Patents

Literature

92results about How to "To achieve a conductive connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

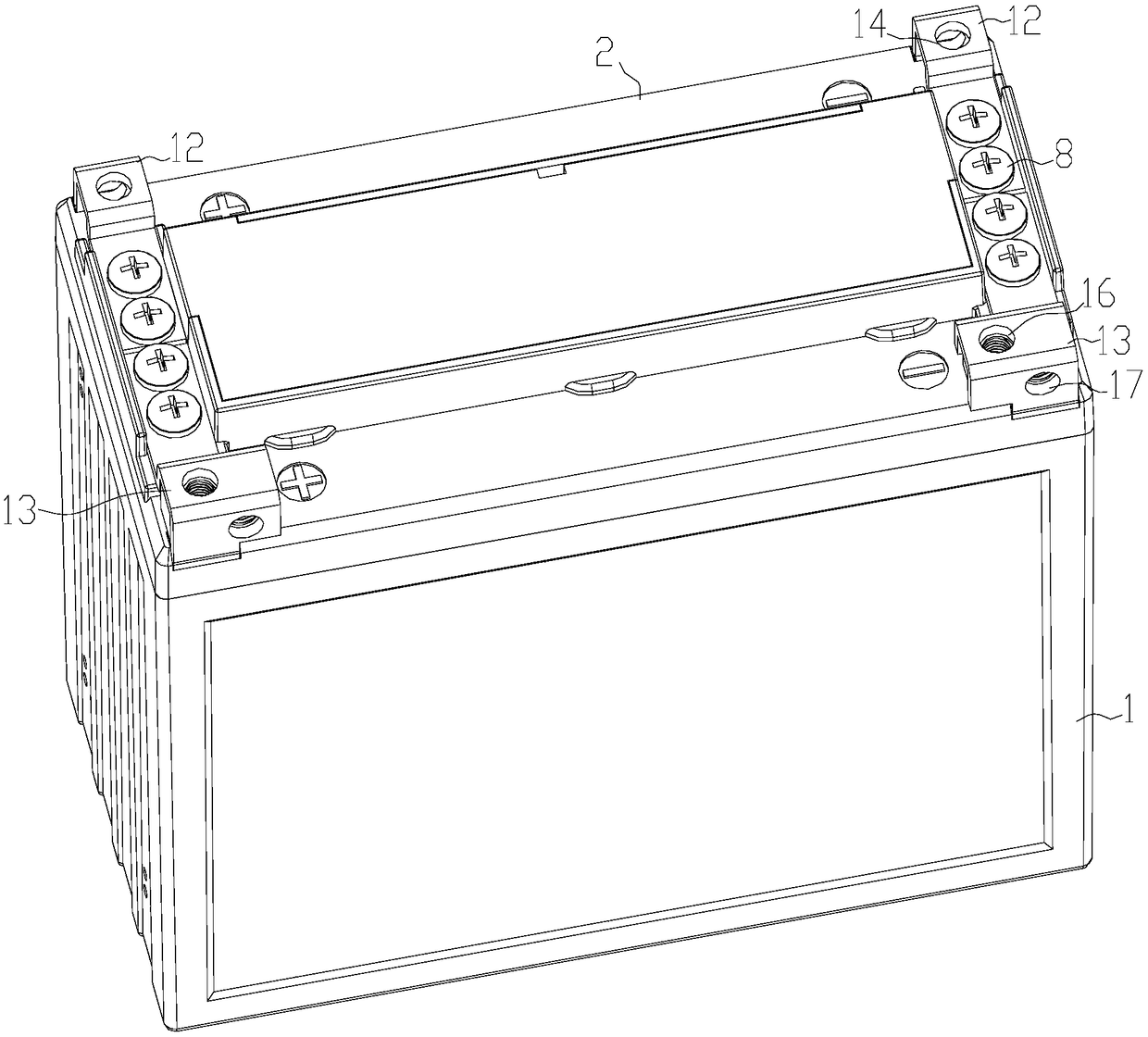

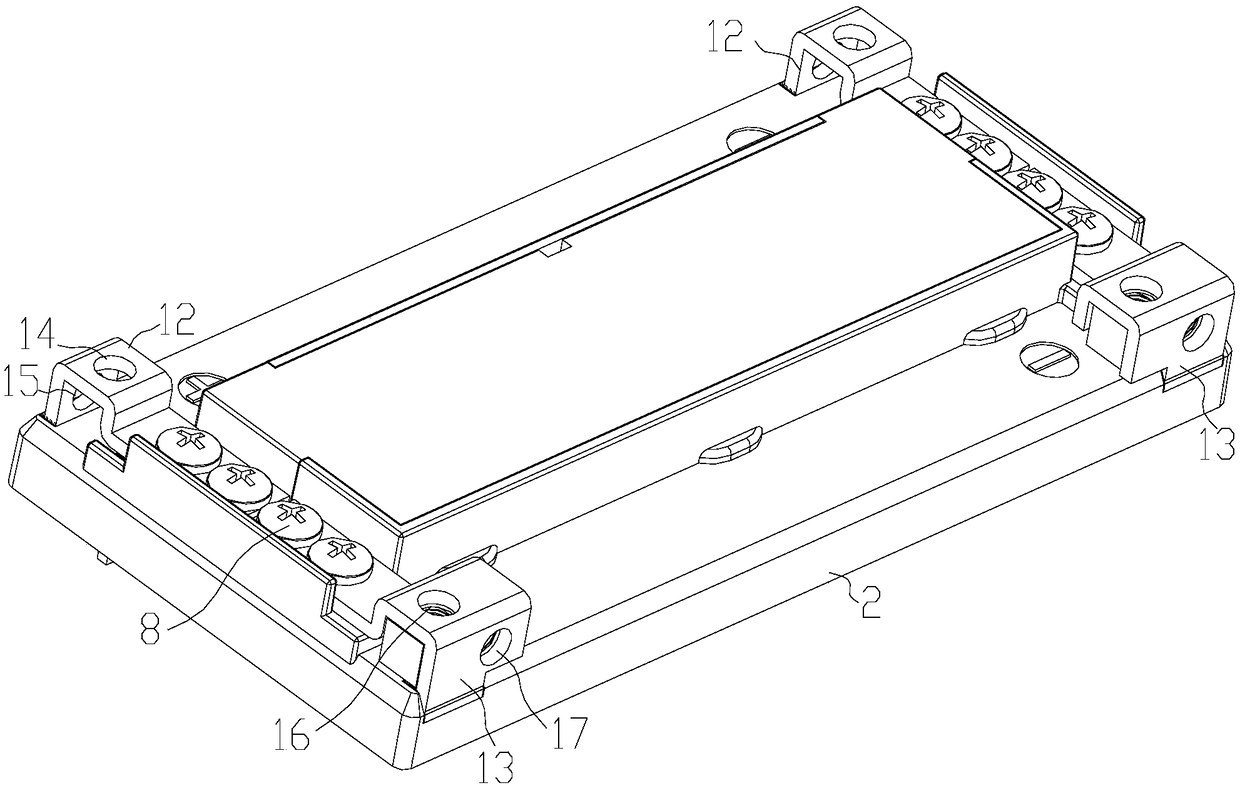

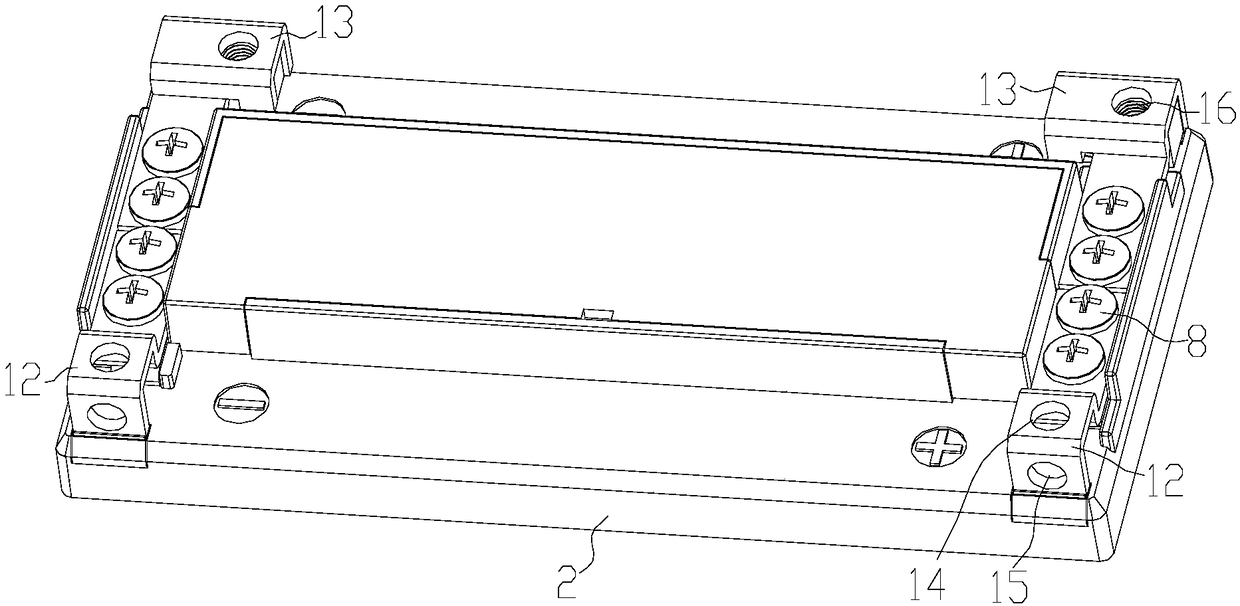

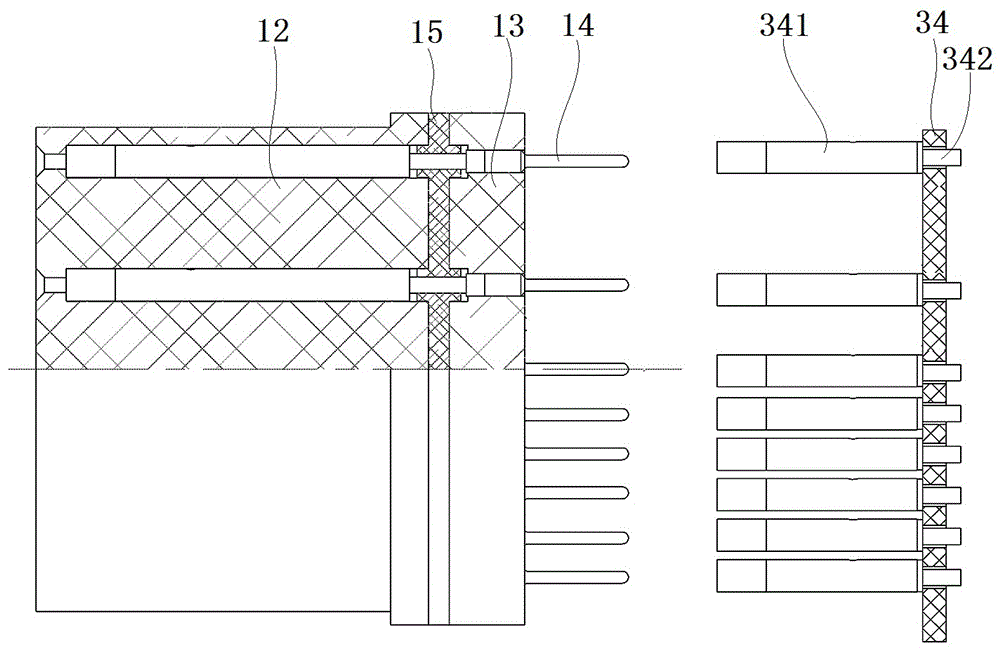

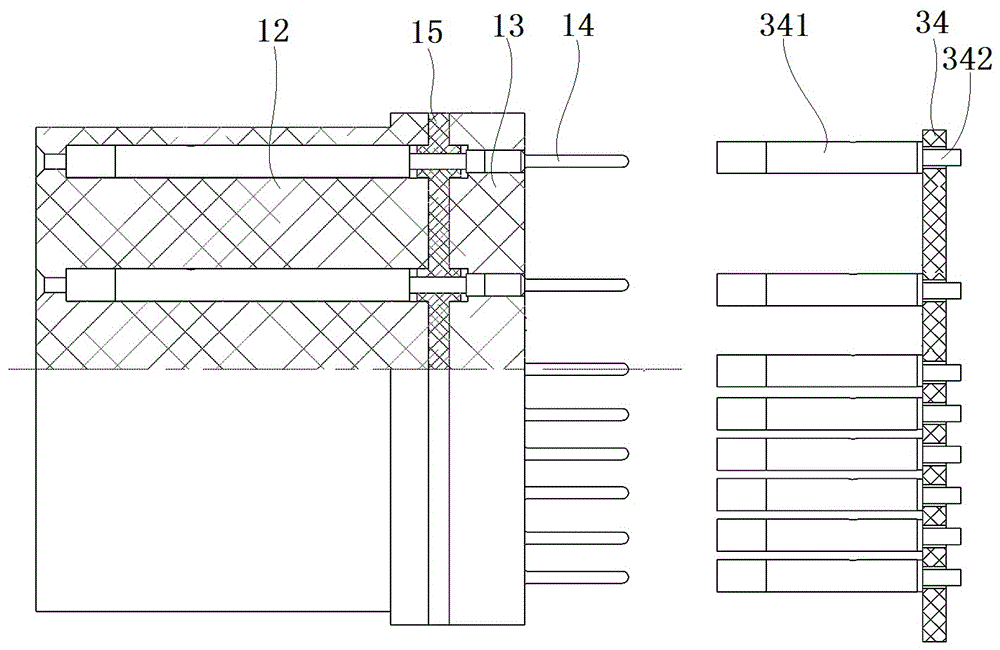

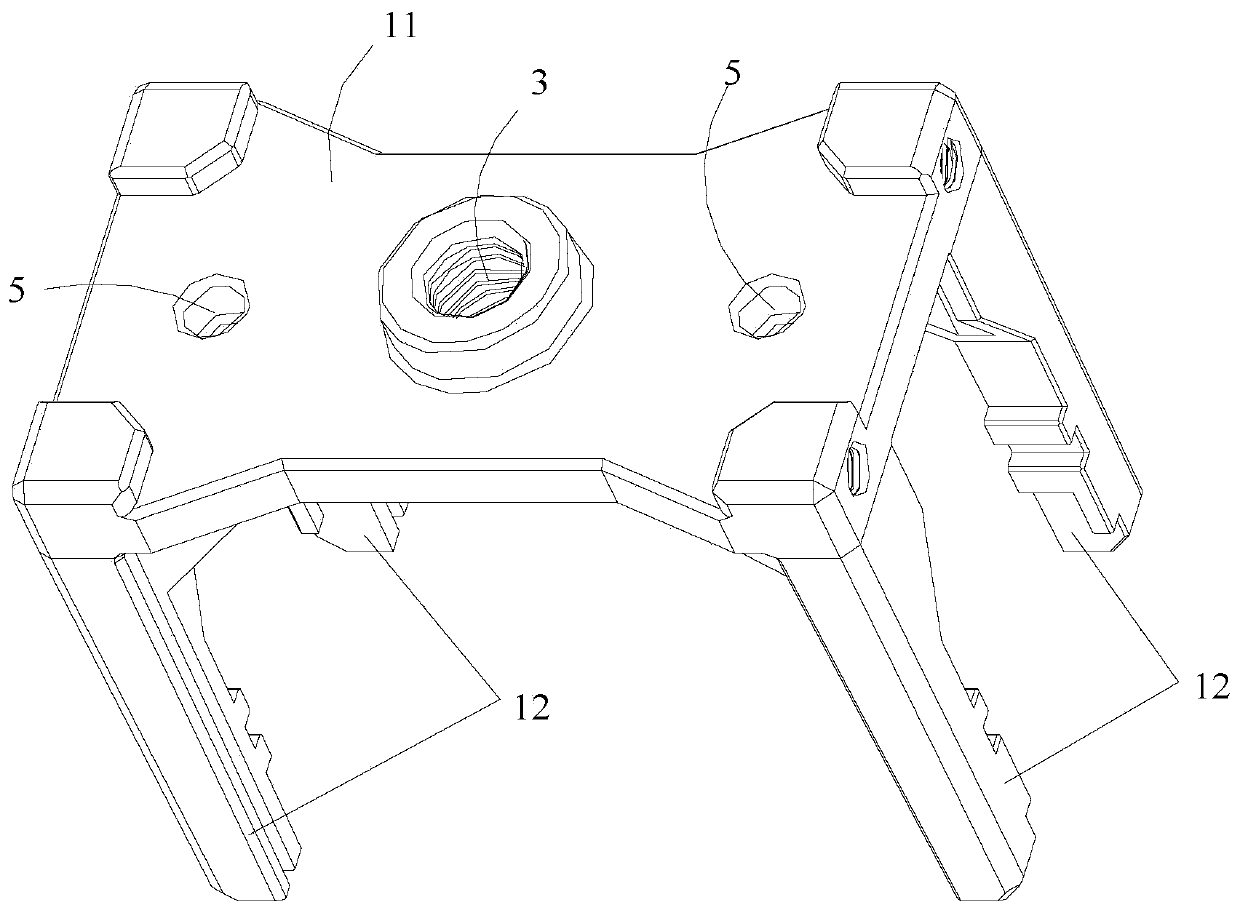

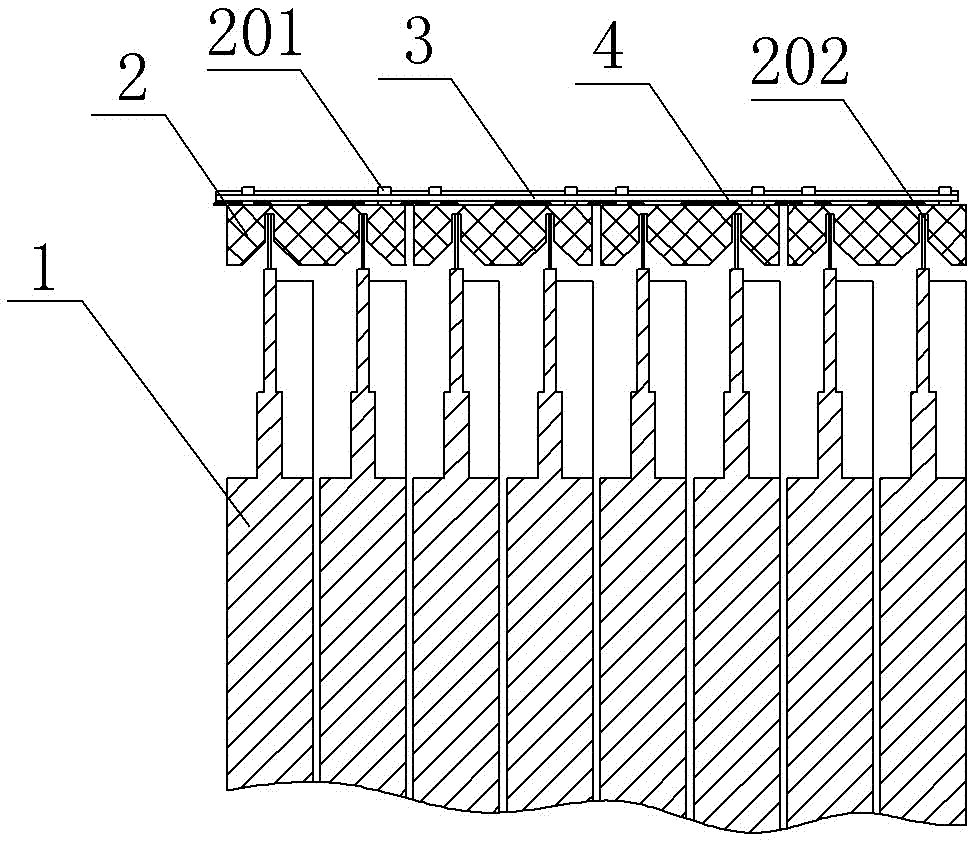

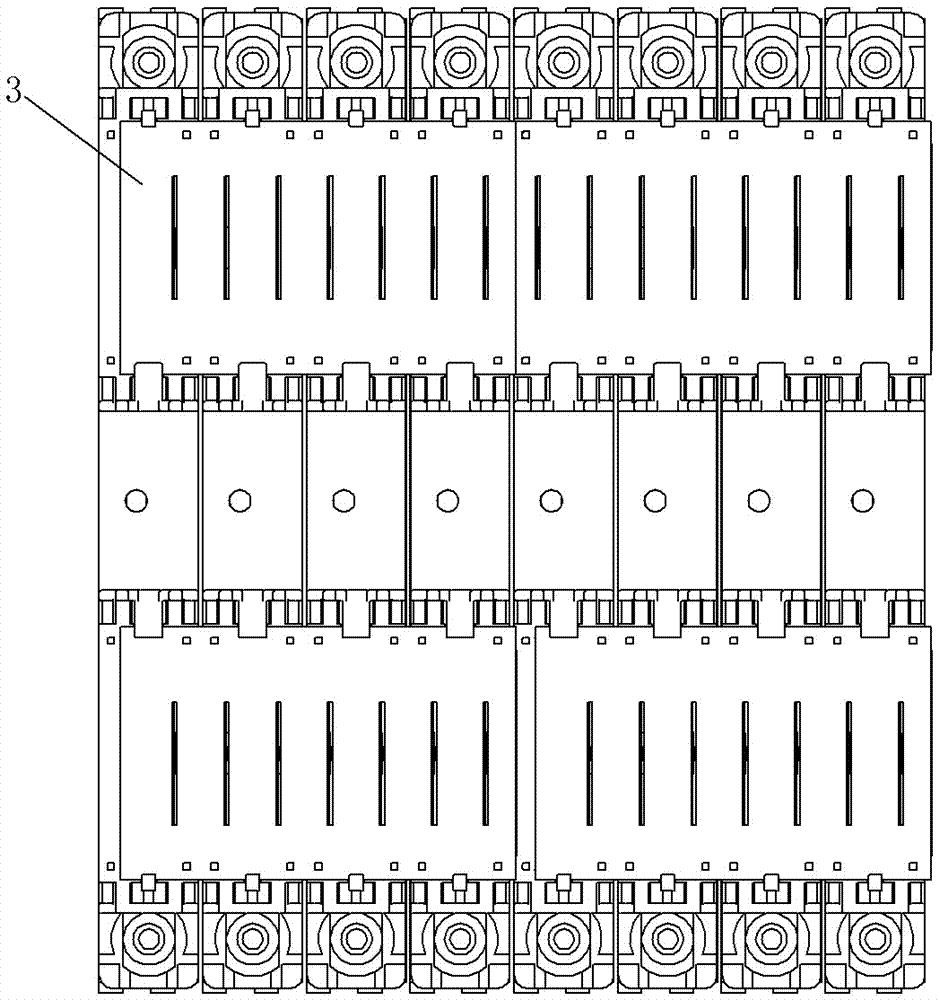

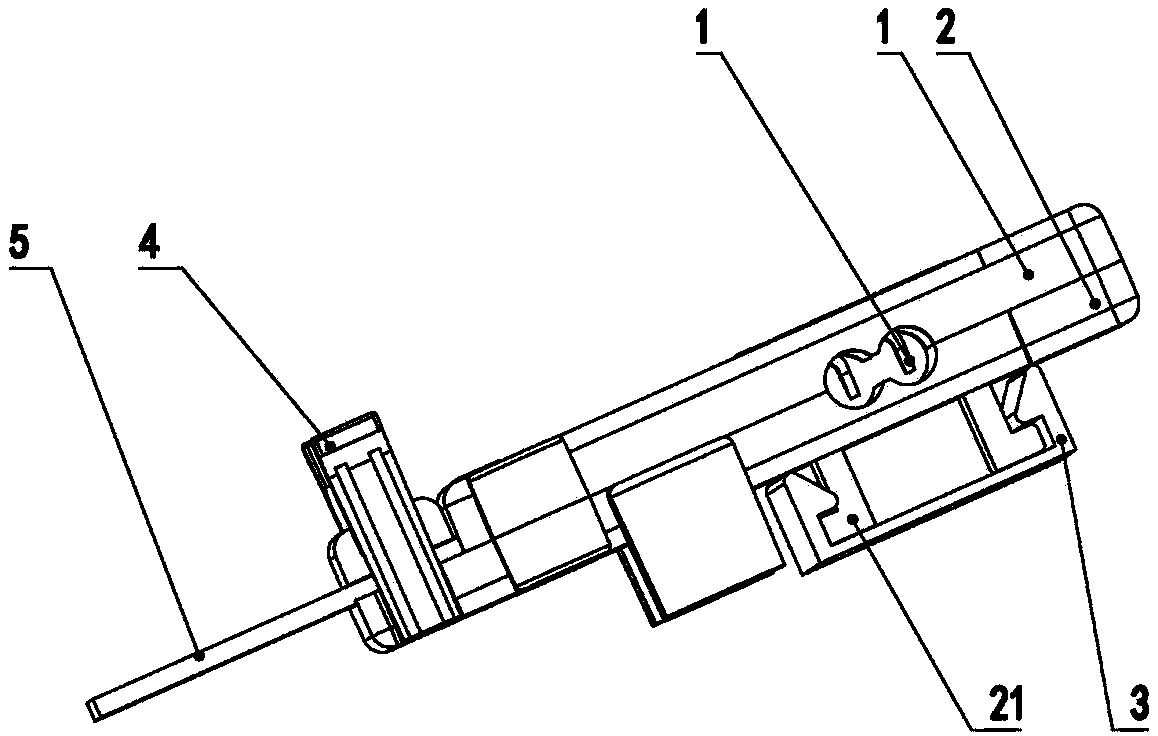

Connection structure of flexible-package lithium ion battery module

ActiveCN105070874ASimplify the assembly processTo achieve a conductive connectionCell component detailsBusbarElectrical battery

