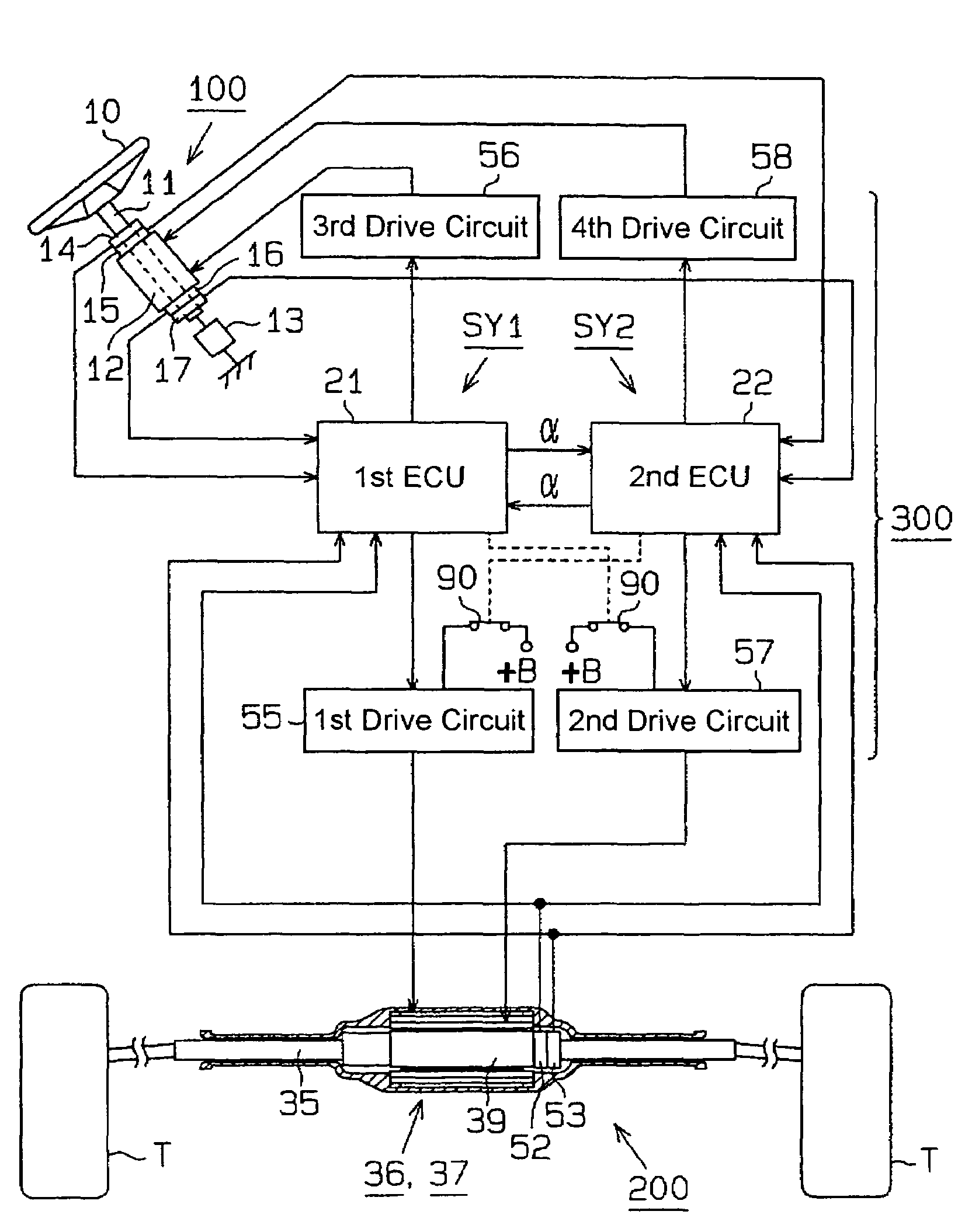

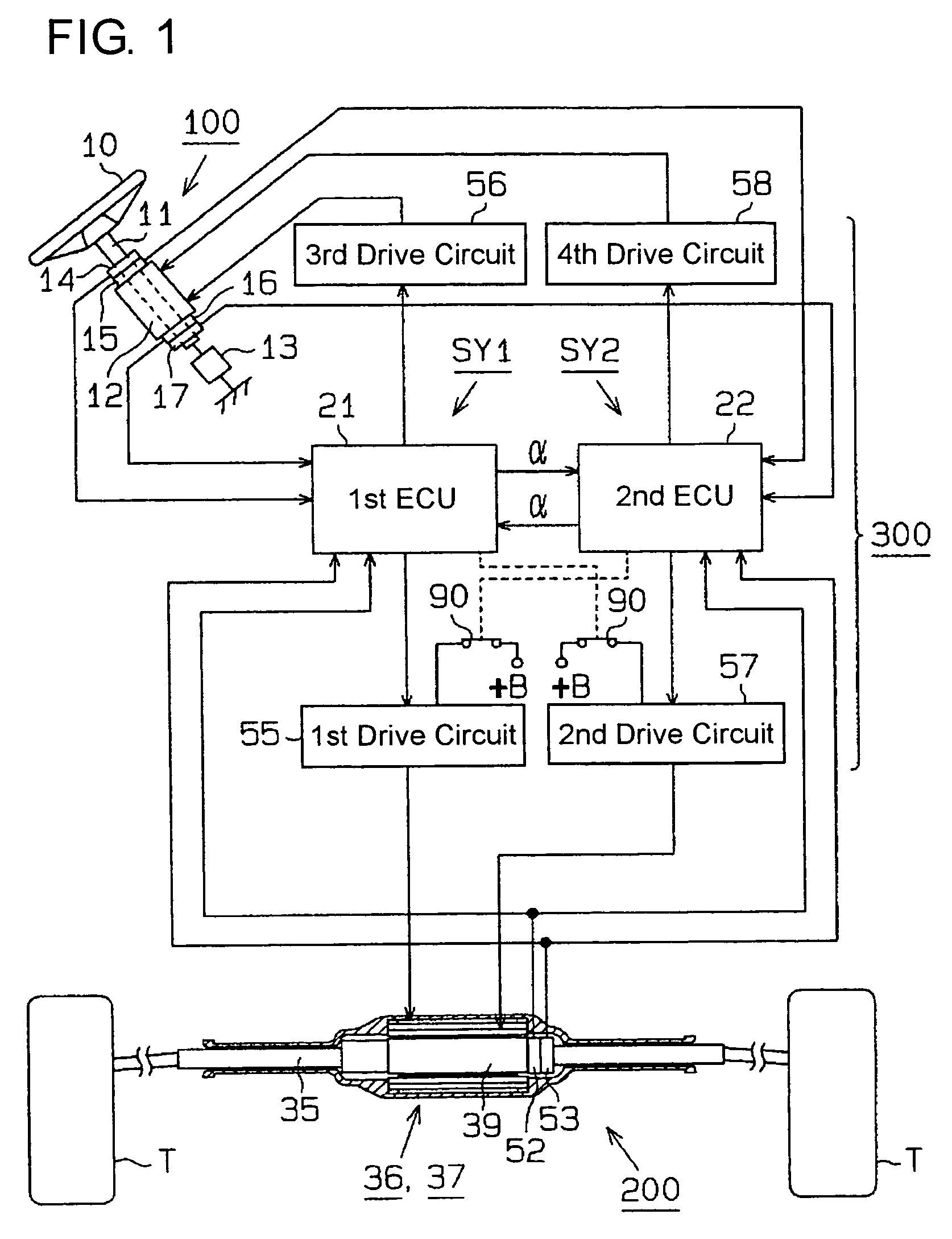

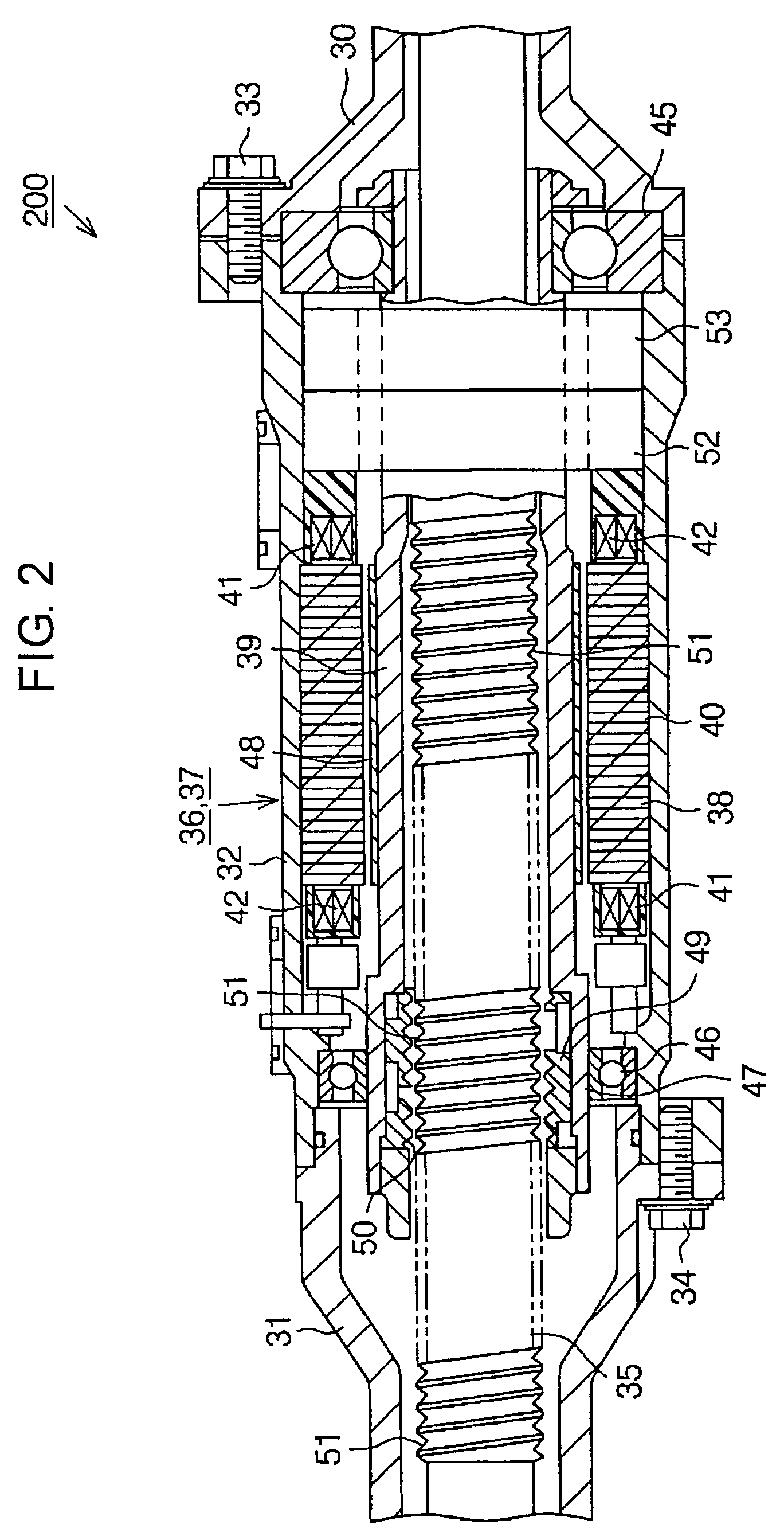

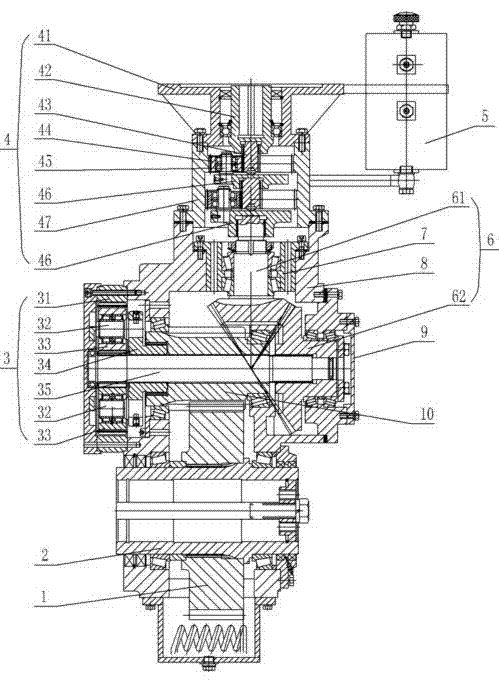

Steering control device and steering control method of motor vehicle

ActiveUS20050159866A1Low costOutput specificationVehicle testingCommutation monitoringSteering wheelMonitoring system

A first system and a second system include a first motor and a second motor for driving a steering mechanism in dependence on the rotational manipulation of a steering wheel. A first ECU and a second ECU mutually monitor abnormalities of the systems each to stop an abnormal system. When the respective systems are normal, the first ECU and the second ECU drivingly control the first motor and the second motor of their own systems to drive the steering mechanism by cooperation of the respective motors. When either one of the both systems is abnormal, the ECU of the other system solely drivingly controls the motor of its own system thereby to drive the steering mechanism. Thus, it can be realized to make the systems low in cost irrespective of the provision of the plural systems.

Owner:JTEKT CORP

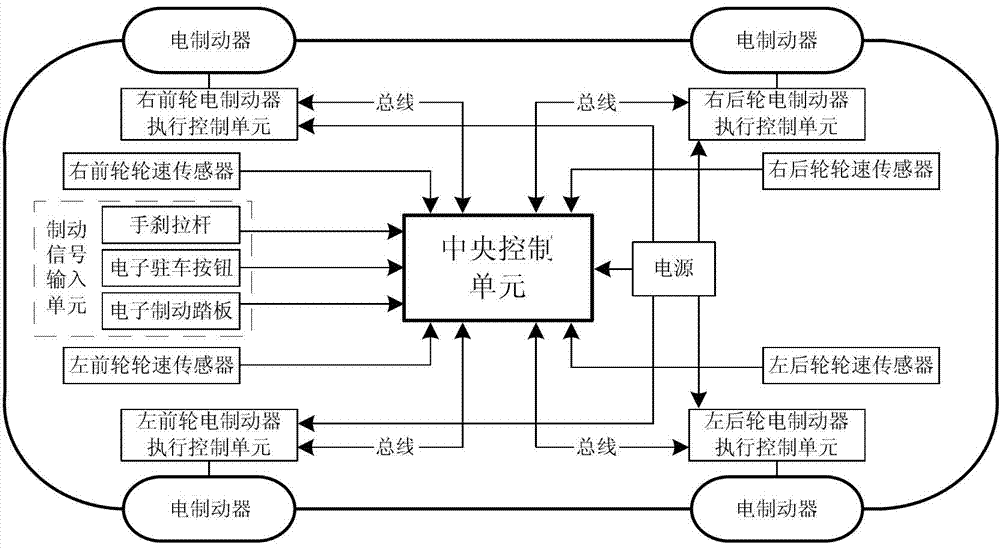

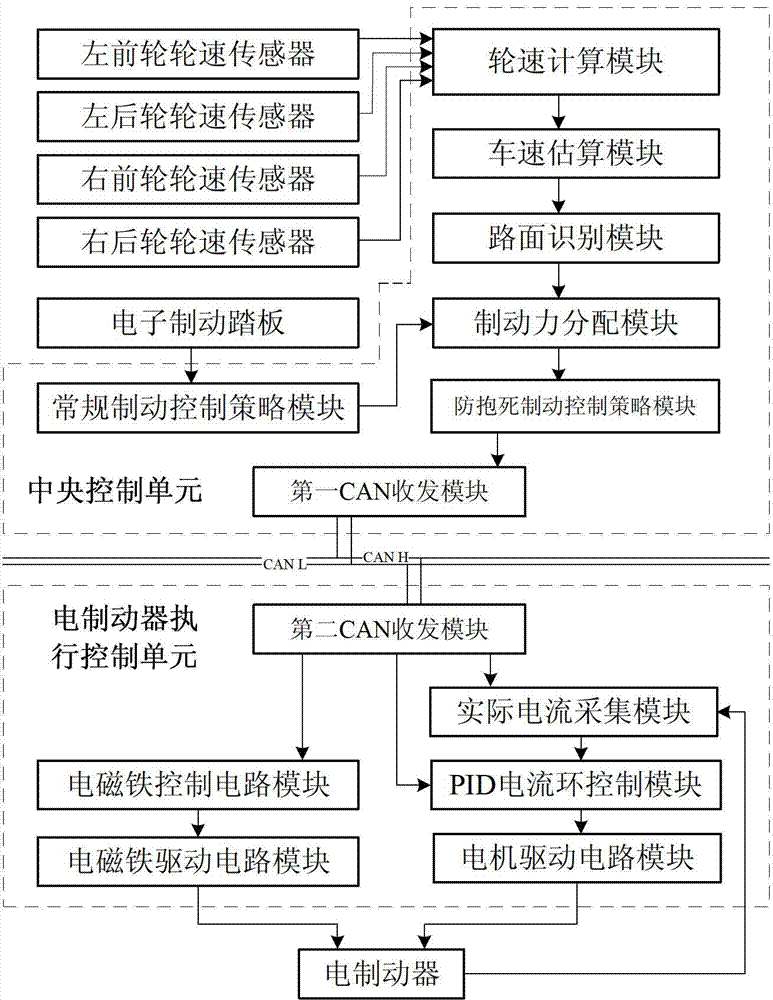

Electromechanical brake system based on automobile bus and automobile

The invention provides an electromechanical brake system based on an automobile bus. The electromechanical brake system based on the automobile bus comprises a brake signal input unit, a central control unit, a plurality of electric brake execution control units and a plurality of electric brakes, wherein the brake signal input unit is used for receiving brake signals and outputting the brake signals to the central control unit in real time; the central control unit is used for outputting multiple paths of brake motor target current signals to corresponding electric brake execution control units in real time according to the received brake signals; the electric brake execution control units are used for respectively driving and controlling corresponding electric brakes in real time according to the received brake motor target current signals; and the electric brakes are used for braking corresponding wheels. Correspondingly, the invention additionally provides an automobile with the brake system. The electromechanical brake system provided by the invention has the advantages of simple structure, small size, convenience in installation, low cost, quick brake response, good stability when used for braking , no pollution and the like.

Owner:CHERY AUTOMOBILE CO LTD

Steering control device and steering control method of motor vehicle

ActiveUS7433767B2Low costReduce outputVehicle testingCommutation monitoringSteering wheelSteering control

A first system and a second system include a first motor and a second motor for driving a steering mechanism in dependence on the rotational manipulation of a steering wheel. A first ECU and a second ECU mutually monitor abnormalities of the systems each to stop an abnormal system. When the respective systems are normal, the first ECU and the second ECU drivingly control the first motor and the second motor of their own systems to drive the steering mechanism by cooperation of the respective motors. When either one of the both systems is abnormal, the ECU of the other system solely drivingly controls the motor of its own system thereby to drive the steering mechanism. Thus, it can be realized to make the systems low in cost irrespective of the provision of the plural systems.

Owner:JTEKT CORP

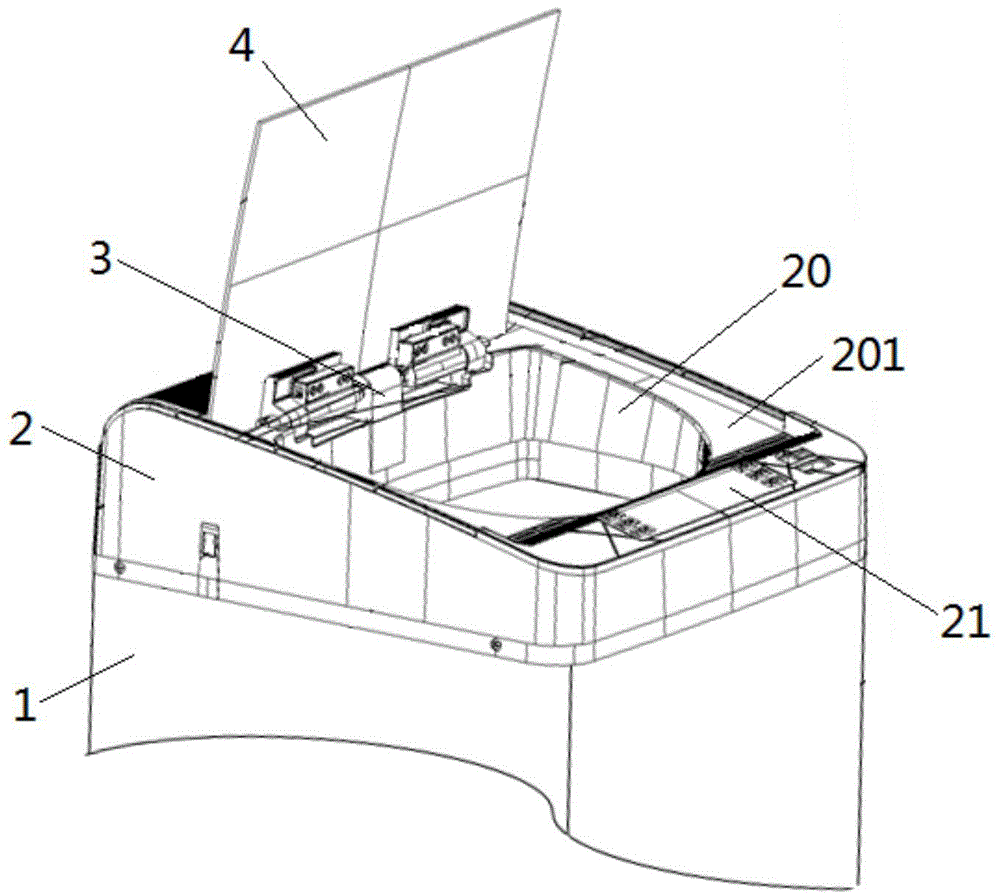

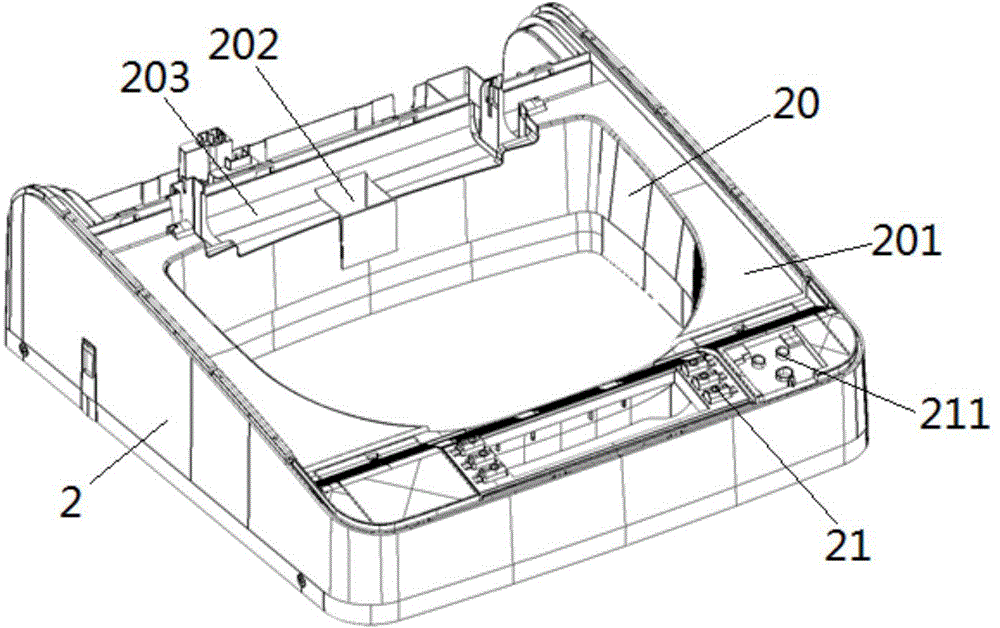

Washing machine with automatic opening/closing machine cover and control method thereof

ActiveCN105734911AAvoid impact collisionCancel noiseOther washing machinesControl devices for washing apparatusTransducerMechanical engineering

Owner:PANASONIC APPLIANCES CHINA CO LTD +1

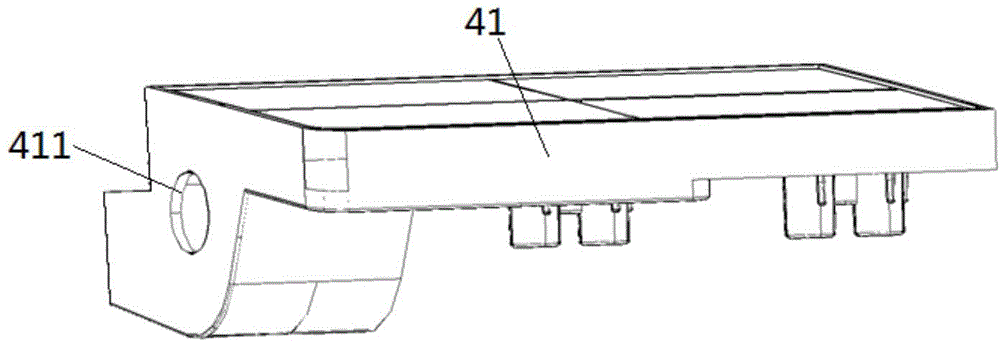

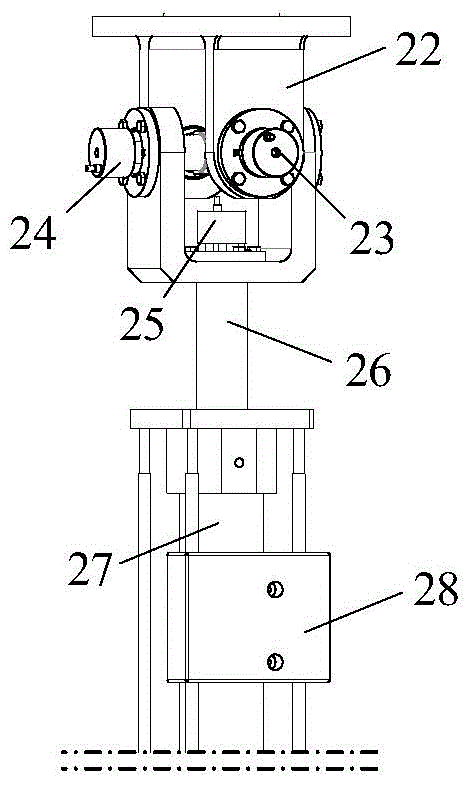

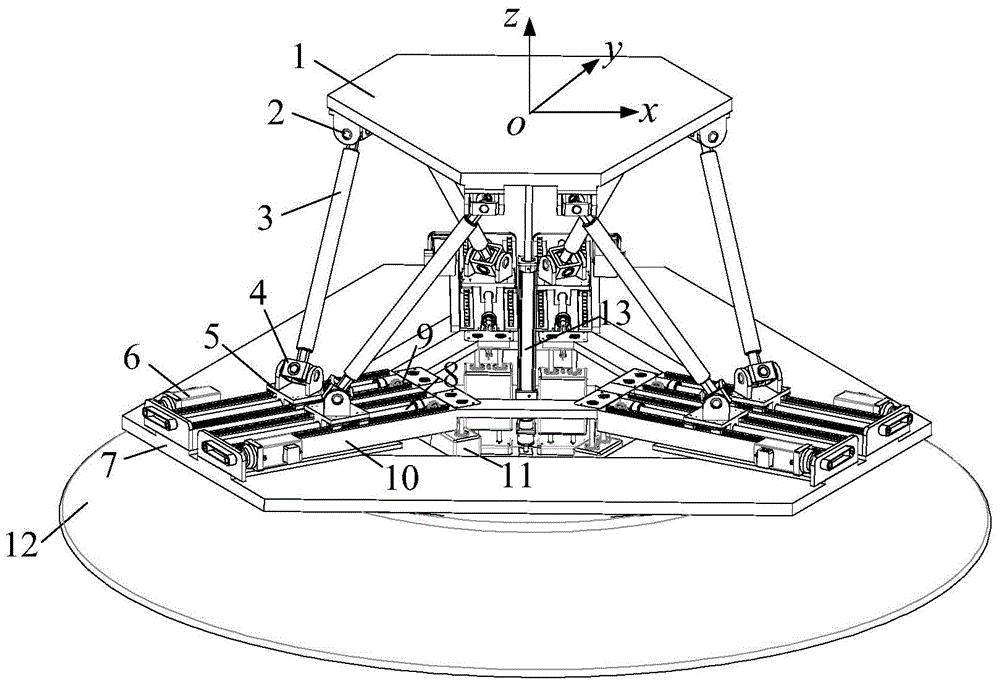

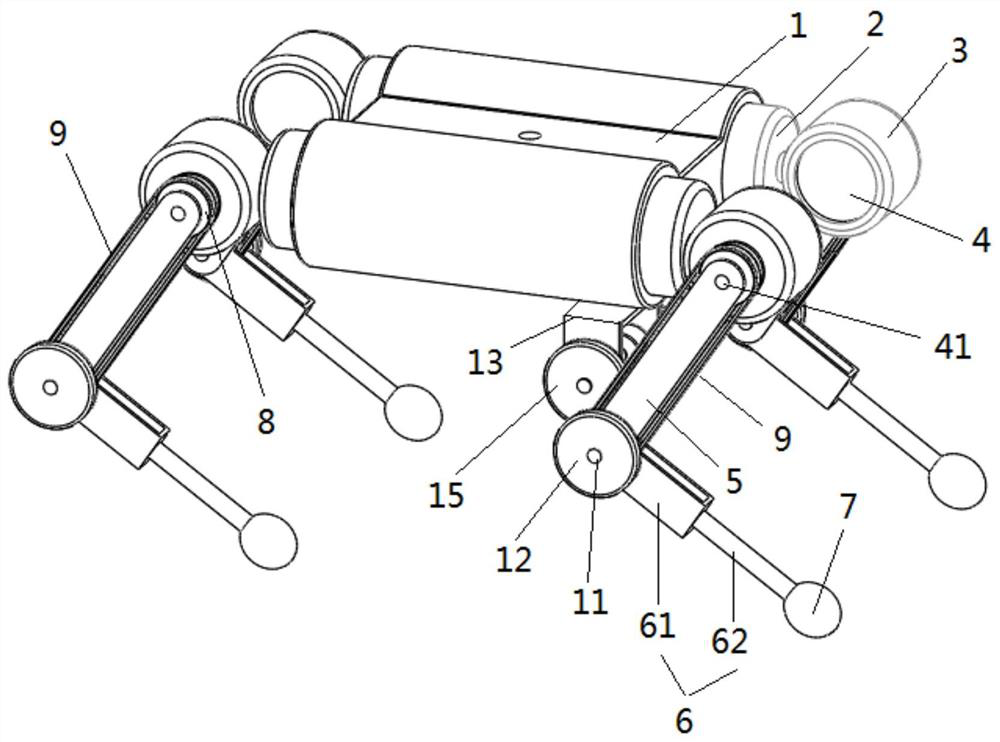

Simulation platform for simulating high and low frequency motion of vehicle and implementation method thereof

ActiveCN104835399ARatio of increasing powerRealize real-time detectionEducational modelsElectric machineryKinematic chain

The present invention relates to a simulation platform for simulating high and low frequency motion of a vehicle and an implementation method thereof. The simulation platform comprises an output platform, a posture adjusting platform and a detection branch; wherein the output platform comprises a moving platform, a spherical hinge, a rectilinear motion actuator and a universal hinge, and is used for simulating high frequency small vibration generated by the vehicle; the posture adjusting platform comprises a slide block, a servo motor, a fixed platform, a ball screw, a linear guide rail, a guide rail base, a pedestal and a static load balancing device, and is used for simulating multidimensional sharp swing; the static load balancing device achieves static load through a counterweight balancing system, so as to reduce output torque of a motor; the detection branch is a six-degree-of-freedom kinematic chain, each single- degree-of-freedom kinematic pair is provided with a sensor for obtaining motion parameters of the moving platform in real time. The simulation platform of the present invention adopts a dual drive control mode to achieve decomposition of simulation motion to two driving platforms, and combines the detection branch and the static load balancing device, thus the simulation platform has the characteristics of large carrying capacity, real-time self detection of the motion parameters, extensive applicability, real simulation, etc.

