Washing machine with automatic opening/closing machine cover and control method thereof

A washing machine and cover technology, which is applied to the control device of washing machines, washing machines with containers, other washing machines, etc., can solve the problems of falling off failure, cover wear, and laborious cover, so as to improve the service life, eliminate noise, avoid The effect of impact collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] Example one:

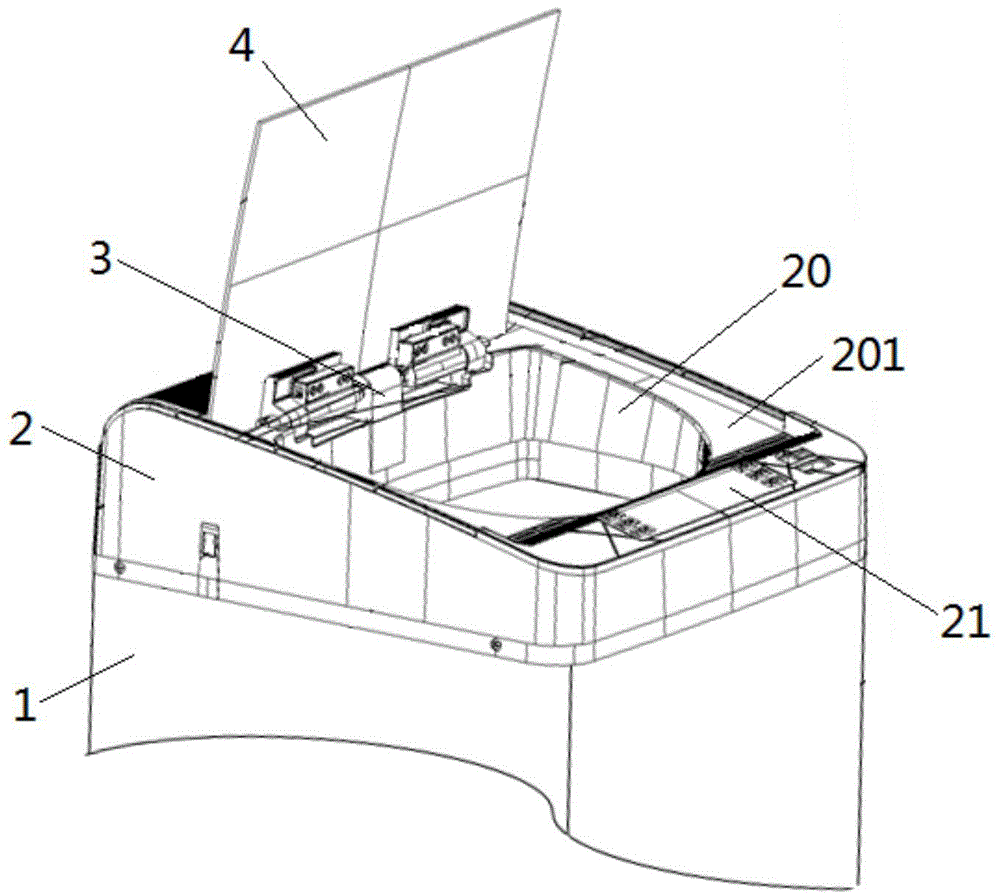

[0041] Basic structure reference of pulsator washing machine figure 1 ,No longer.