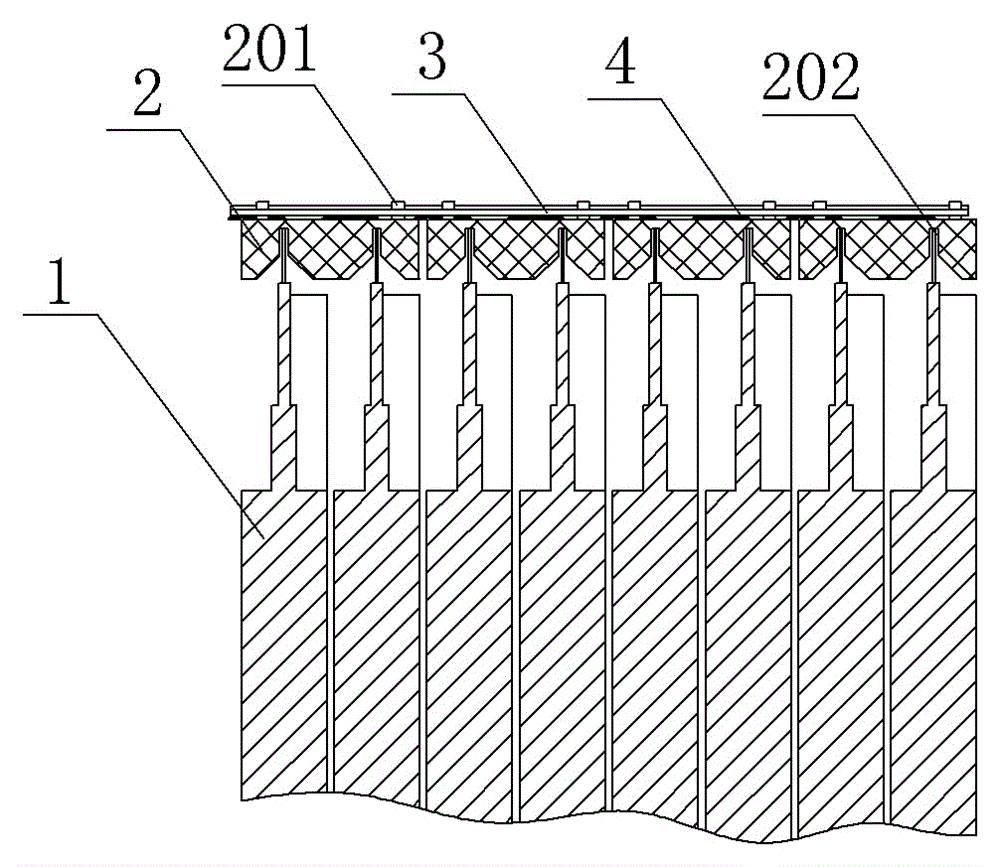

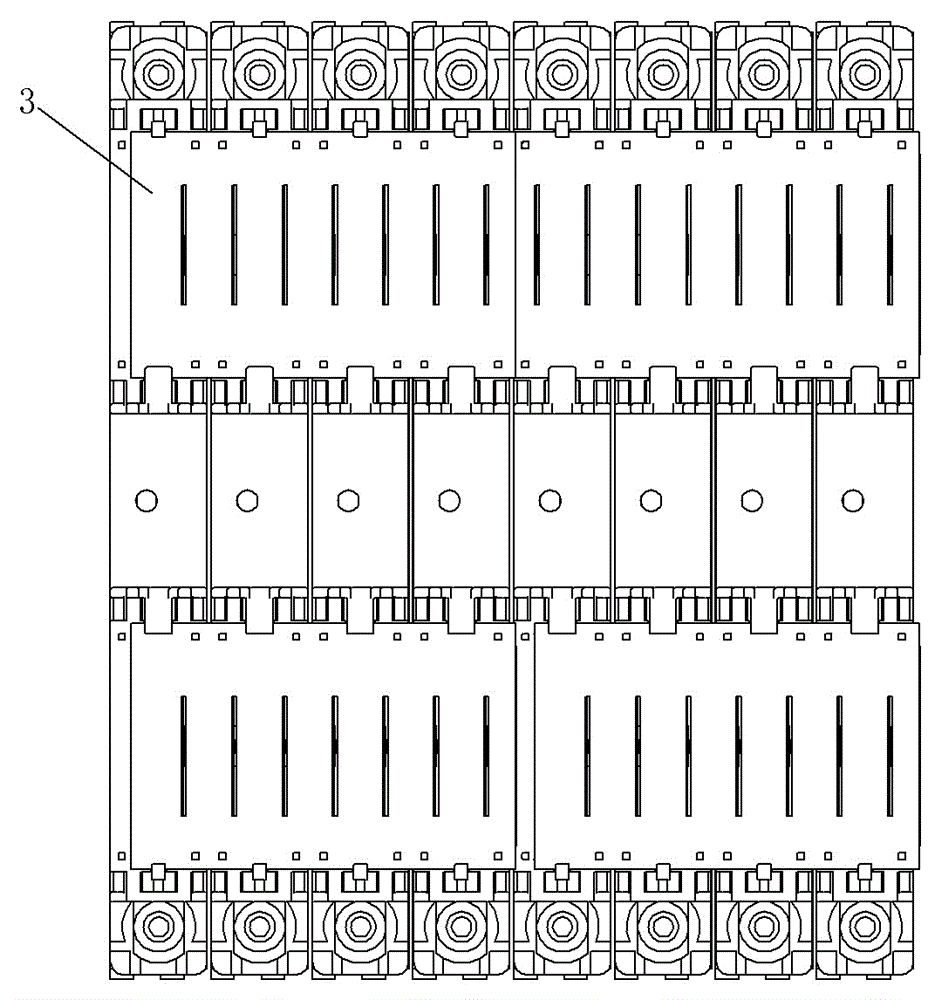

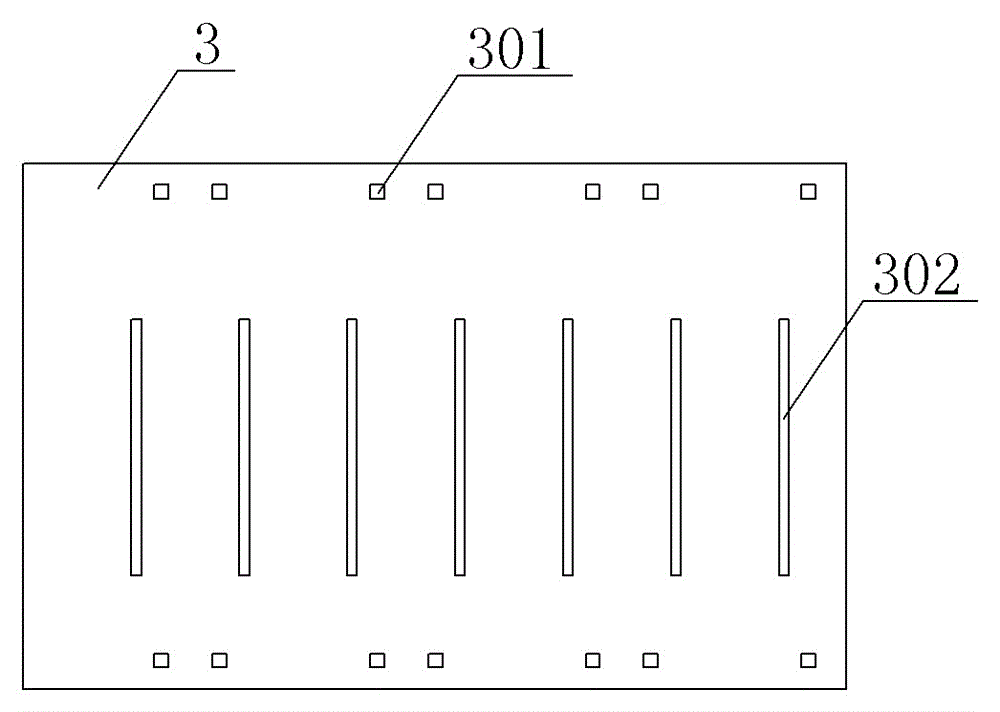

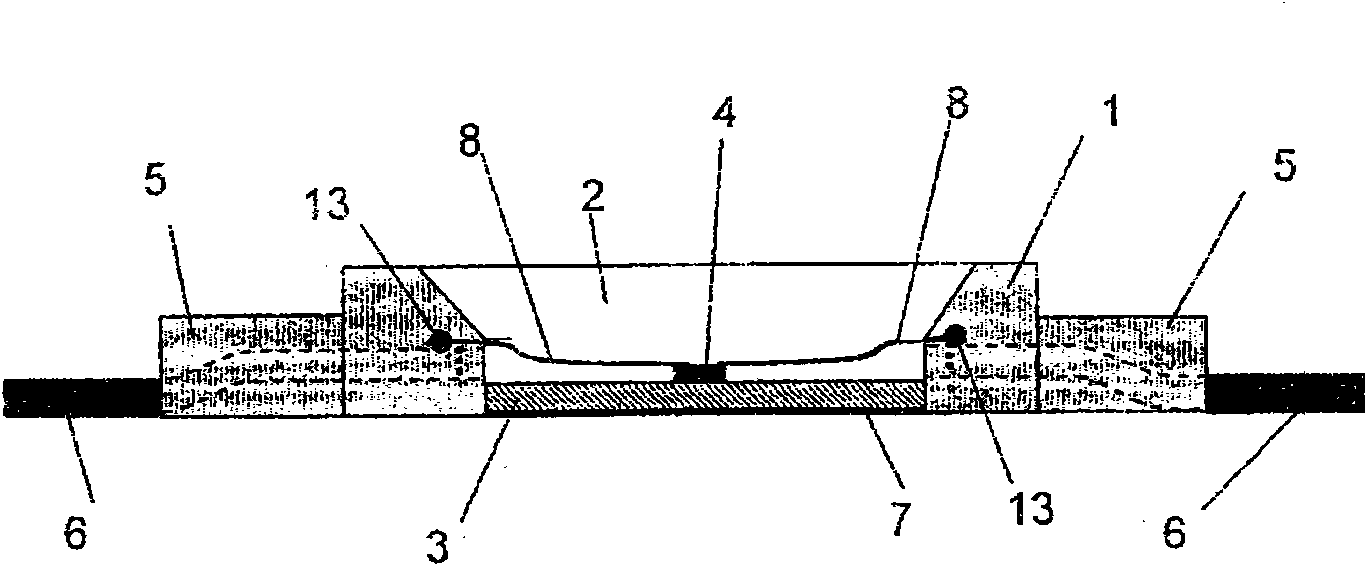

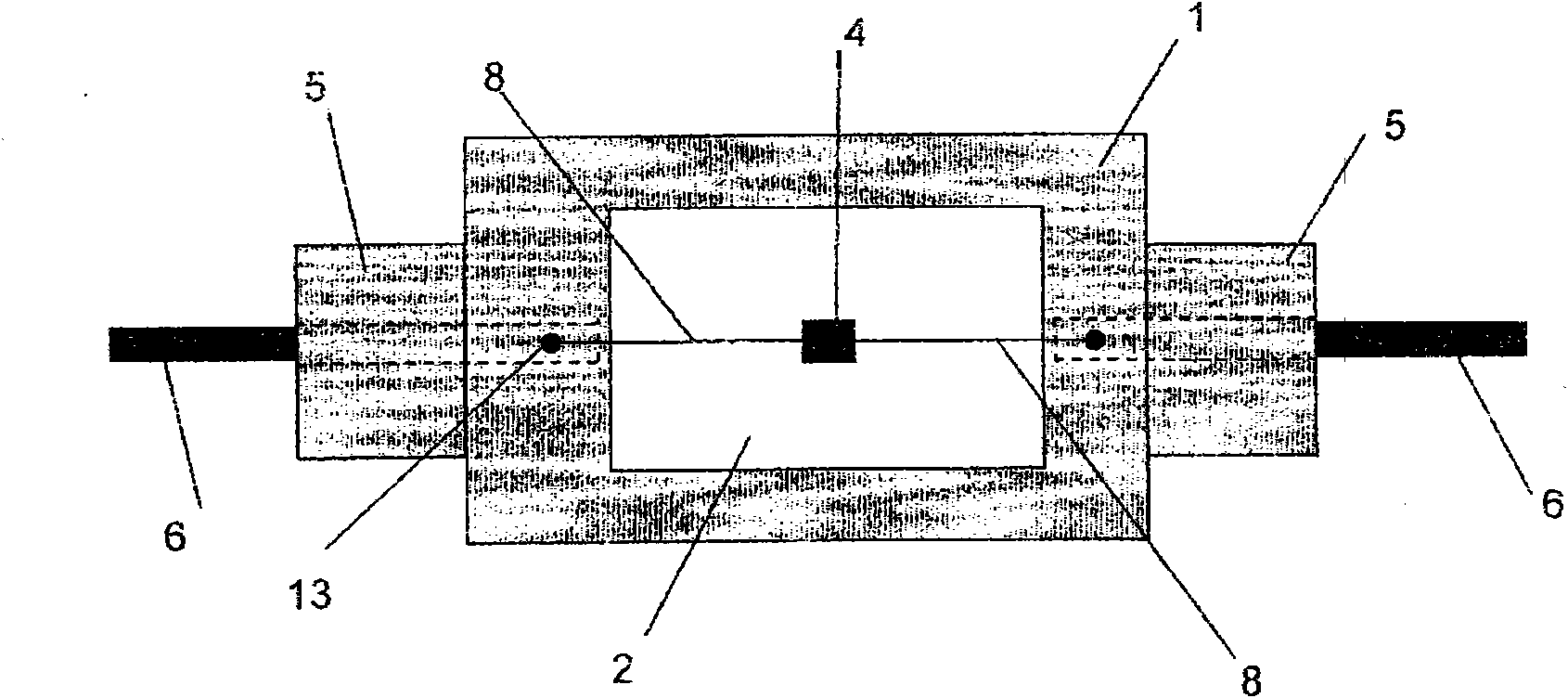

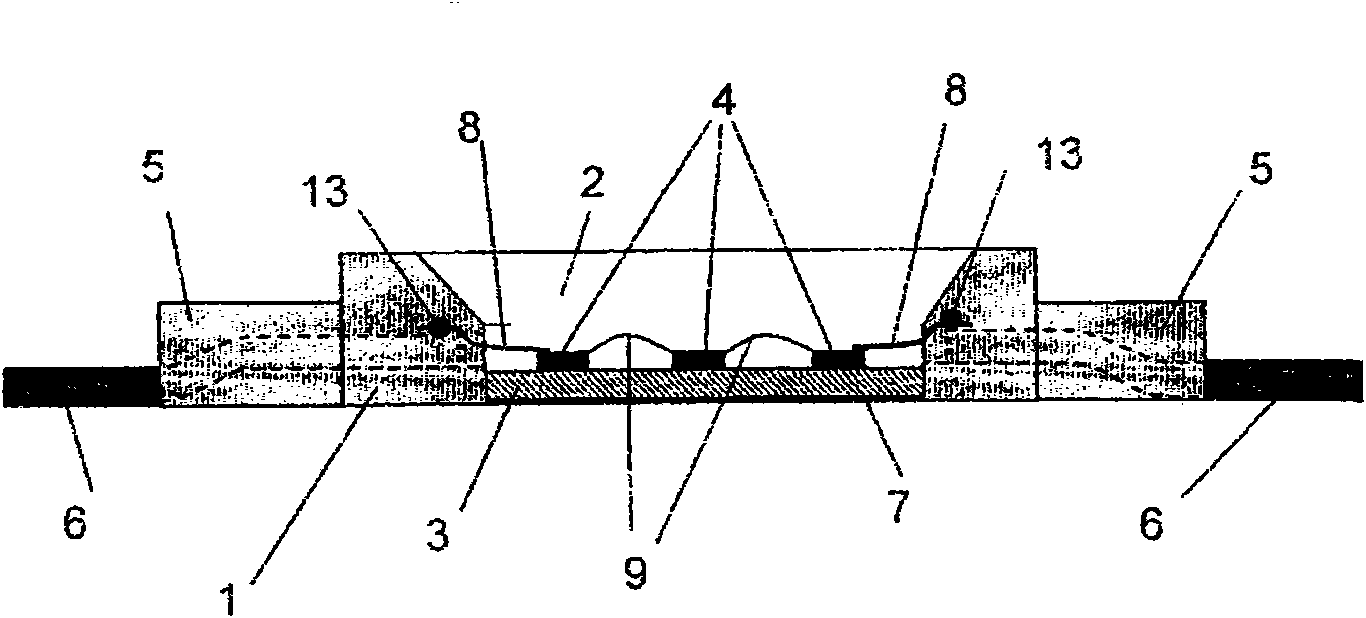

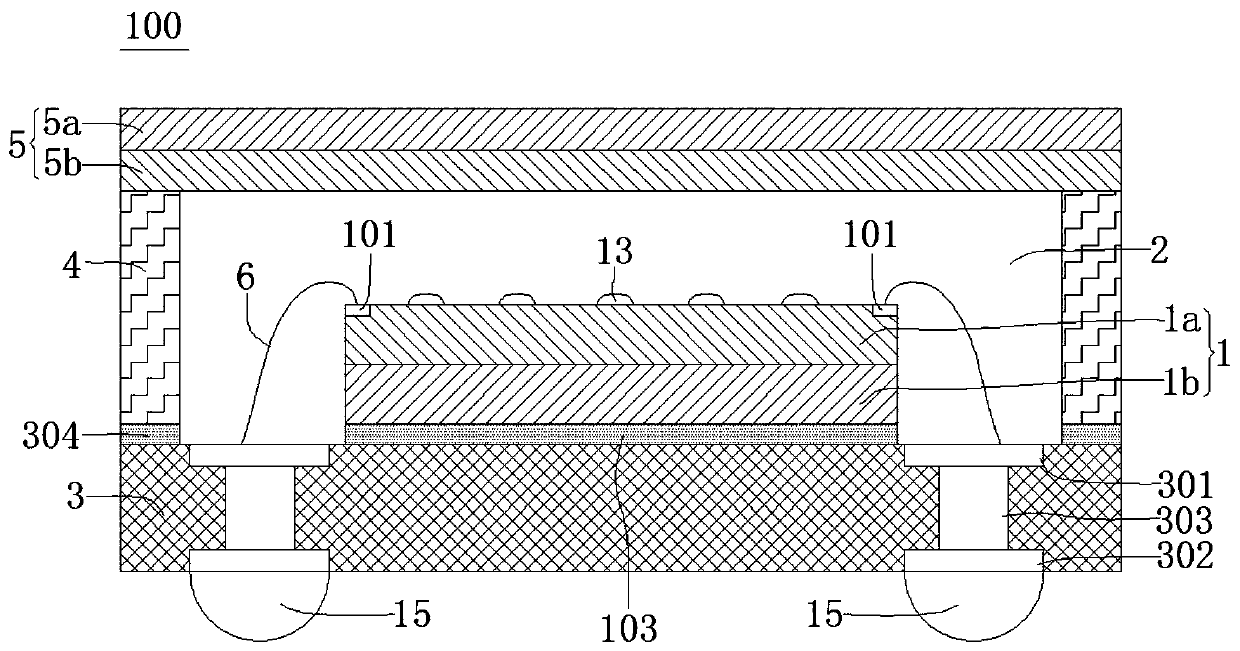

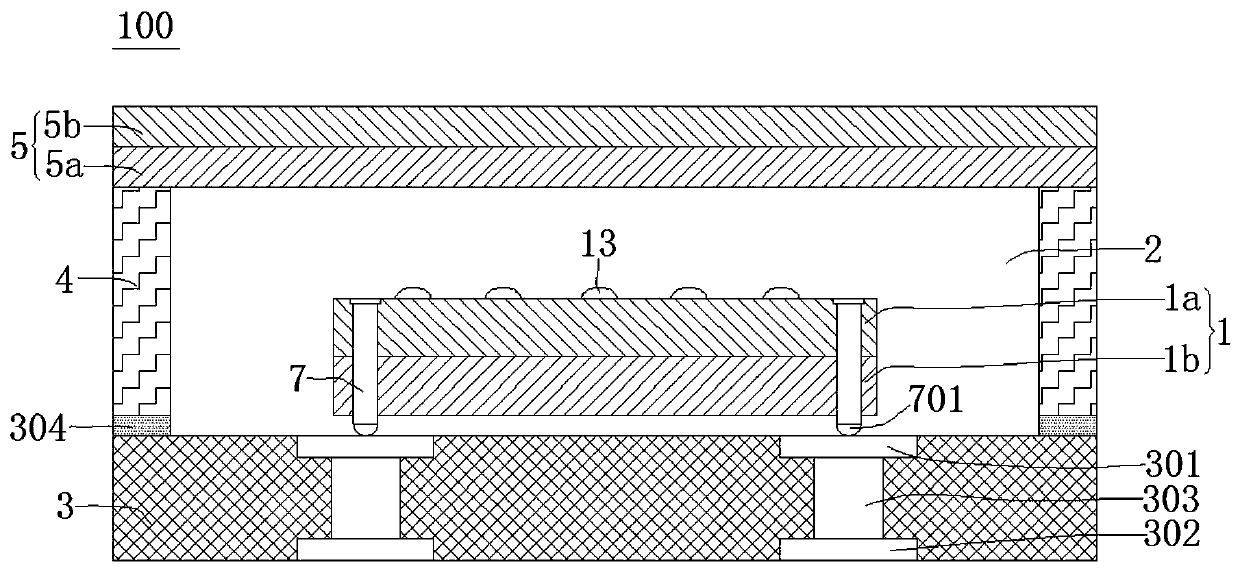

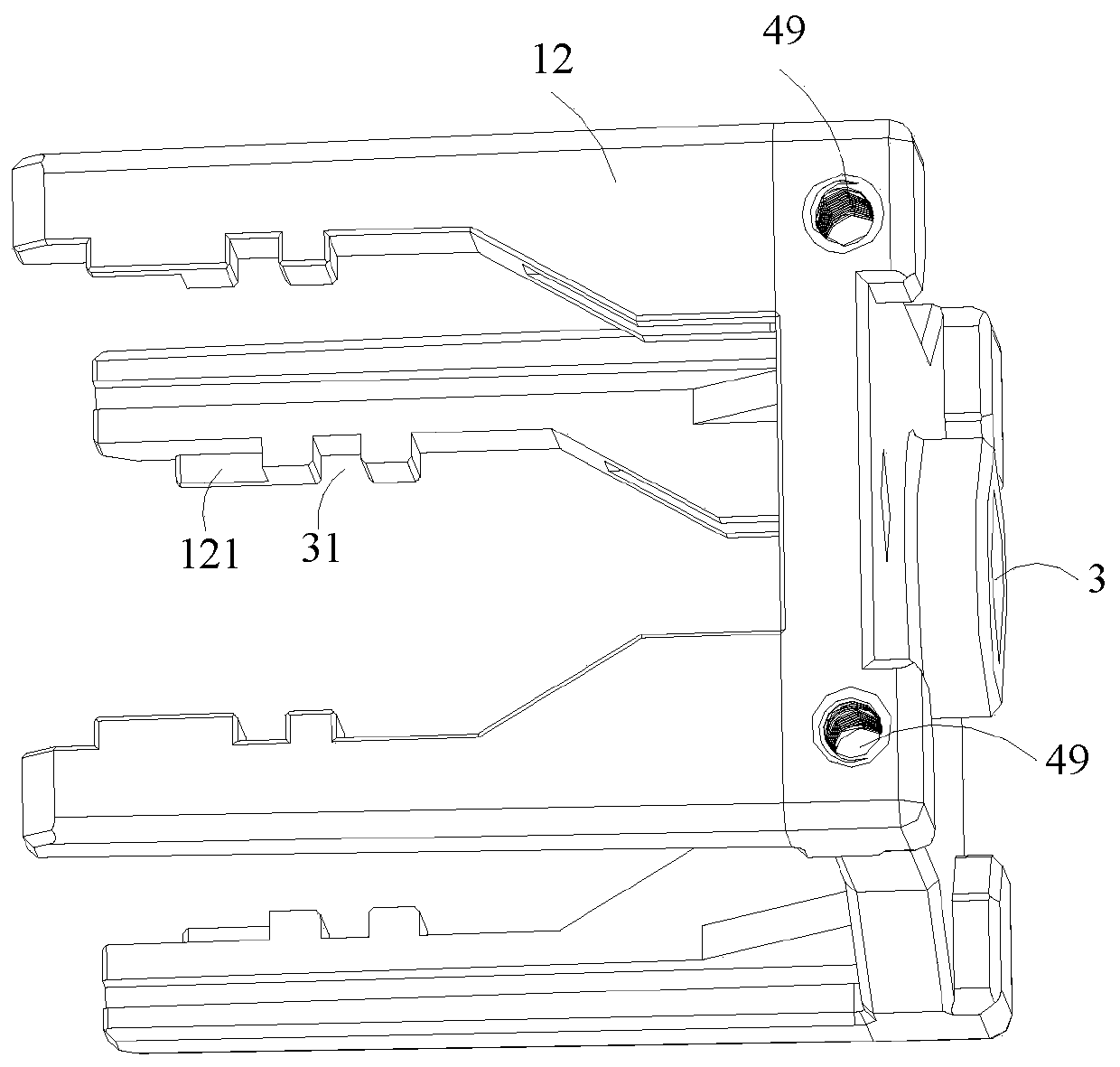

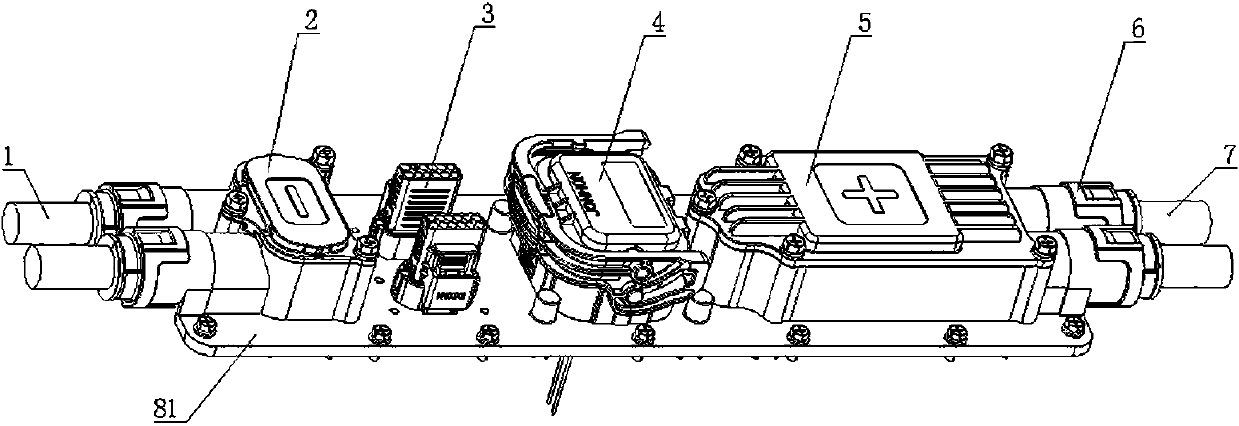

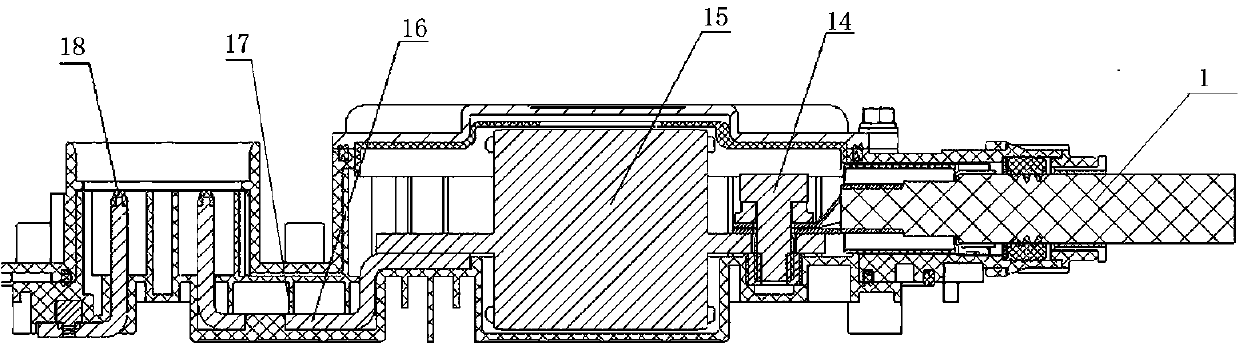

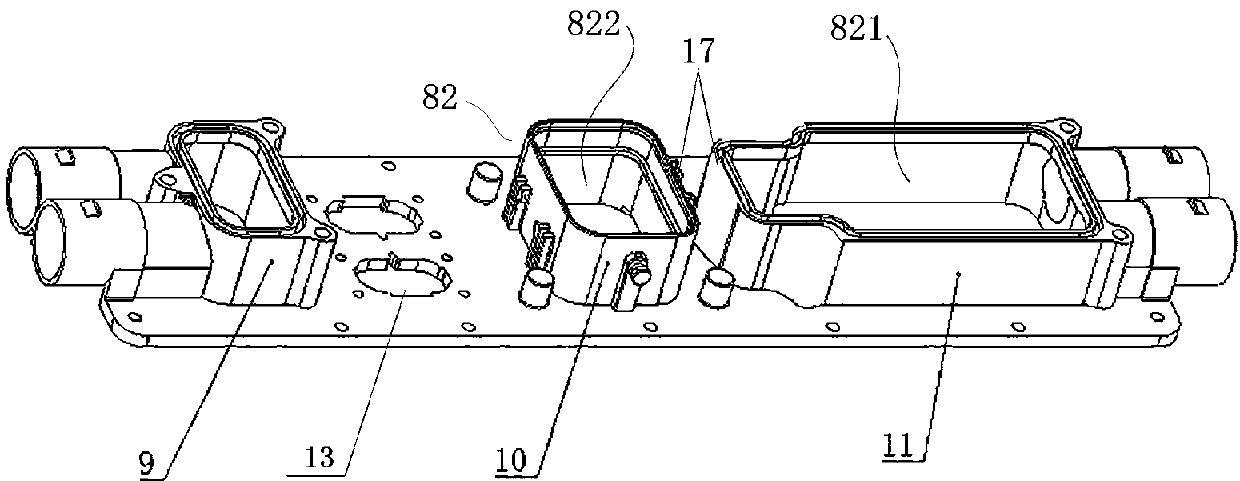

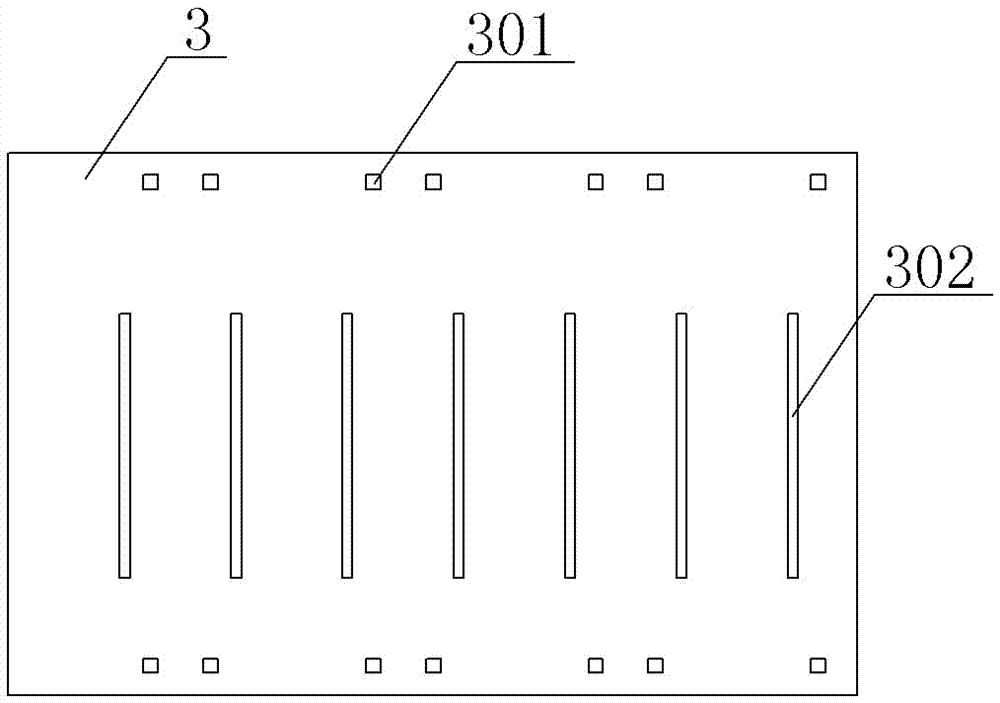

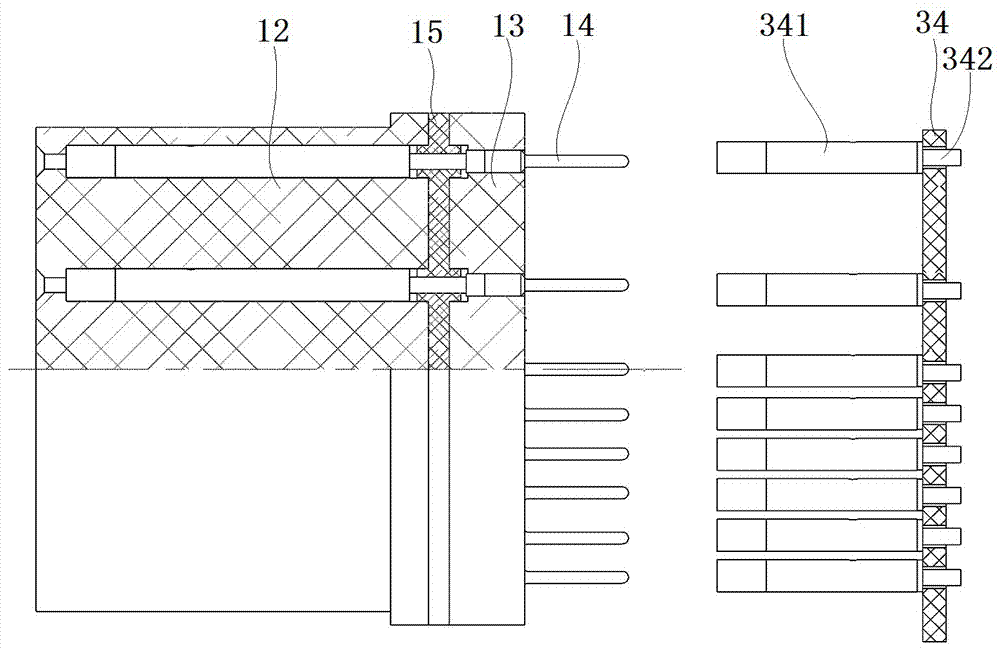

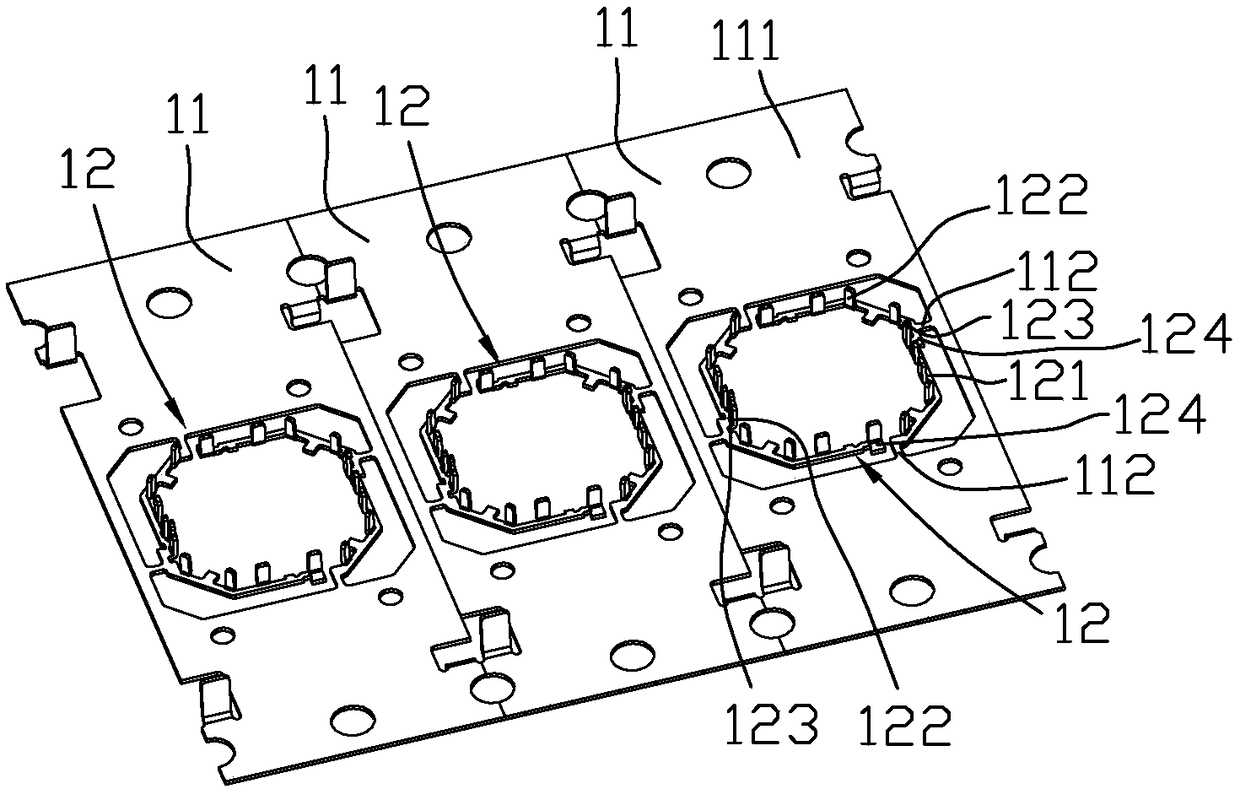

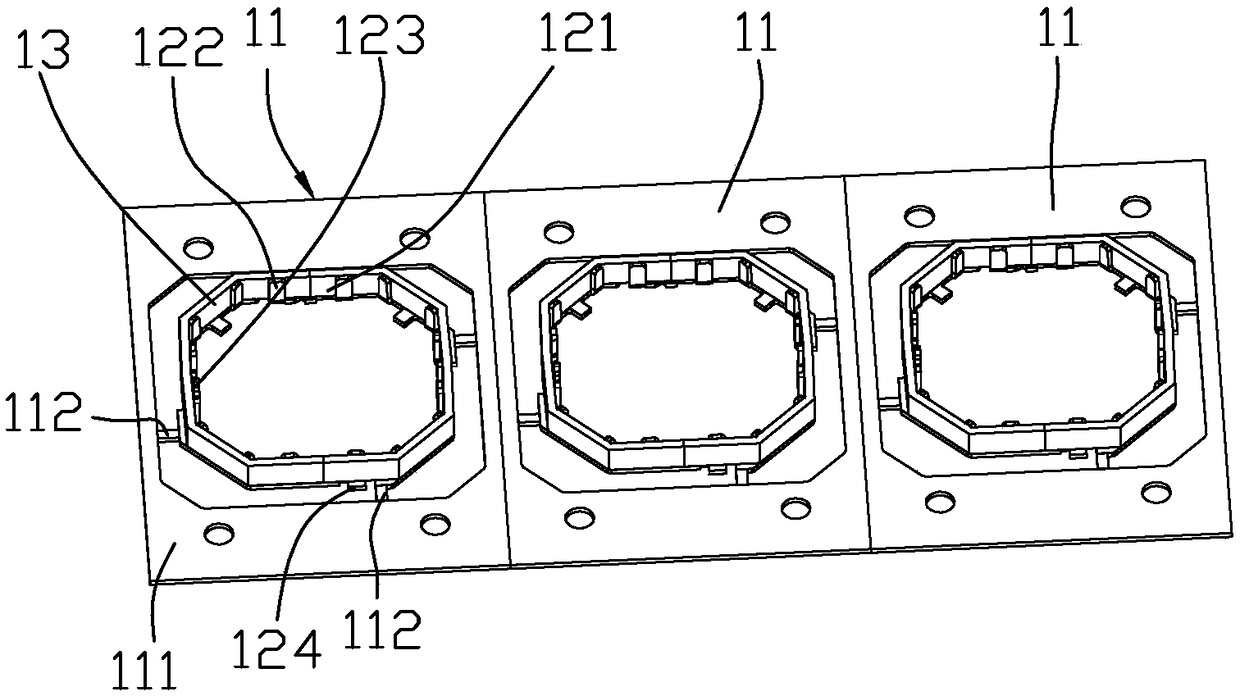

The invention provides a connection structure of a flexible-package lithium ion battery module. The connection structure comprises at least two battery cores and a busbar and also comprises an insulated grid plate, wherein the at least two battery cores are arranged in parallel; the busbar is arranged above the battery cores and electrically connected with tabs of the battery cores; the insulated grid plate is arranged below the busbar and fixedly assembled relative to the battery cores; tab via holes are formed in the insulated grid plate, are corresponding to the tabs of the battery cores and are used for the tabs to pass through; the tops, upwards passing through the tab via holes, of the tabs are provided with bent parts which are bent and are in tight contact with the upper side surface of the insulated grid plate; the busbar is provided with a lower side surface, and the lower side surface is connected onto the bent parts of the tabs in a pressed way and welded and fixedly connected with the bent parts of the tabs. Since the whole busbar is downwards connected onto the bent parts of the tabs in a pressed way, during actual welding and assembling, a corresponding crimping tool is only needed to downwards press the busbar, and the busbar downwards presses the bent parts of the tabs, thus, the problem that a tab crimping tool is required to be additionally arranged is solved, the assembly process of the battery module is effectively simplified, and product cost is reduced.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