Owner:山西交通科学研究院集团有限公司

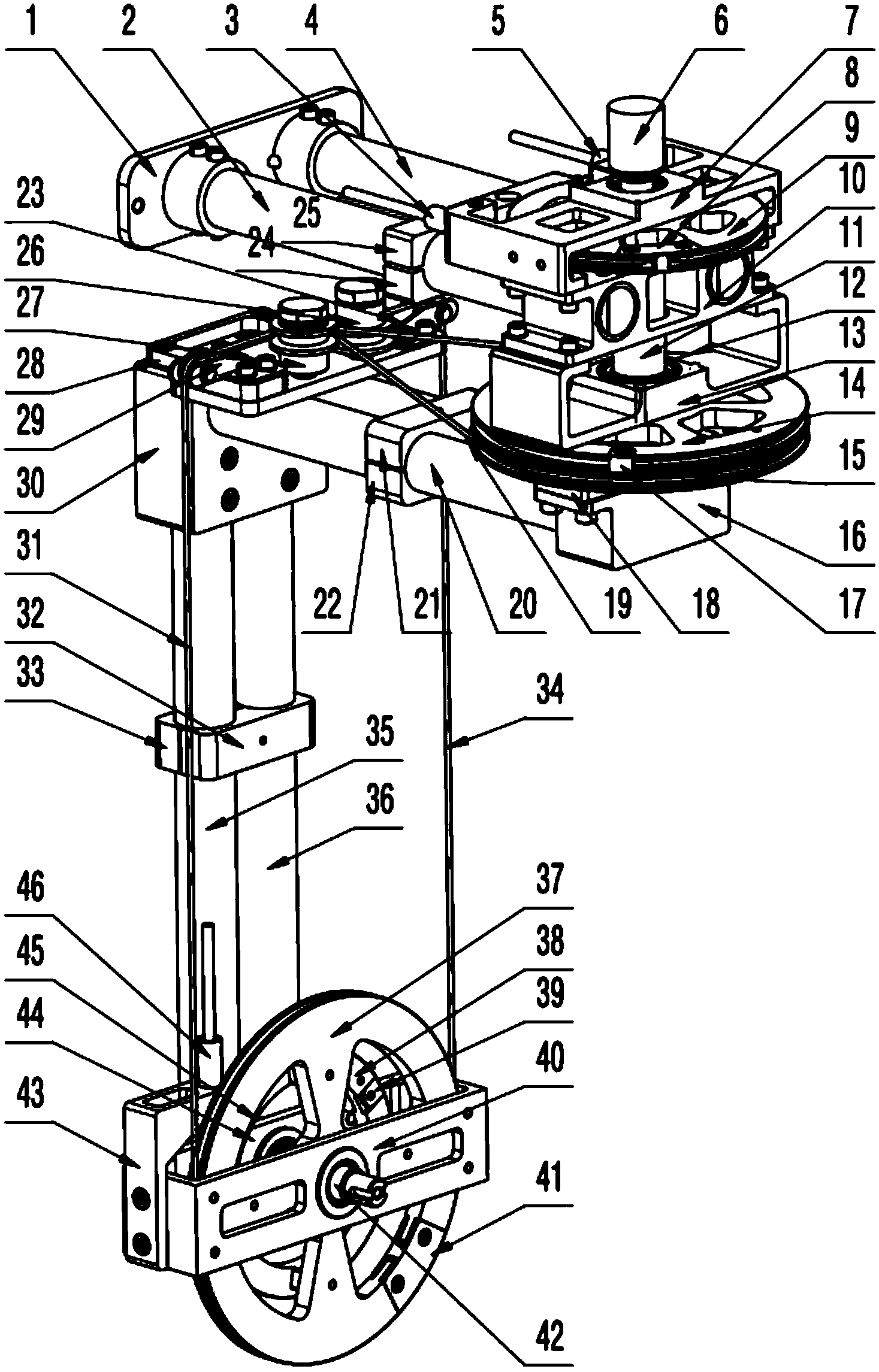

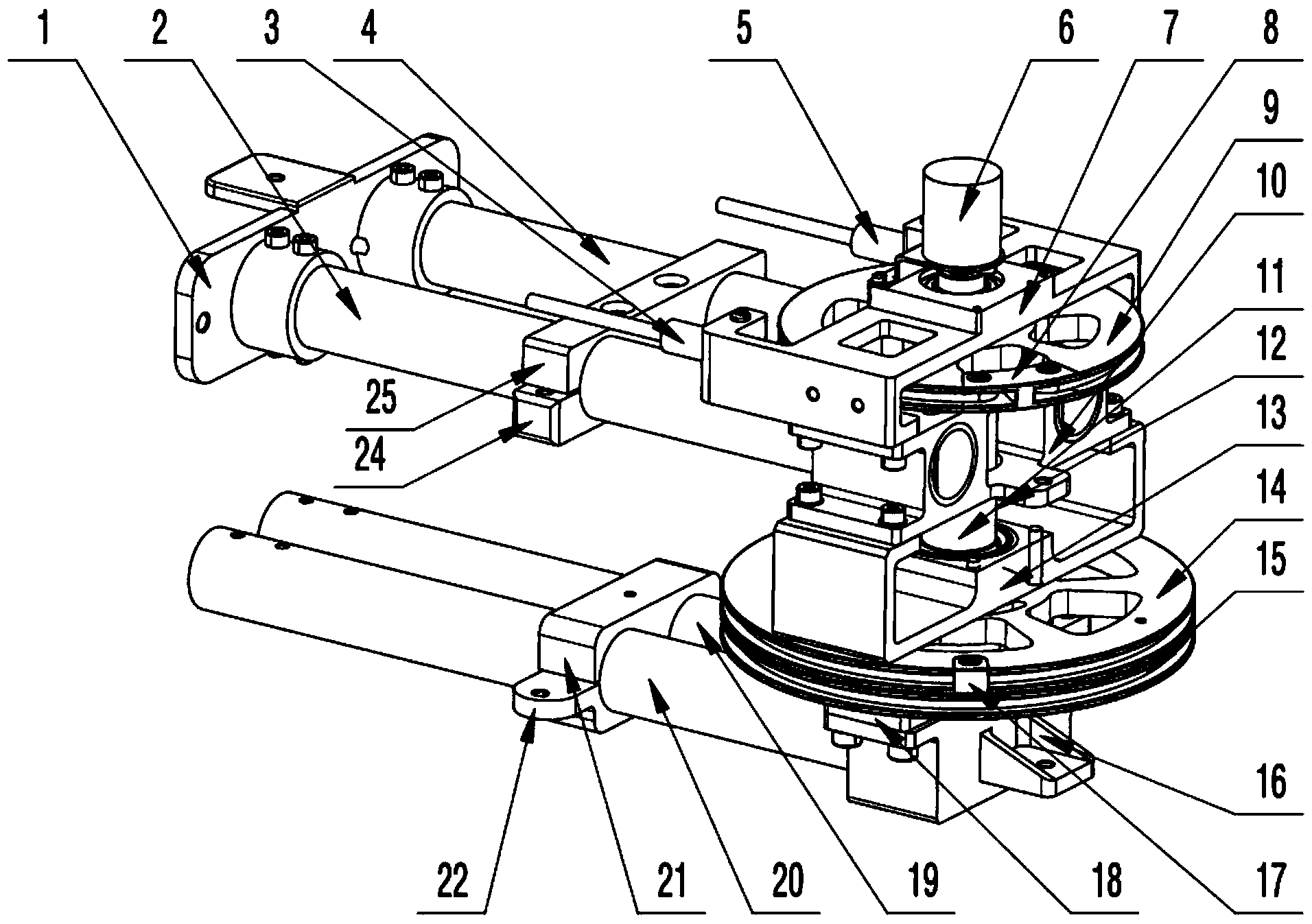

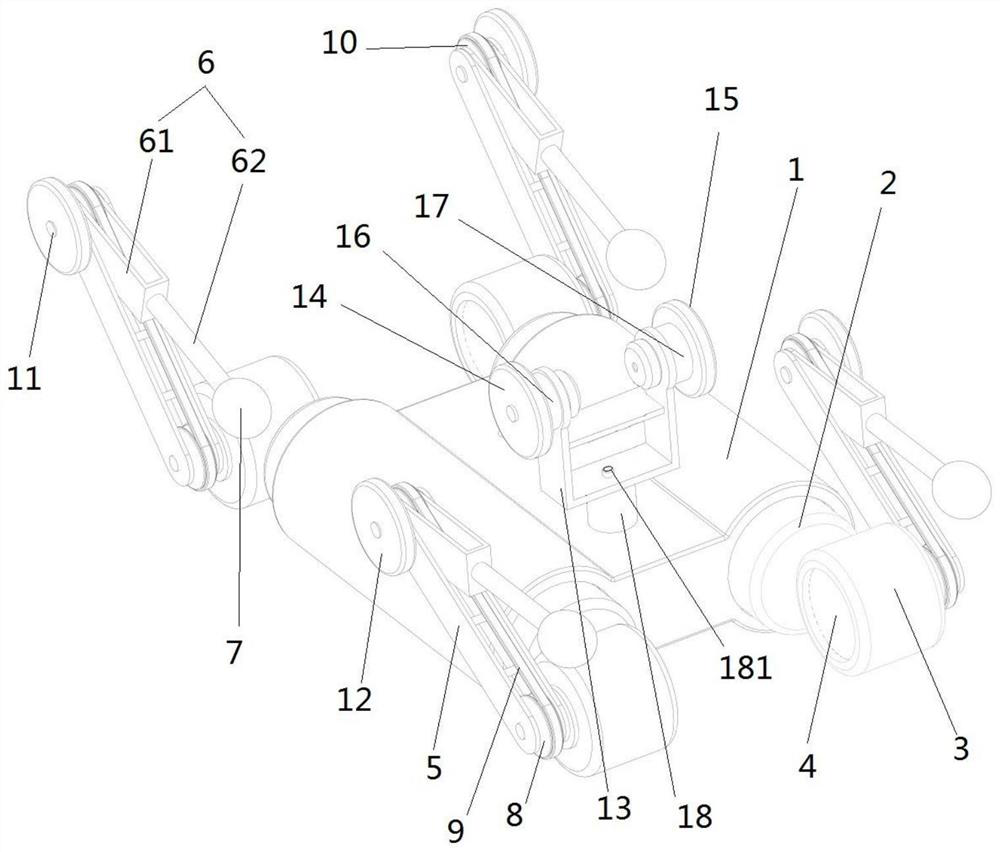

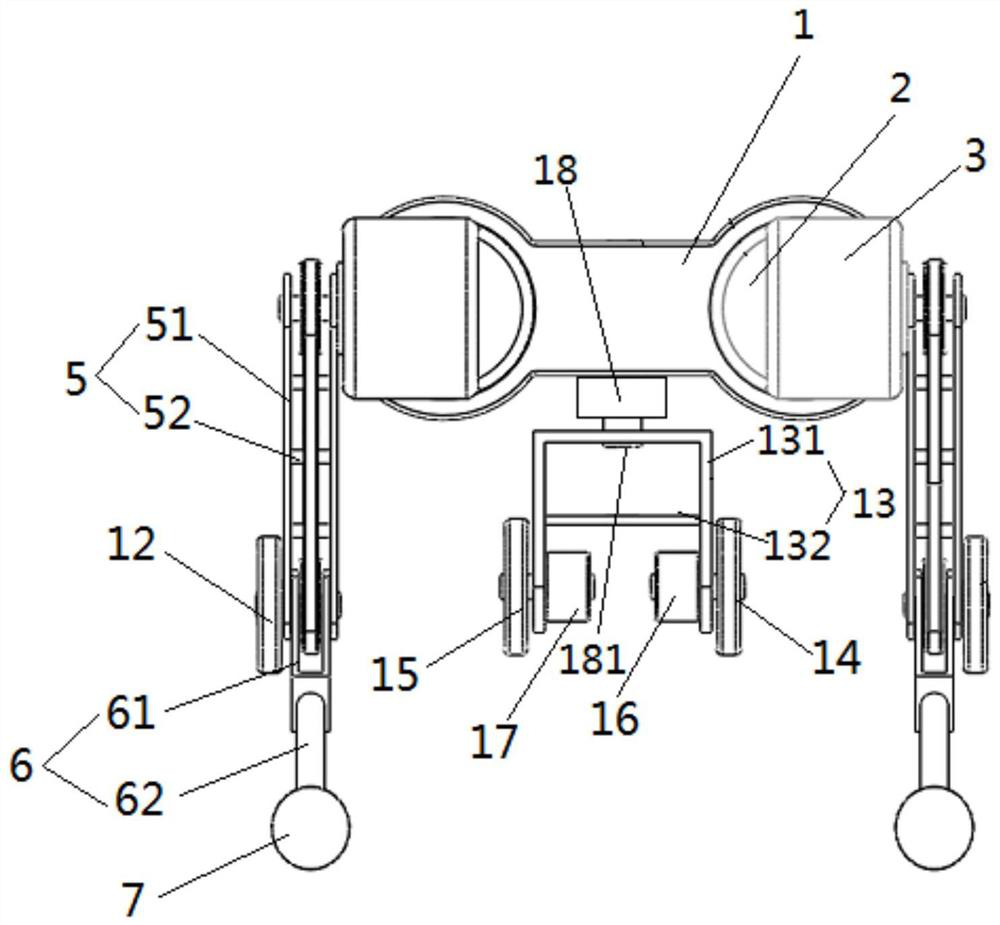

Coupled motion mechanism and shoulder joint rehabilitation training device with same

ActiveCN104287936AImplement coupled motionLimited range of motionChiropractic devicesEngineeringShoulder joint capsule

The invention discloses a coupled motion mechanism applicable to a shoulder joint rehabilitation training device. The coupled motion mechanism comprises a first shoulder component and a second shoulder component which can rotate relative to the first shoulder component. A first disc component is disposed on the first shoulder component. A second disc component is disposed on the second shoulder component. The first disc component and the second disc component are connected through a rope. The rotation of a rotatable part, which can rotate in a first direction, on the first disc component can drive the second shoulder component to rotate relative to the firs shoulder component, acting force on the rope is thus generated, a rotatable part on the second disc component can be driven to rotate in a second direction, and coupled motions with multiple freedom degrees can be achieved. The invention further discloses the shoulder joint rehabilitation training device using the coupled motion mechanism. By the coupled motion mechanism, two motions can be driven by one driver, mechanism coupled driving is achieved, energy is saved, manufacturing cost is lowered, weight is reduced, and system flexibility is enhanced.

Owner:HUAZHONG UNIV OF SCI & TECH

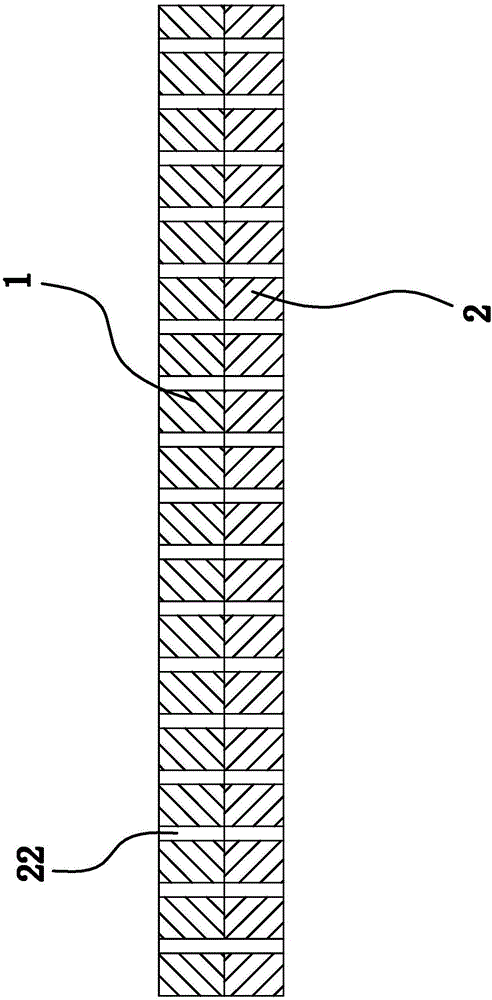

Composite fabric for making suitcases and bags and processing technology of composite fabric

ActiveCN106739353AFresh airEasy dischargeLamination ancillary operationsSynthetic resin layered productsFiltrationEngineering

The invention provides a composite fabric for making suitcases and bags and a processing technology of the composite fabric, and belongs to the field of light industry textiles. The invention solves the problem that an existing fabric has a poor ventilation effect. The composite fabric for making the suitcases and bags comprises a body formed by laminating a PVC film and a skeleton fabric layer, wherein the body is densely covered with through holes which are in the shape of straight holes, the extending directions of axes of the through holes are consistent with distribution directions of the PVC film and the skeleton fabric layer, and the pore size of the through holes is 0.6-1.8mm; the processing technology consists of a PVC film calendering process and a lamination process, wherein the PVC film calendering process comprises the steps of A, measurement, B, stirring mixing, C, internal mixing, D, continuous plasticization with two rolling wheels, E, filtration, F, four-roll calendering, G, sub-surface embossing, H, cooling shaping, and I, coiling; the lamination process comprises the following steps of: J, high-temperature lamination, K, cooling shaping and edge cutting, L, through hole forming, and M, furling. The composite fabric for making the suitcases and bag and the processing technology of the composite fabric have the advantage that the ventilation effect of the composite fabric can be improved.