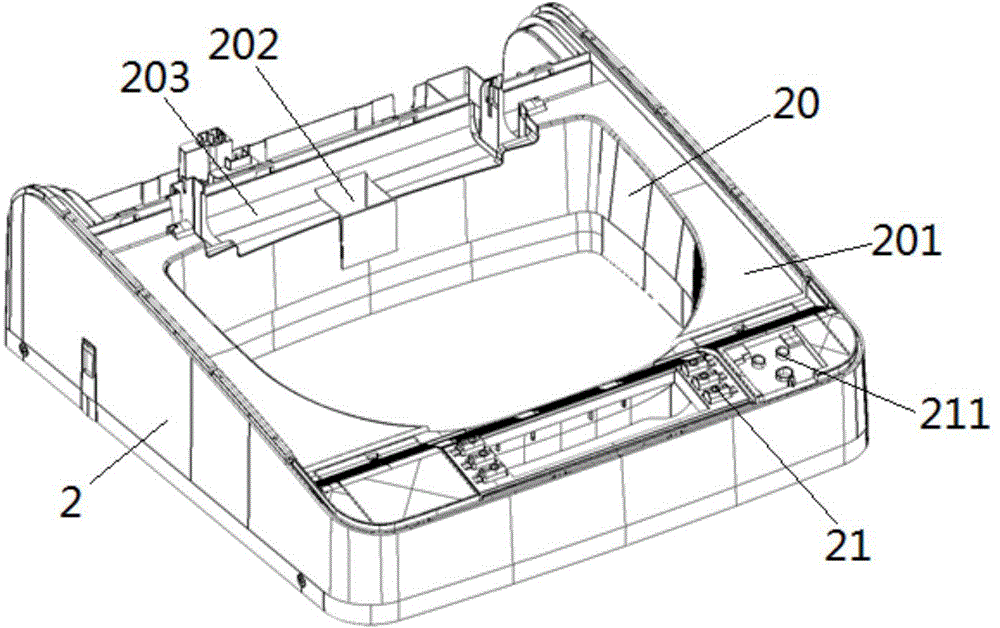

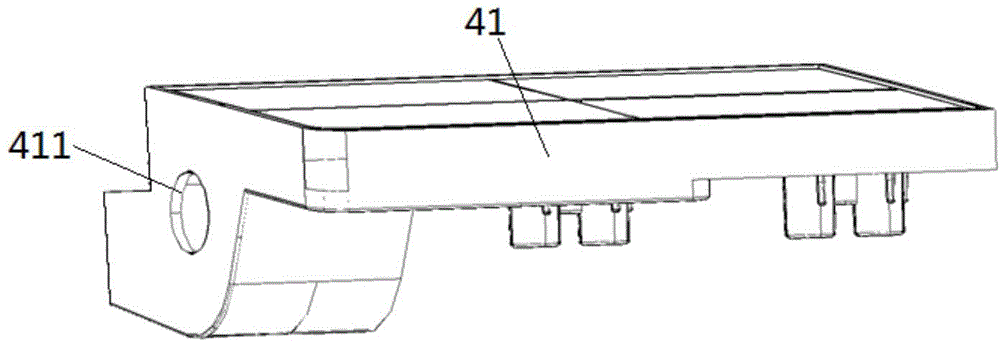

[0042] The rear side of the machine cover 4 is connected to the part of the control seat 2 behind the clothes inserting opening 20 through a rotating shaft 22. The part of the control seat 2 behind the clothes inserting opening 20 is provided with a positioning groove 202 for positioning the motor 3, such as figure 2 Shown. The positioning slot 202 is located in the middle of the rear side of the clothes inserting port 20. The motor 3 has dual output shafts and has bidirectional output capability. There are rotating shafts 22 on both sides of the motor 3, so that the output torque of the motor 3 can be relatively stable, and the weight is relatively high. The large glass cover 4 can ensure smooth opening / closing. The cross section of the positioning slot 202 matches the cross section of the housing of the motor 3. In this embodiment, the housing of the motor 3 is deliberately...

Example Embodiment

[0051] Embodiment two:

[0052] Such as Figure 7 As shown, this embodiment provides a method for controlling a washing machine with the cover automatically opened / closed. The structure of the washing machine has been disclosed in the first embodiment. You can refer to the first embodiment. The specific steps of the control method are as follows:

[0053] a) The user turns on, and the program is initialized, and then proceed to step b);

[0054] b) The control unit controls the cover lock to unlock, the motor executes the command to open the cover, and the obstacle detection module detects whether there is a cover opening obstacle, if yes, proceed to step c), if not, proceed to step d);

[0055] c) The motor pauses to execute the command to open the cover, and the control unit sends an alarm signal to the alarm device to alert the user to prompt the user to remove the obstacle. After a certain period of time, the control unit detects whether there is a cover opening obstacle, and if ye...

Example Embodiment

[0063] Embodiment three:

[0064] Such as Figure 8 As shown, this embodiment provides a method for controlling a washing machine with a cover that automatically opens / closes. The structure of the washing machine has been disclosed in the first embodiment. You can refer to the first embodiment. The steps of the control method are based on the second embodiment. , Some changes are made to step i), and subsequent steps are added. After the washing program is over, the command to open the machine cover is directly executed, and finally the user is reminded that the washing is complete, so steps a) to h) are omitted, and steps a) to h) are omitted. ,details as follows:

[0065] i) The washing machine starts to execute the washing program. In the washing program, the control unit detects whether the command to open the machine cover is received. If yes, the washing program is suspended and proceed to step b). If not, the washing program continues to be executed until the washing progra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com