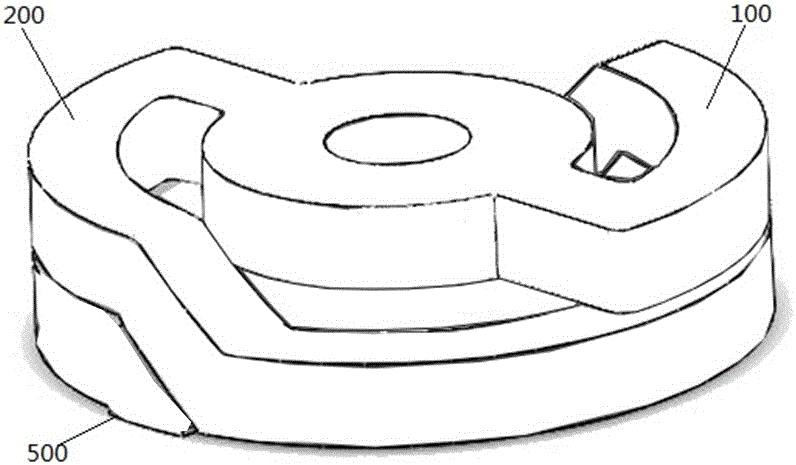

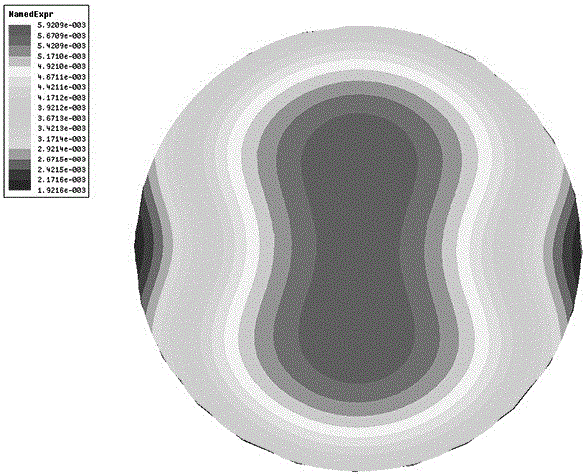

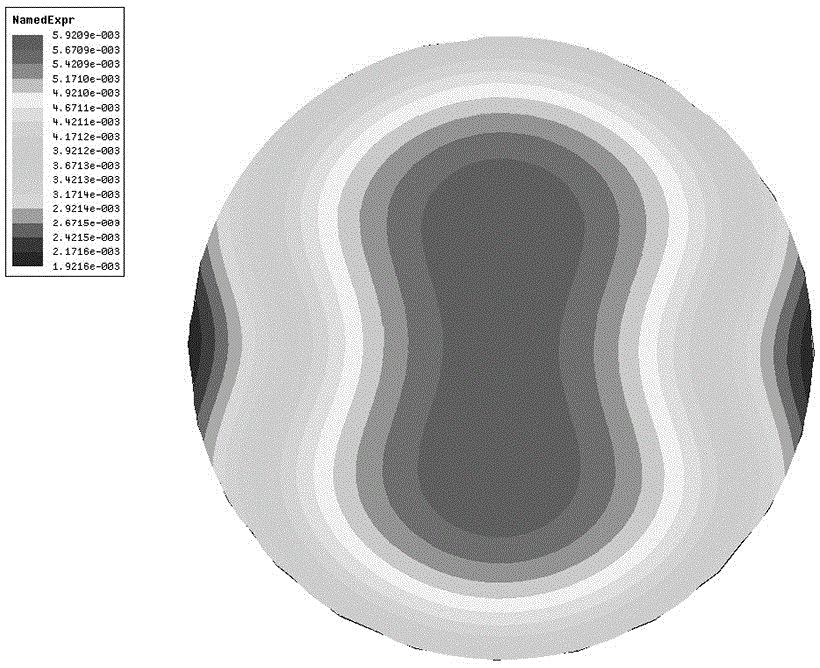

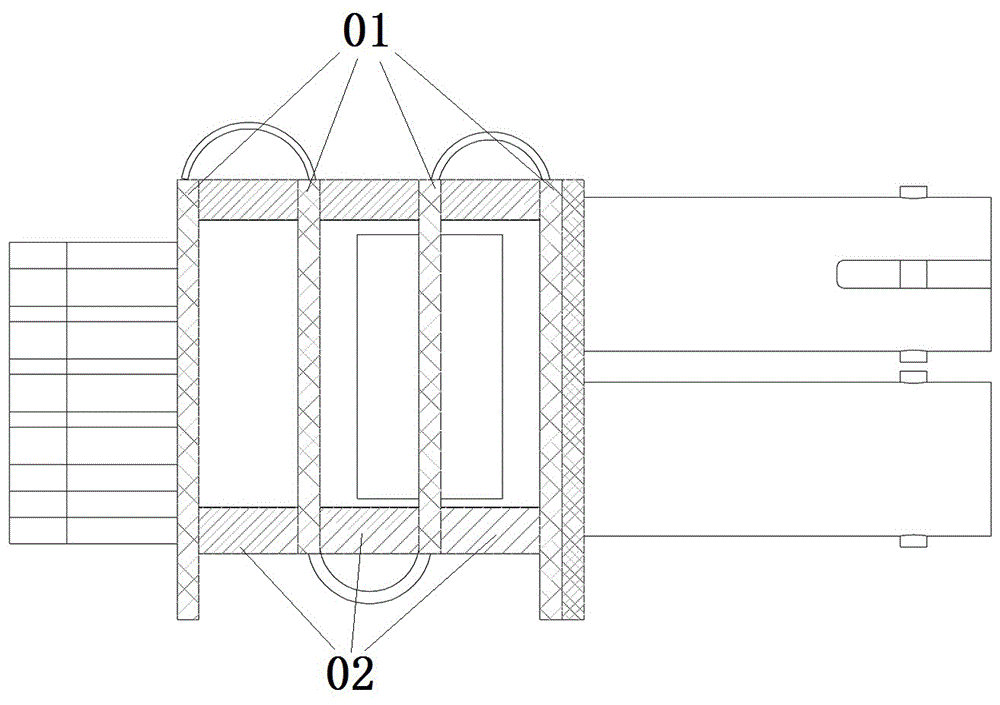

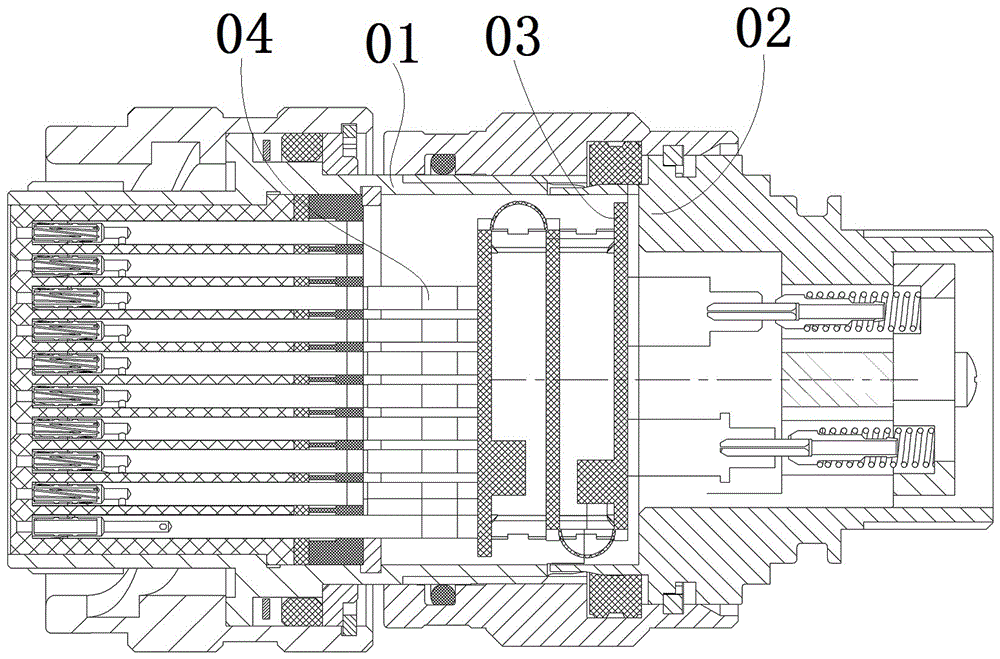

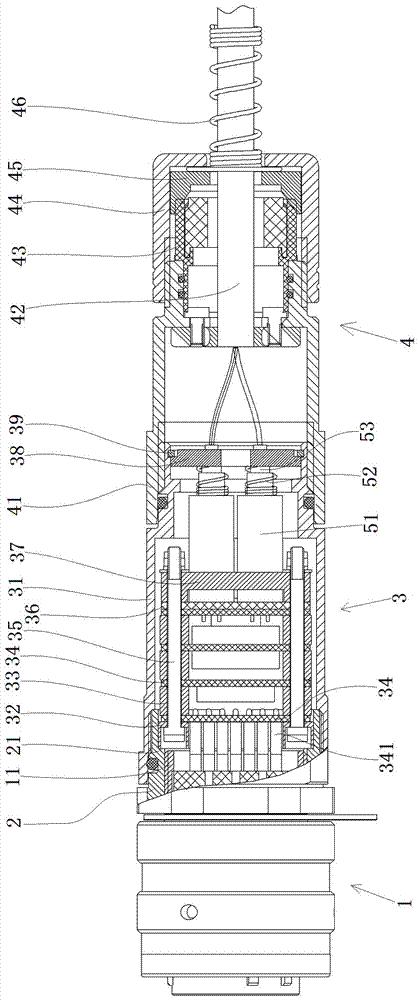

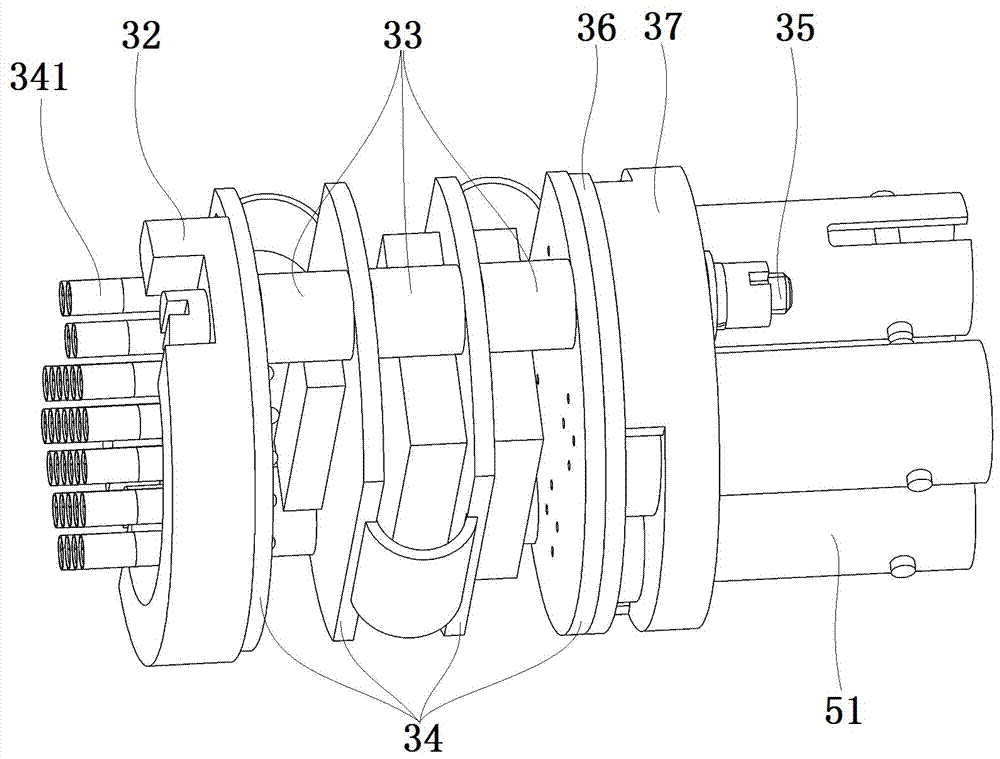

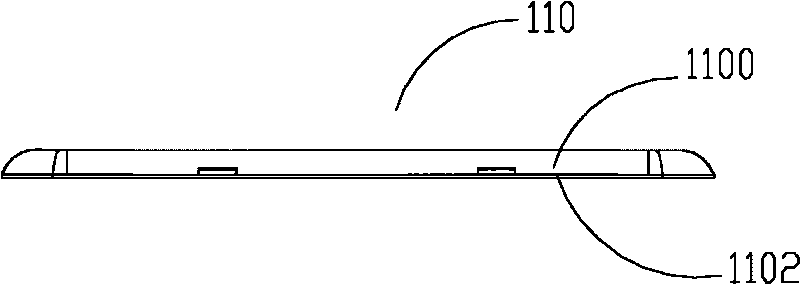

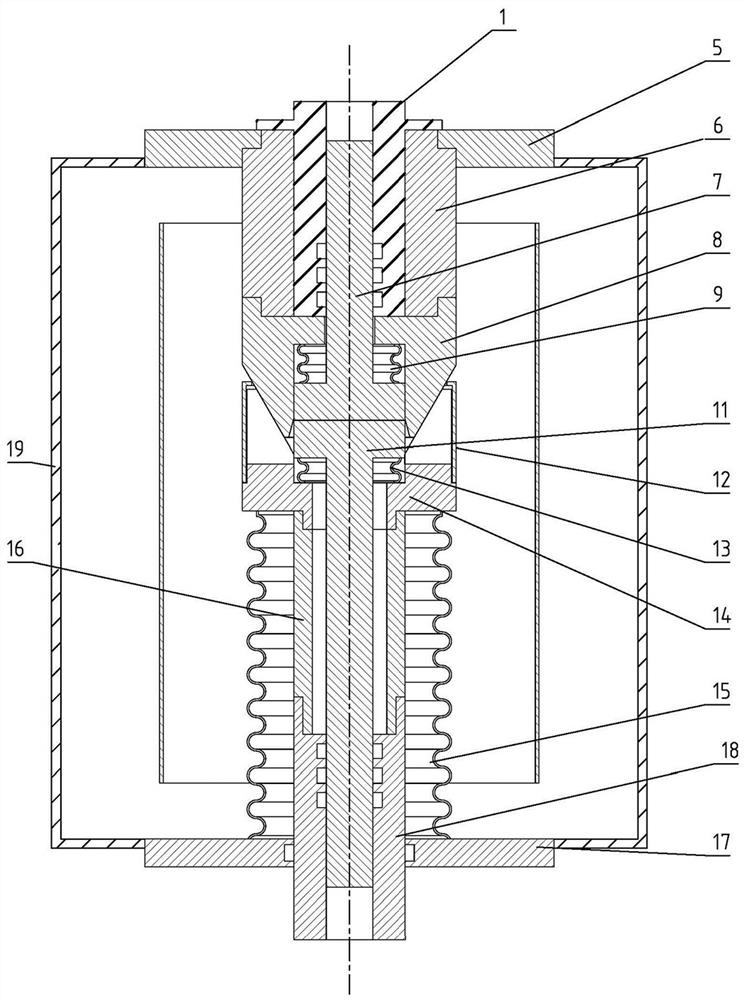

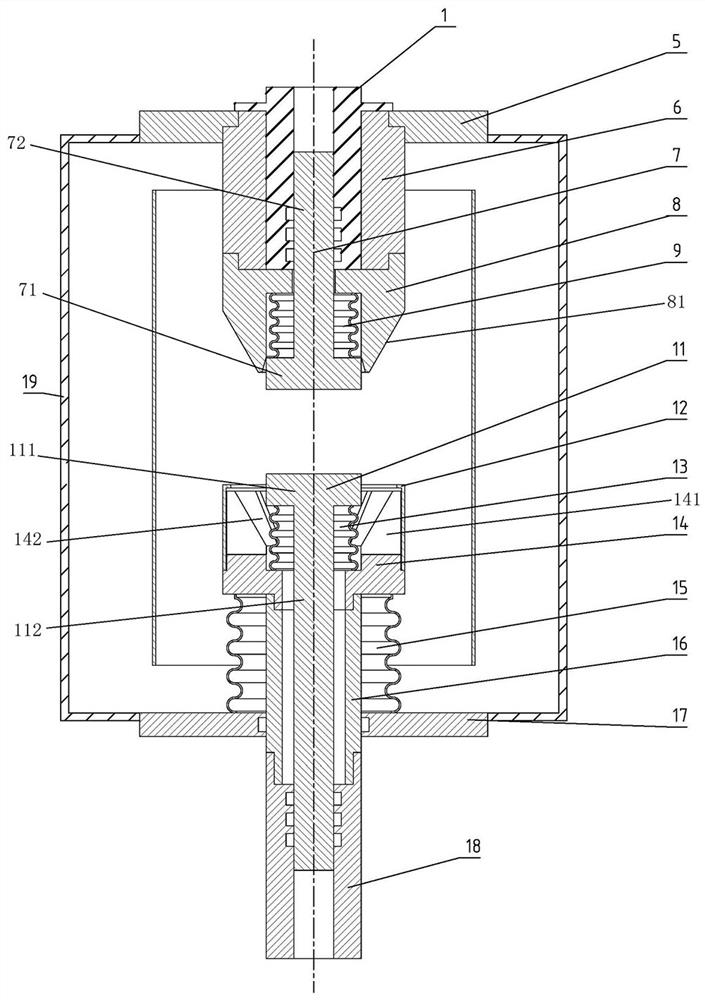

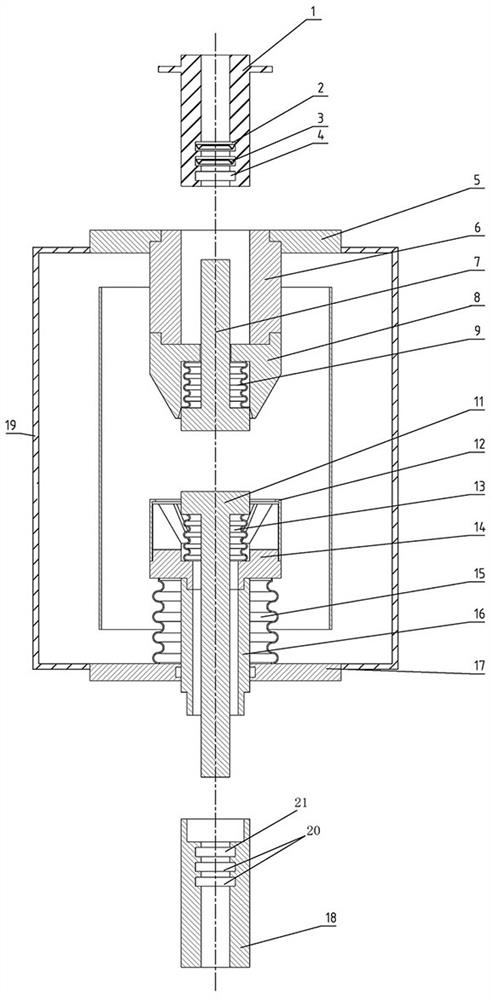

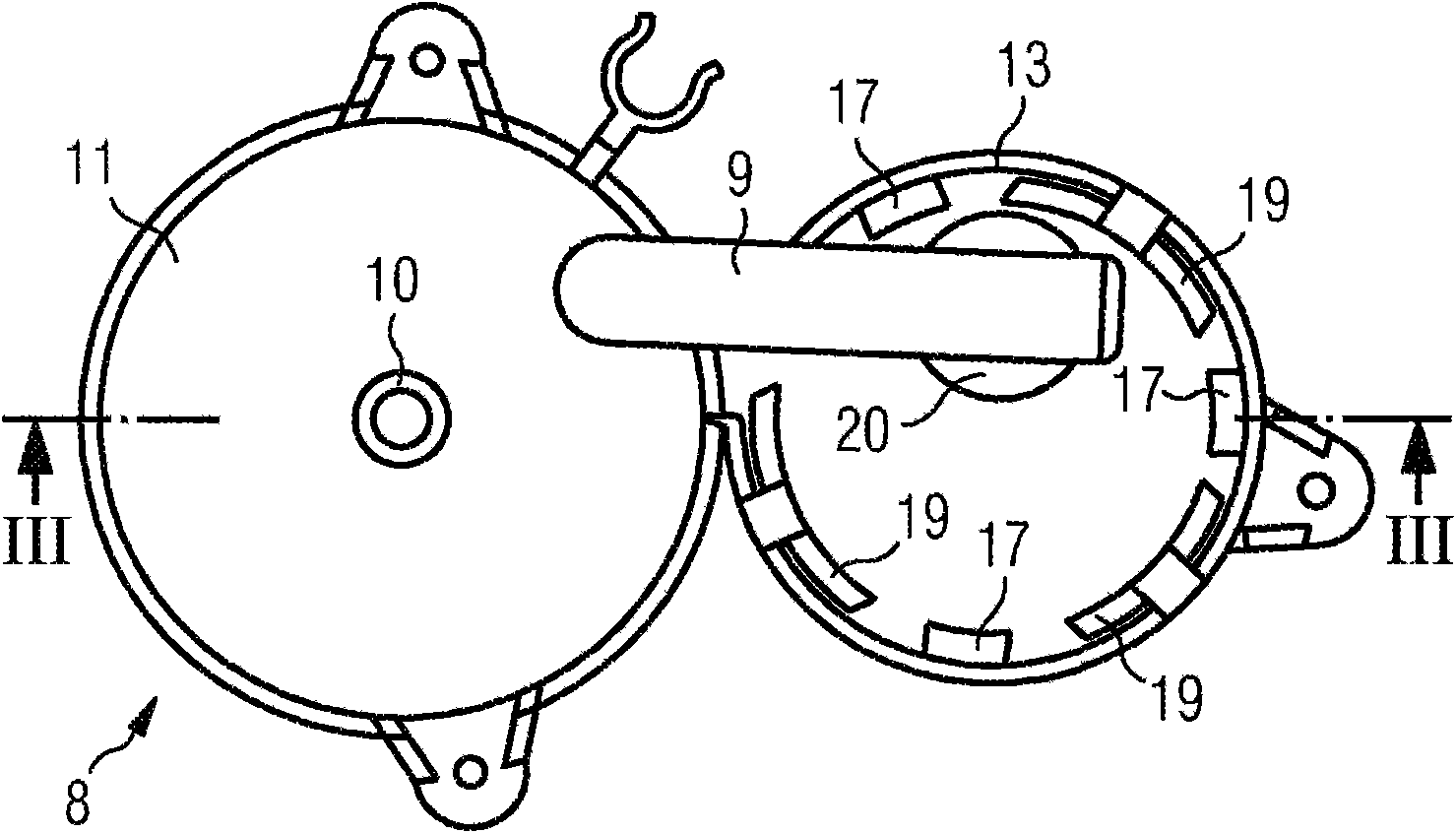

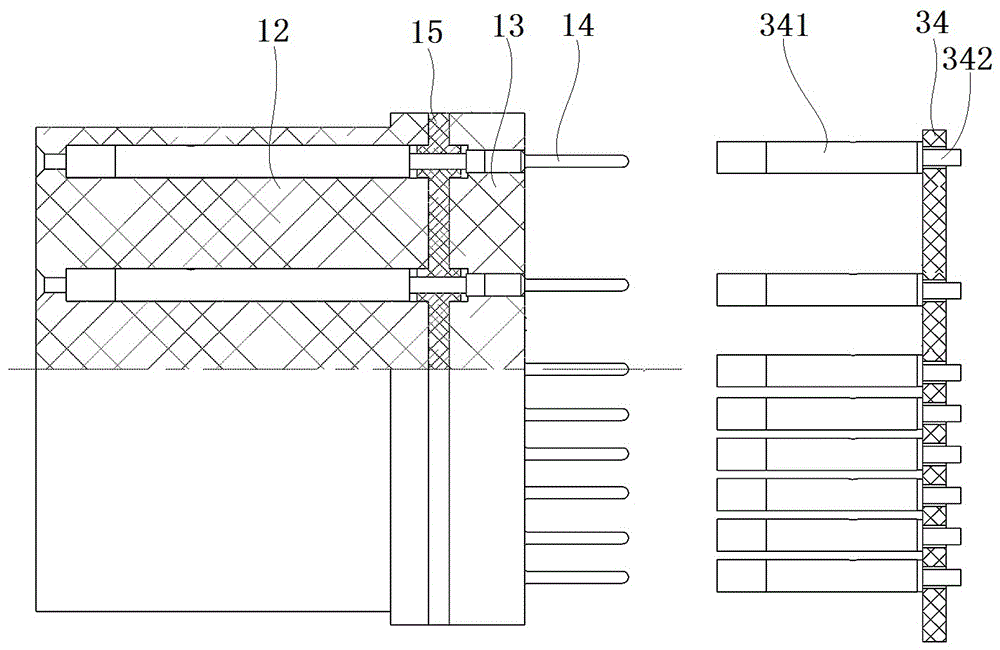

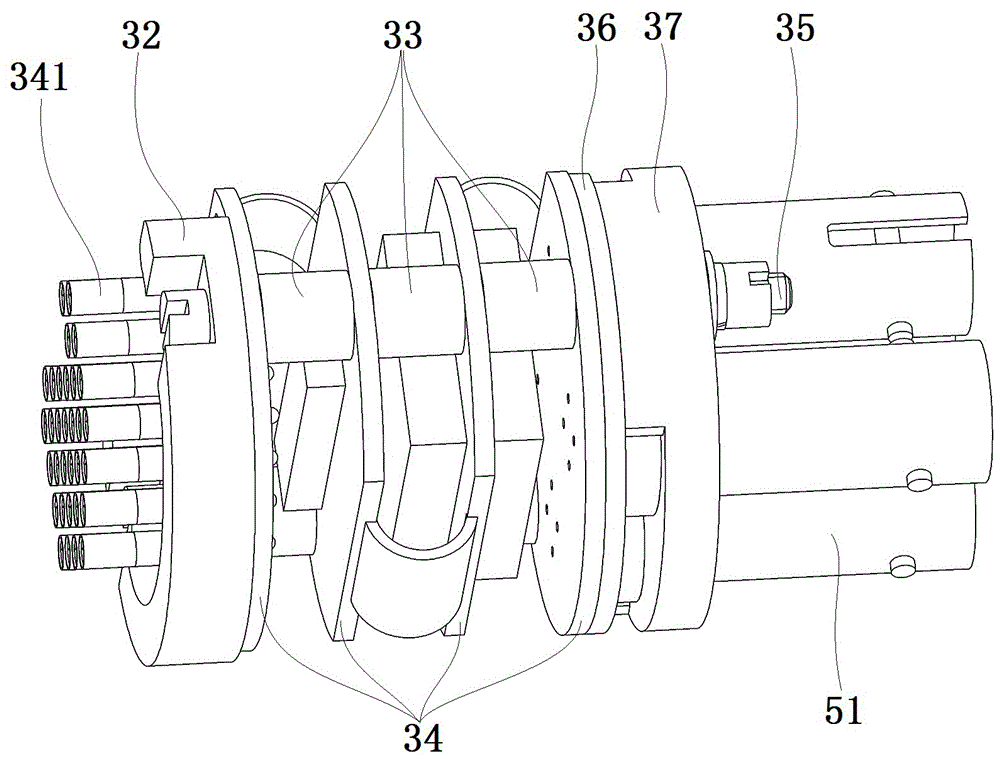

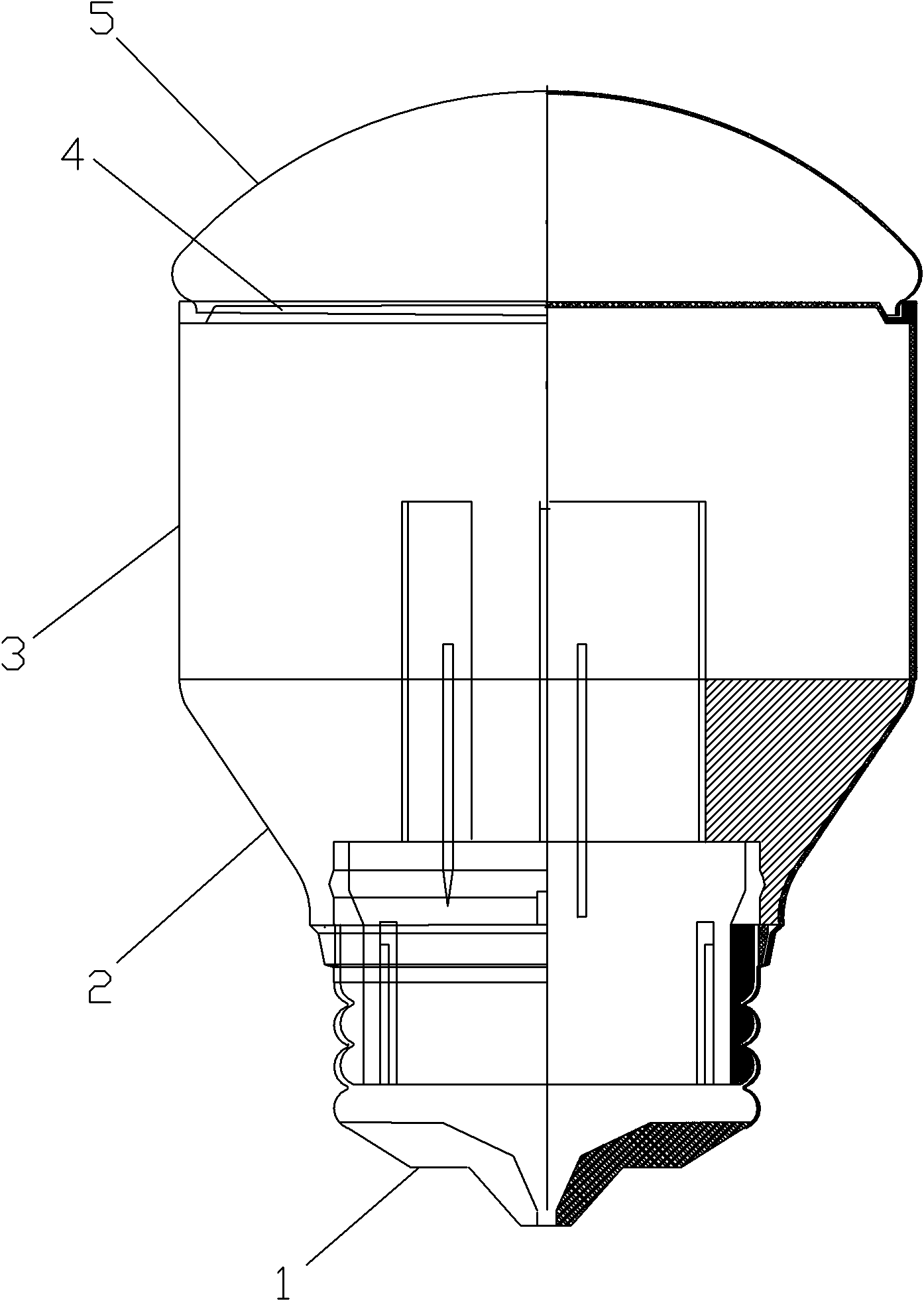

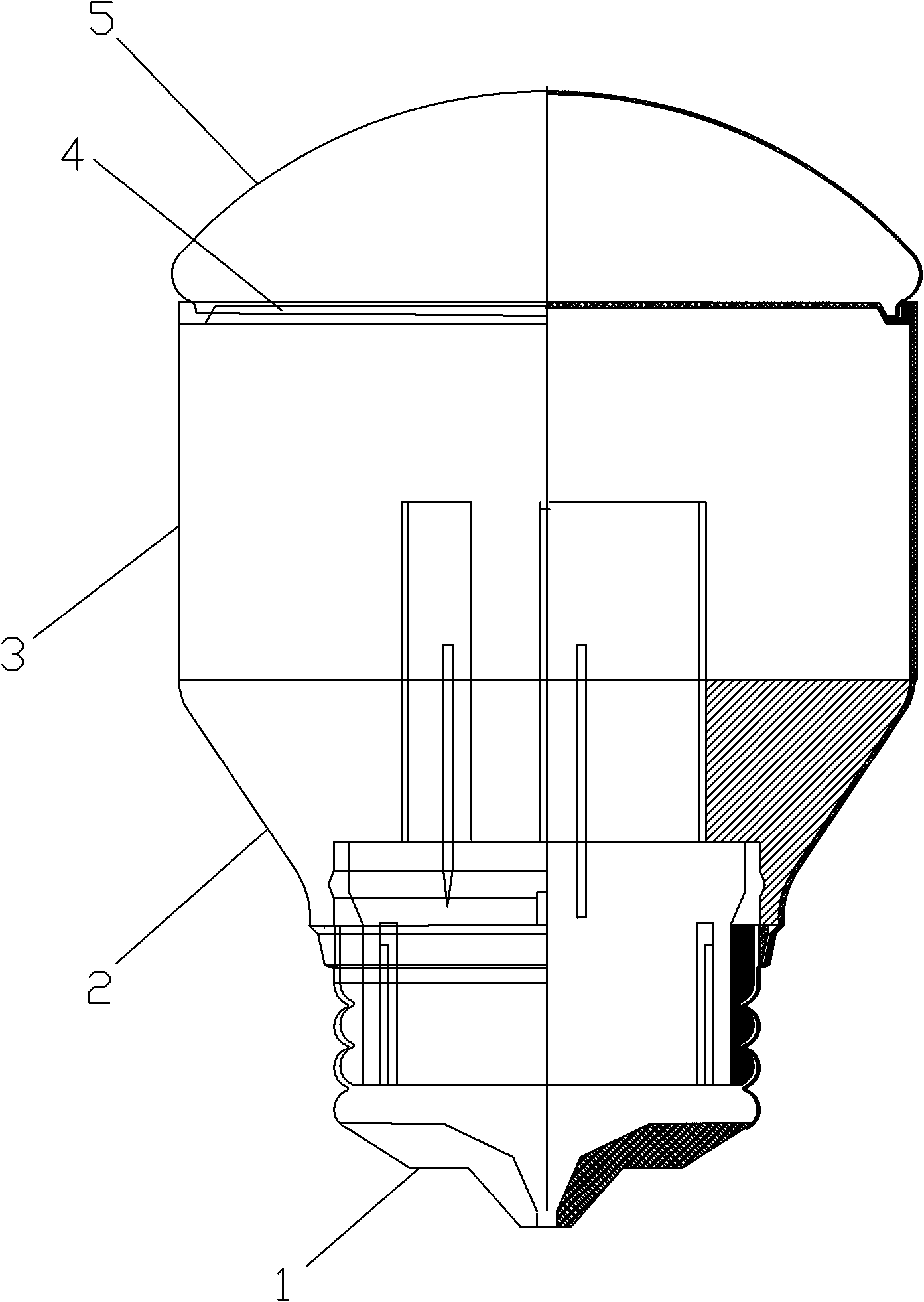

Vacuum arc-extinguishing chamber, contact assembly thereof and current coils used for contact assembly

ActiveCN105006403AImprove breaking performanceIncrease the longitudinal magnetic fieldHigh-tension/heavy-dress switchesAir-break switchesPath lengthVacuum arc

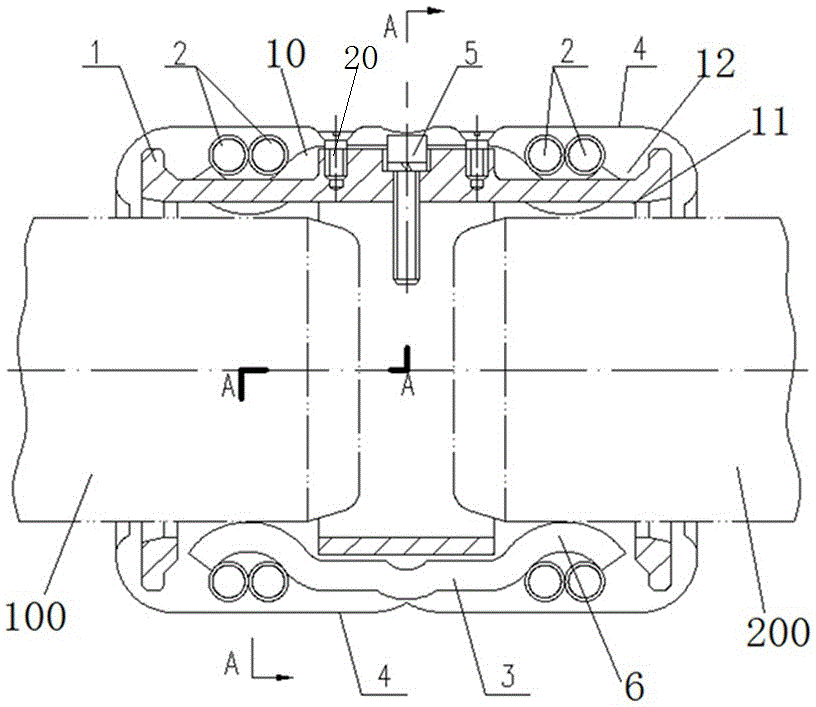

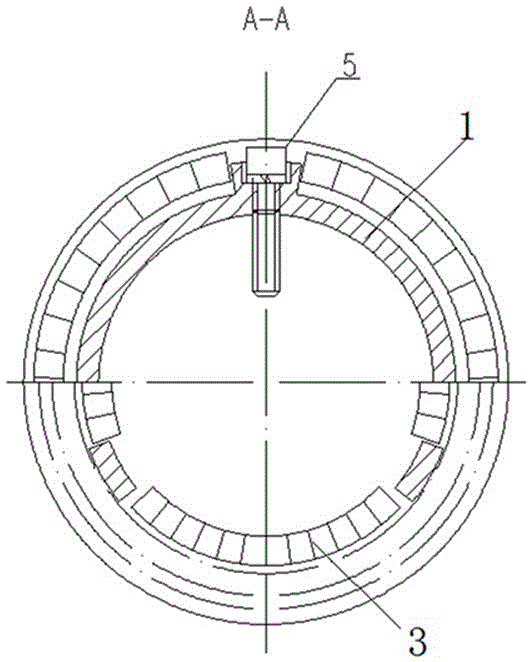

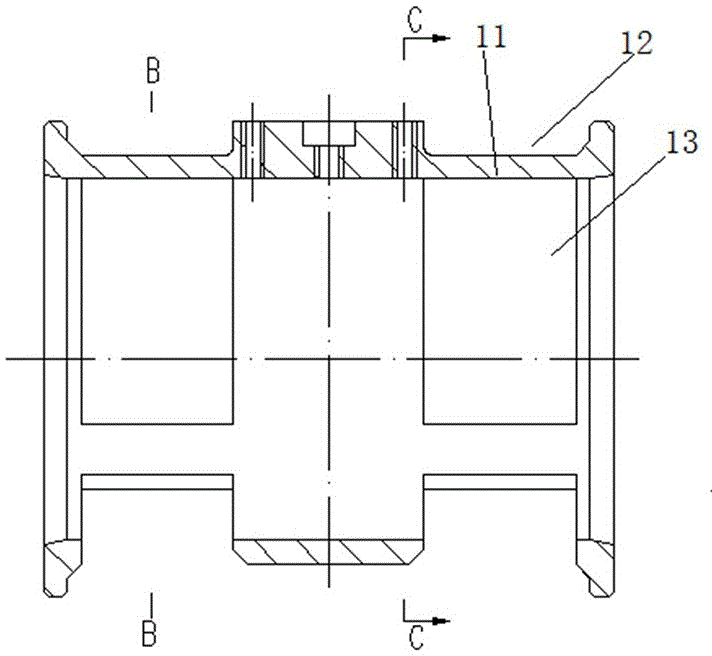

The invention provides a vacuum arc-extinguishing chamber, a contact assembly thereof and current coils used for the contact assembly. The current coils comprise two sub coils which extend in the circumferential direction and are disposed in parallel. Each sub coil comprises an upper coil section and a lower coil section which are arranged in an up-down staggered manner and are electrically connected in series. The two lower coil sections are two one-second turns of coil sections which are symmetrically arranged around a central line of the current coils. Each of the two sub coils is a three-fourths turn of coil section formed by a one-fourth turn of coil section and a one-second turn of coil section. The current of each of two parallel branches formed by the two sub coils flows through the circumferential