Owner:ZHEJIANG BOTAI PLASTIC

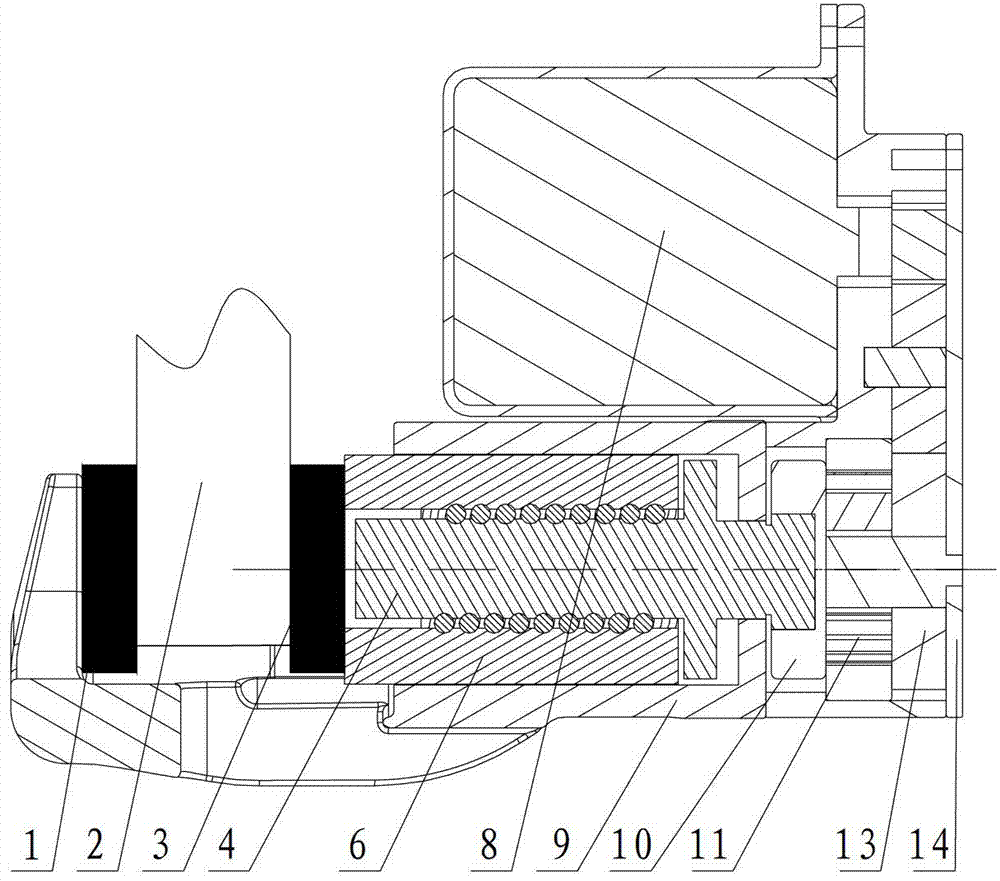

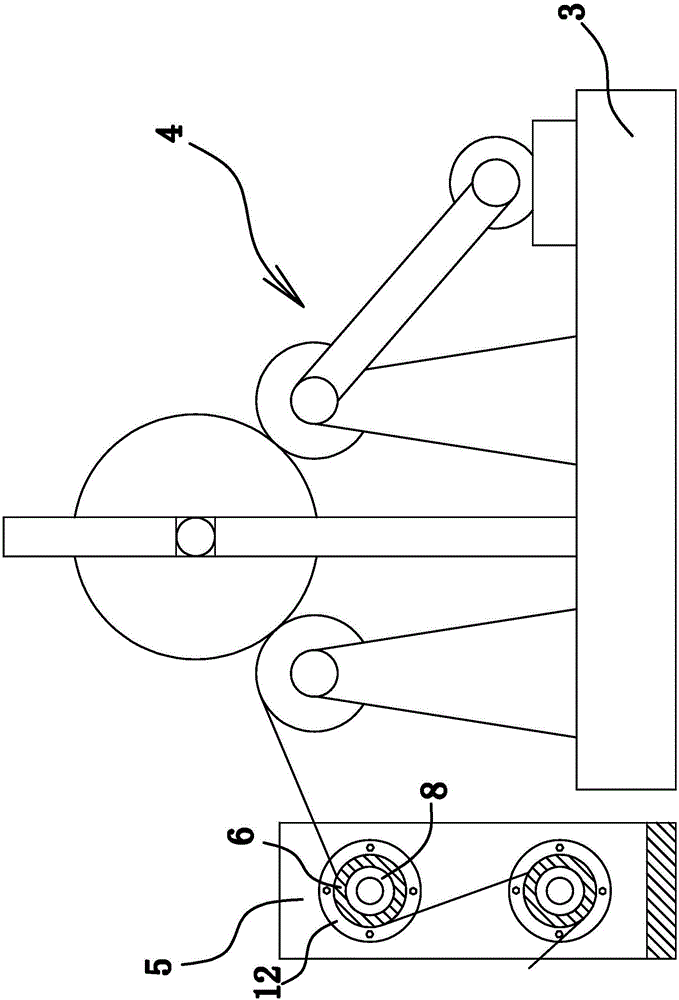

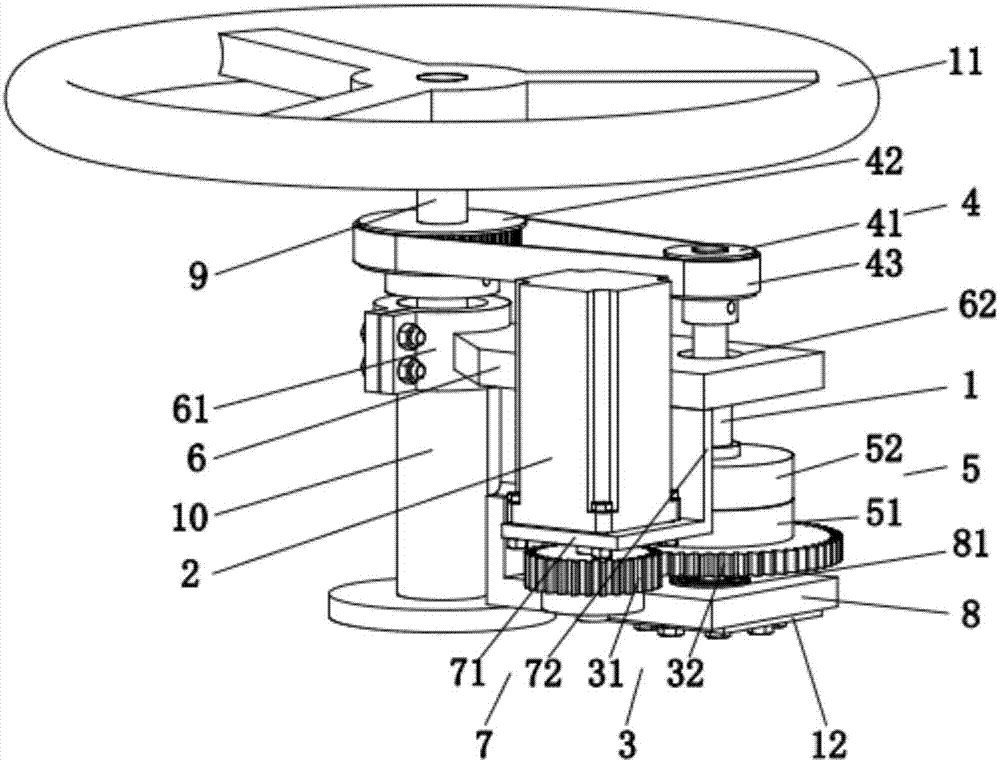

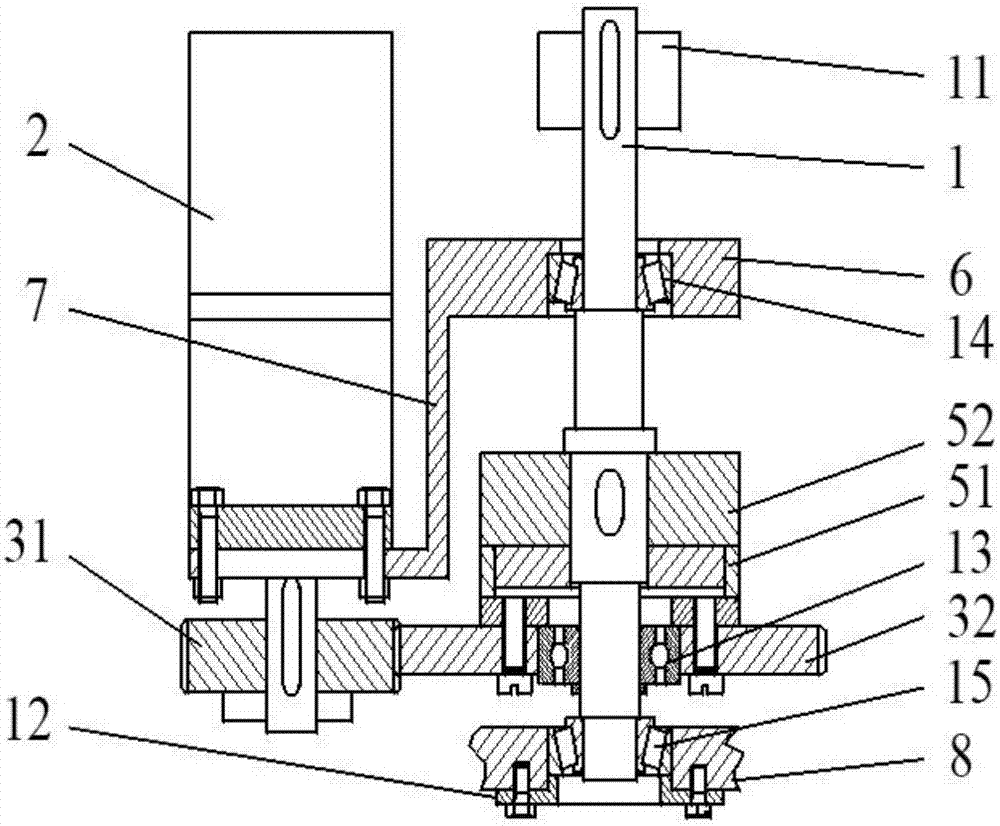

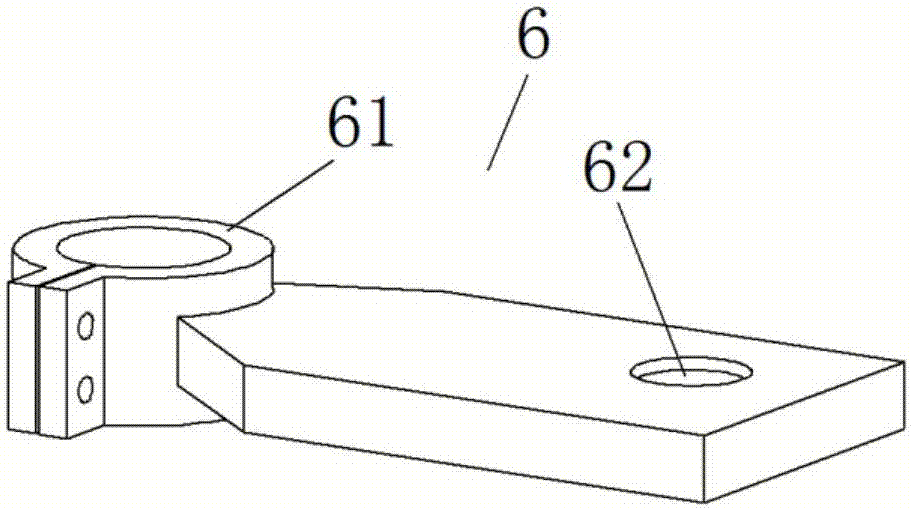

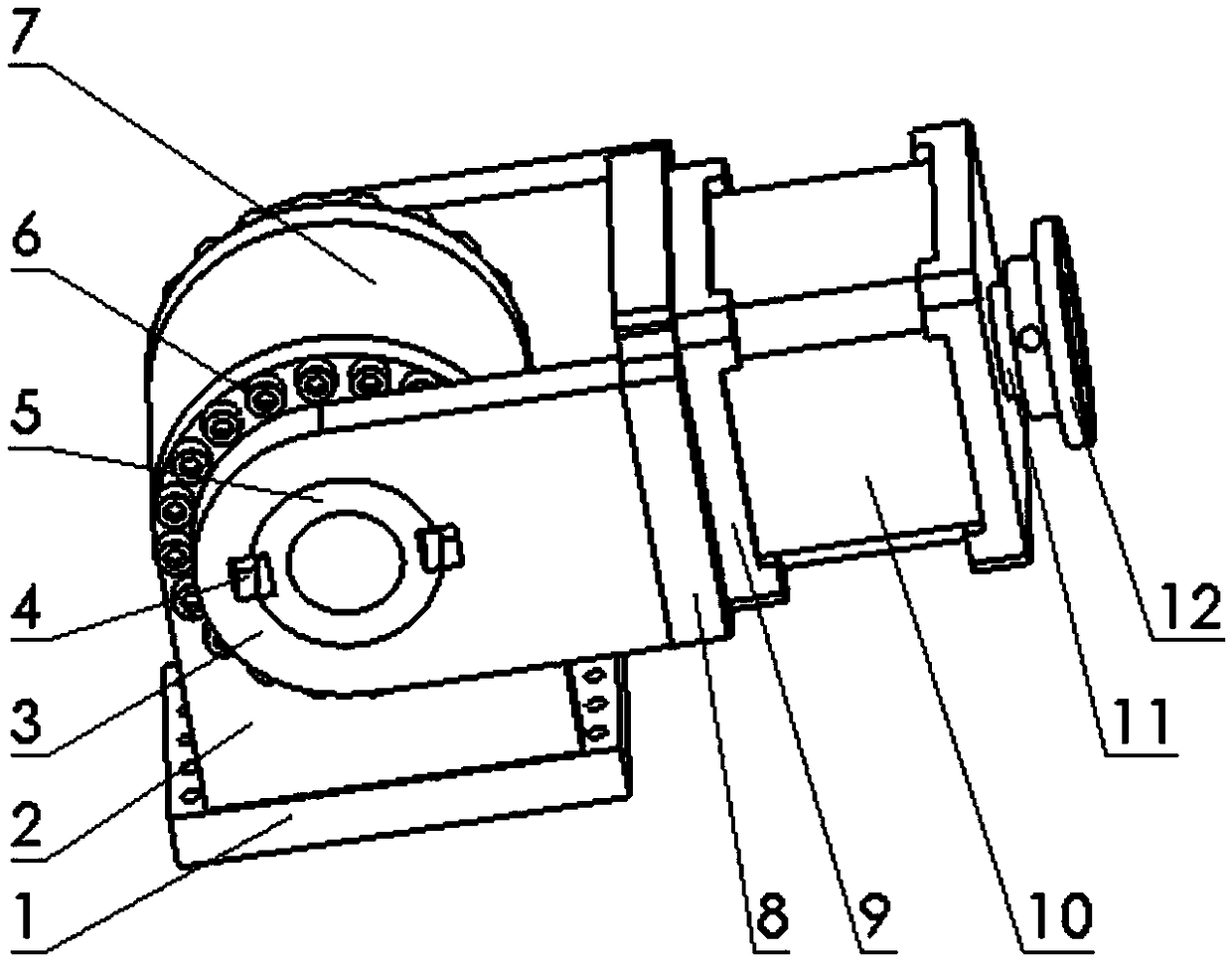

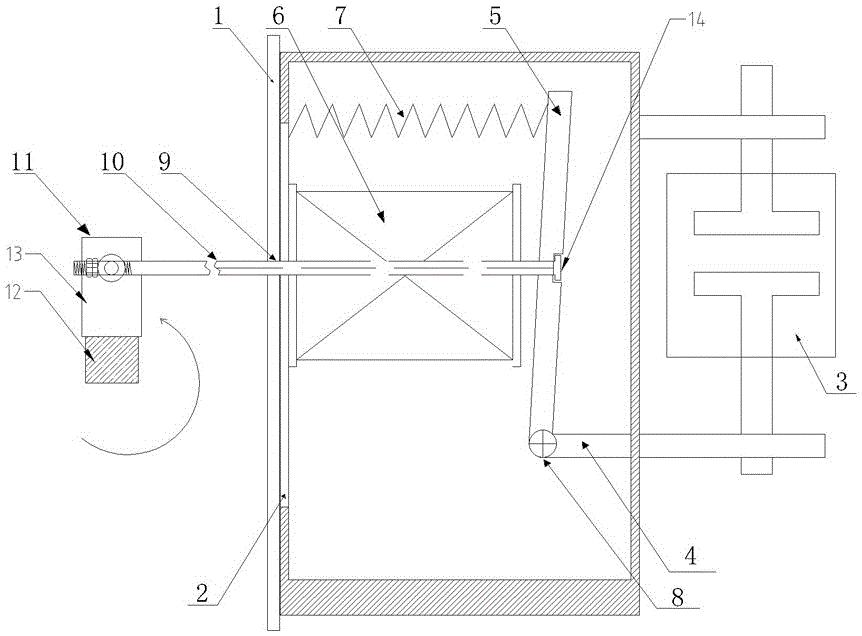

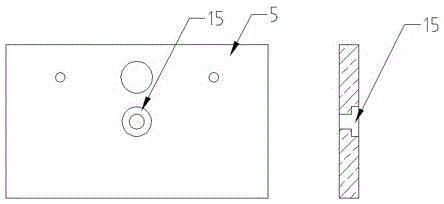

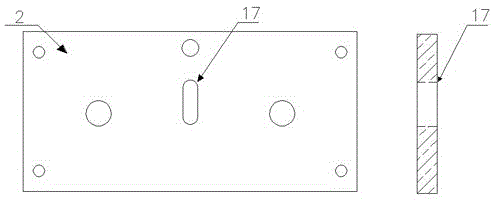

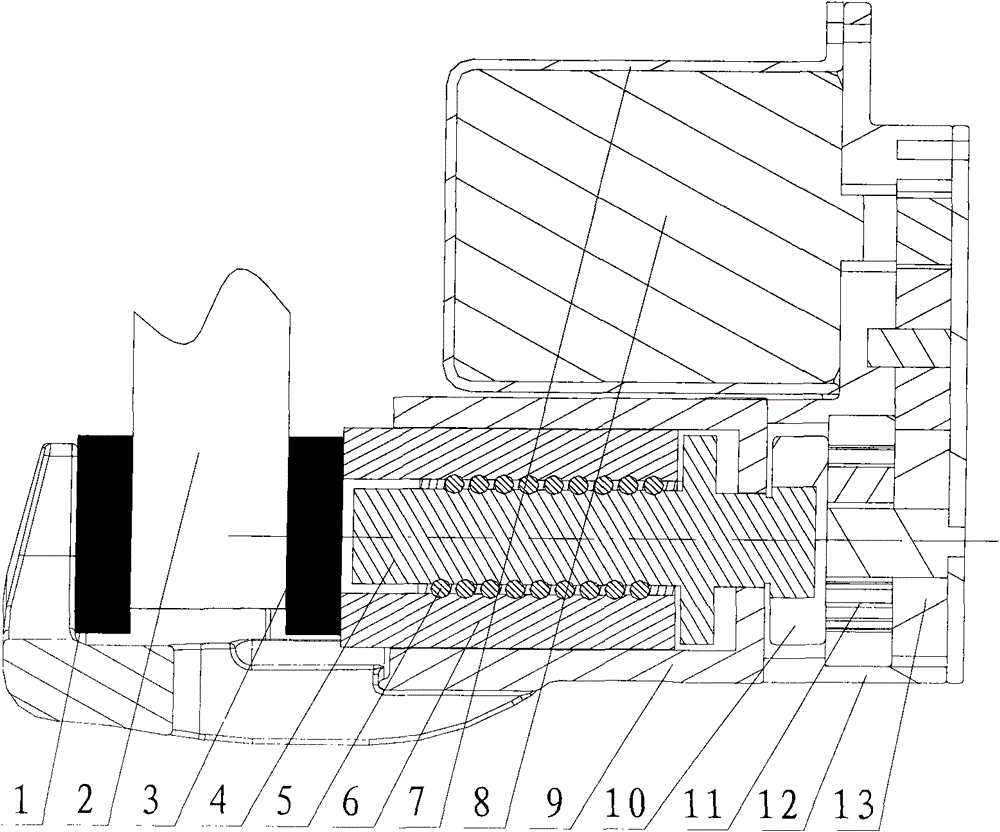

Automatic steering wheel control device and method for mounting same

ActiveCN108001523ASolve the problem of laborious manual operationCompact structureElectrical steeringAutomatic steeringSteering wheel

The invention discloses an automatic steering wheel control device, and belongs to the technical field of engineering machinery. The automatic steering wheel control device comprises an intermediate shaft (1), a motor (2), a first transmission mechanism (3), a second transmission mechanism (4) and an electromagnetic clutch (5). The intermediate shaft (1) is arranged on a side of a steering wheel shaft (9), the motor (2) is positioned on a side of the intermediate shaft (1), the intermediate shaft (1) is connected with the motor (2) by the first transmission mechanism (3) and is connected withthe steering wheel shaft (9) by the second transmission mechanism (4), and the first transmission mechanism (3) is connected with the intermediate shaft (1) by the electromagnetic clutch (5); the intermediate shaft (1) can be driven by the motor (2) via the first transmission mechanism (3) and the electromagnetic clutch (5) to rotate, and the steering wheel shaft (9) can be driven by the intermediate shaft (1) via the second transmission mechanism (4) to rotate. The automatic steering wheel control device has the advantages that the transmission ratio can be increased by the automatic steeringwheel control device, high torque can be outputted, automatic steering wheel control and manual control can be flexibly switched over without mutual interference, the automatic steering wheel controldevice is compact in structure, only small mounting spaces are required, and the like.

Owner:SHANGHAI ALLYNAV TECH CO LTD

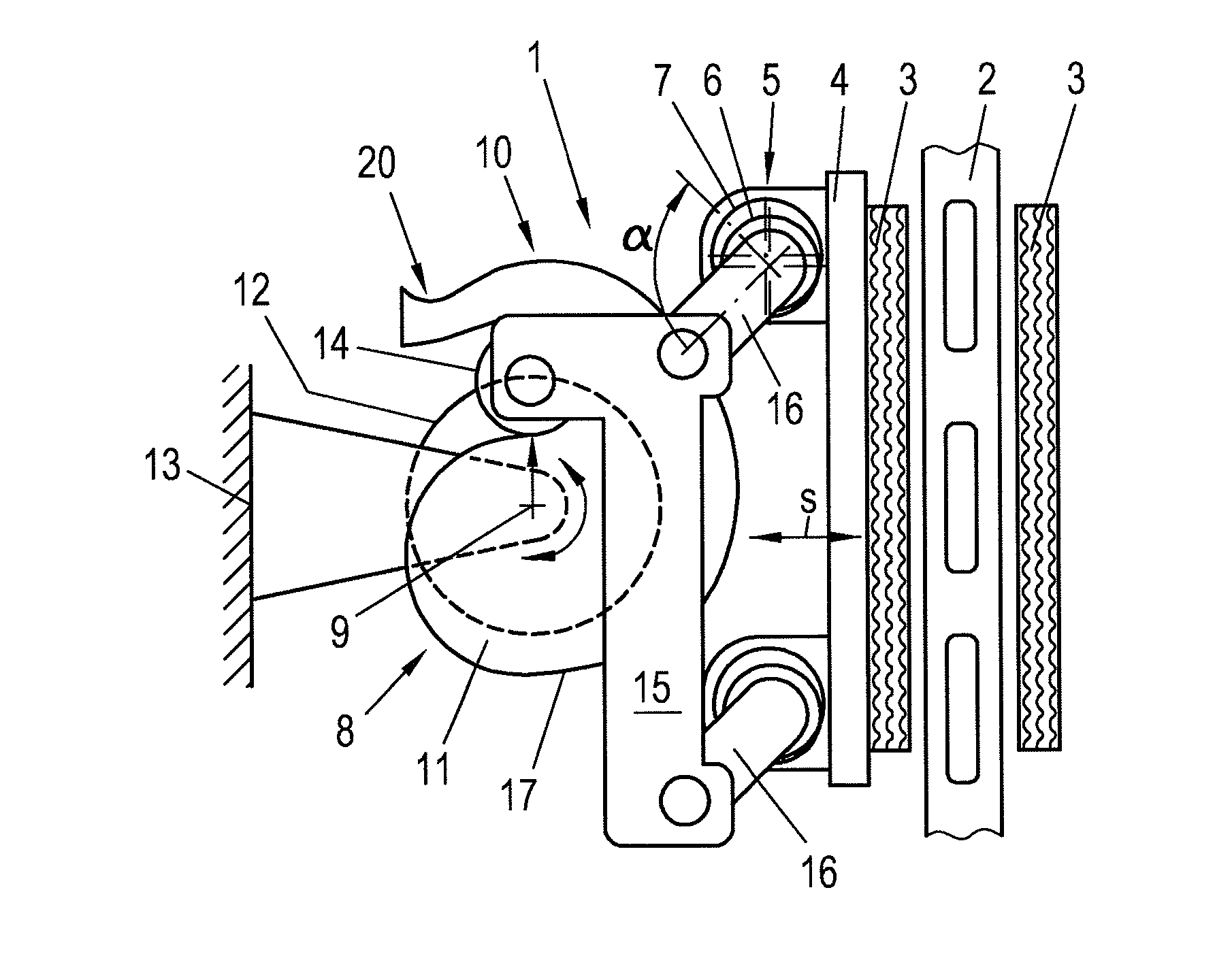

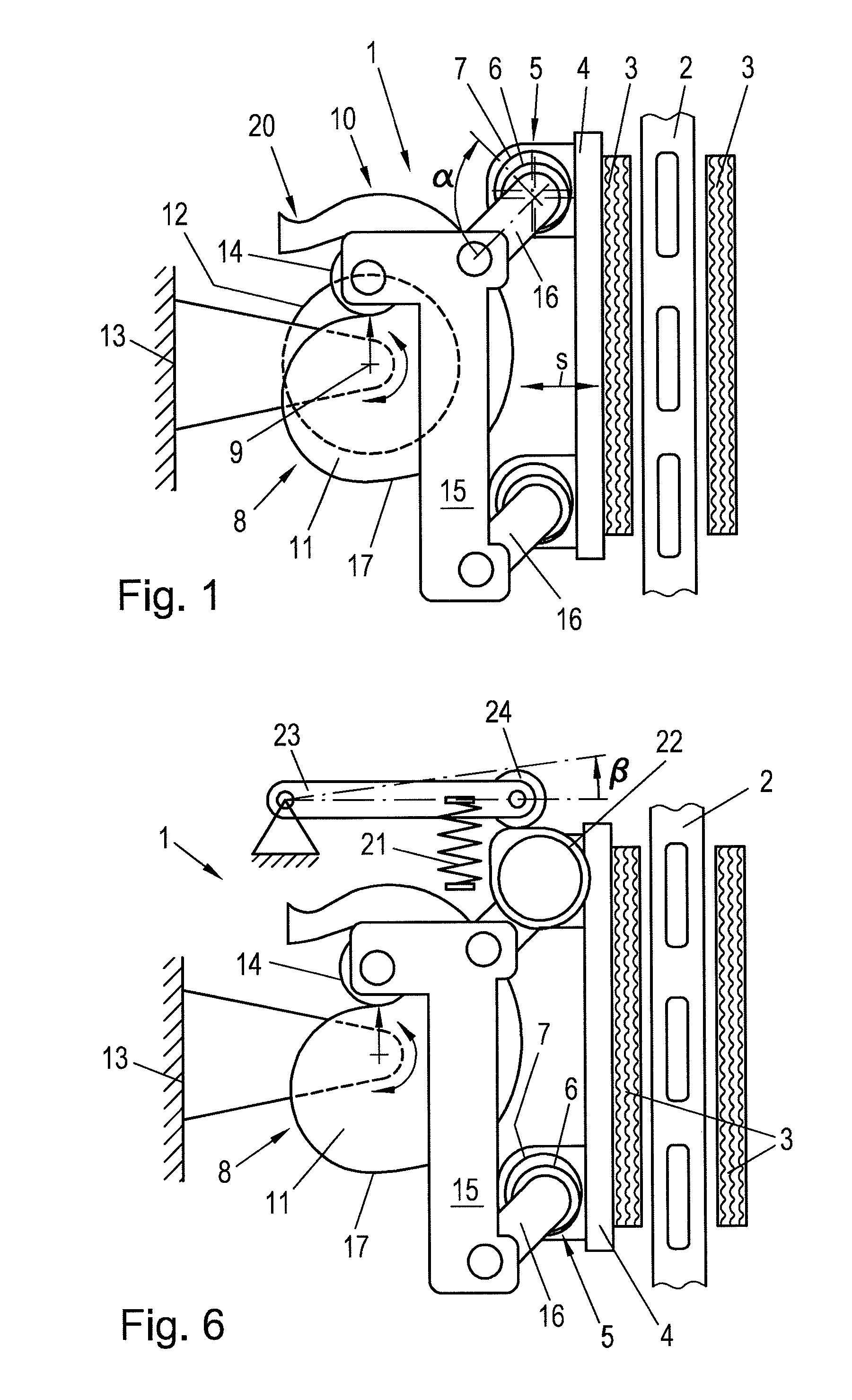

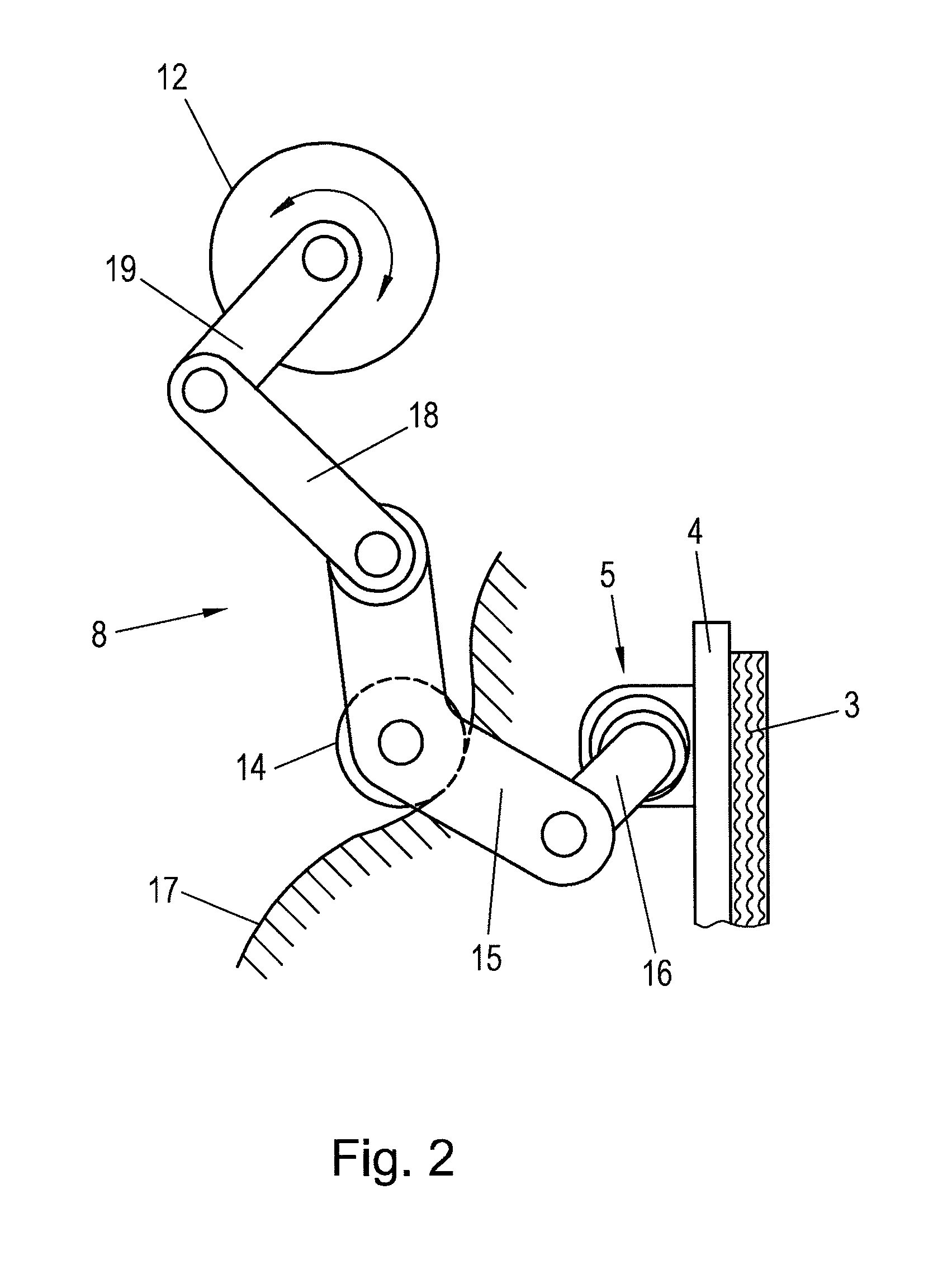

Electrically actuated friction brake

ActiveUS20160025168A1Reduce attainable actuation timeFriction brake inexpensiveMechanically actuated brakesBrake actuating mechanismsCouplingEngineering

Owner:ROBERT BOSCH GMBH

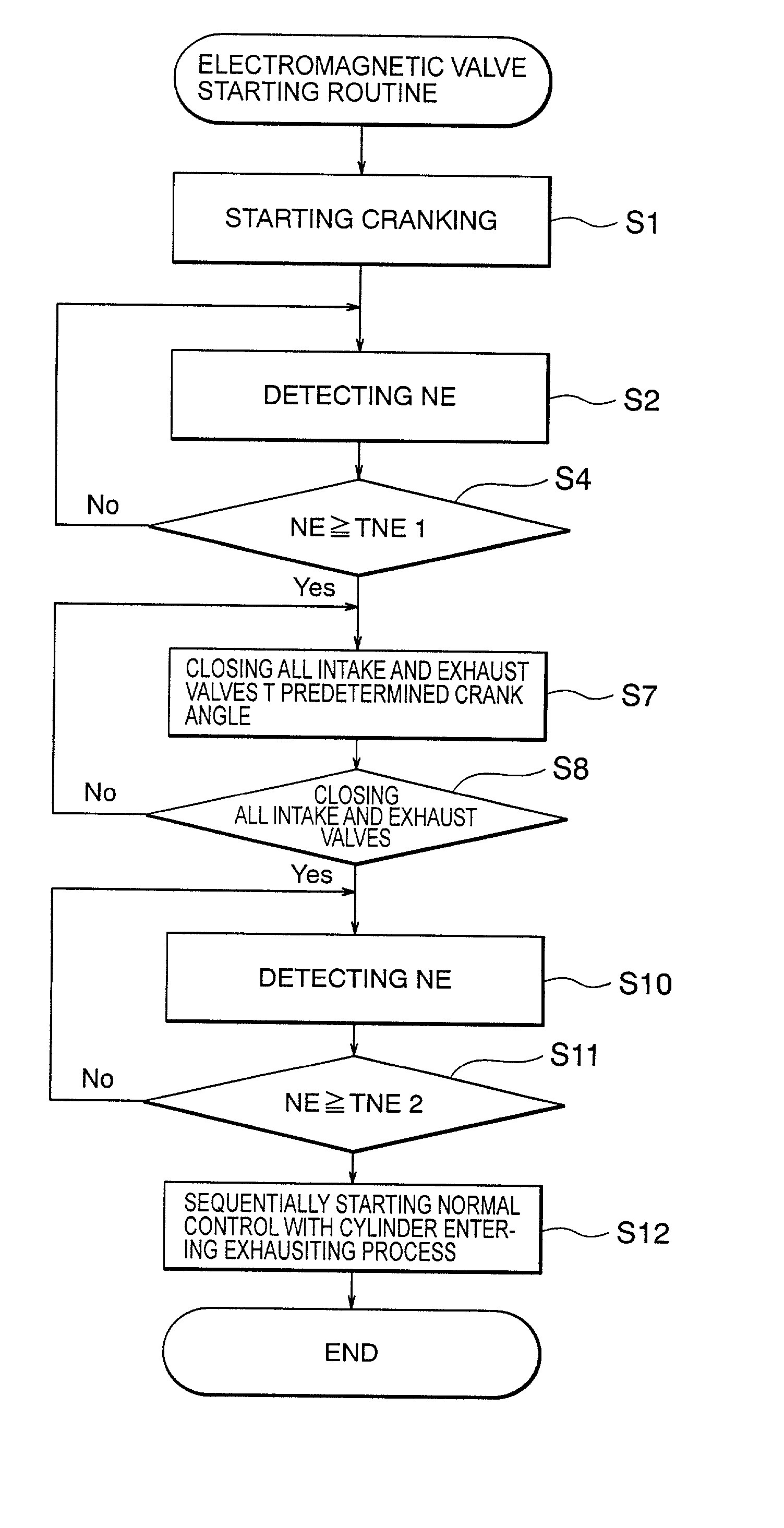

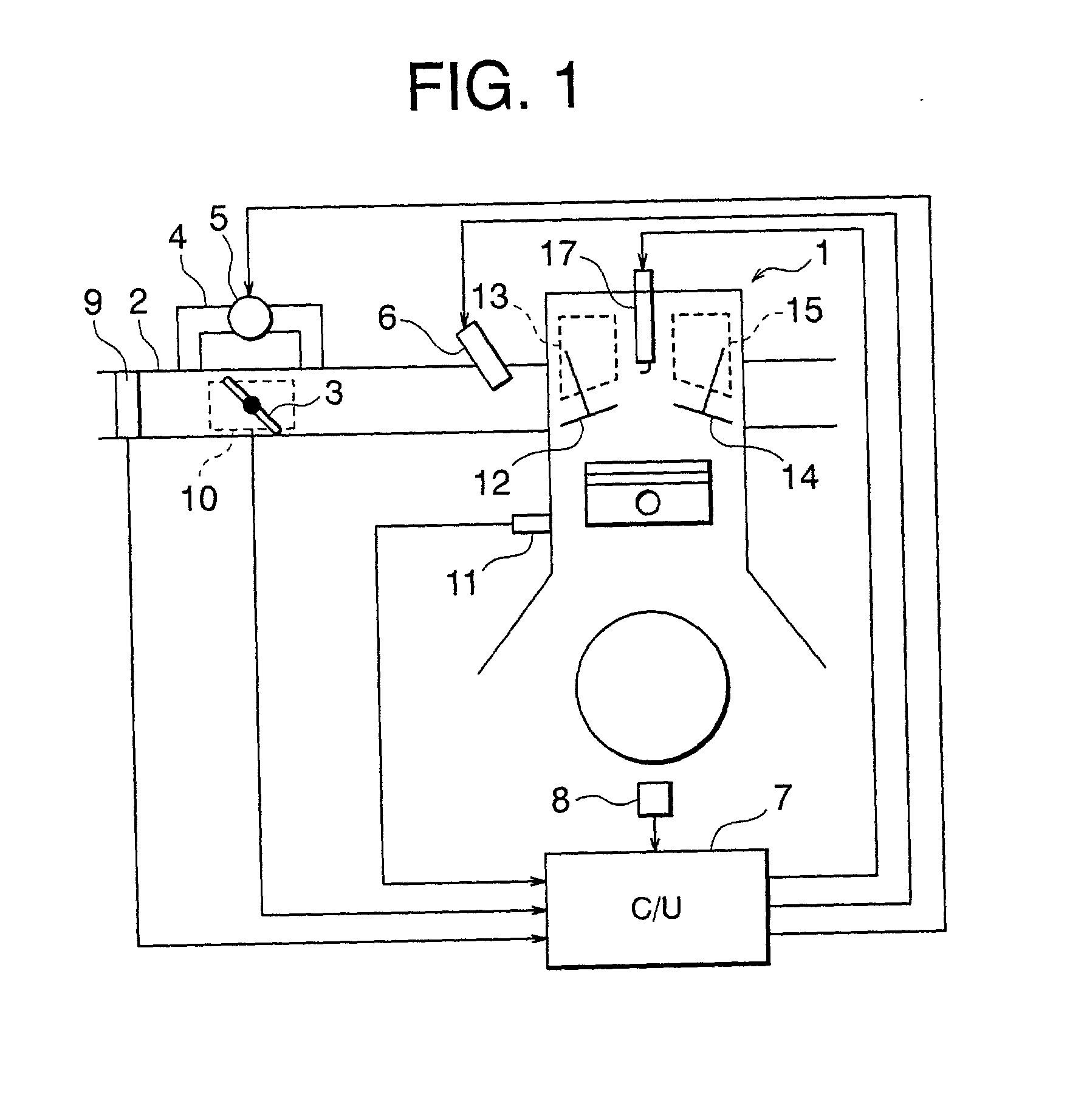

Method and apparatus for controlling electromagnetic driving valve for internal combustion engine

An engine with an electromagnetic driving valve reduces a loss during a cranking operation to shorten a starting time, reduce an electric power consumption for a starter motor, and prevent an interference between a valve system and a piston. Intake and exhaust valves are sequentially excited and started such that, after starting the cranking operation by a starter motor, a first cranking rotating speed can be reached, and the valves can be all closed at a predetermined cranking angle. All intake and exhaust valves are closed and the cranking rotating speed reaches an ignition point by the supply of a fuel and the continuous operation of the engine can be performed at more than a second cranking rotating speed, and the intake and exhaust valves can be switching controlled in the normal cylinder process.

Owner:MITSUBISHI ELECTRIC CORP

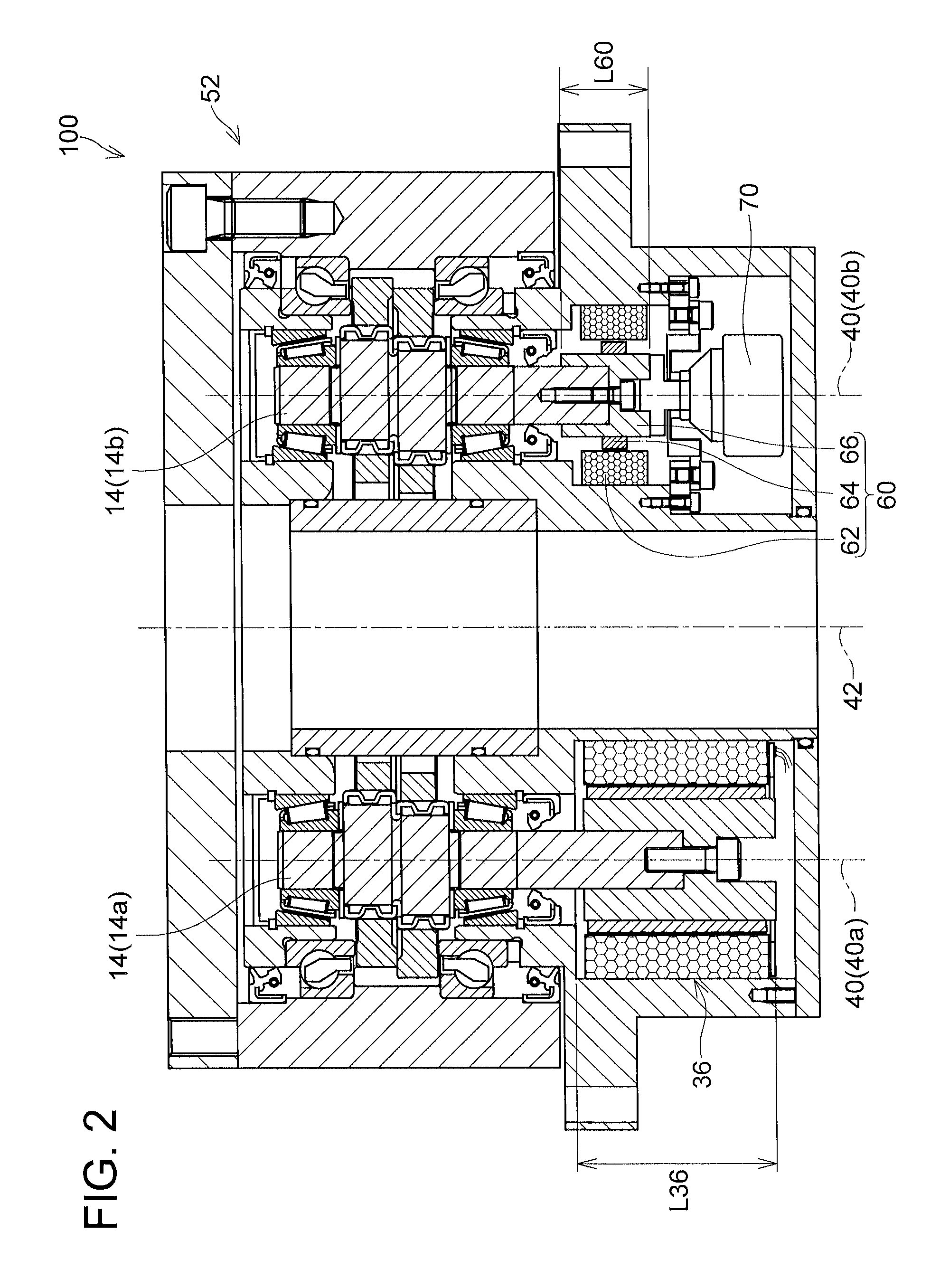

Structure of transmission gear box

InactiveCN102927251ACompact structureReduce volumeGear lubrication/coolingToothed gearingsChemical industryGear wheel

The invention discloses a structure of a transmission gear box. The structure of the transmission gear box is suitable for various industries, such as metallurgy, petroleum, chemical industry, sugar refining, mines and transportation. The structure of the transmission gear box mainly comprises a gear box body, a box cover, a bevel gear transmission mechanism and a first planetary gear transmission mechanism, wherein a first sun wheel shaft of the first planetary gear transmission mechanism is delicately designed to be in a flexible long shaft structure, a first planet carrier and a hollow gear shaft are movably sleeved outside the first sun wheel shaft, and input power passes through the first planetary gear transmission mechanism and the hollow gear shaft and is transmitted to an output stage gear through the bevel gear transmission mechanism, and then is output through an output shaft from multiple angles. The modified structure of the transmission gear box is more compact, and has the advantages of being small in size, light in weight, large in total speed ratio, strong in output torque, large in bearing capacity, stable in transmission, high in transmission efficiency, and the like, can adjust the structure of the power transmission according to different occasions, meets the requirements for special installation of whole equipment, lowers purchase cost of the equipment, widens industrial application scope, and enhances economic advantages.

Owner:宁波东力股份有限公司

Novel mechanical arm joint

The invention discloses a novel mechanical arm joint. The novel mechanical arm joint comprises a swinging oil cylinder driving device and a servo motor driving device, wherein two cylinder body bladesupports which are symmetrically distributed are arranged on the inner wall of a cylinder body of the swing oil cylinder driving device, the cylinder body blade supports are used for installing cylinder body blades, two rotor blade supports which are symmetrically distributed are arranged on the side wall of a swing cylinder rotor, and the rotor blade supports are used for installing the swing cylinder rotor blades, the swing cylinder rotor is installed in the cylinder body, and the two cover plates which are packaged on the two sides of the cylinder body are fixedly supported, the cover plates on the two sides of the cylinder body are installed on a cover plate connecting plate; a servo motor driving device is provided with two motor end covers which are fixedly installed on the two sidesof a servo motor body correspondingly, the servo motor body is connected with a motor output shaft, and an output shaft end flange plate is installed at one end, far away from the servo motor body, of the motor output shaft; and one end, far away from the motor output shaft, of the servo motor driving device is installed at the two ends of the swing cylinder rotor through two force arm rods. According to the arm joint, large torque and large output torque can be borne, and meanwhile, a relatively good swinging angle can be achieved.

Owner:WUHAN UNIV OF SCI & TECH

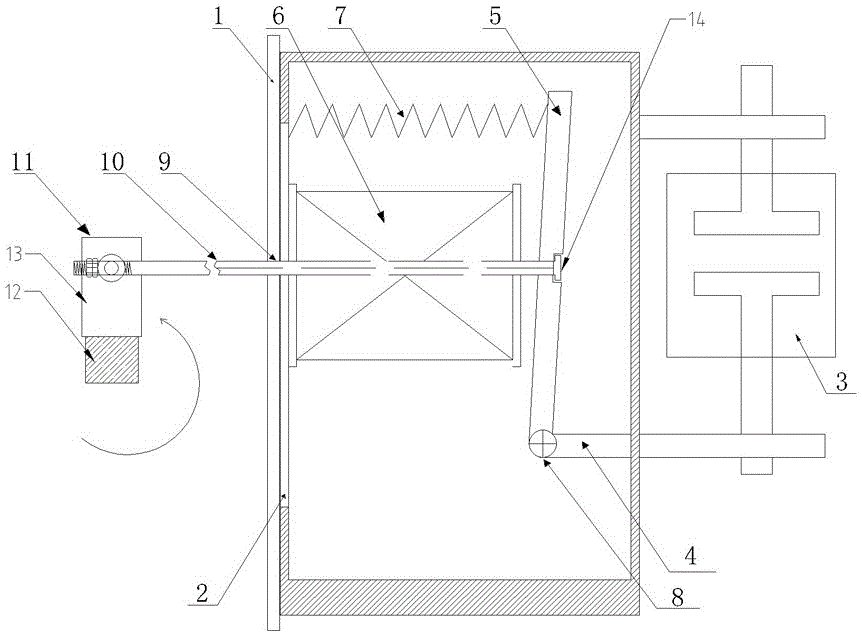

Mechanical emergency starting apparatus for start-delta voltage-reduction starting

InactiveCN106409600AGood consistency of mechanical emergency startMotion synchronizationHigh-tension/heavy-dress switchesAir-break switchesElectricityNational standard

The invention relates to a mechanical emergency starting apparatus for start-delta voltage-reduction starting. The apparatus is composed of an insulation isolating frame, a rear metal sealing plate, two sets of electromagnetic control mechanisms, a manual operating mechanism and two sets of vacuum switch tube parts. Each electromagnetic control mechanism set includes a closing holding buckle plate, a driving connecting lever, a closing armature, a closing coil, and a closing spring; a long pull rod passes through a straight slot formed in the rear metal sealing plate and then connects a counterbore formed in the closing armature; and a thread part formed at the other end of the long pull rod is connected with a U-shaped linkage block arranged on a linkage rod of the manual operating mechanism movably by a positioning pin. According to the invention, two alternating-current vacuum contactors can be driven synchronously to realize mechanical emergency starting. The provided apparatus meets regulations in the mandatory article 11.0.12 in the national standard GB 50974-2014 ''Technical Specifications of Fire-fighting Water Supply and Fire Hydrant System'' implemented on October 1st, 2014.

Owner:CHENZHOU DONGTANG ELECTRIC EQUIP

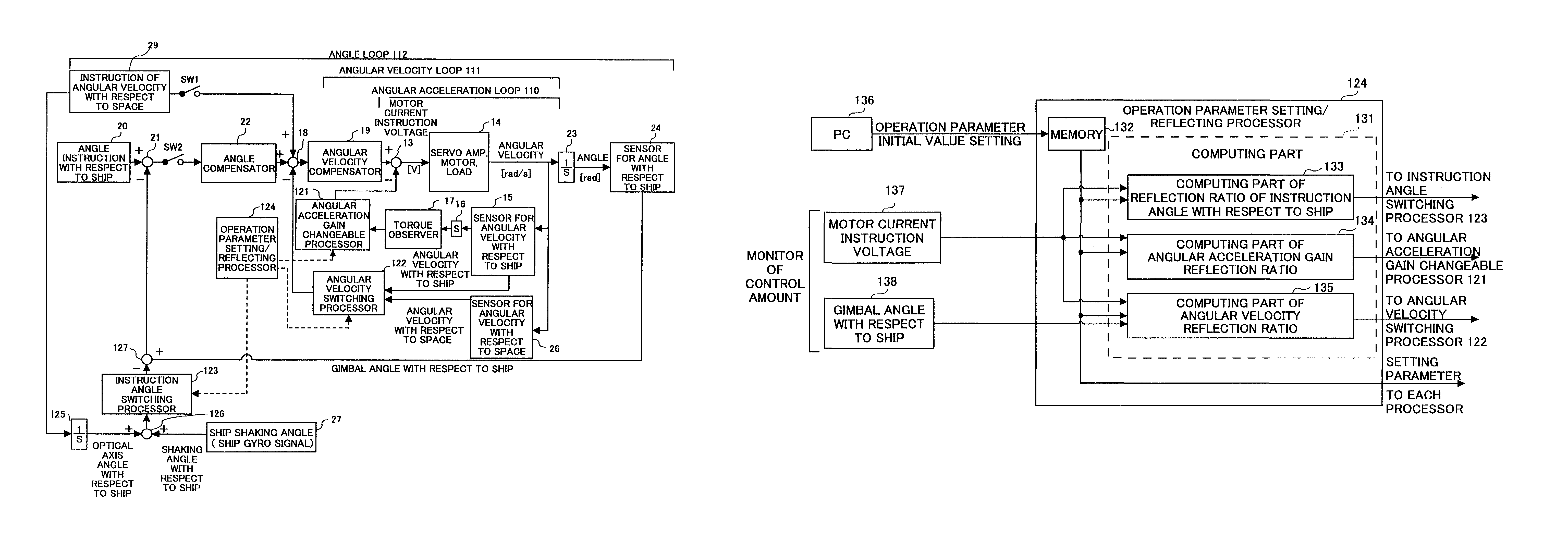

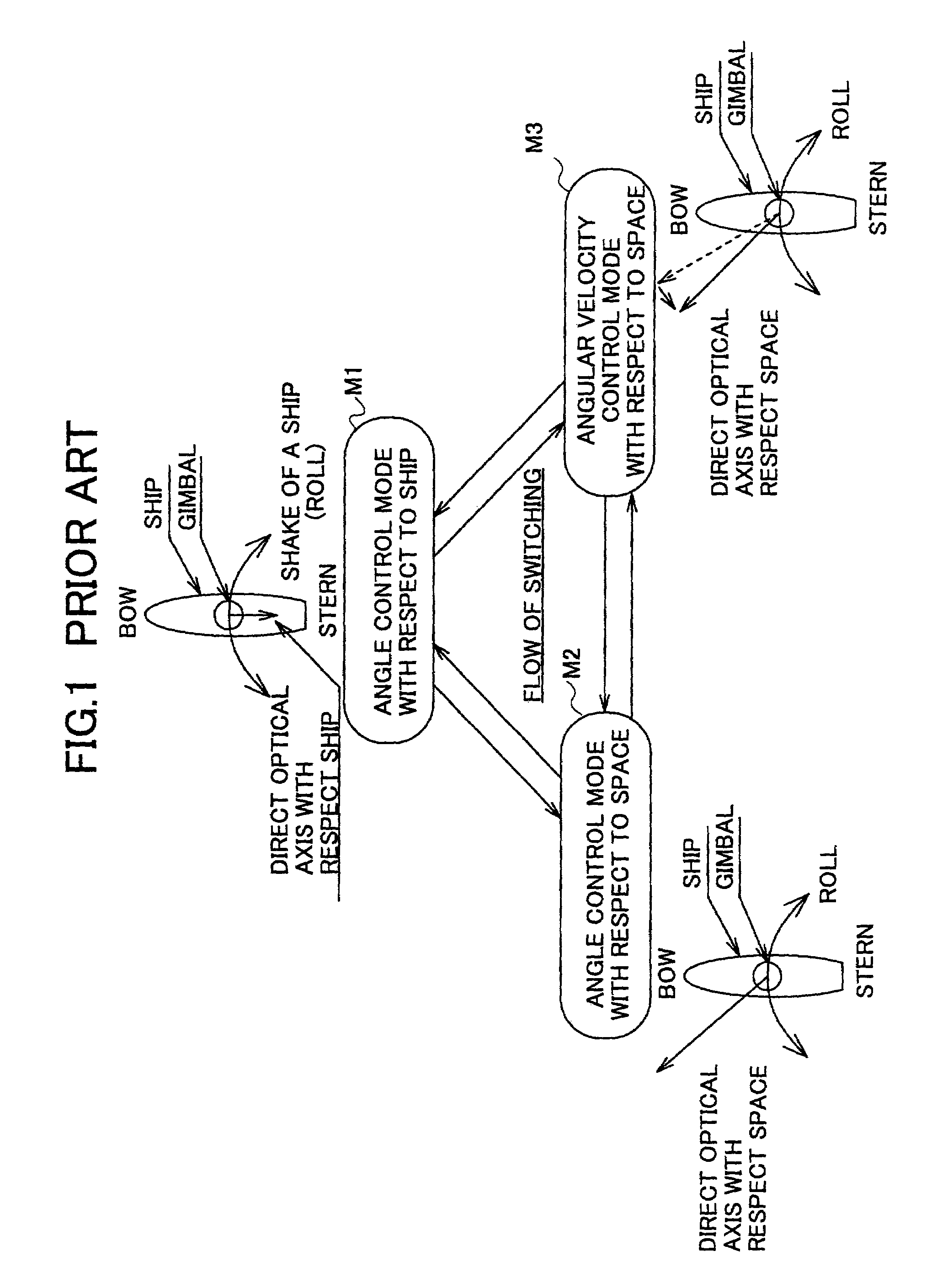

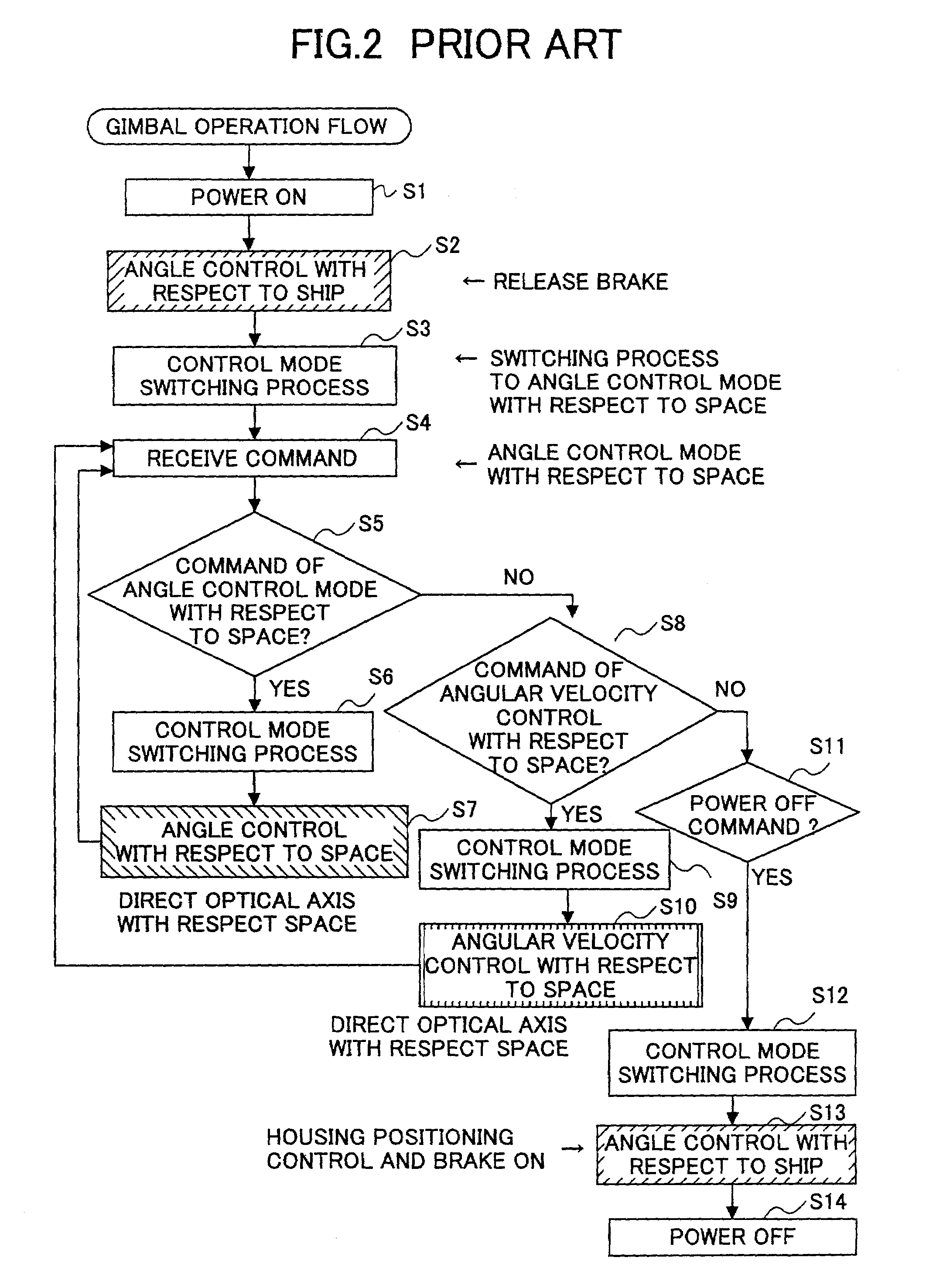

Positioning control apparatus and the method

InactiveUS7437237B2Improve accuracyProcess stabilityAnalogue computers for vehiclesAircraft controlEngineeringPosition control

A positioning control apparatus including feedback loops according to a plurality of control modes which control positioning of an object to be controlled is provided, in which the positioning control apparatus includes a part (121, 122, 123, 124) for reflecting a control process performed by a control mode before being switched in a control process performed by a control mode after being switched when a control mode is switched to another control mode. For example, an operation parameter on the control mode before being switched is dynamically reflected in the control mode after being switched.

Owner:FUJITSU LTD

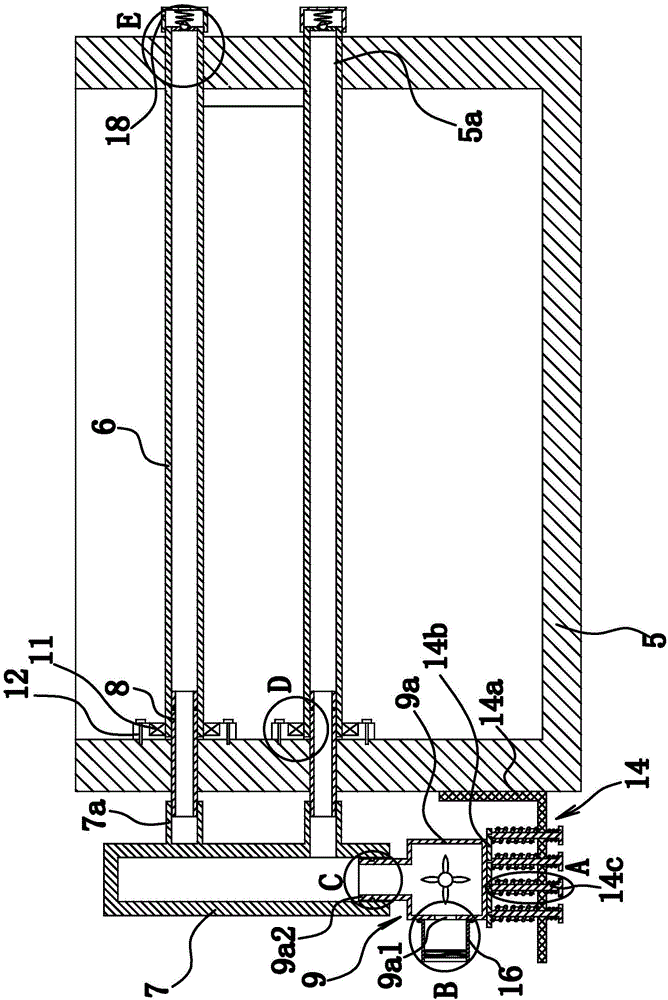

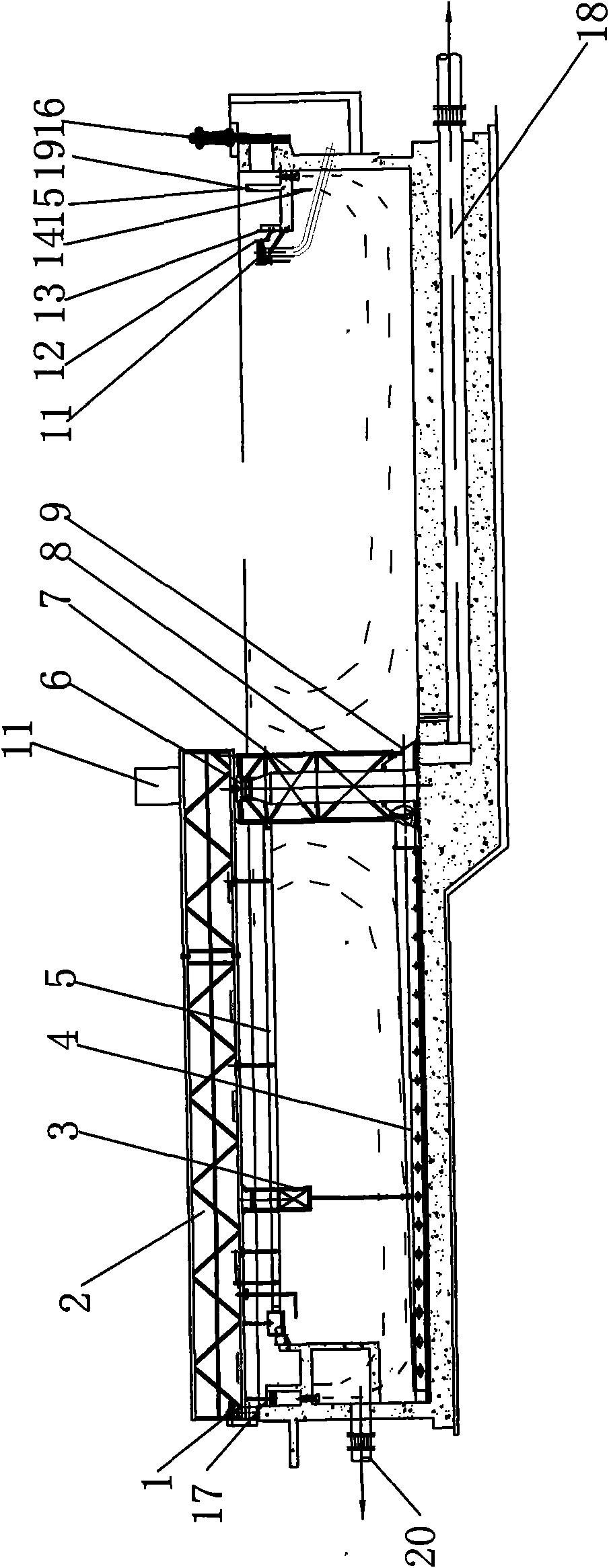

Single-tube suction dredge

InactiveCN101559298ASmall reduction ratioSmall output torqueSettling tanks feed/dischargeSludgeRotating disc

The invention discloses a single-tube suction dredge, comprising a dredging tube which is arranged at the bottom of a sedimentation tank and is movably connected and communicated at the inside and outside thereof by a sealing cylinder in a sealing manner, a traction arranged, a bridging device which is arranged in the sedimentation tank and tows the dredging tube and the sealing cylinder, and a driving device. The bridging device comprises a central column, a central rotating disc, a working bridge, a central vertical frame and a pulling rod of the dredging tube which are fixed in the sedimentation tank; the central rotating disc is movably coupled with the central column to form a revolving support and is coupled with the working bridge and the central vertical frame outside of the central column. A skimming device is coupled below the working bridge; one end of the working bridge is coupled with the central column by the central rotating disc movably and the other end thereof is coupled with the driving device and travels along the edge of the tank; the working bridge is fixedly connected with the dredging tube by the pulling rod of the dredging tube; and the central vertical frame is fixed coupled with the working bridge and the sealing cylinder. As the periphery is adopted to drive the dredging tube, the single-tube suction dredge has simplified structure, less disturbance to muddy water, good skimming effect, light weight for a main machine and low cost, and is particularly applicable to the primary sedimentation tank with larger sewage sludge concentration and the large sedimentation tank of more than 50m.