path of the three-fourths turn of coil section, the current path is short, the integral circuit is relatively small, and the upper and lower coil sections are symmetrically arranged around the center of the current coils, so that the distribution of magnetic fields generated by the current coils is relatively uniform.

Owner:TIANJIN PINGGAO INTELLIGENT ELECTRIC +3

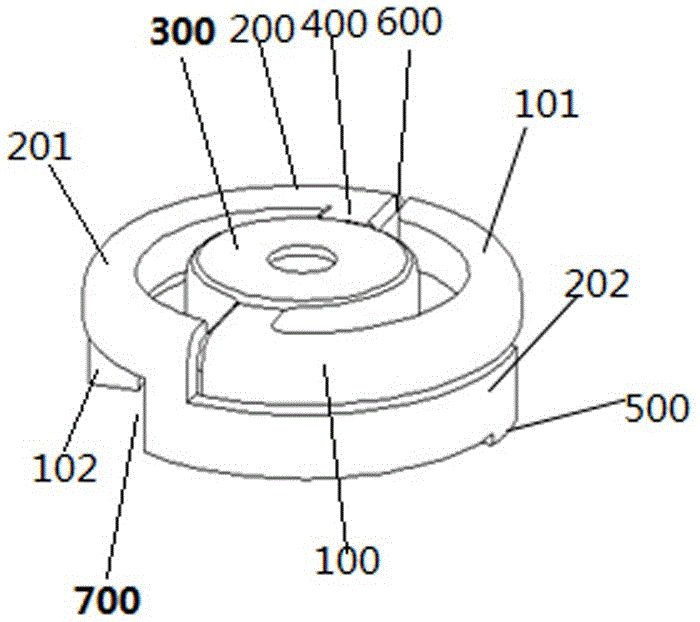

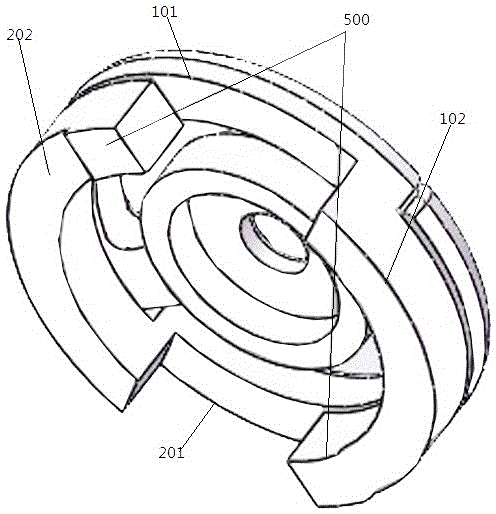

Vacuum arc-extinguishing chamber, coil-type contact element and current coil

ActiveCN105023798AImprove breaking performanceUniform magnetic field distributionHigh-tension/heavy-dress switchesAir-break switchesPath lengthContact element

The invention provides a vacuum arc-extinguishing chamber, a coil-type contact element and a current coil. The current coil comprises two branch coils extending in the circumferential direction and arranged in parallel. Each branch coil comprises an upper coil section and a lower coil section which are distributed to be staggered in an upper direction and a lower direction and in series conductive connection. The two upper coil sections are two half turning coil sections arranged symmetrically with respect to the center line of the current coil. The two lower coil sections of the two branch coils are two quarter turning coil sections arranged symmetrically with respect to the center line of the current coil. Each branch coil is a three-fourths turning coil section formed by the quarter turning coil section and the half turning coil section. A current in each of two parallel connection branches formed by the two branch coils passes by the circumferential path of the three-fourths turning coil section, the current path is short, the whole circuit is small, the upper coil section and the lower coil section are arranged in central symmetry with respect to the center line of the current coil respectively, and thus distribution of the magnetic field generated by the current coil is uniform.