Owner:广东新环环保产业集团有限公司

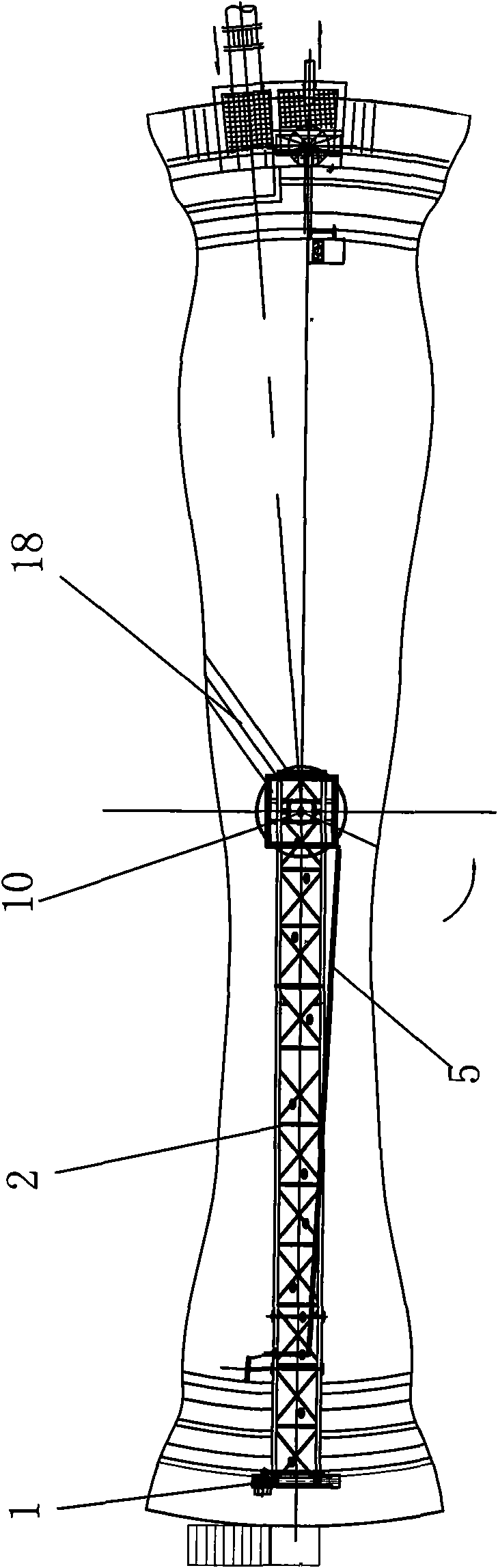

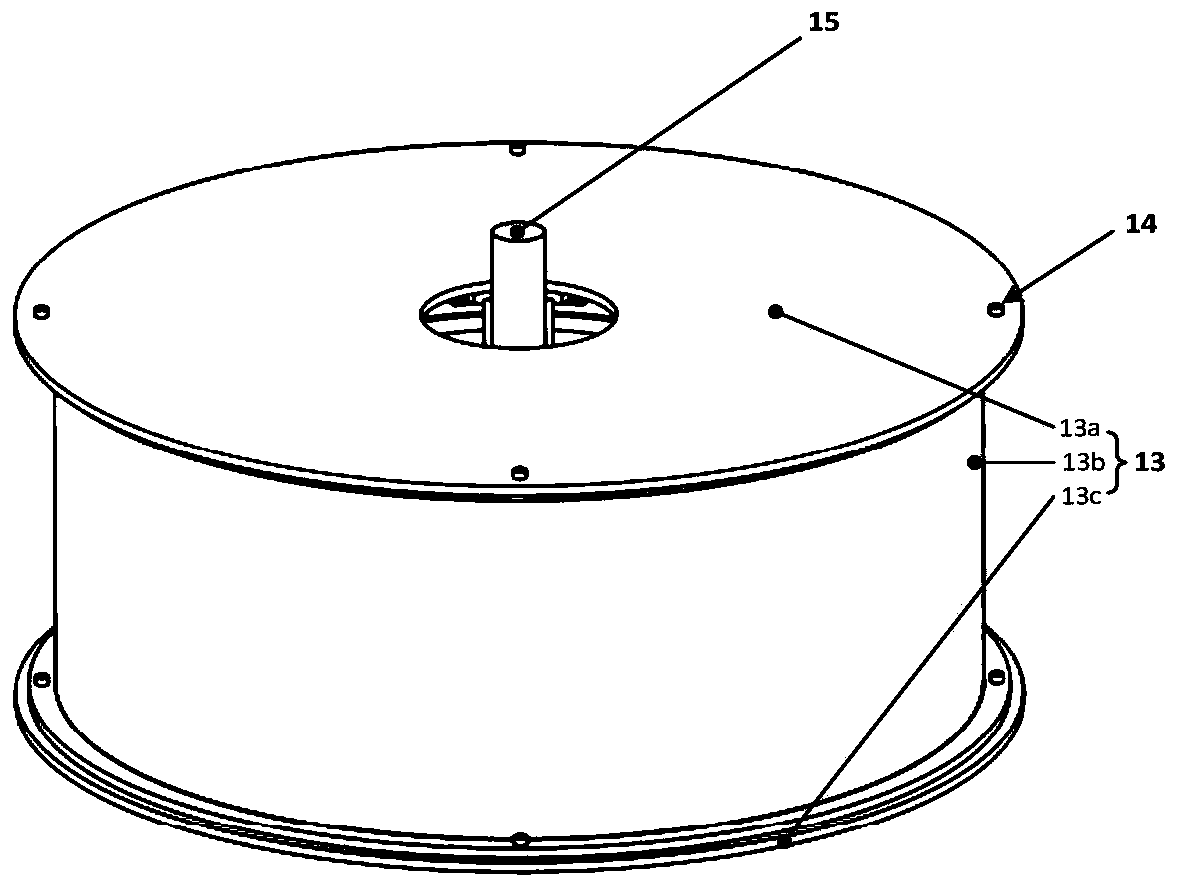

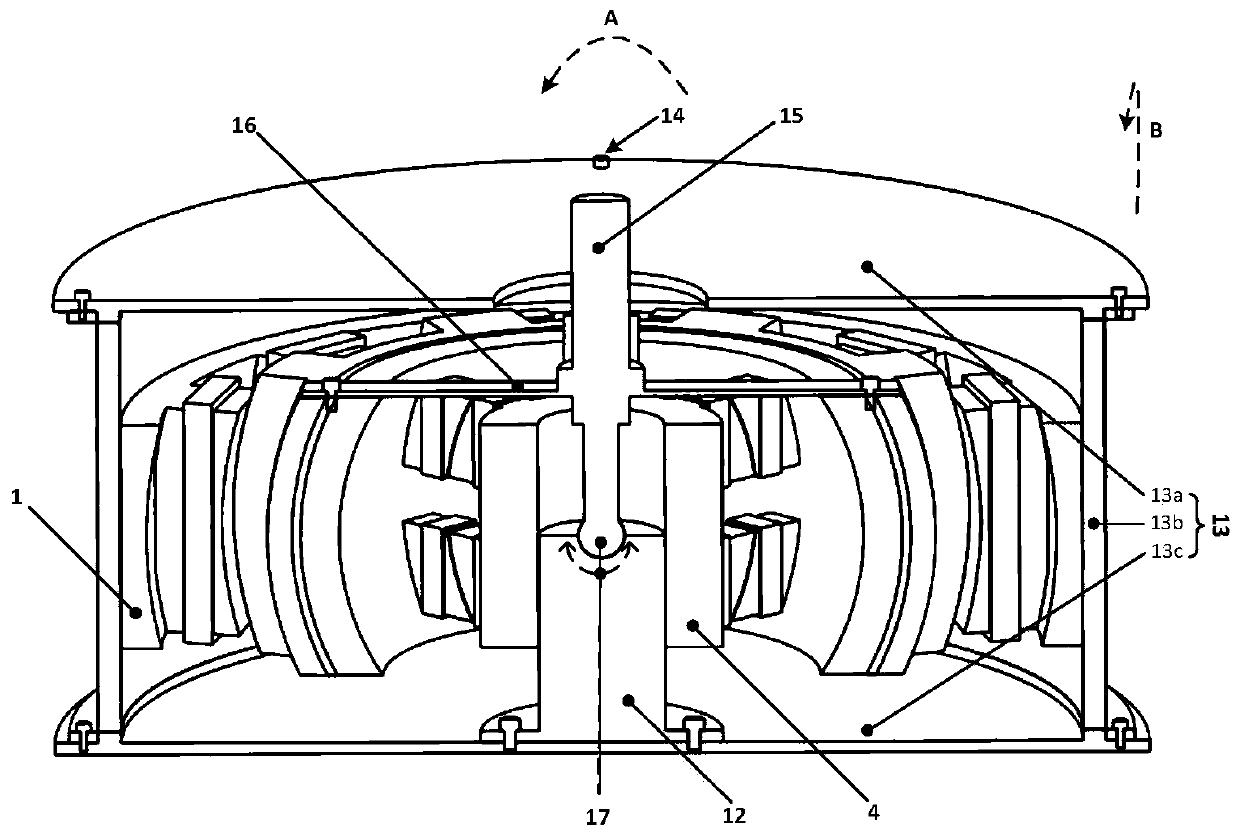

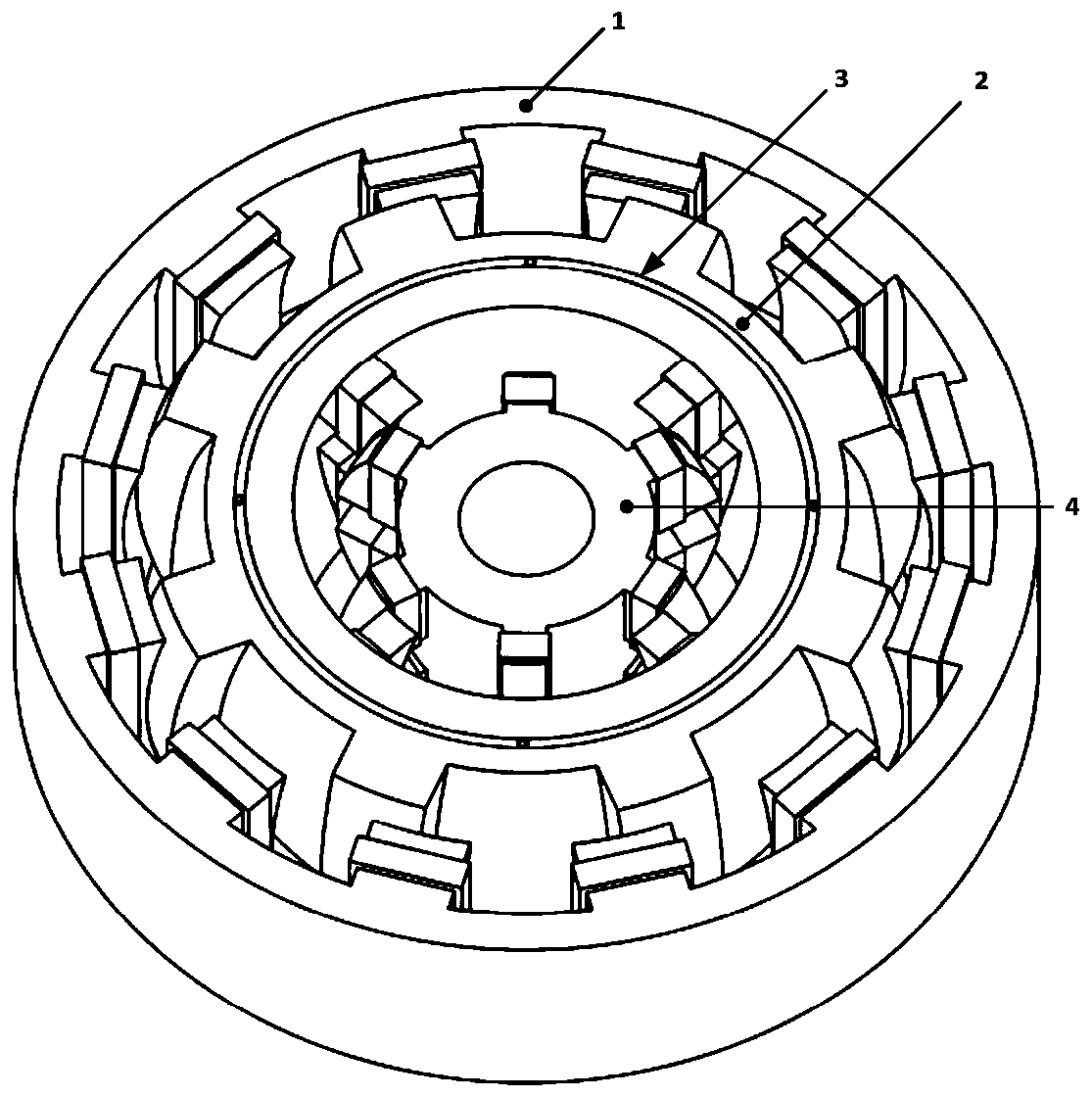

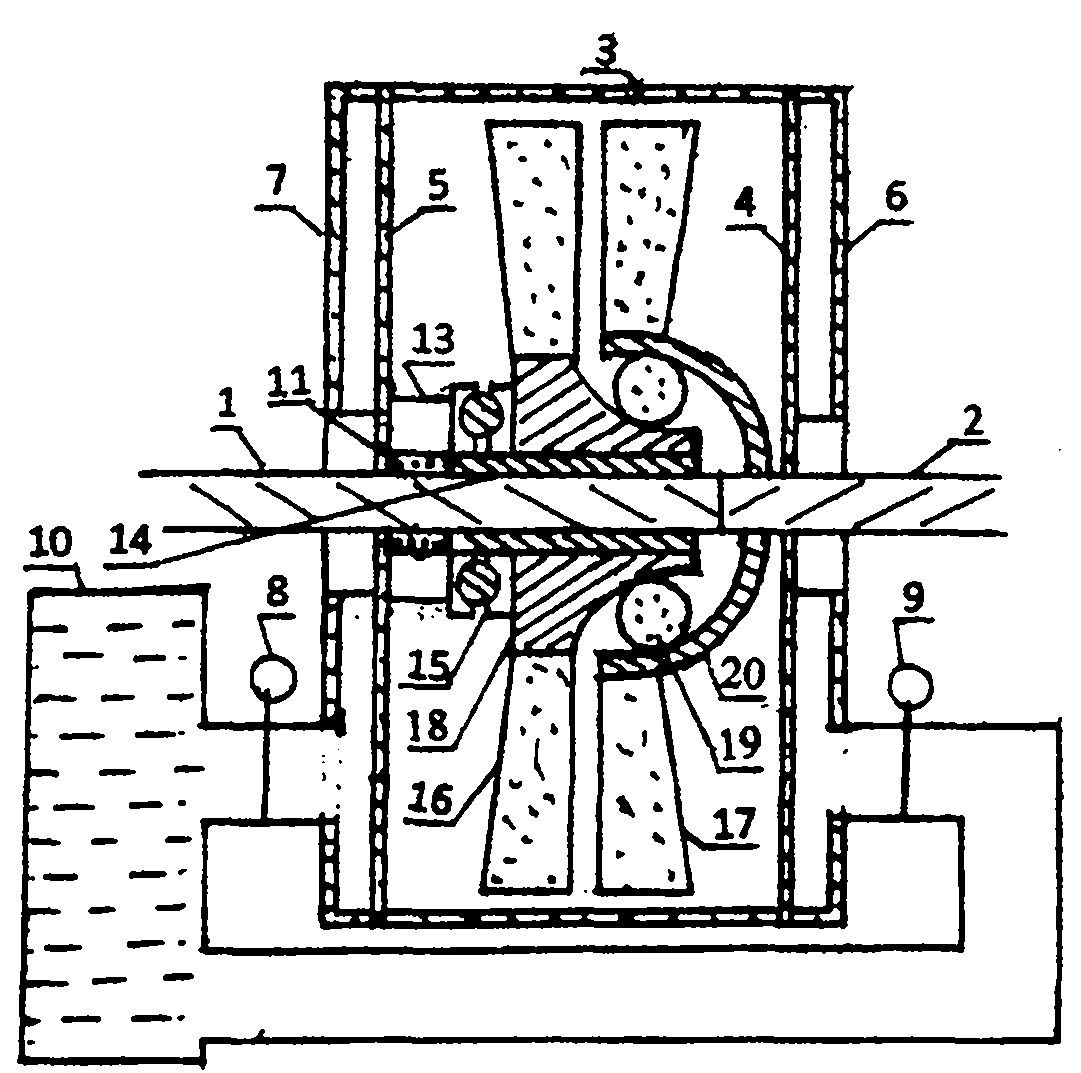

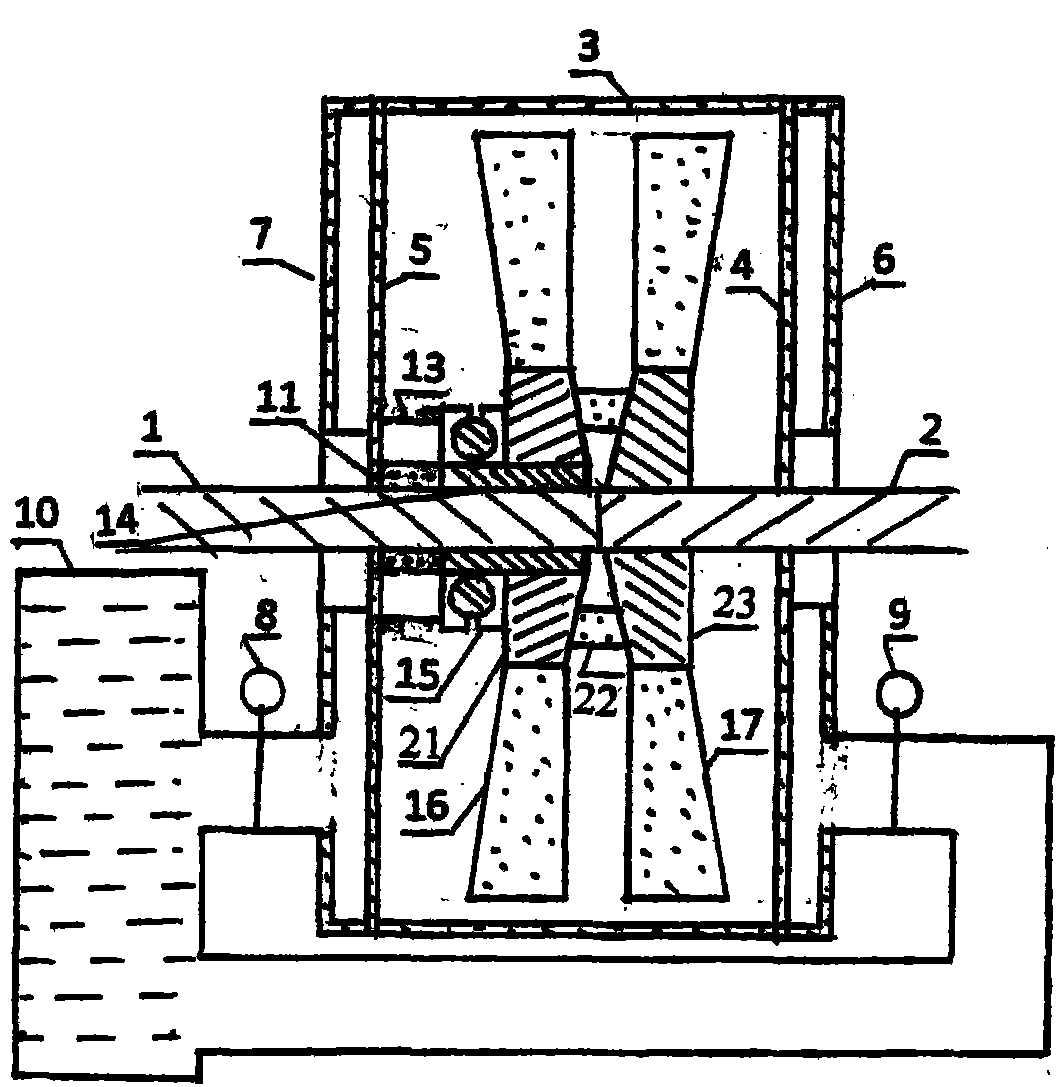

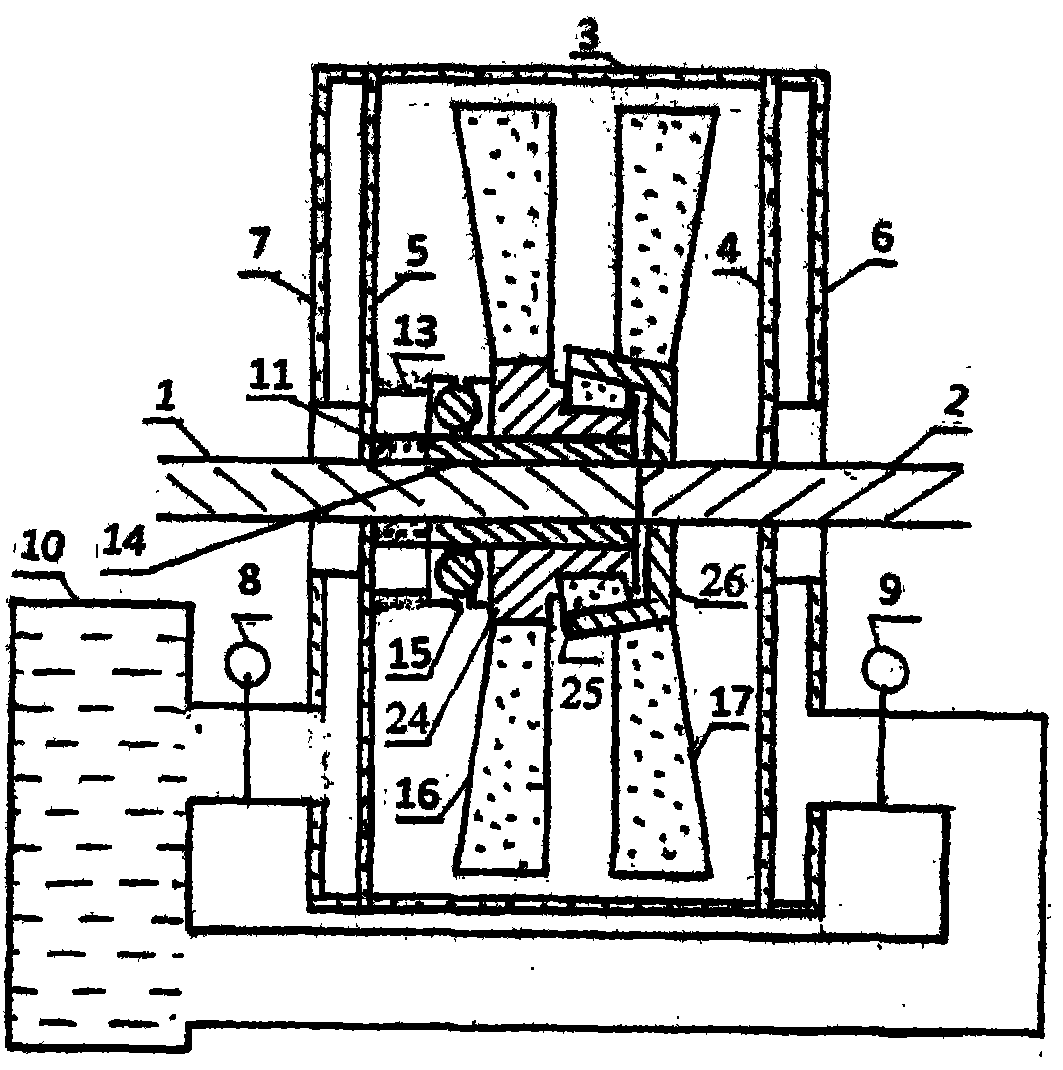

Dual-stator multi-degree-of-freedom motor

ActiveCN109728699AHigh output torqueHigh output average torqueMagnetic circuit rotating partsMagnetic circuit stationary partsStatorMulti degree of freedom

The invention provides a dual-stator multi-degree-of-freedom motor, which relates to the technical field of multi-degree-of-freedom motors. A rotor is located between an outer stator and an inner stator. A magnetic isolation plate is embedded between the inner and outer sides of the rotor. Windings are arranged on the inner sides of the outer stator and the rotor and on the toothed poles of the inner rotor respectively, and permanent magnets or toothed poles are arranged on the outer side of the rotor. The inner side of the outer stator, the outer and inner sides of the rotor and the outer sides of the toothed poles of the inner stator are spherical in shape. The lower end of the shaft of the rotor is connected with the connecting shaft of the inner stator through a joint bearing. The rotor is fixed to the upper part of the output shaft through a rotor connecting plate. The length of the rotor shaft is at the upper opening position of the outer stator and the inner stator, and the rotor shaft can rotate and deflect. The invention mainly aims to solve the problem that the existing multi-degree-of-freedom motor has small output torque. The dual-stator multi-degree-of-freedom motor can realize coordinated control of rotation and deflection, has the characteristics of large output torque, simple and compact structure, small occupied space and low cost, and can be applied to the field of driving devices requiring multi-degree-of-freedom motion in space.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

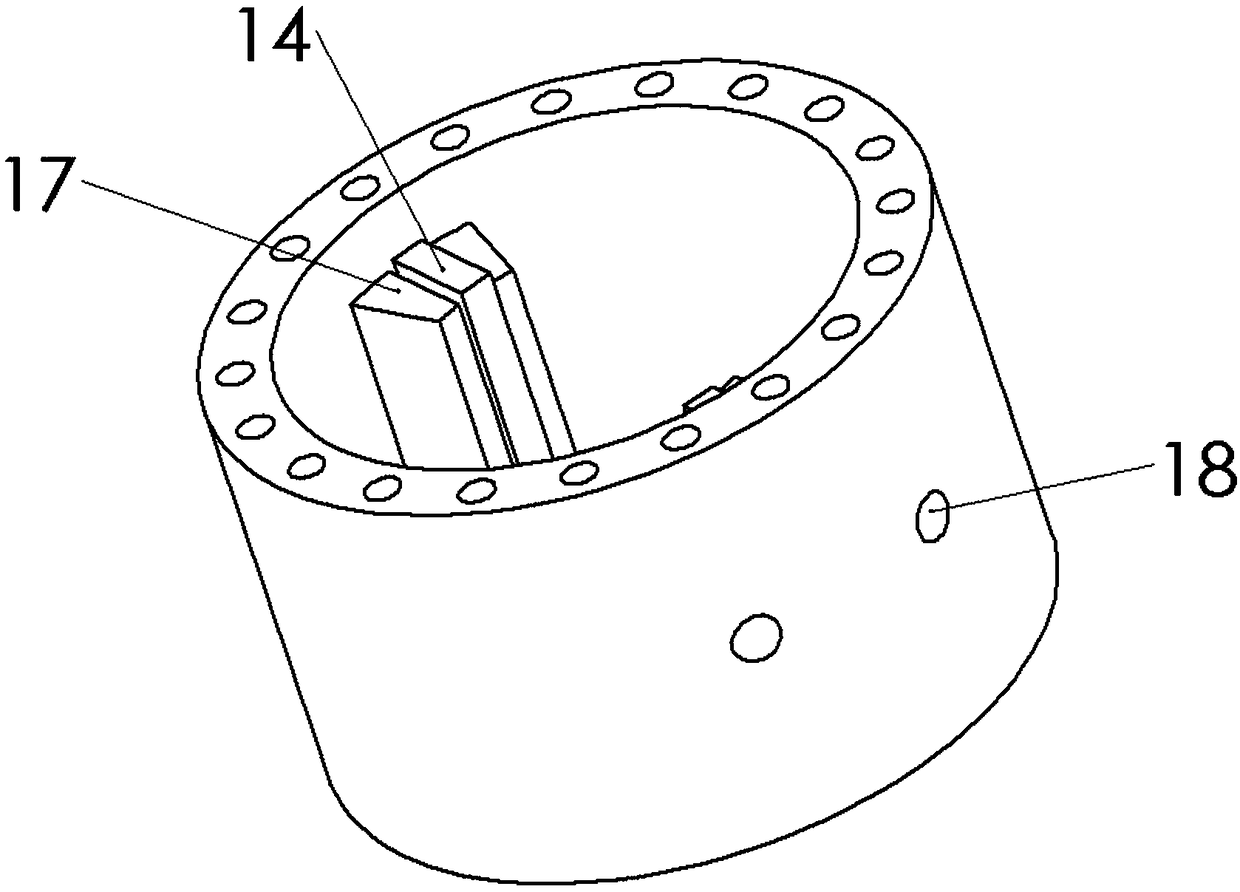

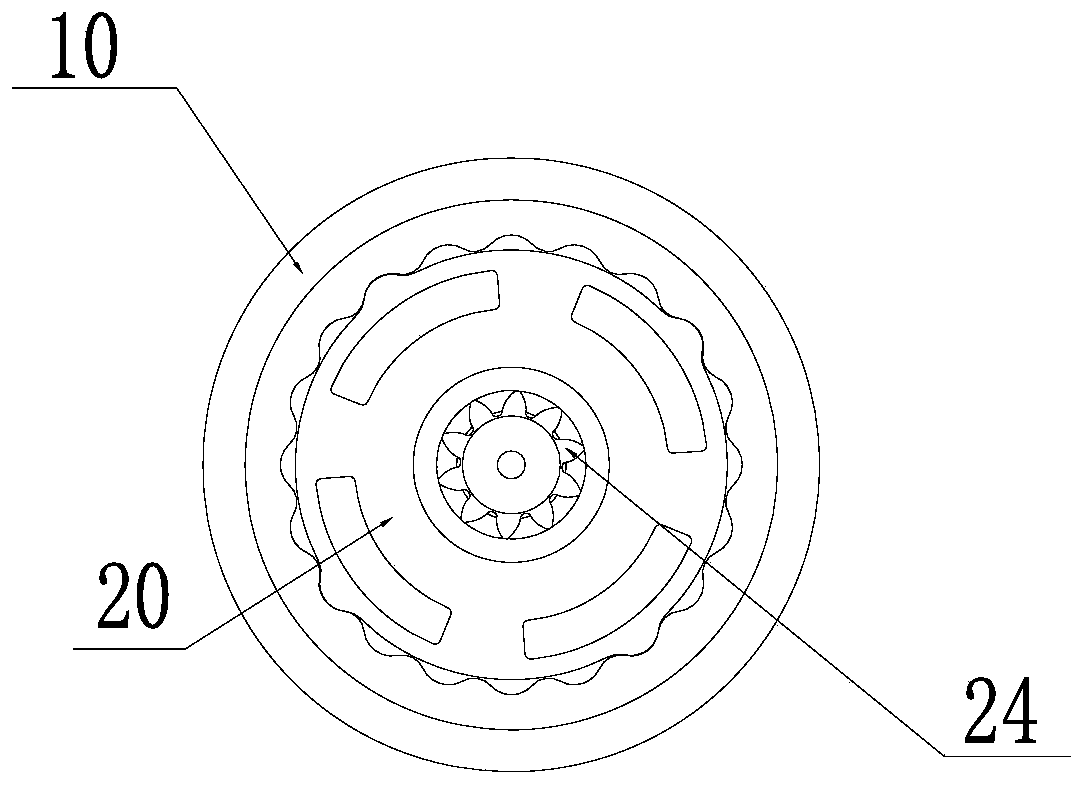

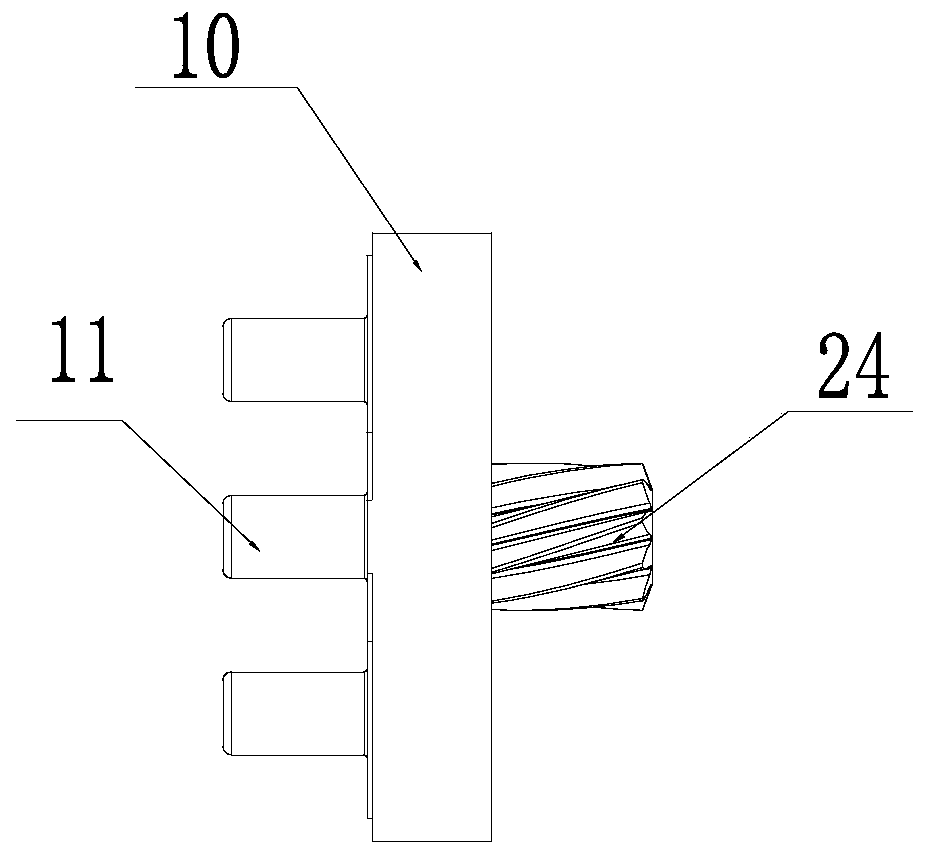

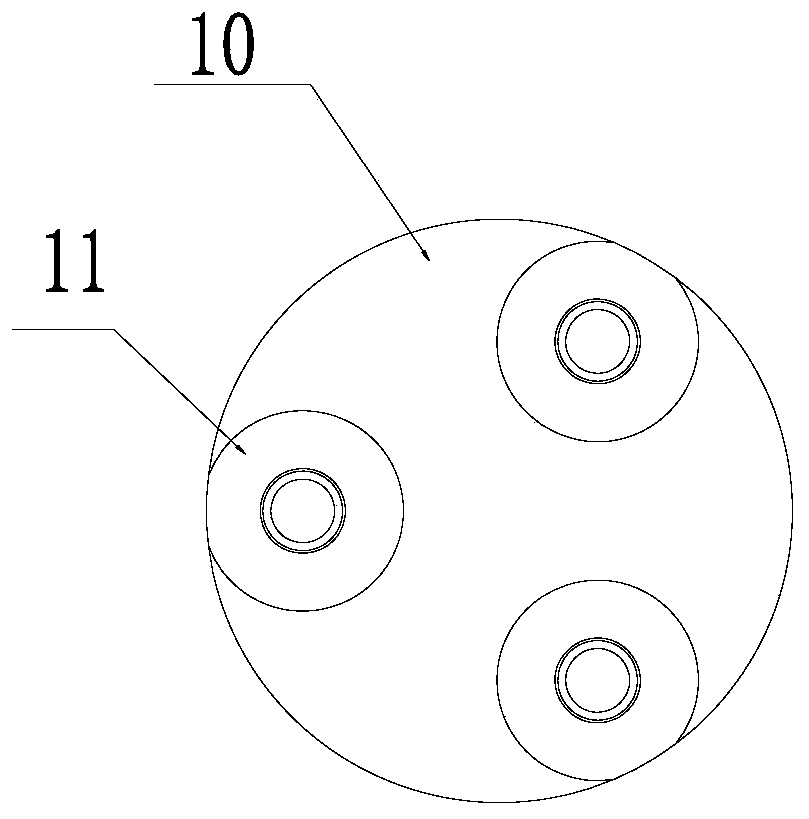

Mechanical overload protection device, speed reduction mechanism and electrically-driven flip driver

PendingCN109826875AExtended service lifeEasy to placeSlip couplingToothed gearingsElectricityMechanical overload

The invention discloses a mechanical overload protection device. The mechanical overload protection device comprises a power disc of a round structure and an overload protection disc, wherein the power disc is provided with a structure piece in power connection with the outside, one side surface of the power disc is provided with a round containing cavity, and the inner wall of the containing cavity is in a continuous closed sinusoid shape; the overload protection disc is used for being connected with the power disc and provided with an arc avoiding groove, and an elastic overload deformationpart is formed between the outer arc surface of the arc avoiding groove and the outer periphery of the overload protection disc; flanges are uniformly distributed in the middle of the outer peripheralwall of the elastic overload deformation part and are consistent with wave troughs of the sinusoid of the inner wall of the containing cavity in shape; one side of the overload protection disc is provided with a power output component; and the overload protection disc is put in the containing cavity of the power disc, and the flanges are located in the wave troughs of the inner wall of the containing cavity. The invention further discloses a speed reduction mechanism and an electrically-driven flip driver. The mechanical overload protection device, the speed reduction mechanism and the electrically-driven flip driver have the characteristics of being small in size, low in weight, high in bearing capacity, long in service life, stable in operation, low in noise and safe in performance, andthe product using safety is greatly improved.

Owner:TIANJIN SNEIJDER PRECISION MACHINERY

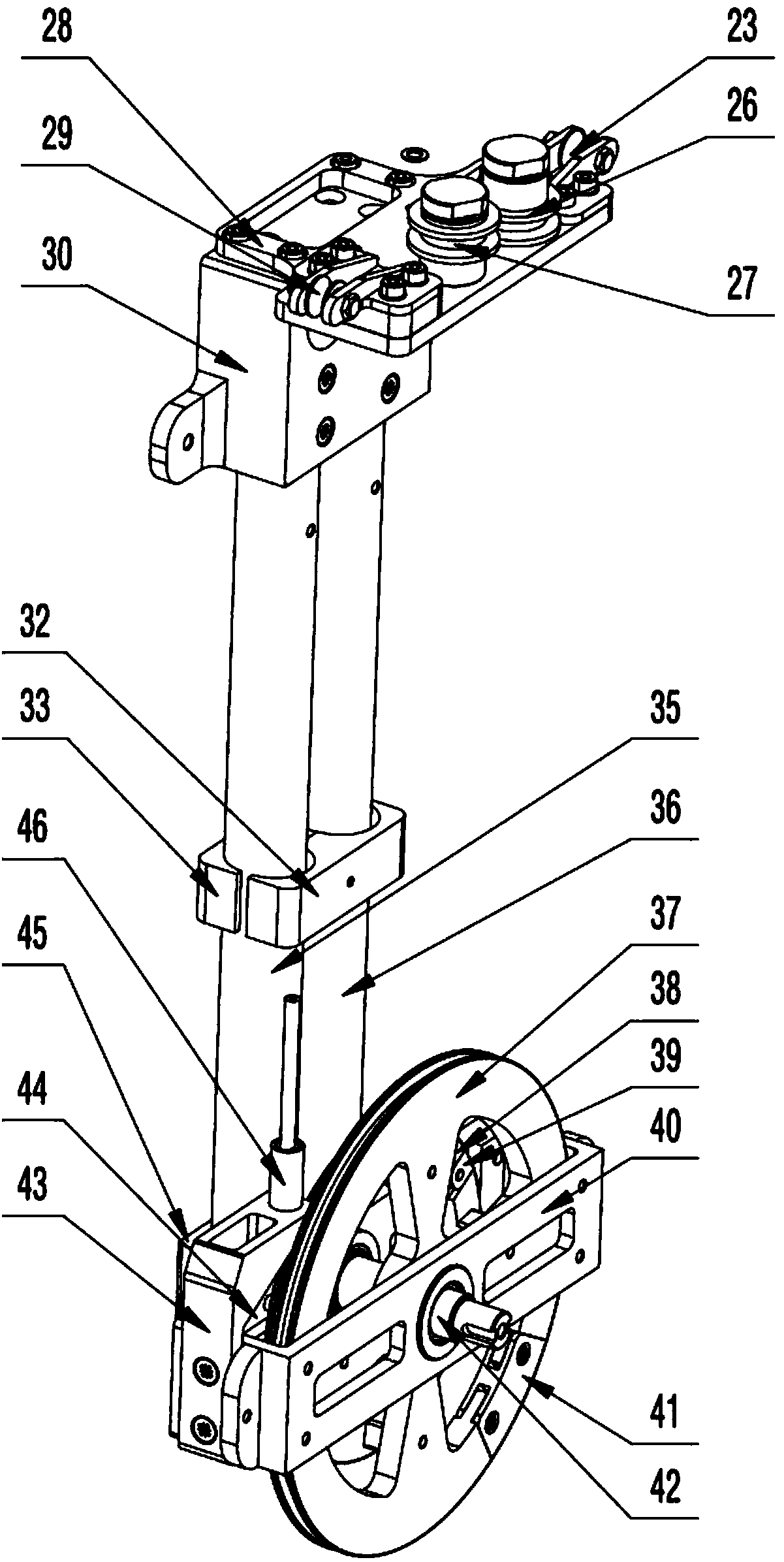

Wheel-foot hybrid robot

PendingCN112519916AImproved location transfer efficiencyGuaranteed working radiusVehiclesPhysical medicine and rehabilitationDrive wheel

The invention provides a wheel-foot hybrid robot. The wheel-foot hybrid robot comprises a robot body, first leg modules and a second leg module. each first leg module comprises a foot part and a supporting wheel; the second leg module comprises a steering motor, a first driving wheel and a second driving wheel; the leg module has two working modes: a foot mode and a wheel mode; in the wheel mode,the supporting wheels assist in supporting the robot body, the first driving wheel and the second driving wheel drive the wheel-foot hybrid robot to move together, and steering of the wheel-foot hybrid robot is achieved through steering of the steering motor. In the foot mode, the second leg module and the supporting wheels are suspended, and the feet of the first leg modules alternately touch theground so as to drive the wheel-foot hybrid robot to move. Compared with the prior art, the position transfer efficiency is greatly improved. In addition, in the foot mode, rapid steering of the wheel-foot hybrid robot can be achieved.

Owner:THE 21TH RES INST OF CHINA ELECTRONIC TECH GRP CORP

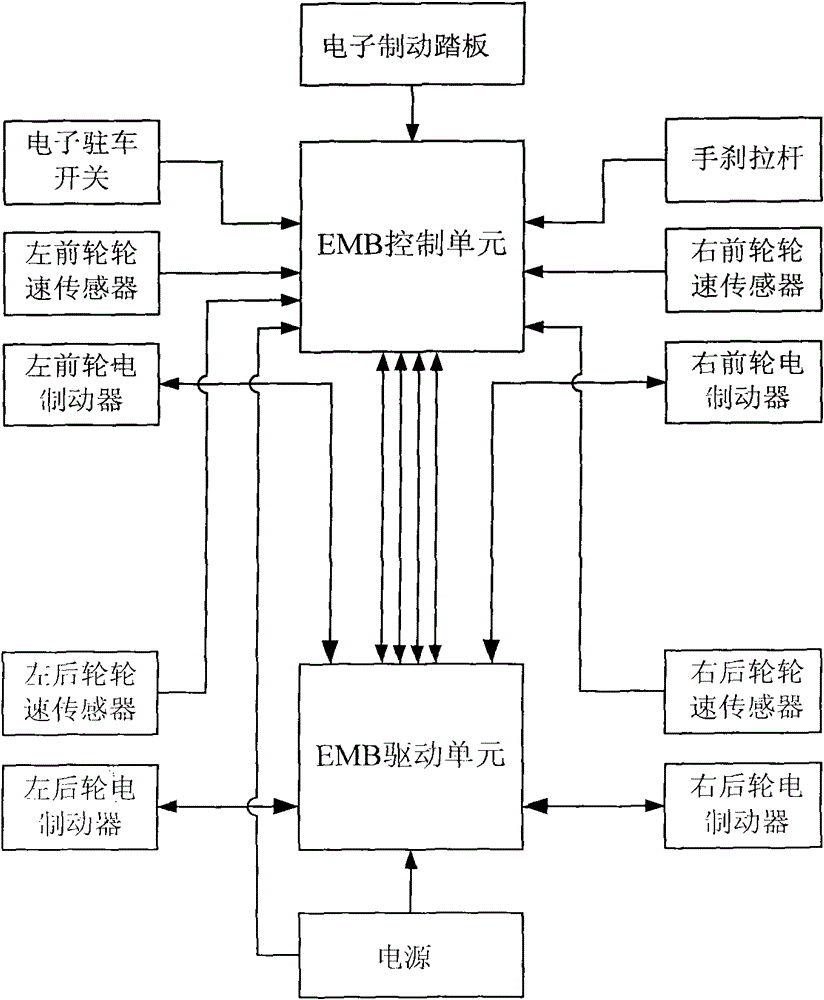

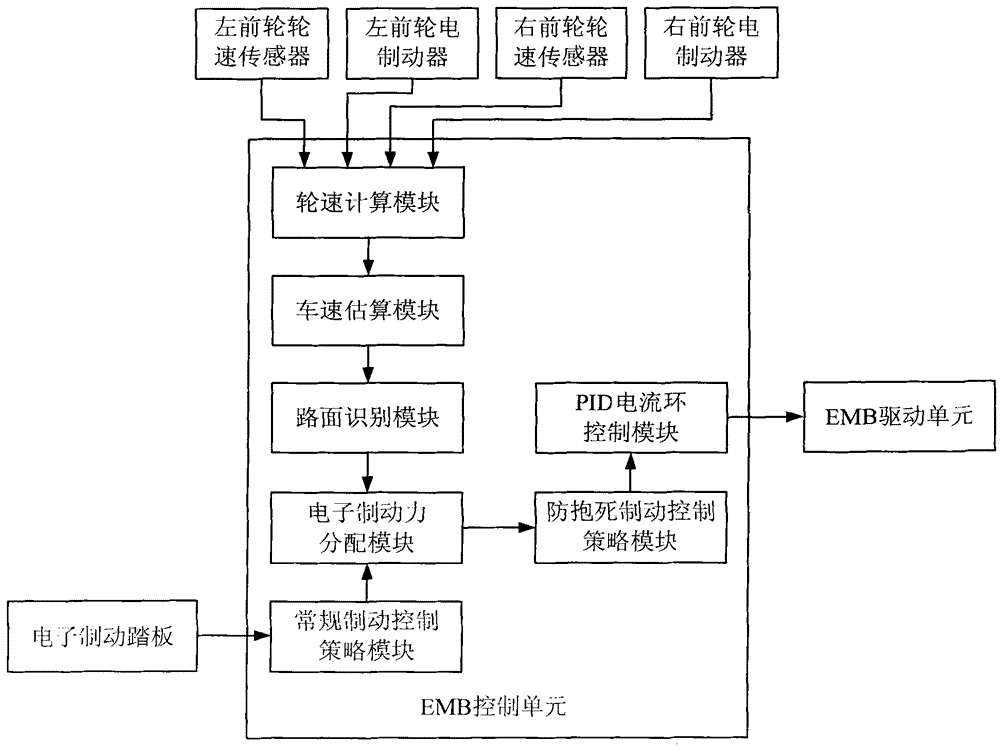

Electronic mechanical brake system and automobile adopting same

The invention provides an electronic mechanical brake system which comprises a brake signal inputting unit, an EMB (electromechanical brake system) control unit, an EMB drive unit, and a plurality of electric brakes corresponding to a plurality of wheels respectively, wherein the signal inputting unit is used for generating brake signals and outputting the brake signals to the EMB control unit in real time; the EMB control unit is used for receiving the brake signals and outputting a plurality of paths of duty ratio signals to the EMB drive unit; the path number of the duty ratio signals is equal to that of the electric brakes; the EMB drive unit is used for receiving the duty ratio signals in real time and driving and controlling the plurality of electric brakes according to the duty ratio signals; and the plurality of electric brakes are respectively used for braking the corresponding wheels. Correspondingly, an automobile adopting the braking system is provided. The electronic mechanical brake system has the advantages of simple structure, small volume, convenience in installation, low cost, fast braking response, good braking stability, no pollution, and the like.

Owner:CHERY AUTOMOBILE CO LTD

Mechanical friction and hydraulic transmission collection type stepless speed change device

ActiveCN104006138AReduce speed differenceSmall output torqueGear lubrication/coolingGearing controlFuel tankWater cooling

The invention discloses a mechanical friction and hydraulic transmission collection type stepless speed change device. A reset spring sleeves an input rotating shaft; a sleeve pipe sleeves an input rotating shaft portion through a spline, wherein the input rotating shaft portion is located in front of the reset spring; the front end of the rest spring is fixed at the rear end of the sleeve pipe; the rear end of the reset spring is fixed on the inner side of a rear end cover; a front section of the sleeve pipe is provided with an input friction part and an input pump blade; a rear section of the sleeve pipe is provided with a pressure-bearing bearing; an annular hydraulic jack or an annular hydraulic capsule sleeves the reset spring; an output friction part and an output pump blade are fixed on an output rotating shaft; a flexible friction part is clamped between the input friction part and the output friction part; the machine oil is arranged in a housing; a front end cover and the rear end cover are provided with a plurality of small holes respectively; a front cover covers on the front end cover; a rear cover covers on the rear end cover; an oil pipe which is connected out of the front cover is connected onto a cooling oil tank through an output electric regulating oil valve; the oil pipe which is connected out of the cooling oil tank is connected onto the rear cover through an input electric regulating oil valve; the machine oil in the cooling oil tank is cooled through an air cooling or water cooling mechanism.

Owner:张英华

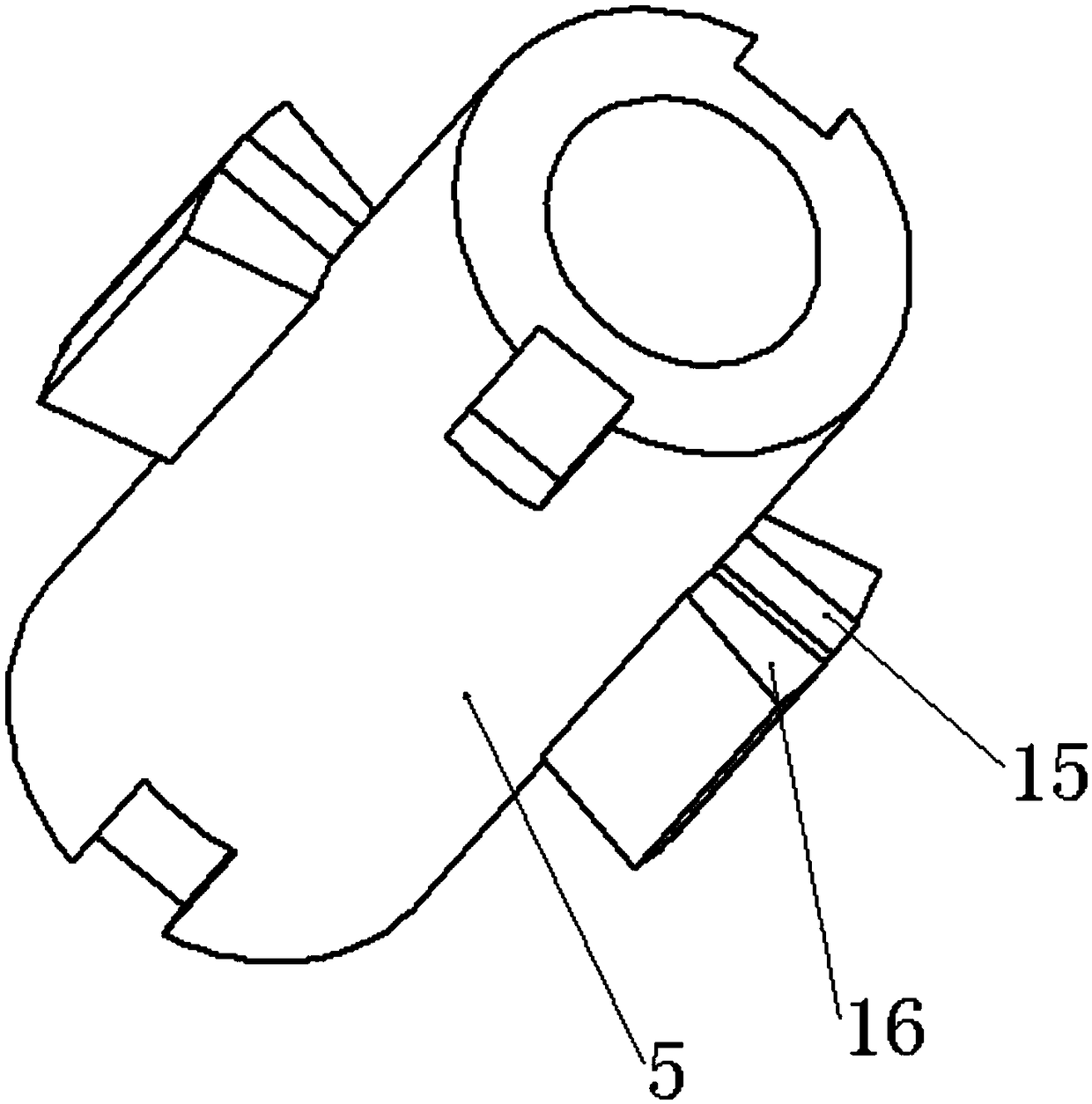

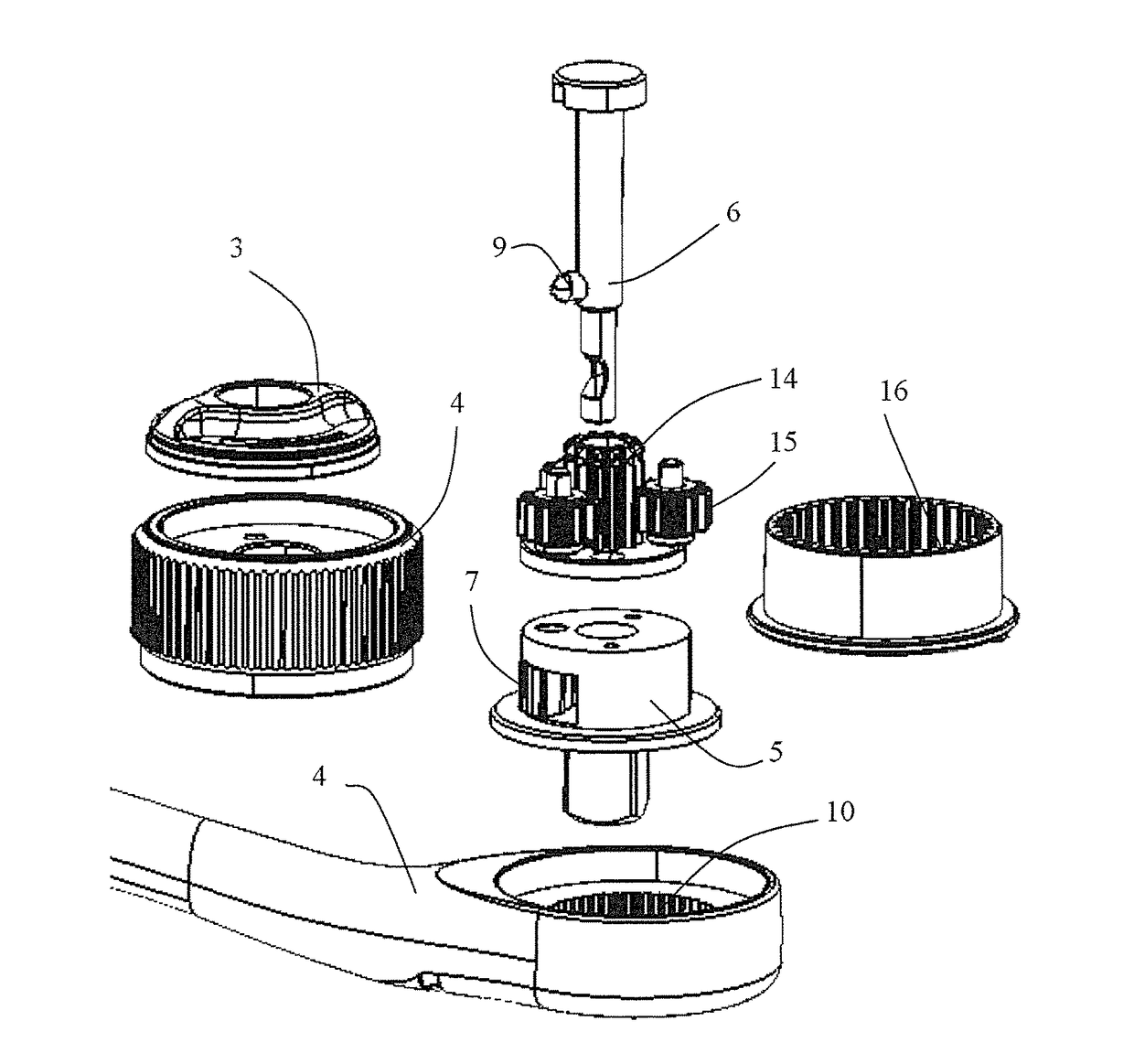

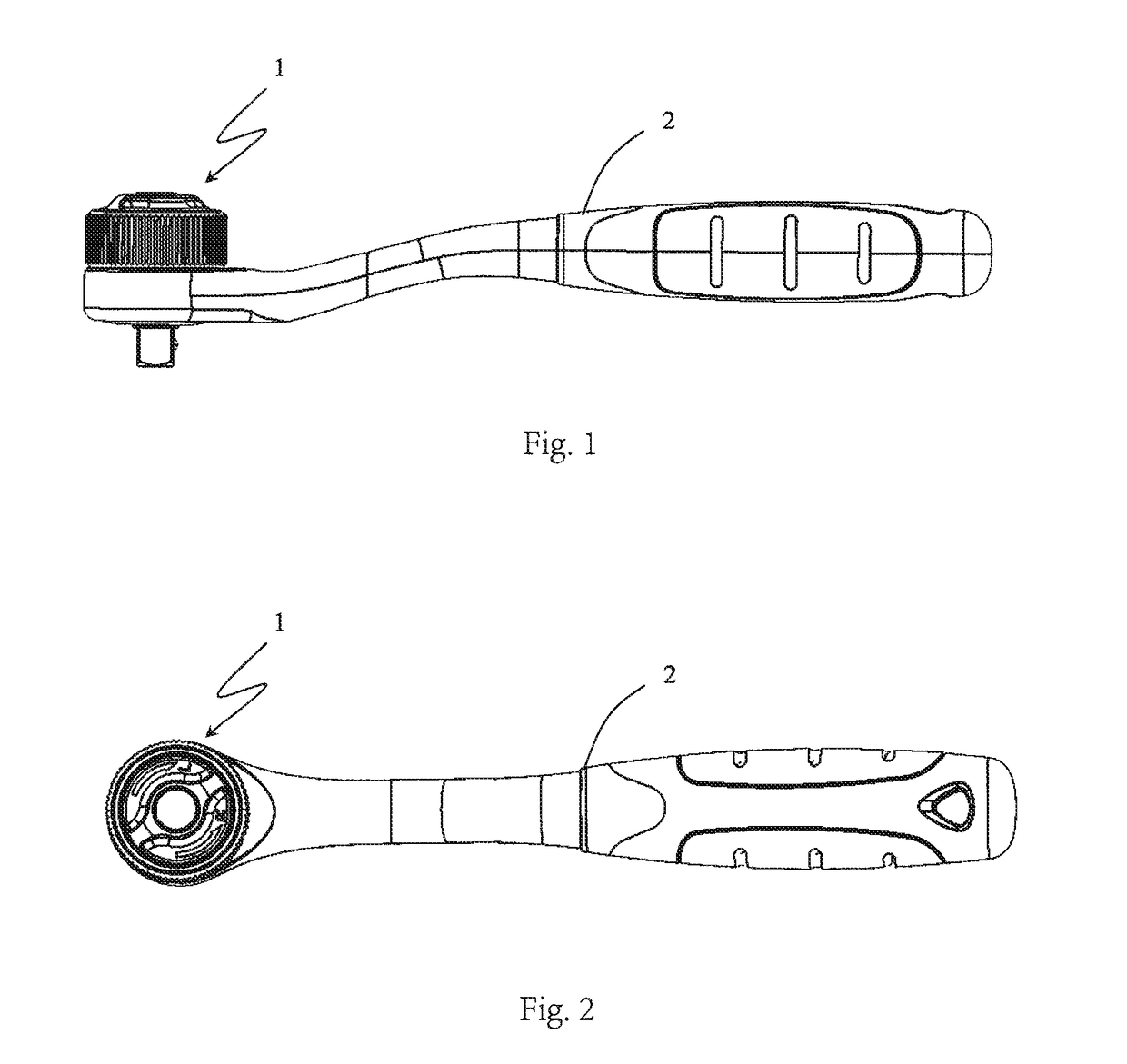

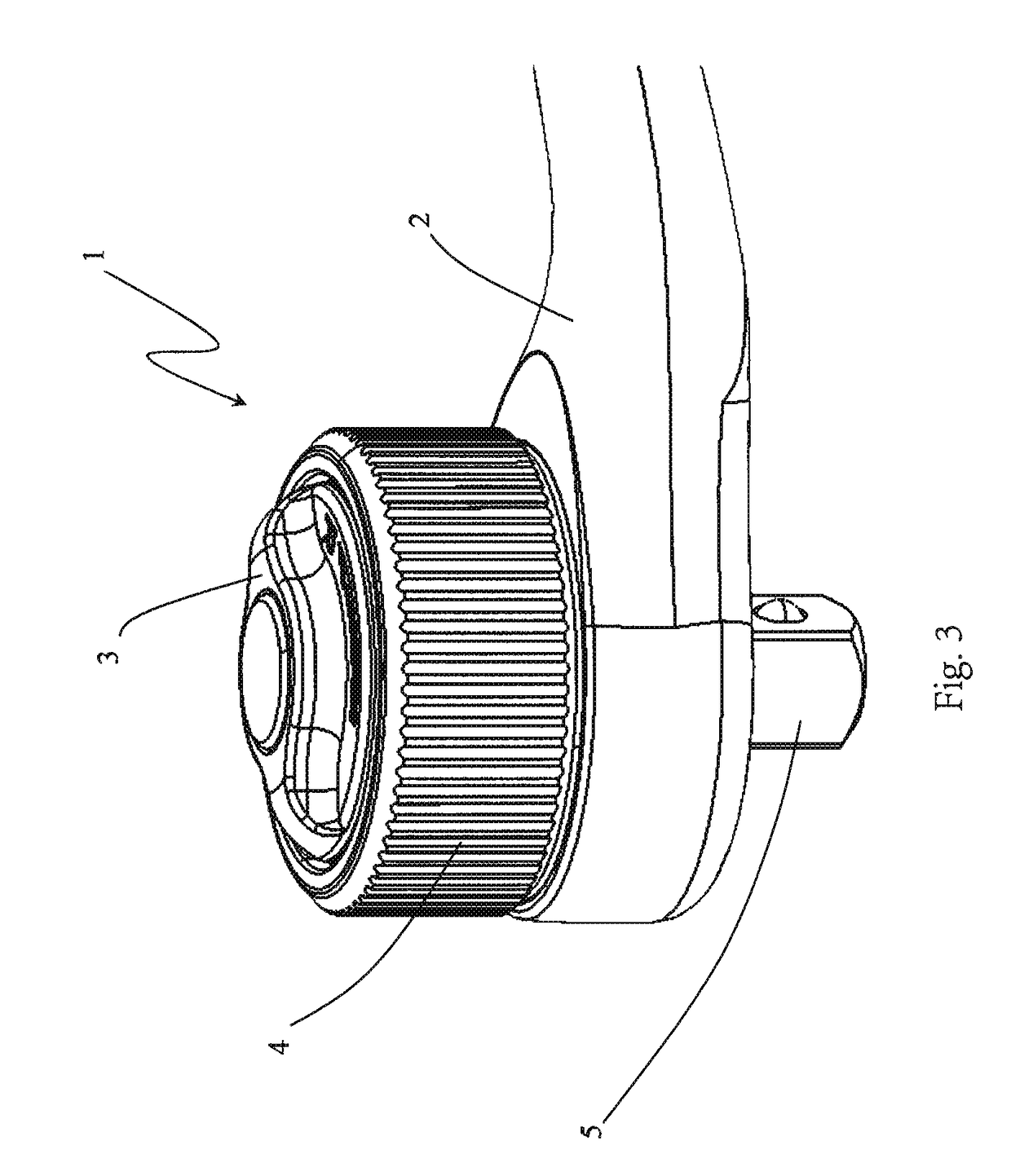

Wrench

The present invention provides a wrench, which comprises a working part and a handle, the working part includes a main axle perpendicular to the handle and mutually cooperated bidirectional pawl and ratchet wheel, in which the ratchet wheel is arranged so as to be caused by the handle, the bidirectional pawl is arranged to rotate the main axle and has a first pawl and a second pawl which are opposite to the clutch direction between the ratchet wheel, the working part also includes a direction switching mechanism for setting clutch direction of the bidirectional pawl and the ratchet wheel; the direction switching mechanism is arranged such that a first pawl and a second pawl are engaged with the ratchet wheel selectively, such that when handle is rotated in the direction set by the direction switching mechanism, the ratchet wheel is engaged with the bidirectional pawl, then rotates the main axle; when the handle is rotated in the direction opposite to the direction set by the direction switching mechanism, the ratchet wheel and the bidirectional pawl slide over each other, and the main axle remains stationary; the working part also includes a planetary gear speed increasing mechanism acting on the main axle, the planetary gear speed increasing mechanism includes a sun gear, a planetary gear and a ring gear, in which the sun gear is arranged to rotate the main axle together, the rotation ring is arranged so as to cause the planetary gear to rotate, the gear ring is fixedly connected with the handle, so that when the handle is gripped and the rotation ring is rotated, the planetary gear speed increasing mechanism increases the speed of the rotation inputted by the rotation ring and then outputs via the main axle.

Owner:HANGZHOU GREAT STAR TOOLS +1

Mechanical emergency starting apparatus of fire pump

InactiveCN106653473AGood consistencyImprove synchronicityHigh-tension/heavy-dress switchesAir-break switchesContactorMetal backed

The invention relates to a mechanical emergency starting apparatus of a fire pump. The mechanical emergency starting apparatus comprises an insulating electric-insulating framework, a metal back sealing plate, an electromagnetic control mechanism, a manual operating mechanism and a vacuum switching tube part, wherein the electromagnetic control mechanism is provided with a switching-on holding pinch plate, a transmission connecting lever, a switching-on armature, a switching-on coil and a switching-off spring; a long pull rod passes through a through slot in the metal back sealing plate and is connected with a countersunk head hole in the switching-on armature; and a screw thread part at the other end of the long pull rod is movably connected with a U-shaped linking block on a linking rod of the manual operating mechanism. The mechanical emergency starting apparatus can drive an alternating current vacuum contactor to realize mechanical emergency starting; and regulation of No. 11.0.12 clause of national standard GB 50974-2014 ''fire water supply and hydrant system technical specification'' implemented on 1st, Oct. 2014 is satisfied.