Owner:TIANJIN PINGGAO INTELLIGENT ELECTRIC +3

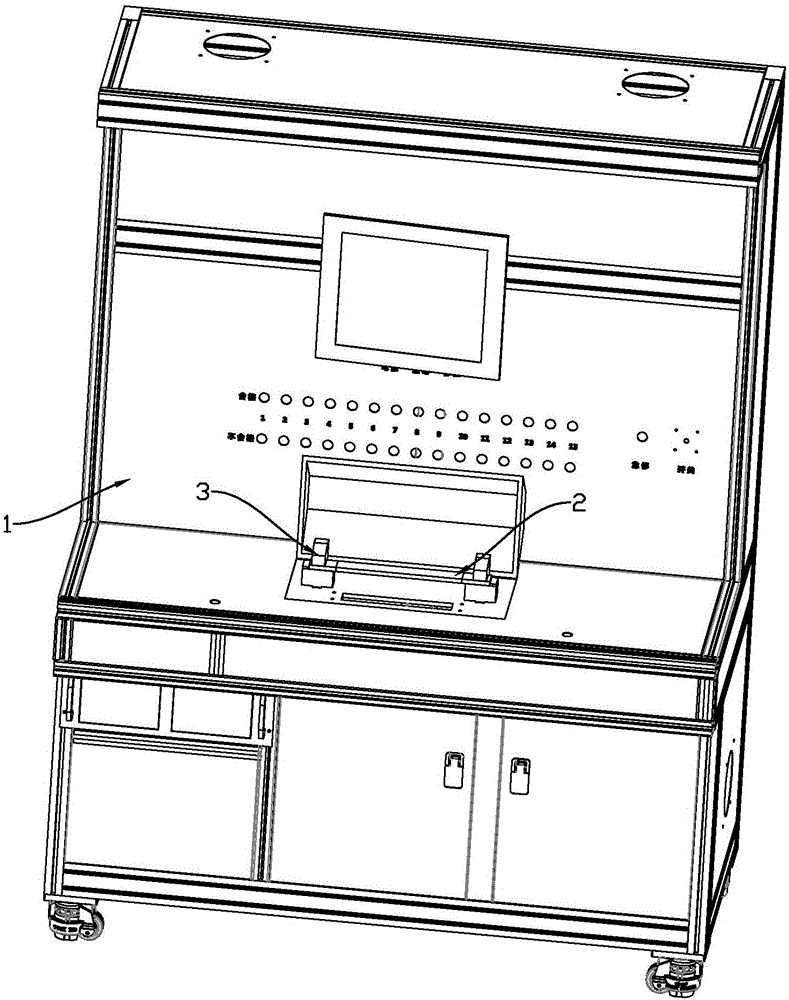

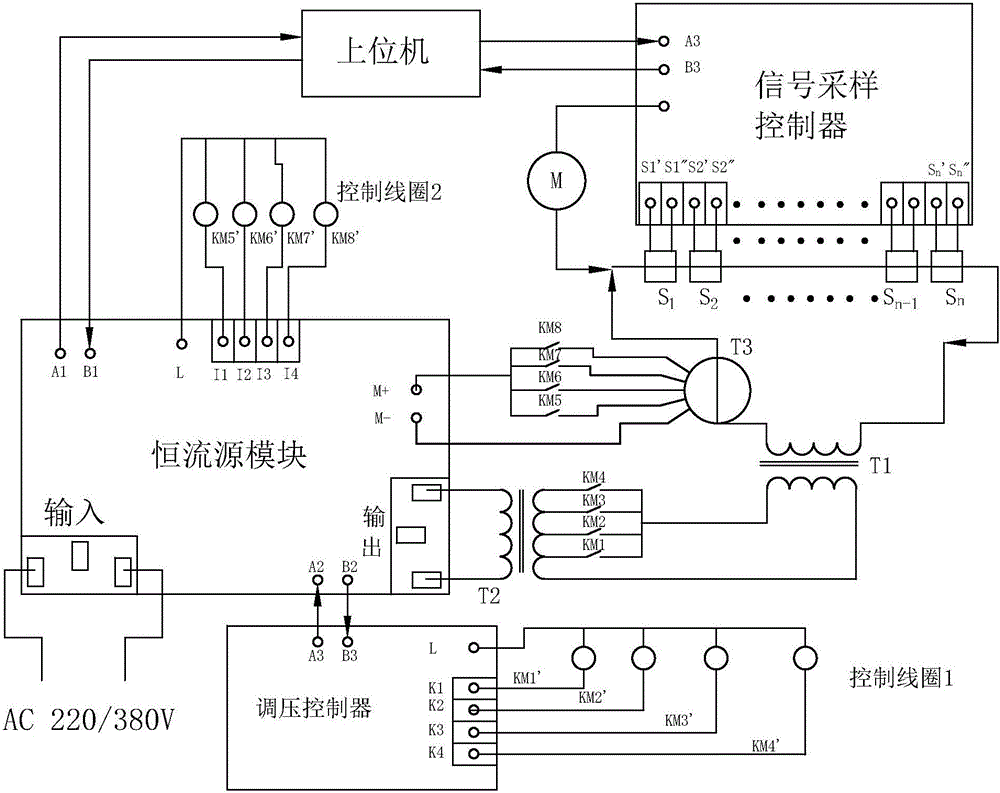

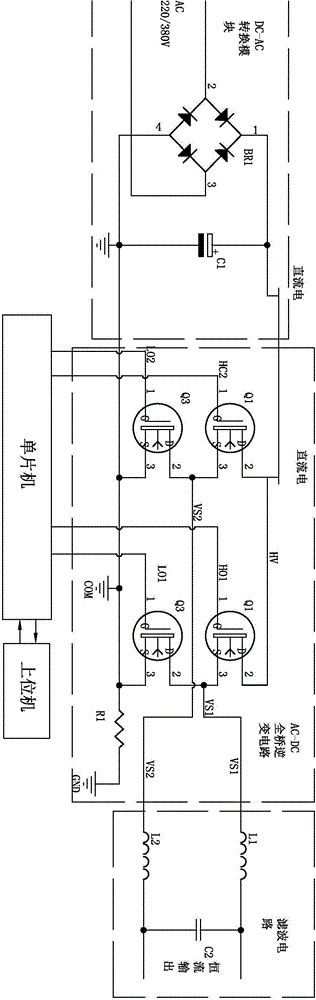

Transformer tester based on programmable constant current source

ActiveCN106125032AMeet factory inspectionGuaranteed to workElectrical testingMeasurement instrument housingLoad circuitTransformer

The invention relates to a transformer tester based on a programmable constant current source. A transformer loading clamp comprises a strip-shaped conductive plate serially connected in a load circuit; and two ends of the strip-shaped conductive plate are electrical connection ends, and the middle part is a transformer loading section coated with an insulated layer. The programmable AC constant current source comprises a constant current source circuit module and a current feedback circuit module, wherein the constant current source circuit module completes AC-DC-AC conversion, through carrying out pulse width control on a DC-AC full-bridge inverter circuit, high-voltage small current is acquired, the high-voltage small current outputted by the constant current source circuit module is subjected to voltage reduction and current boosting via a current boosting transformer to be supplied to a load circuit; the duty cycle D of a pulse width modulation driving signal outputted by a single chip microcomputer control unit to the DC-AC full-bridge inverter circuit is controlled to be 20% to 80%; and the current feedback circuit module is used for detecting the magnitude of the current of the load circuit. The transformer tester based on the programmable constant current source has the advantages of fast response speed, high precision and high detection efficiency.