Owner:CHENZHOU DONGTANG ELECTRIC EQUIP

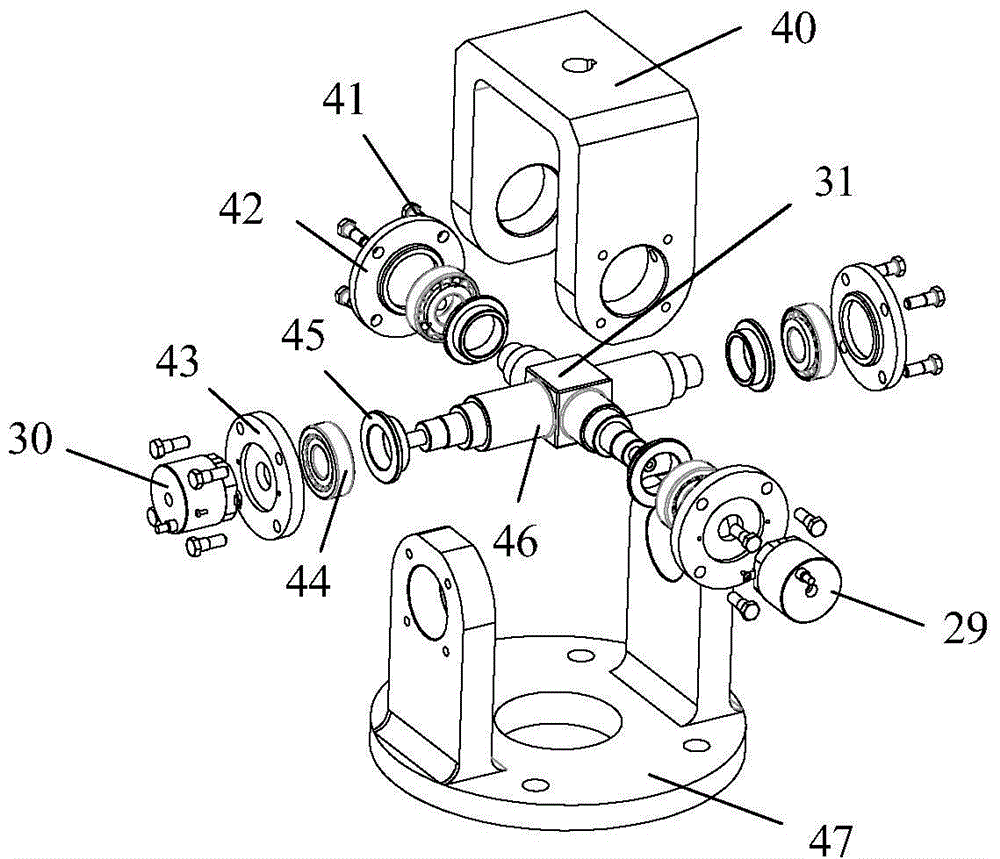

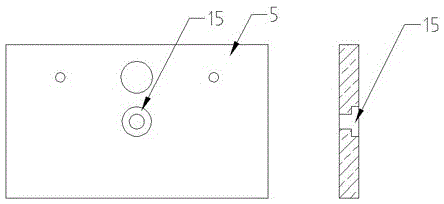

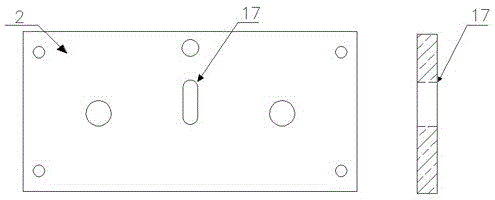

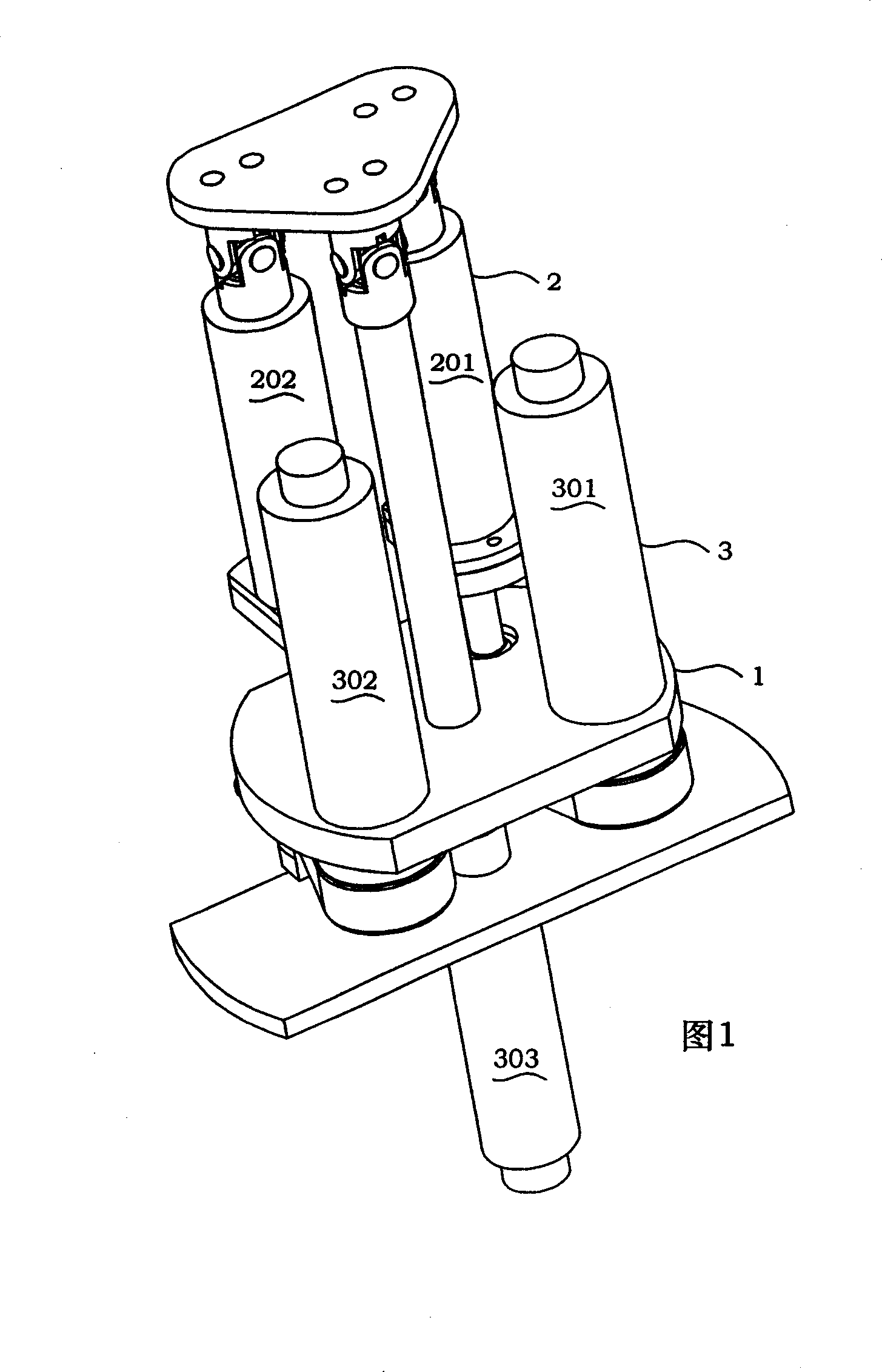

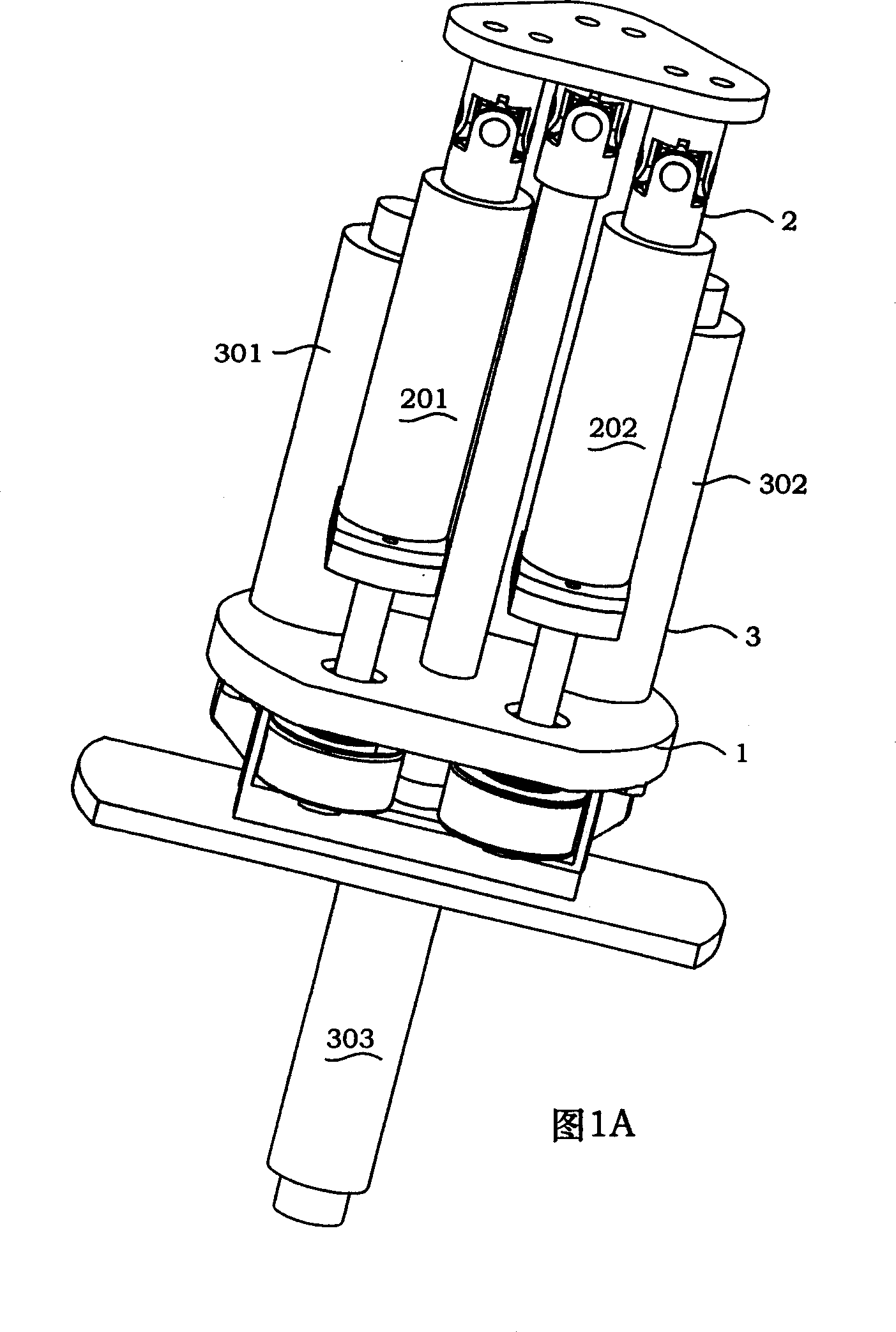

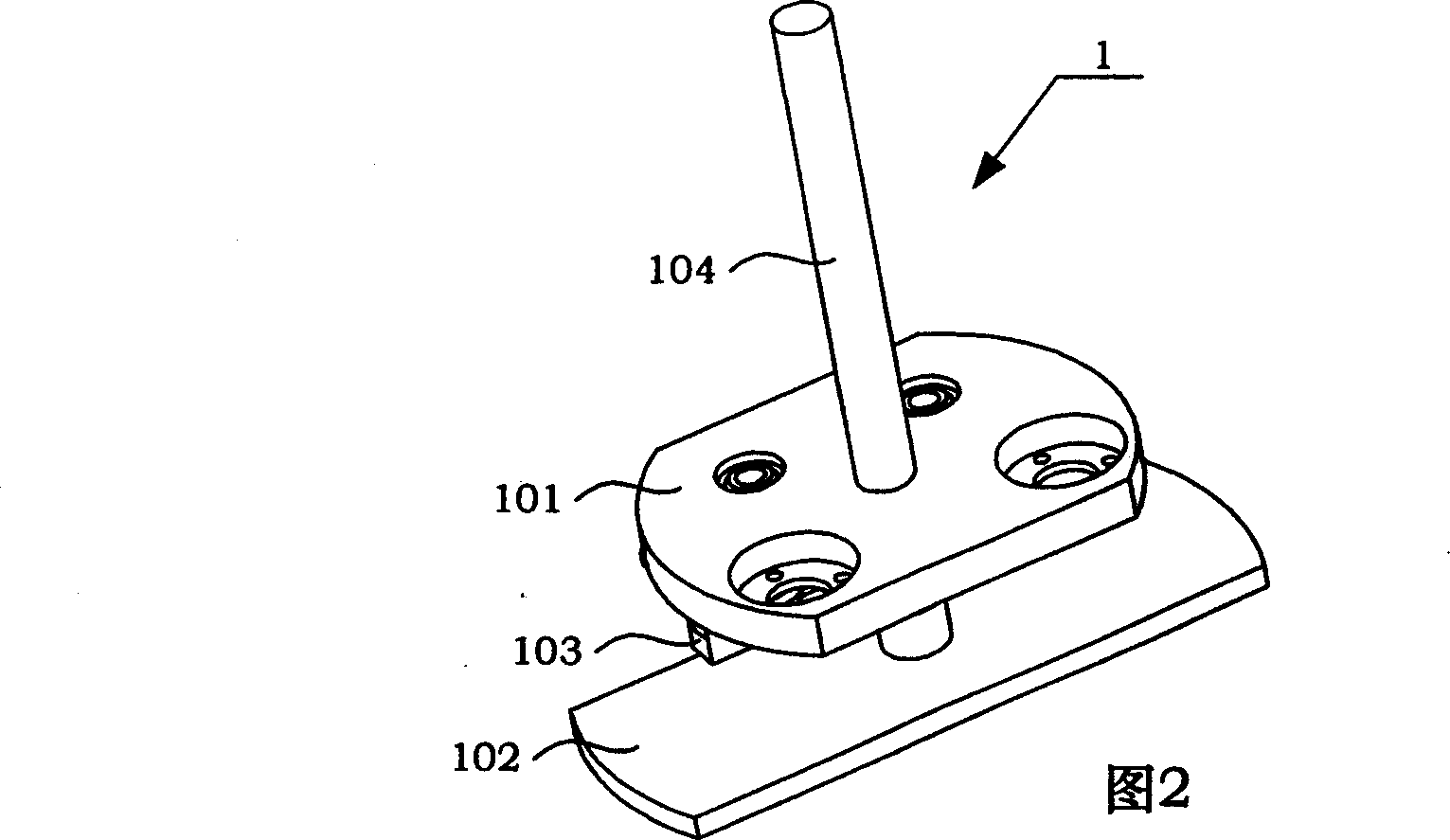

Series-parallel connection active equivalent ball-joint mechanism

InactiveCN1861329ASmall output torqueCompact structureProgramme-controlled manipulatorCouplingEngineering

A serial-parallel mechanism equivalent to an active ball joint is composed of supporter module, connection module and drive module, and is a posture regulating mechanism able to actively and individually rotate around three coordinate axis's X, Y and Z. Its parallel drive mechanism for rotating around X or Y axis consists of two sets of leading screw-nut drive unit, front connection plate, U-shaped base and 3 cross-type universal axle couplings. A serial mechanism for rotating around Z axis is composed of motor, back connection plate, connection axle and U-shaped base.

Owner:BEIHANG UNIV

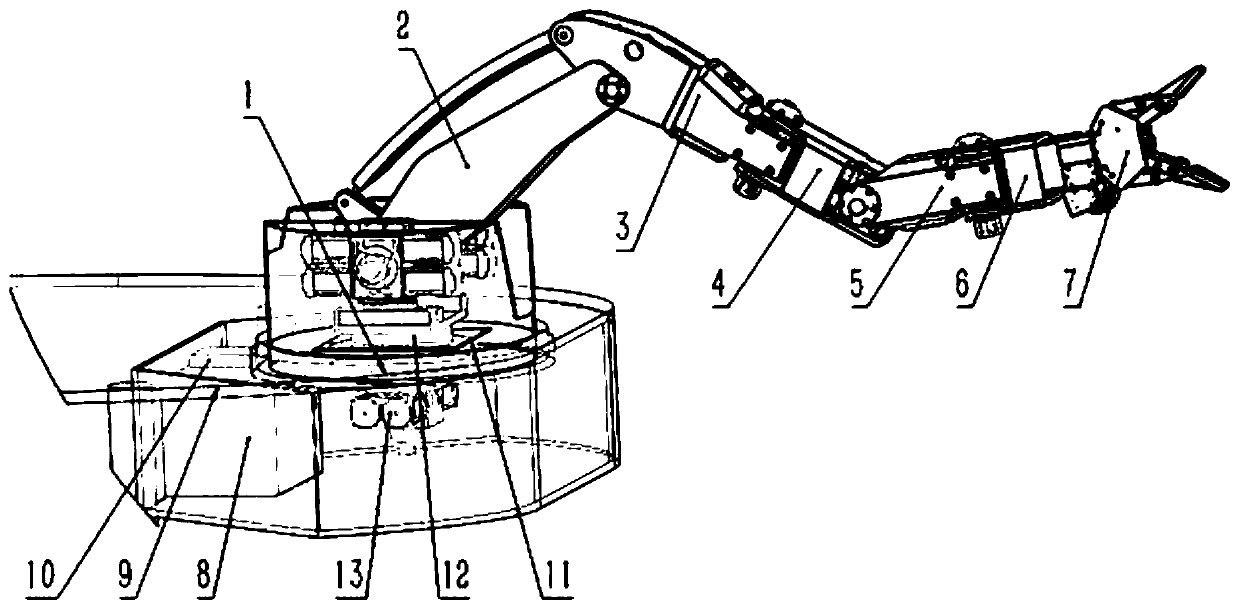

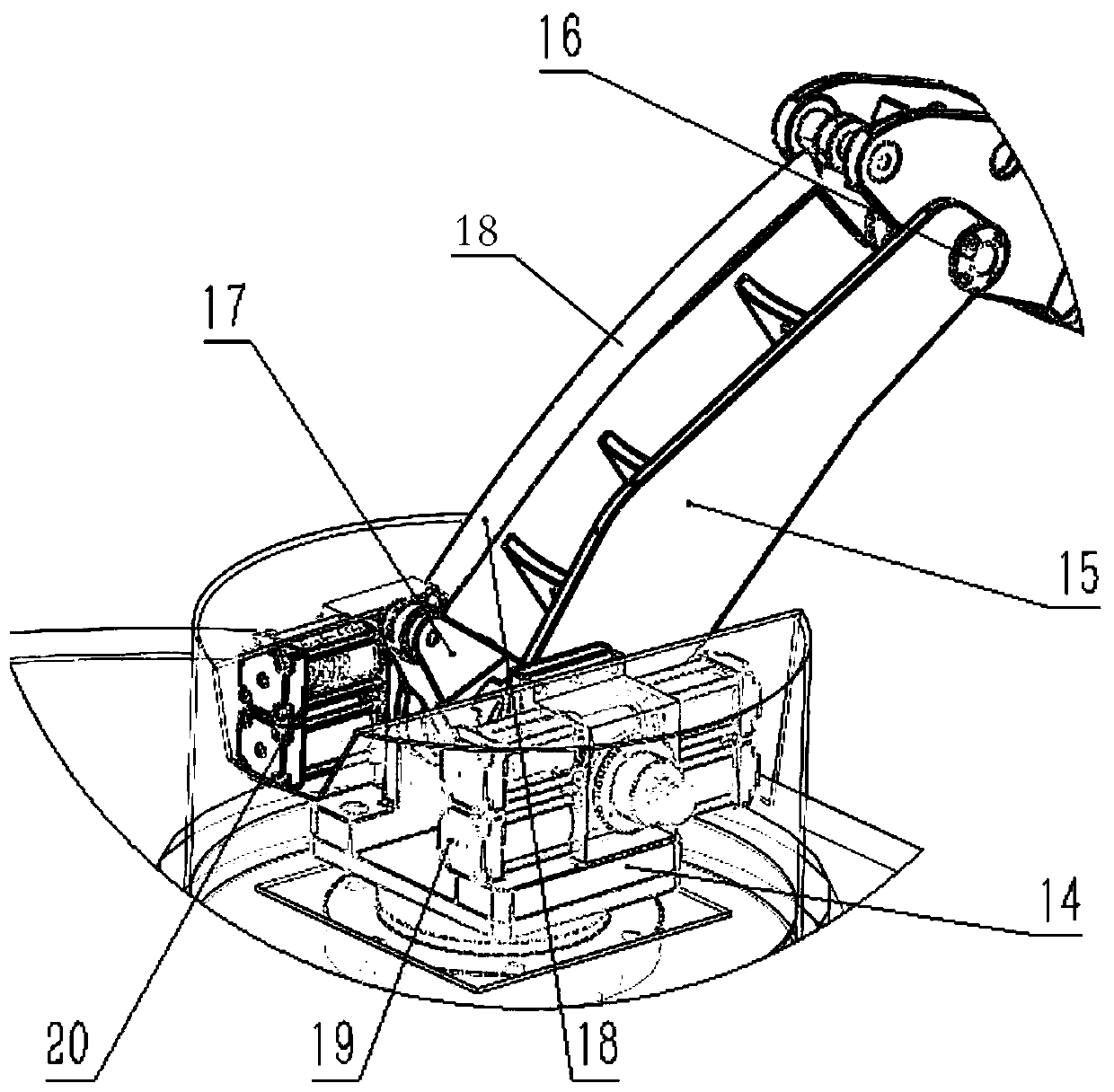

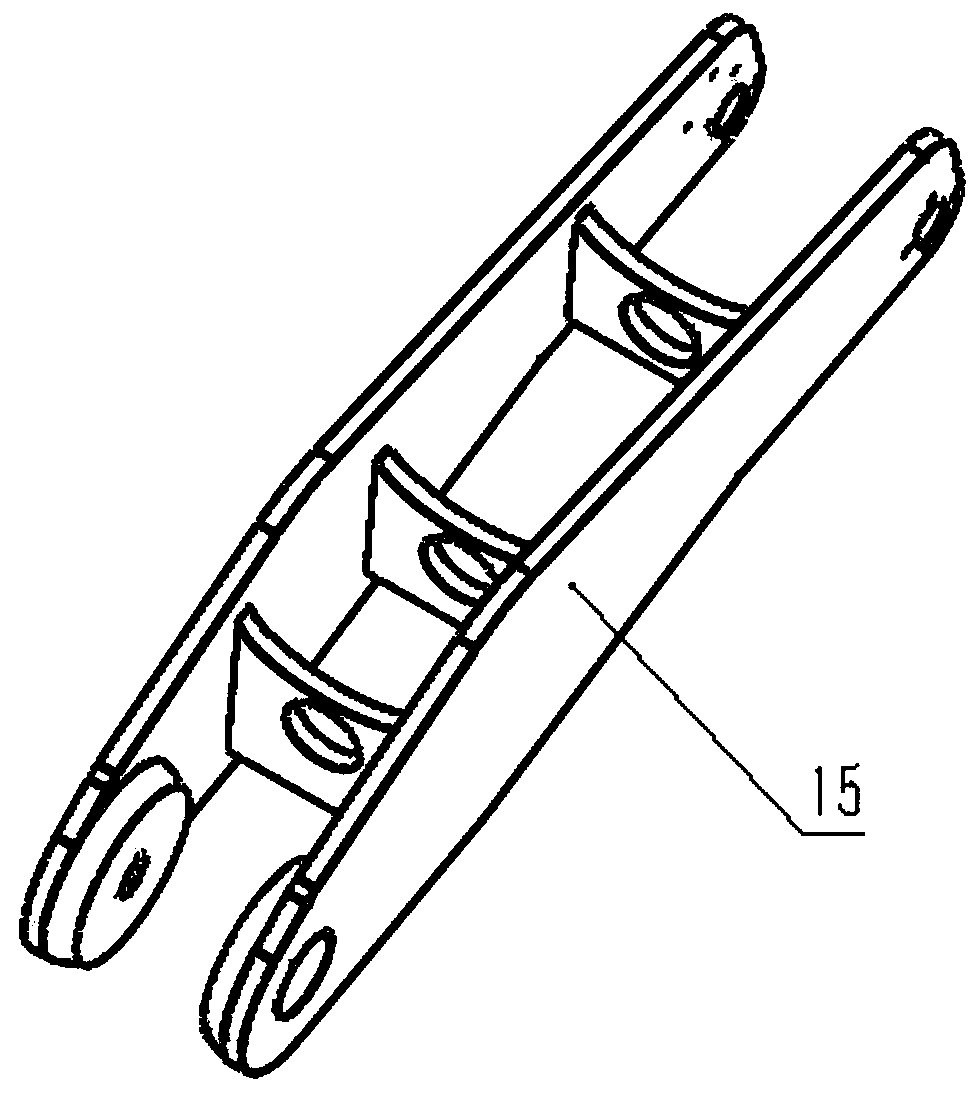

Underwater redundant hydraulic mechanical arm and work method thereof

ActiveCN110630596ALarge working spaceCompact structureServomotor componentsAccumulator installationsMarine engineeringUnderwater

The invention relates to an underwater redundant hydraulic mechanical arm and a work method of the underwater redundant hydraulic mechanical arm and belongs to the technical field of underwater mechanical robots. The underwater redundant hydraulic mechanical arm adopts a chain type series structure and comprises a rotating arm, a big arm, a middle arm, a forearm A, a forearm B, a wrist arm, a gripper, a hydraulic system and an STM32 control panel. The rotating arm, the big arm, the middle arm, the forearm A, the forearm B, the wrist arm and the gripper are sequentially connected. The hydraulicsystem provides power for the whole mechanical arm. The STM 32 control panel is used for controlling the mechanical arm to act. The rotating arm is installed on an underwater moving platform to support the whole hydraulic mechanical arm and achieves fixation and rotation of the whole mechanical arm. The big arm and the middle arm achieve pitching within a large range of the mechanical arm. The forearm A achieves transverse swinging of the mechanical arm. The forearm B achieves pitching within a small range of the mechanical arm. The wrist arm achieves transverse swinging and rotation of the gripper. The gripper achieves the clamping function. The underwater redundant hydraulic mechanical arm is compact and reasonable in structure, large in effective operation space, capable of expanding the freedom degree and suitable for different water depths.

Owner:SHANDONG UNIV

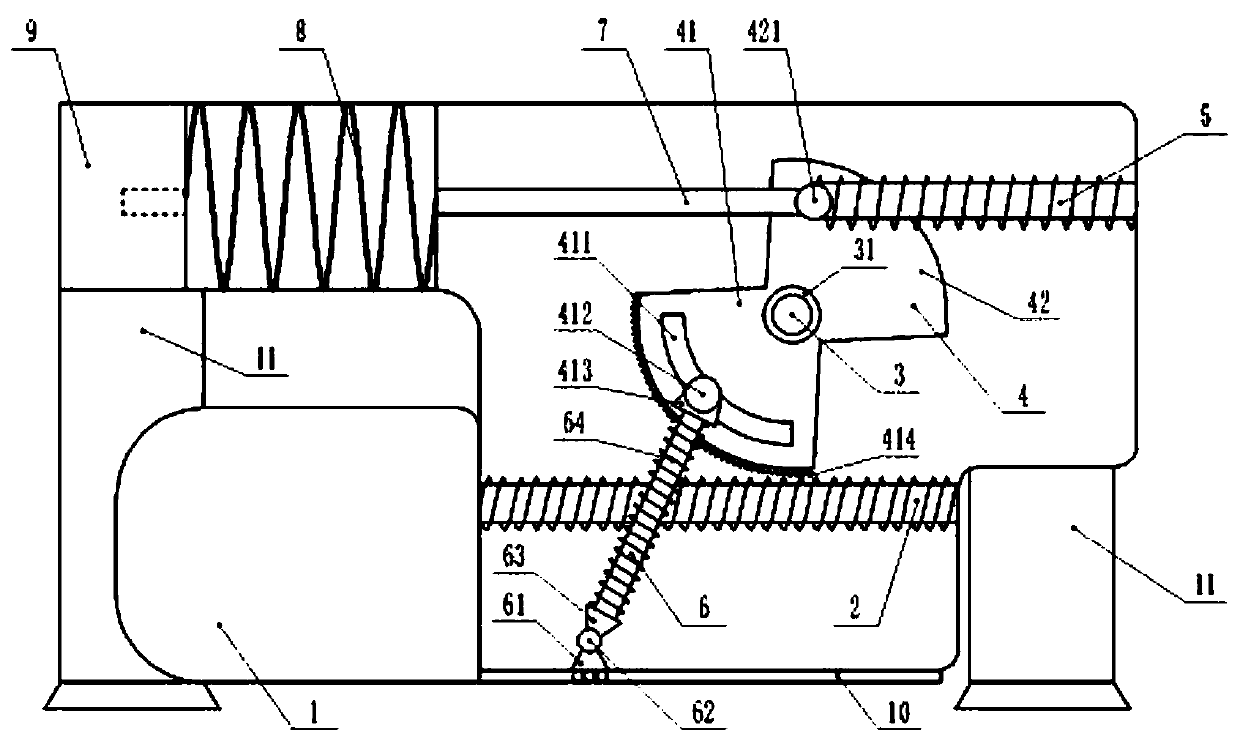

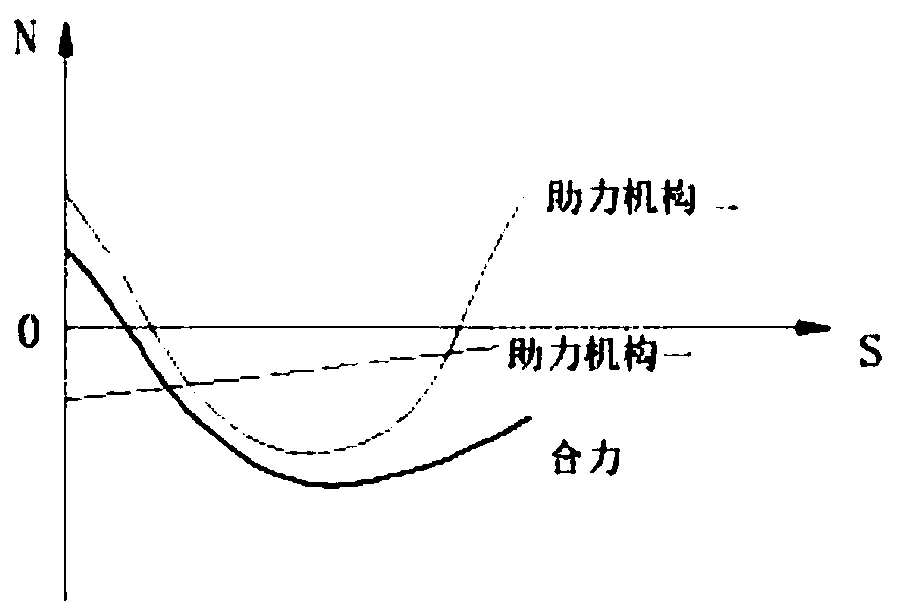

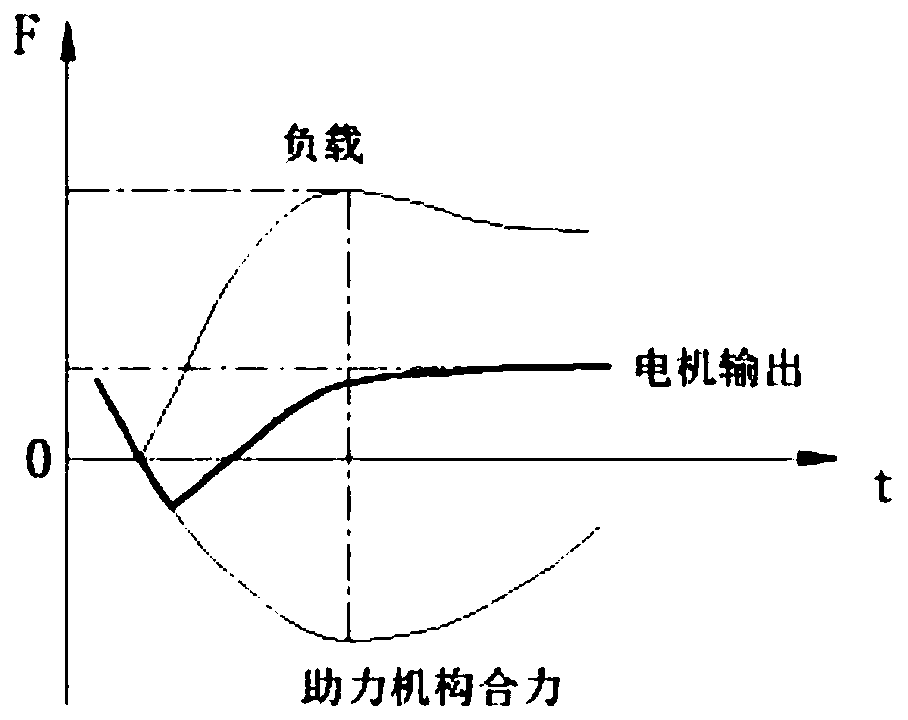

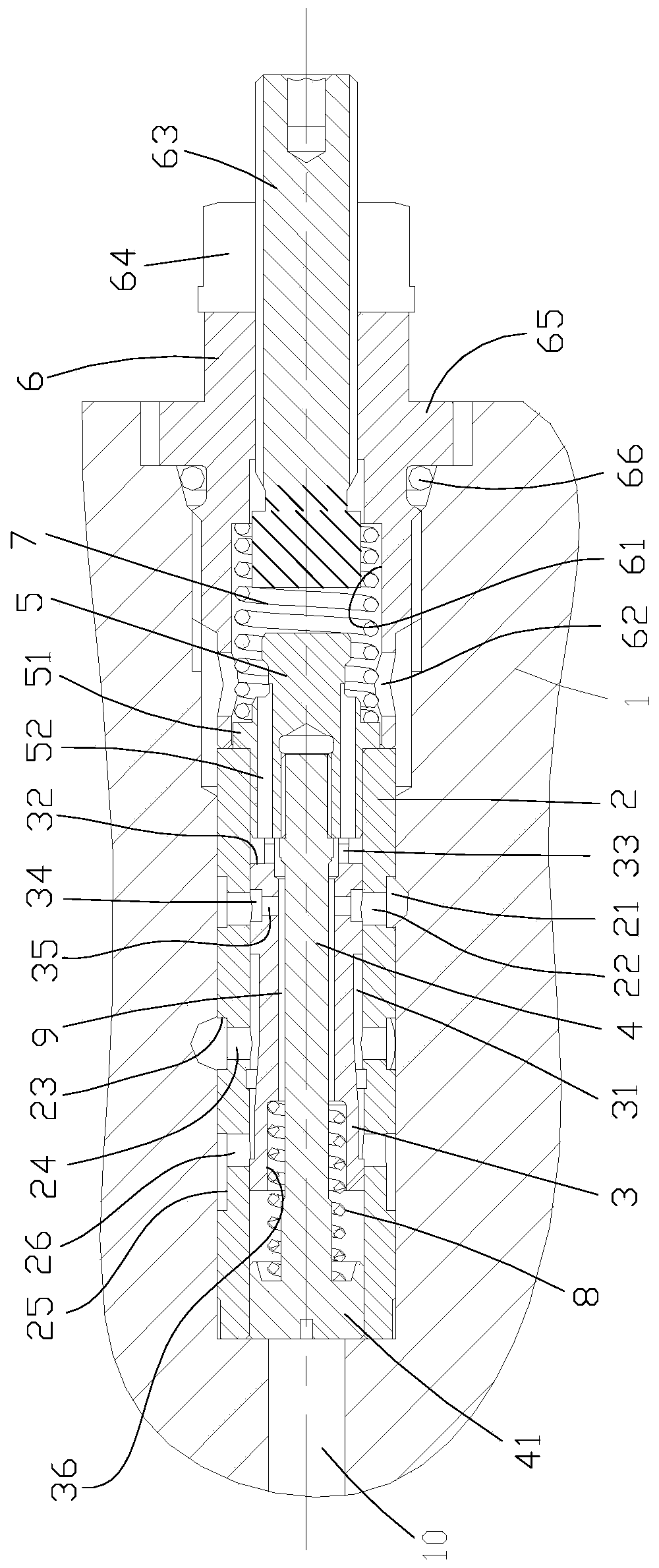

Worm-oblique gear transmission mechanism with load fitting characteristic and in form of dual-assistance mechanism

ActiveCN109873529ASmall output torqueReduce output requirementsMechanical energy handlingGear transmissionElectrical and Electronics engineering

The invention discloses a worm-oblique gear transmission mechanism with load fitting characteristic and in form of a dual-assistance mechanism. The worm-oblique gear transmission mechanism comprises amotor, a transmission lead screw, a core shaft, a rotation disc, a first assistance mechanism, a second assistance mechanism, a transmission rod, a buffer mechanism and an external load, wherein themotor is arranged at a left lower part of the transmission mechanism, the transmission lead screw is connected with an output end of the motor, the rotation disc fixedly sleeves the core shaft and comprises a driving disc and a driven disc, the driving disc comprises an adjustment groove, a regulator, a first connector and a transmission gear, the transmission gear is engaged with the transmissionlead screw, a connection disc is fixedly arranged on the driven disc, two ends of the first assistance mechanism are respectively and fixedly connected with a right side of the transmission shaft andan inner wall of a right side of the transmission mechanism, the second assistance mechanism comprises a sliding seat, a rotation shaft, a second connector and a spring rod, the transmission rod is connected with the external load, and the buffer mechanism is arranged at a middle part of the transmission rod.

Owner:西安涡普动力系统股份有限公司

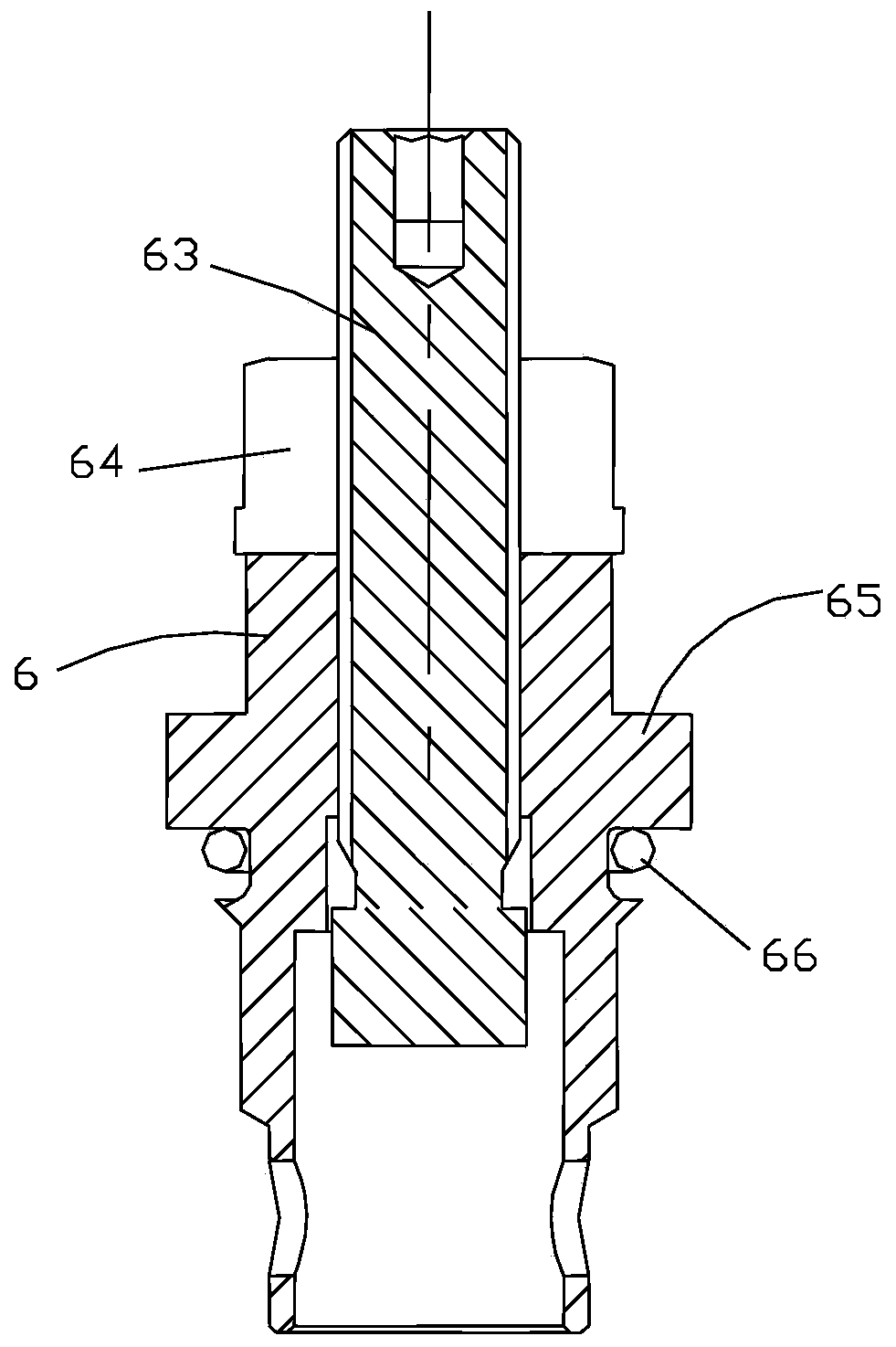

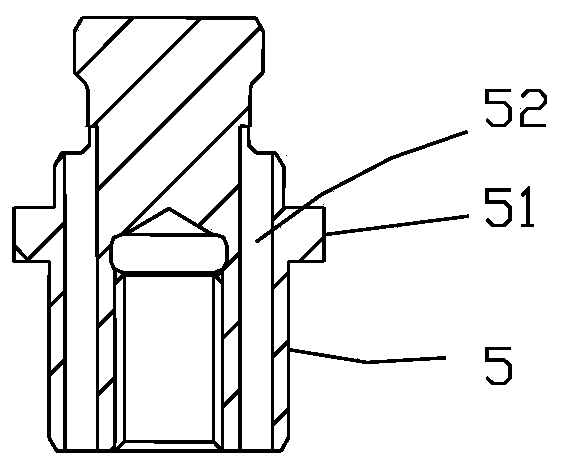

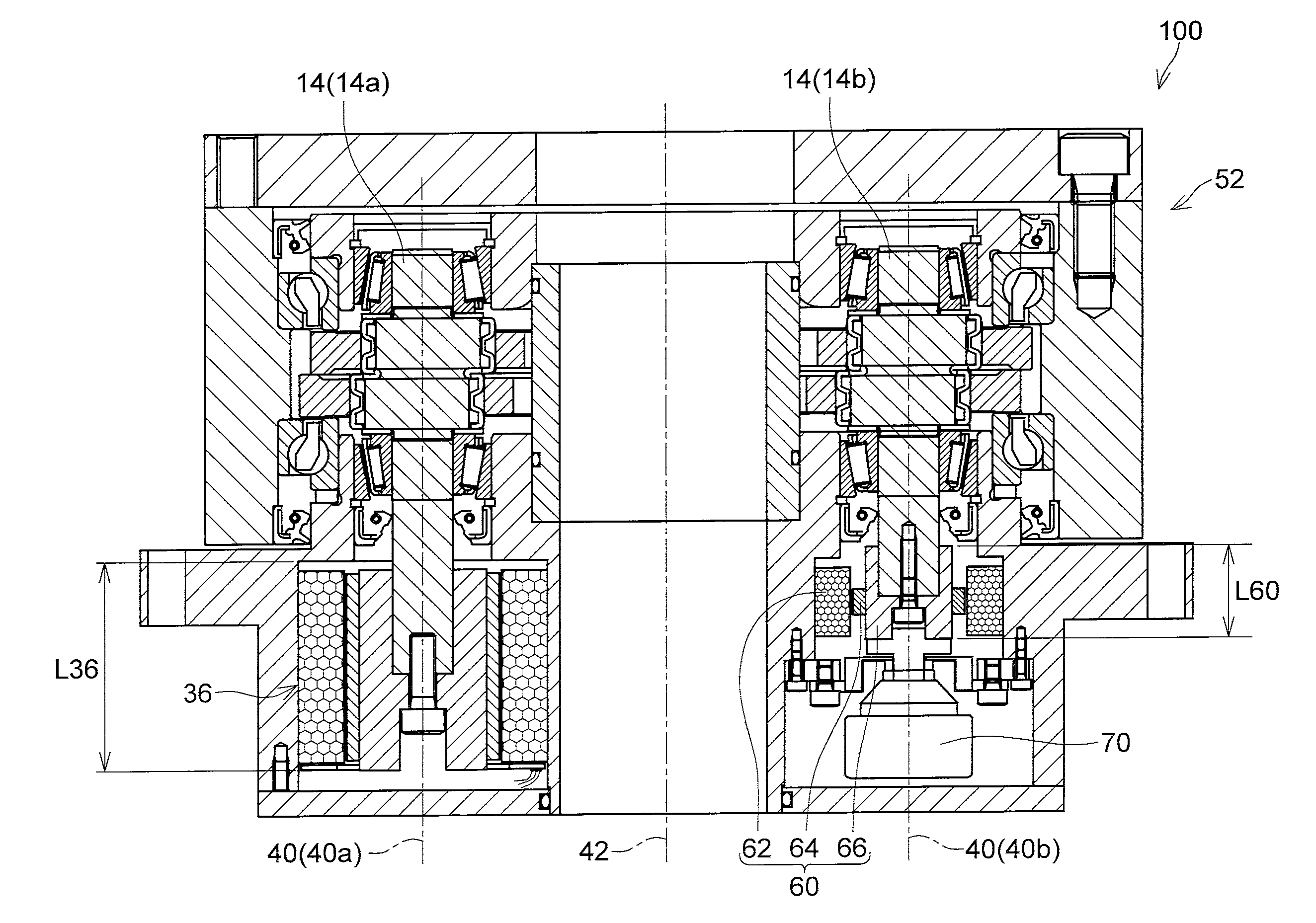

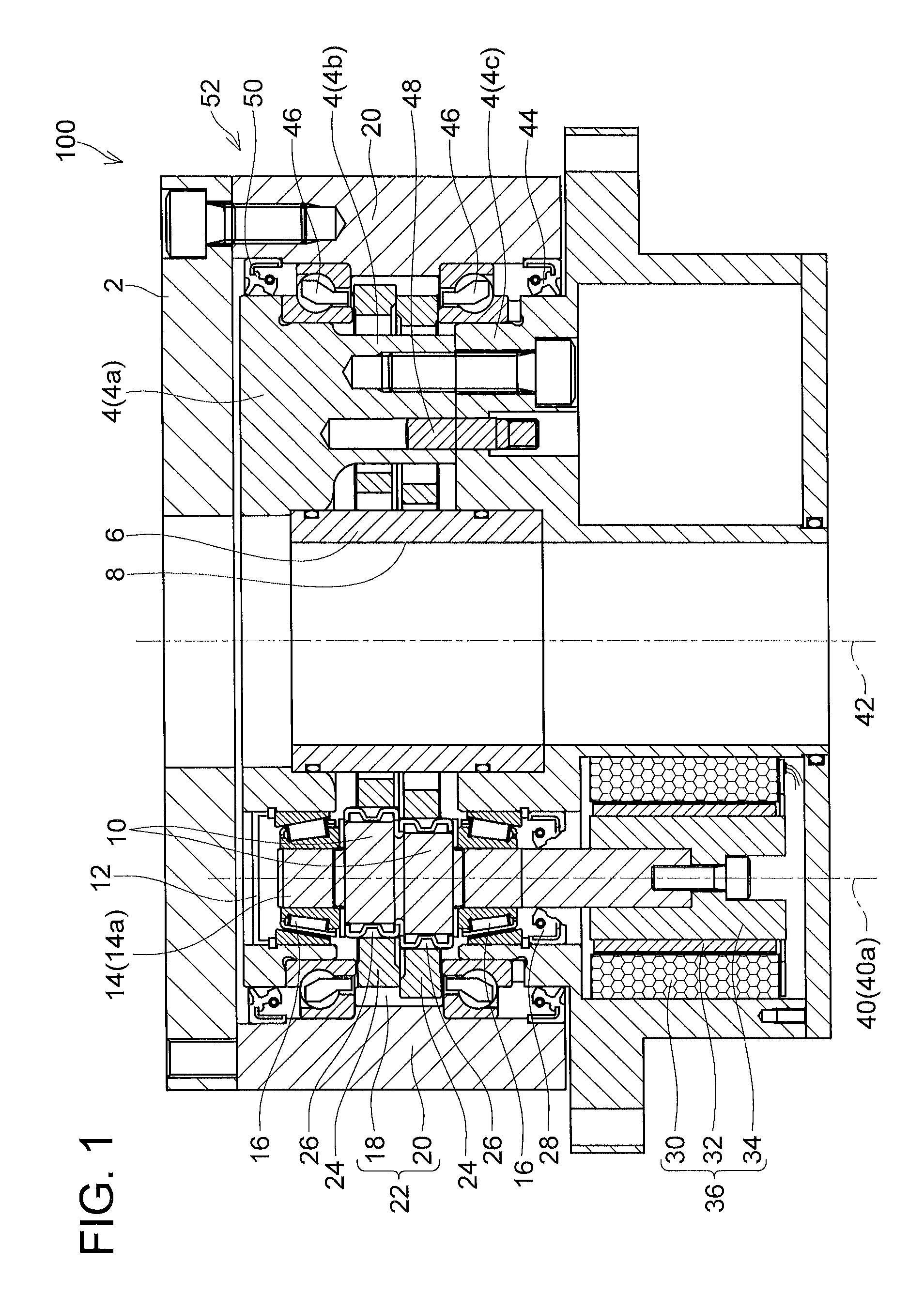

Device for implementing external control and high-pressure automatic control

PendingCN110410377ASmall output torqueReduce after-sales pressureServomotor componentsServomotorsAutomatic controlEngineering

The invention discloses a device for implementing external control and high-pressure automatic control. The device comprises a basic body. A blind hole is formed in the basic body. An oil inlet is formed in the bottom surface of the blind hole. A control valve sleeve is arranged in the blind hole. A control valve element is arranged in the control valve sleeve. A valve element is arranged in the control valve element. A spring seat is arranged at one end of the valve element. A limiting base is arranged on the outer side of the spring seat. An external control spring is arranged between the spring seat and the limiting base. The other end of the valve element extends out of the control valve seat and radially extends externally to form a plunger. The plunger makes contact with the bottom surface of the blind hole. A high-pressure spring is arranged between the plunger and the control valve element. The device further comprises an oil return way, a first oil way, a first annular groove,a second oil way, a high-pressure oil way and a third oil way. The device for implementing external control and high-pressure automatic control has the advantages that with the device, engineering machines in the prior art can cause low after-sales pressure, and are not prone to causing fatigue to operators during operation.

Owner:LIYUAN HYDRAULIC (SUZHOU) CO LTD

Gear transmission

ActiveUS20160186836A1Small sizeGenerationToothed gearingsMechanical energy handlingGear transmissionElectric motor

A gear transmission is provided with a gear structure and a plurality of motors. The gear structure is provided with a plurality of crank shafts, an eccentric rotation gear, and a rotation gear. Each motor is attached to one of the crank shafts. At least one of the plurality of motors is a first motor, and at least another of the plurality of motors is a second motor. The second motor has a length in an axial direction shorter than that of the first motor.

Owner:NABLESCO CORP

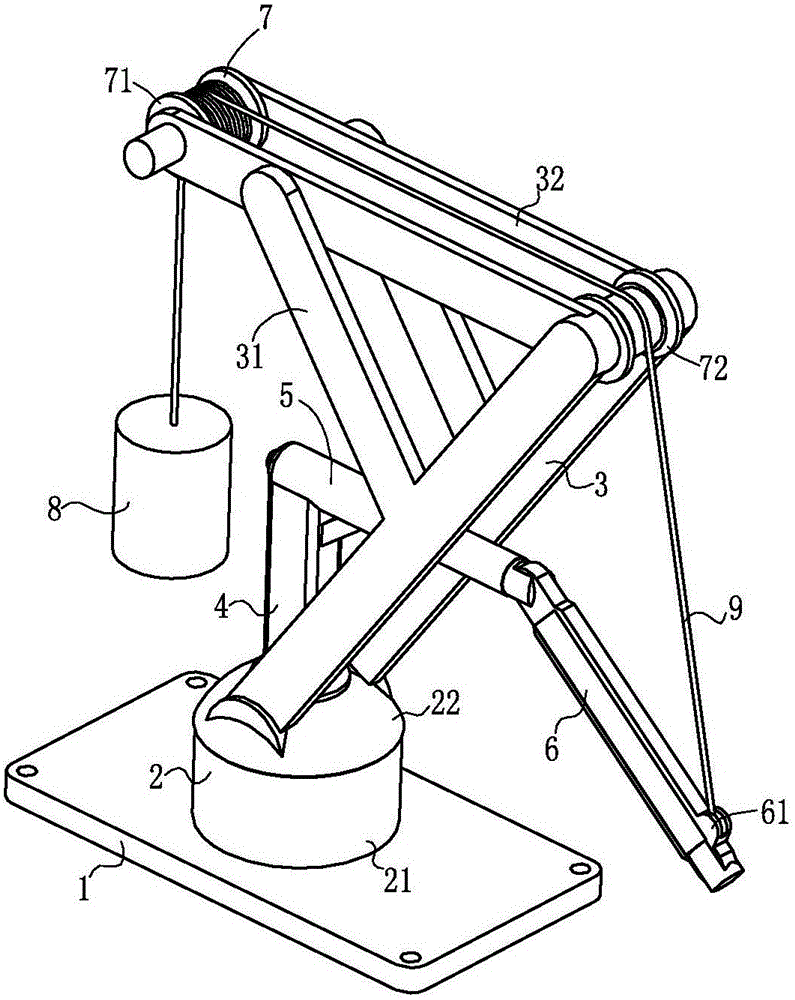

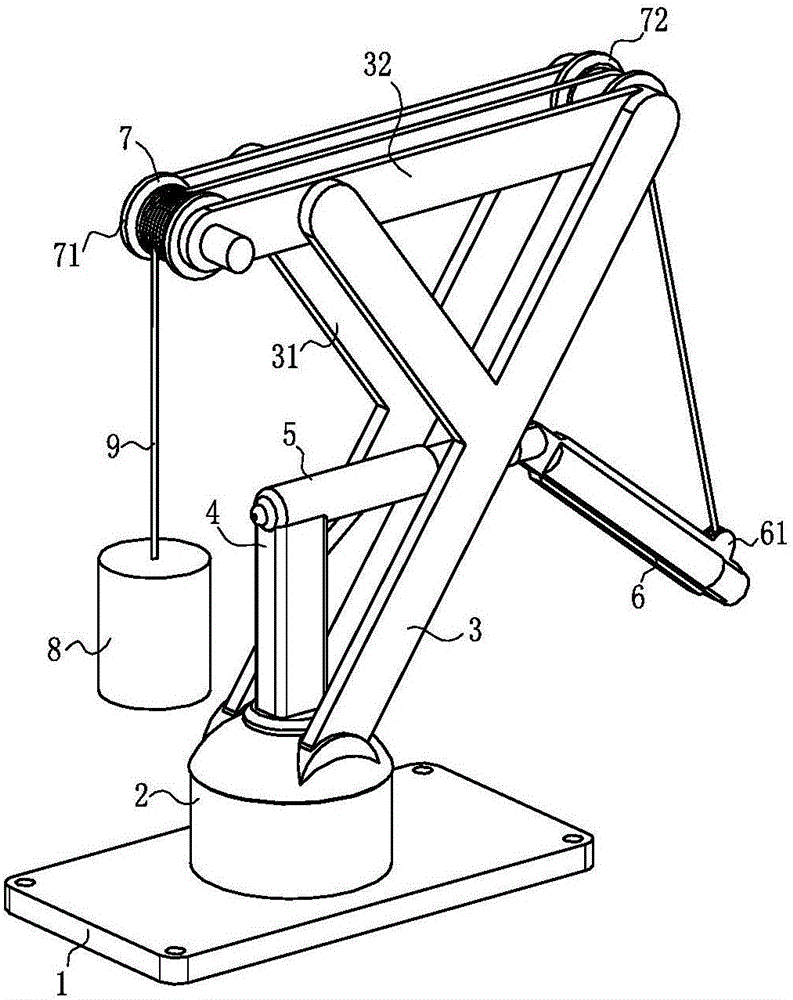

Pulley type stacking mechanical arm

ActiveCN106003011AImprove utilization efficiencySmall output torqueProgramme-controlled manipulatorStacking articlesHydraulic pumpEngineering

The invention relates to the field of stacking machines, in particular to a pulley type stacking mechanical arm. The pulley type stacking mechanical arm comprises a base plate, a base, a support, a supporting column, a hydraulic arm, a movable arm, a pulley, a balance block and a pull rope. The base comprises a fixed base body arranged on the base plate and a rotary base body arranged on the fixed base body. The support is fixed to the base. The supporting column is vertically fixed to the rotary base body. The two ends of the hydraulic arm are hinged to the supporting column and the movable arm correspondingly. The pulley comprises an active rolling wheel and a fixed pulley body, the active rolling wheel and the fixed pulley body are arranged on the support, and the side face of the active rolling wheel is connected with a motor. One end of the pull rope is fixed to the other end of the movable arm, the middle portion of the pull rope winds across the fixed pulley body, and the other end of the pull rope is wound on the active rolling wheel by a plurality of circles. The balance block is connected with the other end of the pull rope and arranged in a suspended mode. According to the pulley type stacking mechanical arm, the rope and the pulley are used for force transmission, and the stress difference between the two ends of the rope is made smaller so that the output torque of the driving motor can be smaller when the mechanical arm moves, and the mechanical arm can save more energy.

Owner:沈阳实发汽车配件有限公司

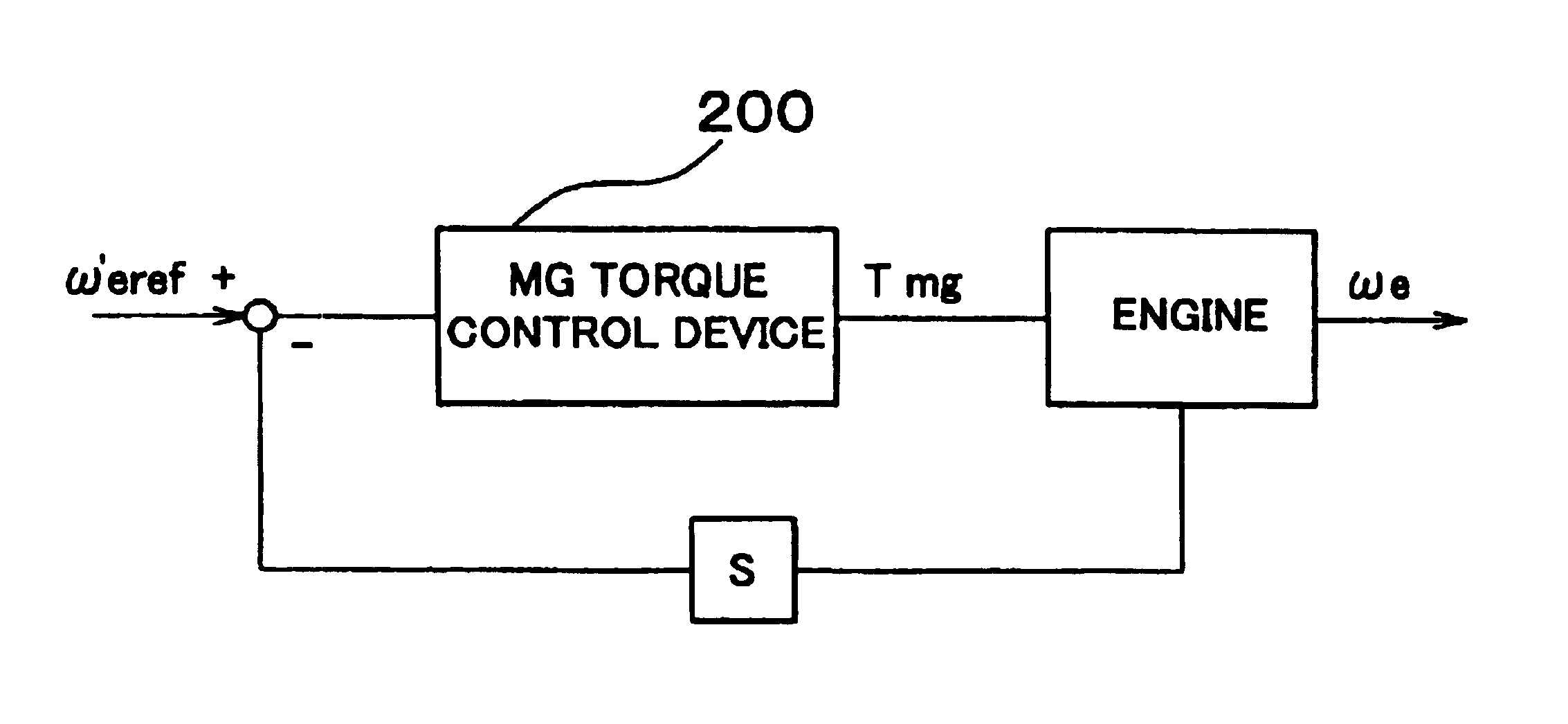

Cranking-caused vibration suppressing apparatus and method for internal combustion engine

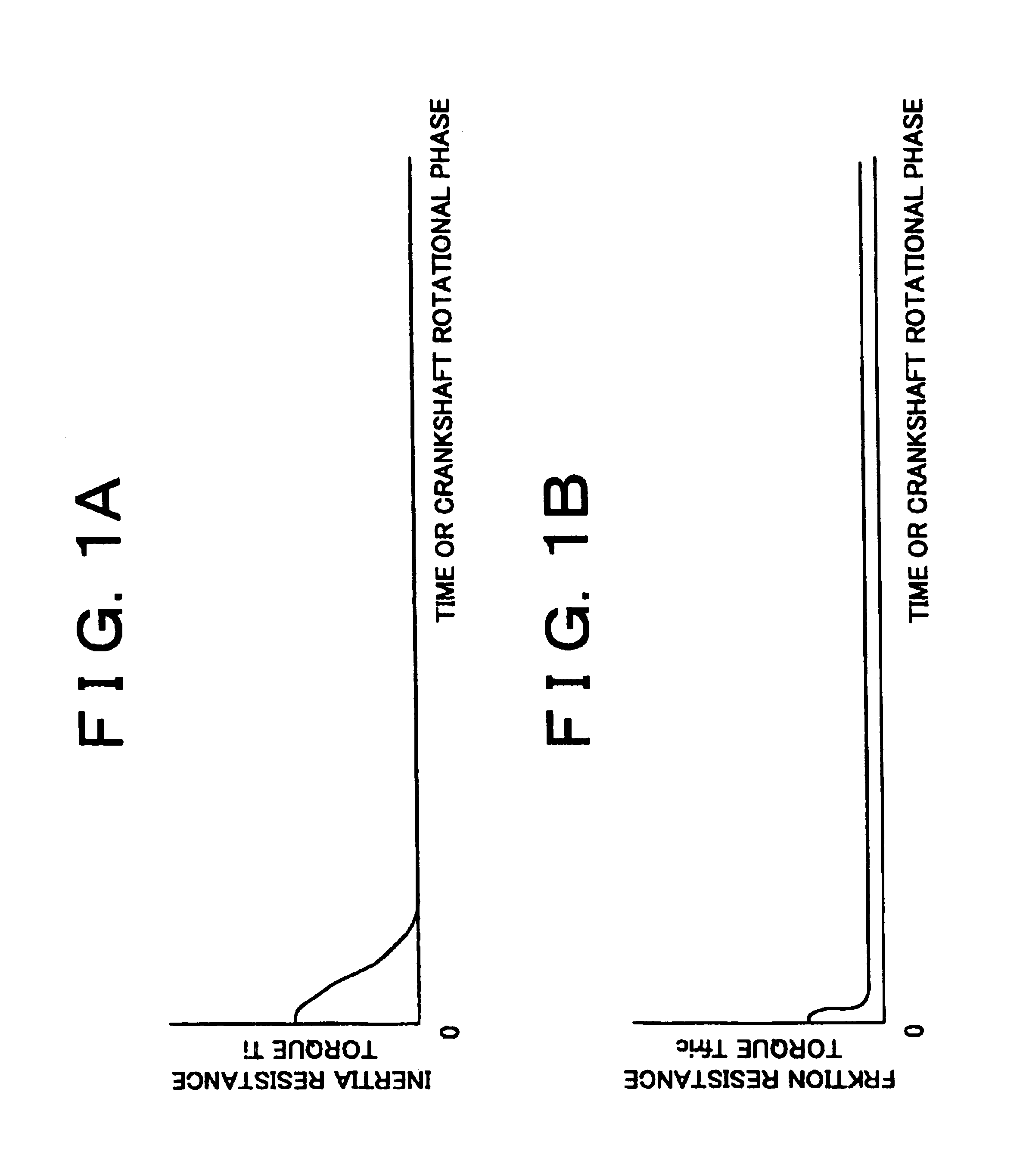

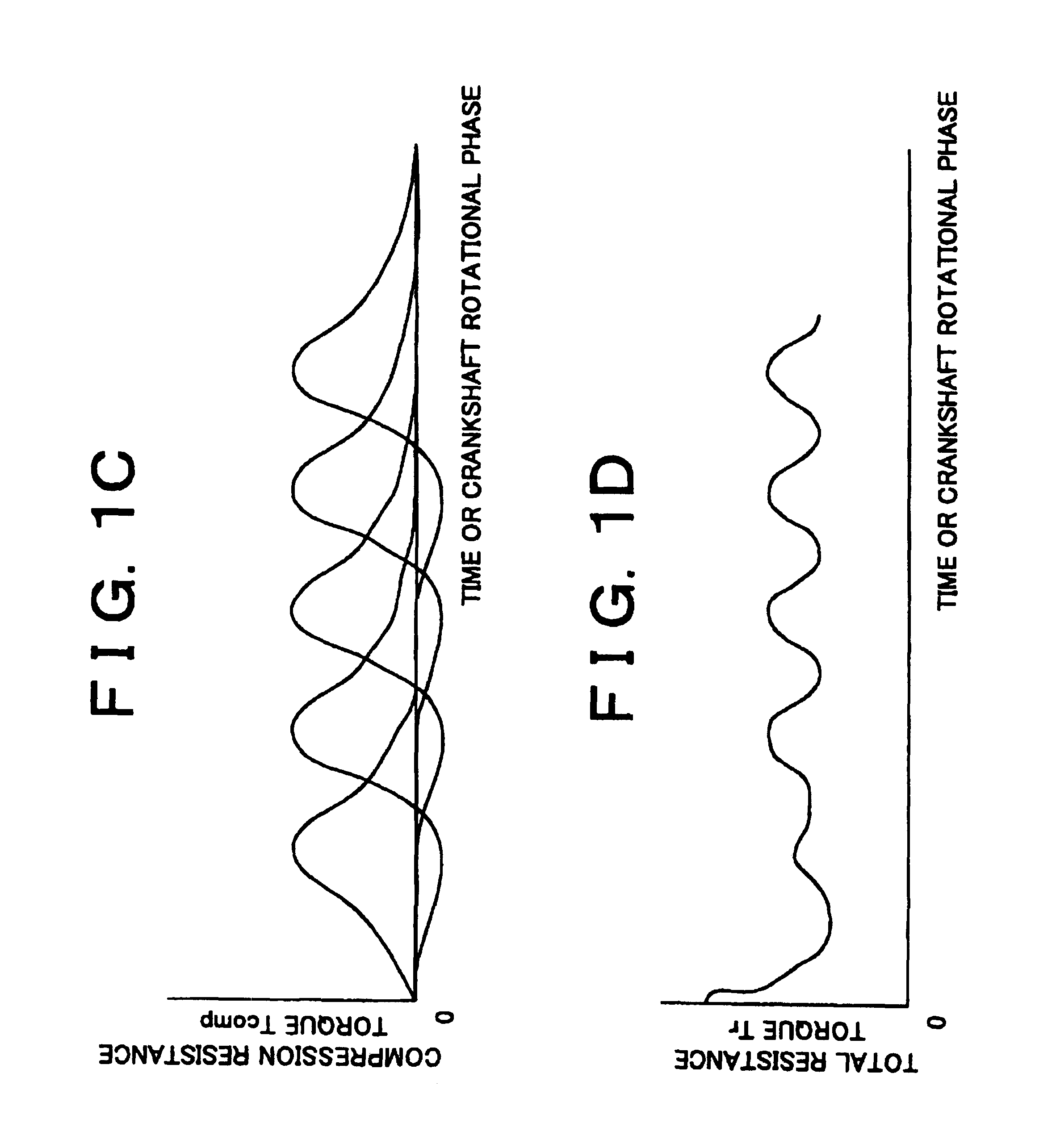

InactiveUSRE39965E1Noise affectingHigh output torqueHybrid vehiclesElectrical controlPhase detectorExternal combustion engine

At the time of (i.e., during) cranking of an internal combustion engine, an engine cranking-caused vibration suppressing apparatus and method controls the operation of an electric motor that cranks the internal combustion engine based on the rotational phase of the crankshaft detected by a crankshaft rotational phase detector so that the output torque of the motor fluctuates similarly to fluctuations in resistance torque against the cranking of the engine that the crankshaft presents in accordance with the rotational phase thereof. Thus, the apparatus and method are able to suppress vibrations during the cranking of the engine, leading to improvements in the riding comfort and the noise suppression of a vehicle.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com