Owner:WENZHOU UNIVERSITY +1

Led housing

InactiveCN101790802AFirmly connectedTo achieve a conductive connectionPoint-like light sourceCoupling device detailsEngineering

LED housing with a housing cavity, a carrier element and at least one LED chip, wherein the LED housing is shaped in such a way that it can connect a plurality of LED housings with an identical design and, as a result of its shape, can furthermore be mounted in various ways.

Owner:OSRAM OPTO SEMICON GMBH & CO OHG

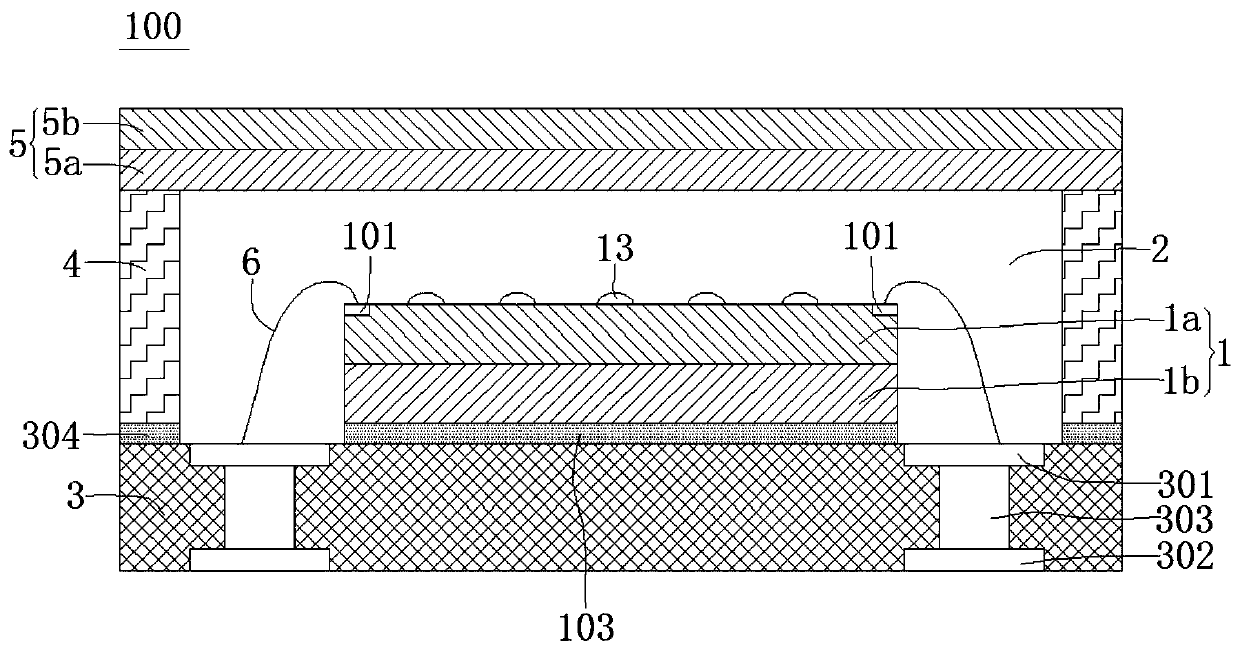

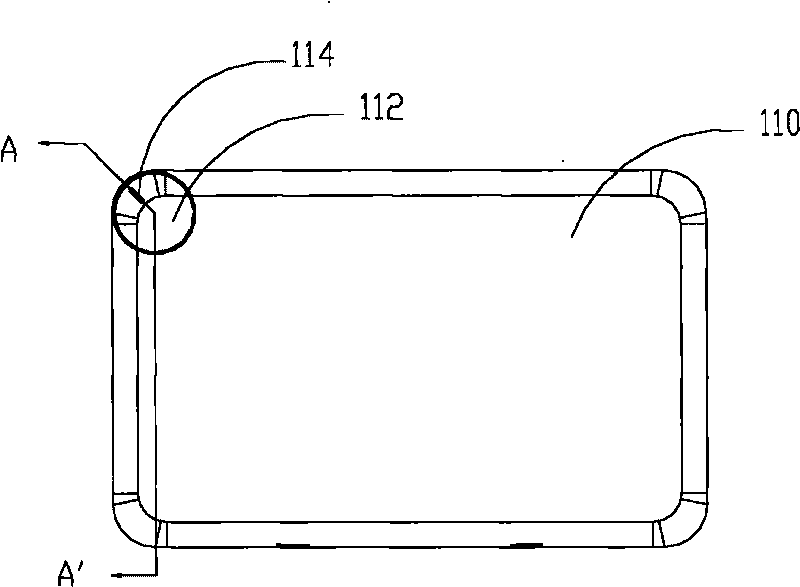

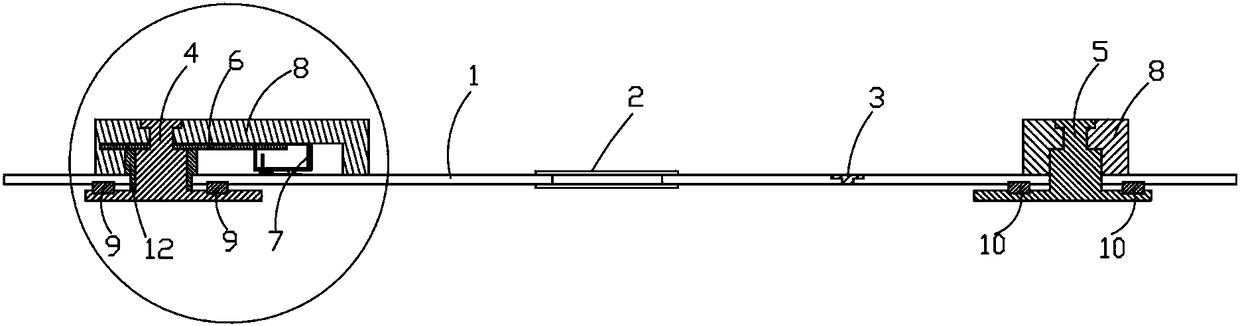

An under-screen optical fingerprint identification module and an electronic device

ActiveCN109815891ATo achieve a conductive connectionIncrease productivityCharacter and pattern recognitionBiological bodyLight sensing

The invention provides an under-screen optical fingerprint identification module and an electronic device. The identification module comprises a conductive substrate, an identification assembly arranged on the conductive substrate, a light sensing chip which is used for receiving the target signal light reflected by a target organism above the display screen when the identification assembly moduleis below the display screen and at least comprises a metal layer, a protection assembly located above the light-sensitive chip and provided with a light-transmitting area, and the target signal lightreaches the light-sensitive chip through the light-transmitting area, wherein a target signal arrives at the light sensing chip via the light-transmitting area, a protection cavity used for protecting the metal layer is formed below the protection assembly, and the metal layer is accommodated in the protection cavity, or the light-sensitive chip forms a part of the inner wall of the protection cavity; and a conductive path of which one end is conductively connected with the metal layer, and the other end is conductively connected with the conductive substrate through reflow soldering. The identification module provided by the embodiment of the invention is relatively higher in production and assembly efficiency.

Owner:SILEAD

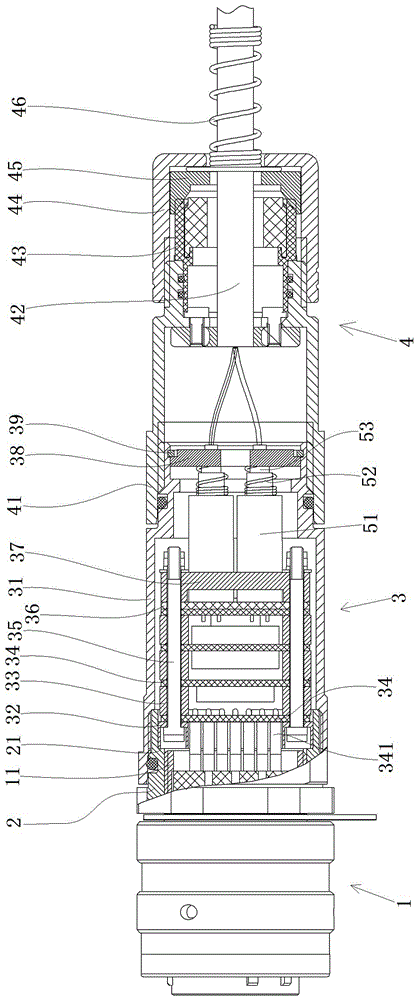

Motor bearing electric corrosion-prevention structure and plastic packaging brushless direct current motor

ActiveCN104821683ATo prevent the phenomenon of electro-corrosionGuaranteed service lifeSupports/enclosures/casingsPlastic packagingElectric machine

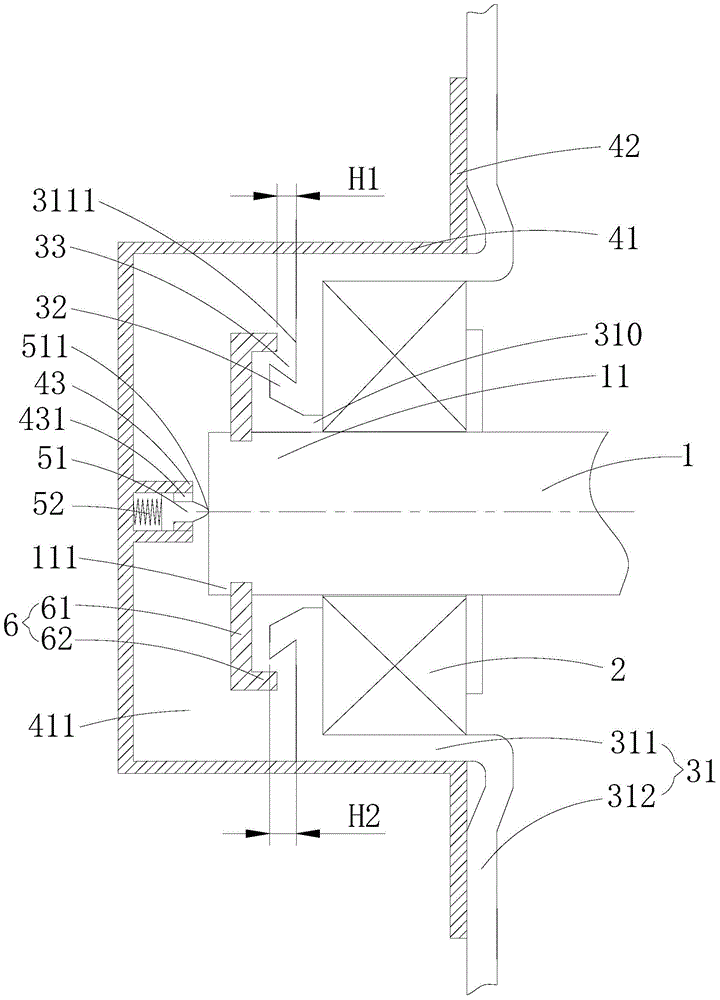

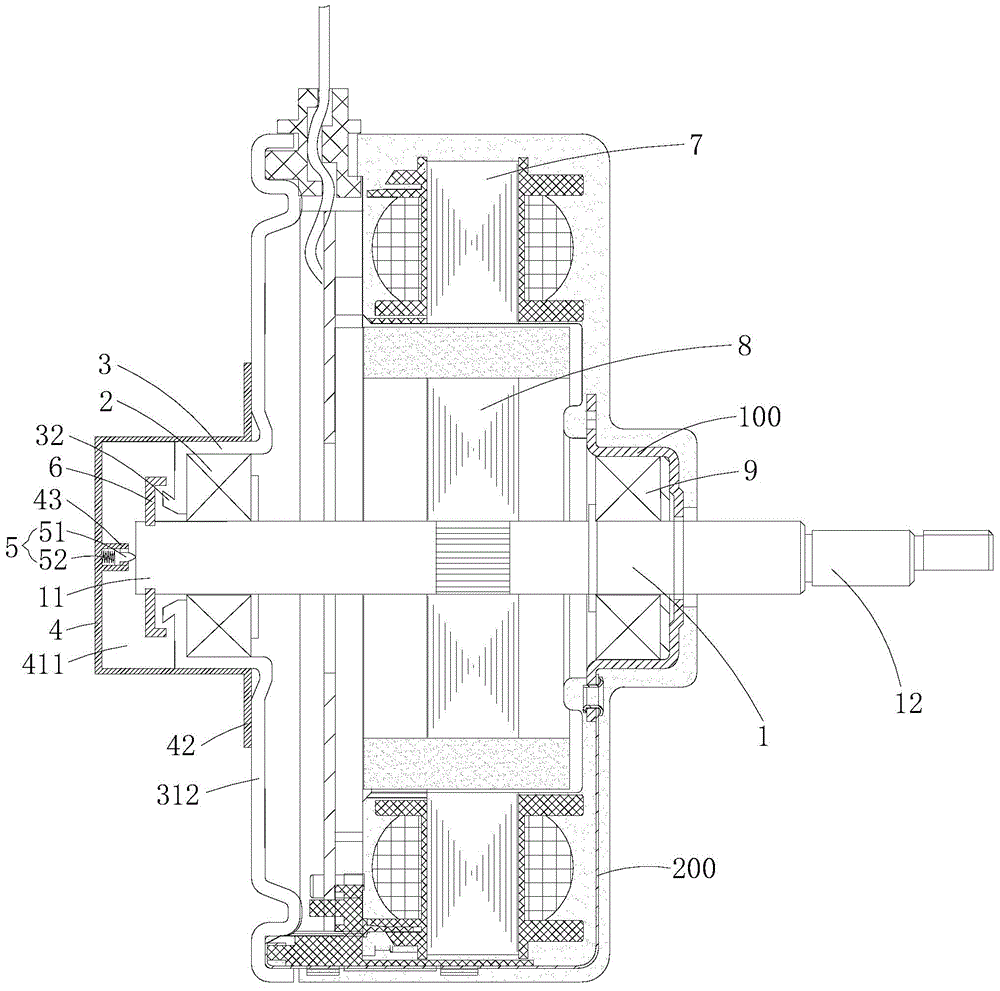

The invention belongs to the motor field and discloses a motor bearing electric corrosion-prevention structure and a plastic packaging brushless direct current motor. The motor bearing electric corrosion-prevention structure includes a rotating shaft, a first bearing installed at one end of the rotating shaft, a first bearing supporting frame which sleeves the first bearing, an electric conduction cover which is in electric conduction connection with the first bearing supporting frame, an elastic electric conduction assembly which is electrically connected between the electric conduction cover and the rotating shaft; the electric conduction cover sleeves the first bearing supporting frame; the rotating shaft is provided with an extension portion which extends out from the interior of the first bearing supporting frame and extends into the electric conduction cover; and the elastic electric conduction assembly is installed in the electric conduction cover and is elastically connected between the electric conduction cover and the extension portion. According to the motor bearing electric corrosion-prevention structure of the invention, the electric conduction cover and the elastic electric conduction assembly are adopted, so that electric conduction connection between an inner peripheral support and an outer peripheral support of the first bearing can be realized, and potential difference between the inner peripheral support and the outer peripheral support of the first bearing can be eliminated, and electric corrosion of the first bearing can be avoided, and the first bearing can have the advantages of low manufacture cost, high shock resistance and high load capacity.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

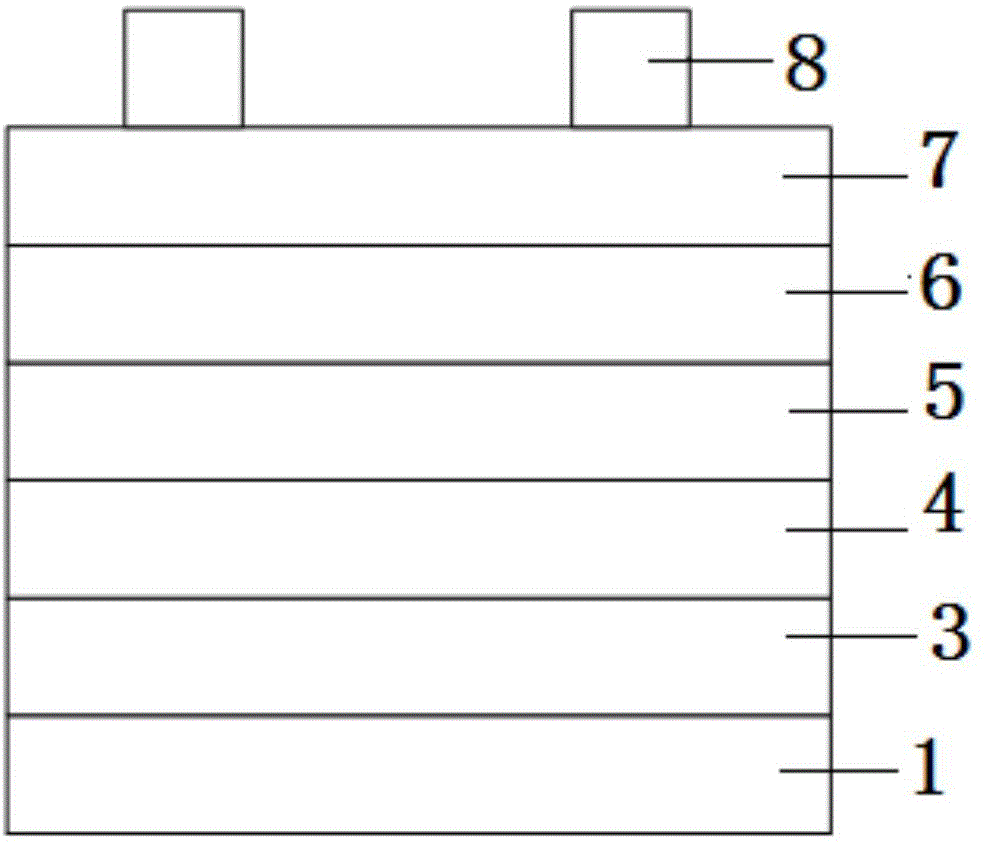

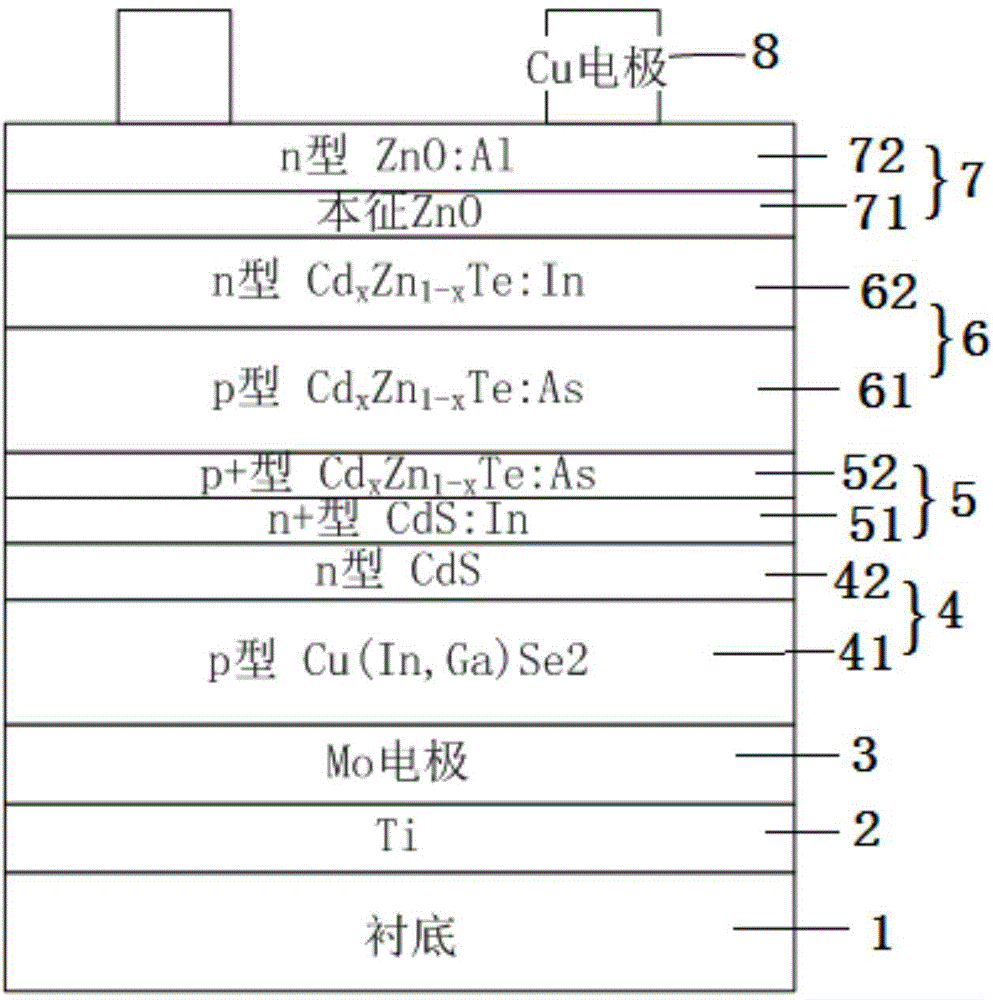

Laminated thin film solar battery and preparation method thereof

ActiveCN105742390AImprove reliabilityImprove efficiencyFinal product manufacturePhotovoltaic energy generationElectrical batteryOptical transmittance

The invention relates to a laminated thin film solar battery. The laminated thin film solar battery includes a substrate as well as a back electrode, a bottom cell, a top cell and a window layer which are arranged on the substrate sequentially; a tunnel junction is arranged between the bottom cell and the top cell; the tunnel junction includes an n+ type semiconductor layer and a p+ type semiconductor layer; the n+ type semiconductor layer contacts with an n type semiconductor layer of the bottom cell; and the p+ type semiconductor layer contacts with a p type semiconductor layer of the top cell. The invention also provides the preparation method of the above structure. According to the laminated thin film solar battery and the preparation method thereof of the invention, the bottom cell and the top cell are connected with each other through the tunnel junction, so that electric conduction connection between the two cells can be realized, and the adjustment of optical transmittance and electrical resistivity can be facilitated compared with a mechanical lamination mode; the appropriate tunnel junction is adopted to achieve continuous growth of the laminated layers, and therefore, compared with the mechanical lamination method, process steps can be reduced, the reliability of the battery can be improved, the overall efficiency of the battery can be improved, and carrier interface recombination can be weakened.

Owner:紫石能源有限公司

Battery cover structure with replaceable terminal

PendingCN109273629AImprove applicabilityEasy to replaceSmall-sized cells cases/jacketsCell lids/coversEngineeringStructural engineering

Owner:GUANGZHOU KAIJIE POWER SUPPLY INDAL

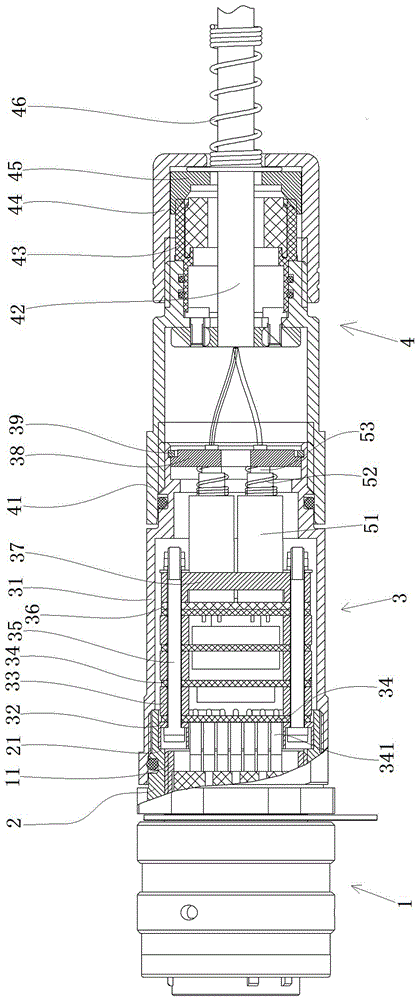

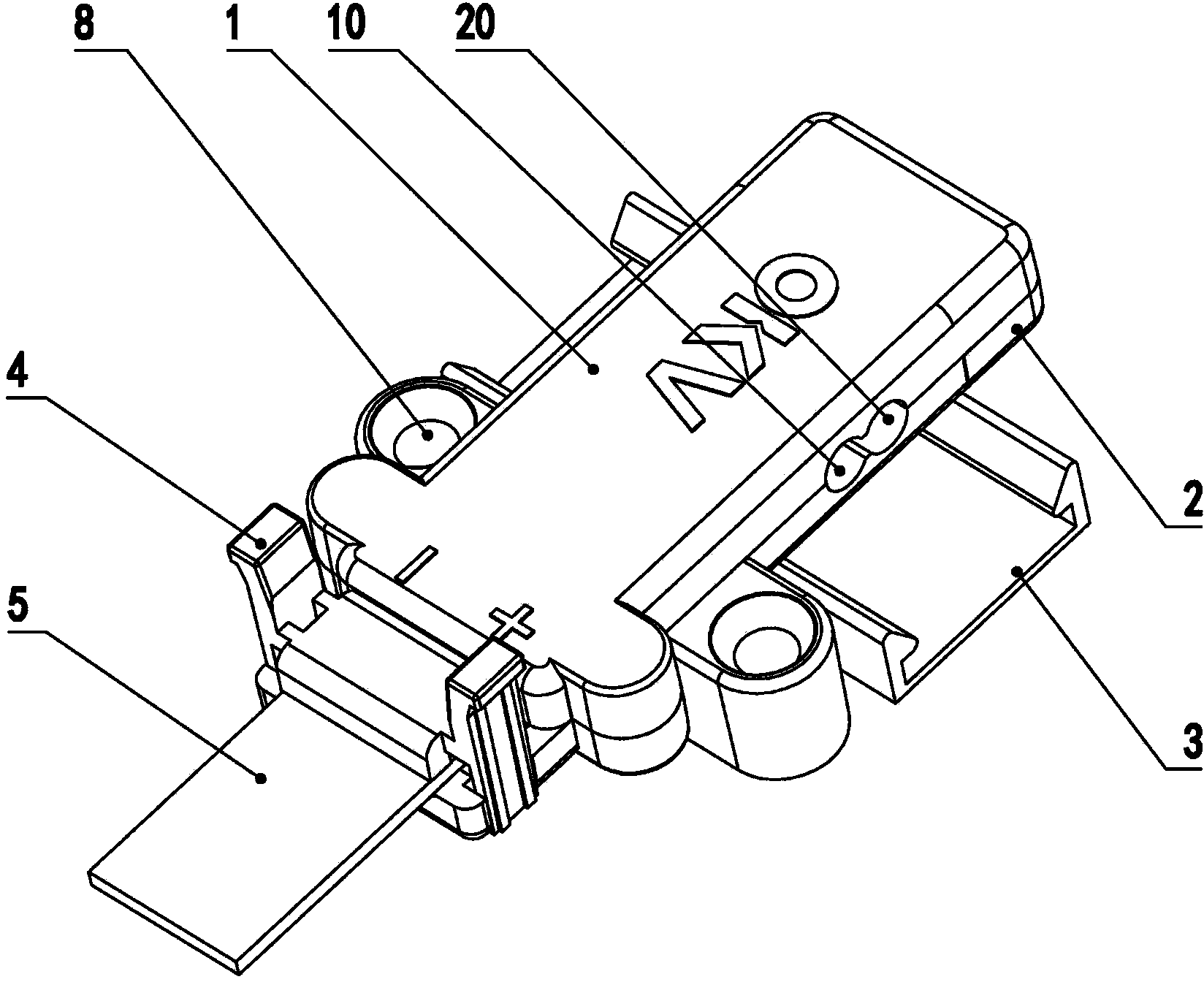

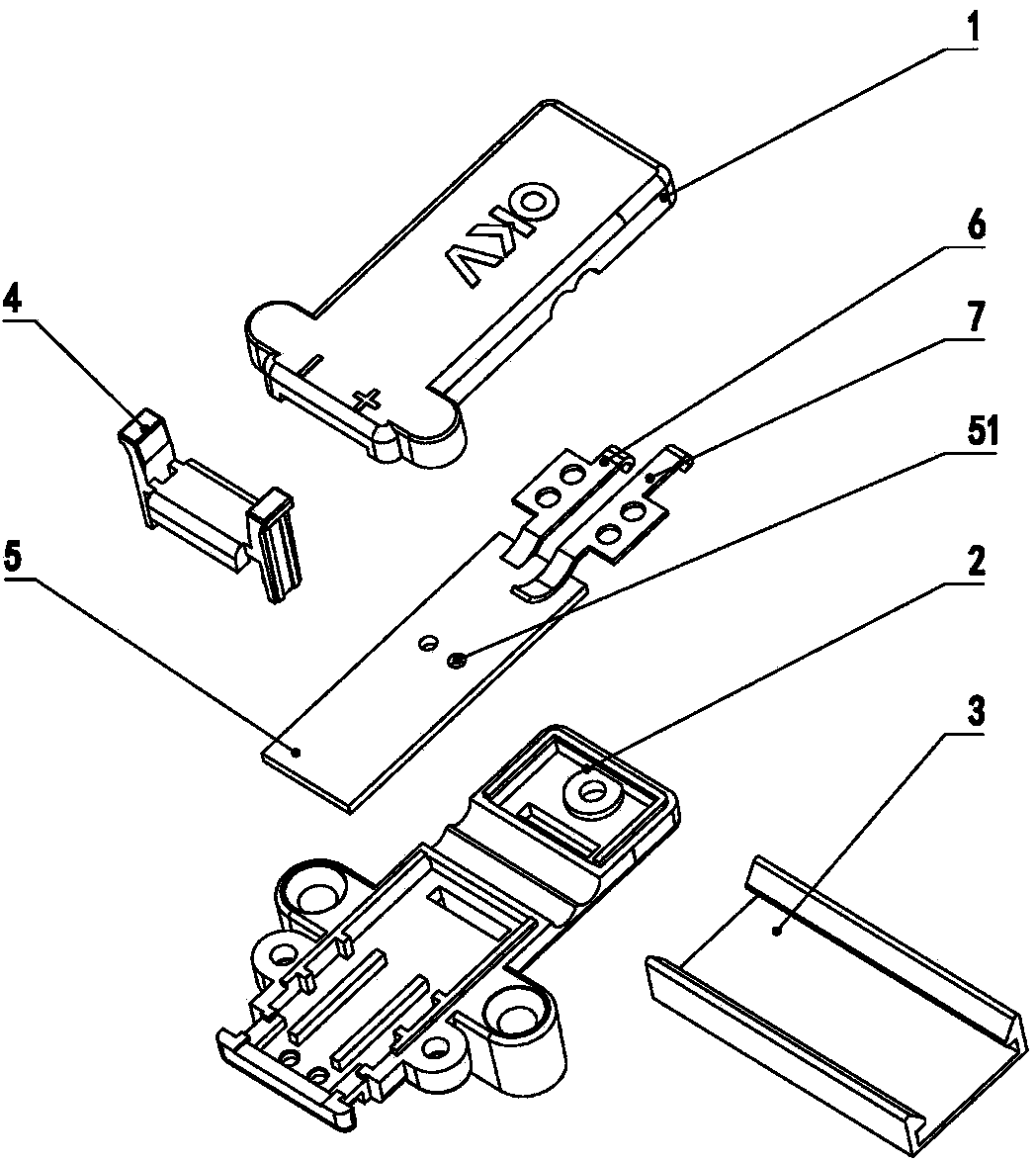

Active optical cable connector, active optical cable assembly and photoelectric conversion unit

ActiveCN106842447AExcellent reworkabilityTo achieve a conductive connectionCoupling light guidesPhotoelectric conversionEngineering

The invention relates to an active optical cable connector, an active optical cable assembly and a photoelectric conversion unit. The active optical cable assembly comprises an active optical cable and active optical cable connectors arranged at two ends of the active optical cable, wherein each active optical cable connector comprises a connector shell assembly and a photoelectric conversion unit arranged in an inner cavity of the connector shell assembly; each photoelectric conversion unit comprises printed boards and a support part arranged between the printed boards, wherein the printed boards are arranged from front to back at an interval; and a fastening device is used for tightening or clamping the printed boards along the front and back direction, so that the printed boards are separated by dismantling the fastening device when the printed boards need to be repaired in the using process, and individual printed boards can be inspected, repaired or exchanged, thereby improving the repair performance of the active optical cable connectors.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Active optical cable assembly and active optical cable connector

ActiveCN106842445AAvoid deformationSolve the problem of easy conduction failureCoupling light guidesElectricityPhotoelectric conversion

The invention relates to an active optical cable assembly and an active optical cable connector. The active optical cable connector comprises a connector shell assembly and a photoelectric conversion unit arranged in an inner cavity of the connector shell assembly, wherein an electric plug in conductive connection with the photoelectric conversion unit is arranged at a front end of the active optical cable connector; a stop structure is arranged in the inner cavity of the connector shell assembly in front of the photoelectric conversion unit; a pressing structure in the inner cavity of the connector shell assembly is used for pressing the photoelectric conversion unit against the stop structure forwards, and the photoelectric conversion unit is clamped and fixed in the inner cavity of the connector shell assembly and is located between the pressing structure and the stop structure; and when the connector is vibrated, the stop structure and the pressing structure bear action force of vibration, so that the conductive connection structure, in conductive connection with the electric plug, of the photoelectric conversion unit is prevented from deforming due to stress, and the problem of conductive failure of the photoelectric conversion unit and the electric plug is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

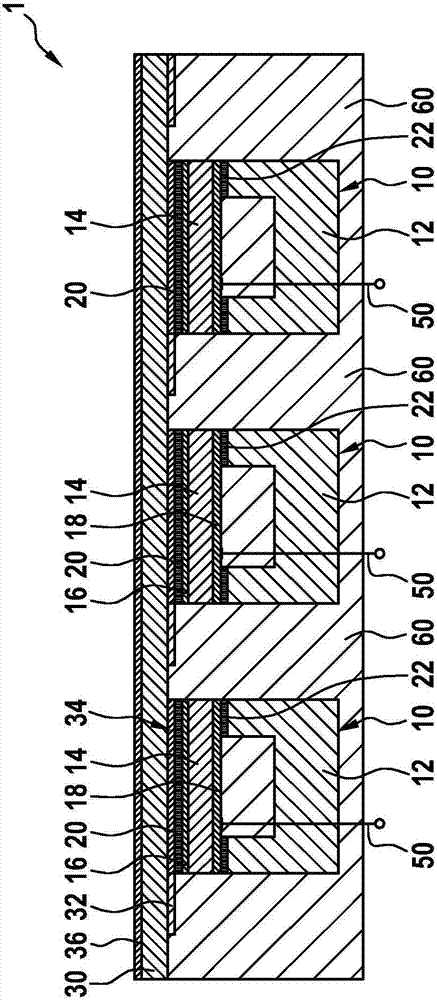

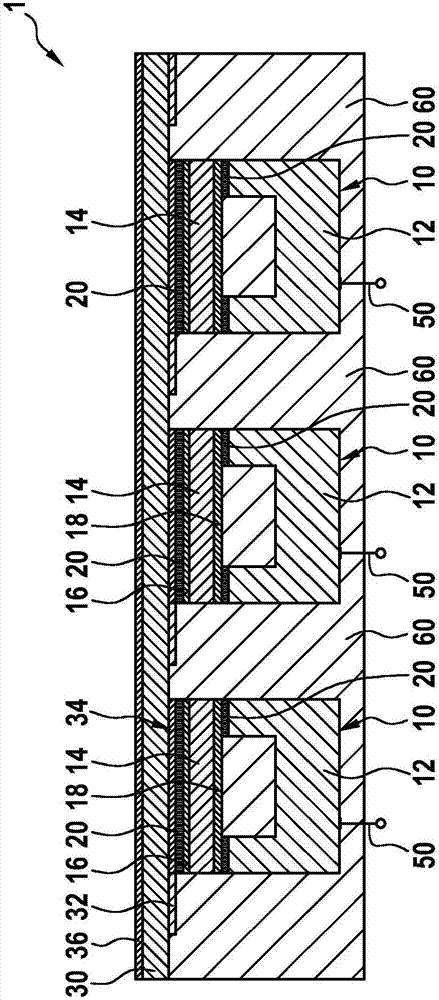

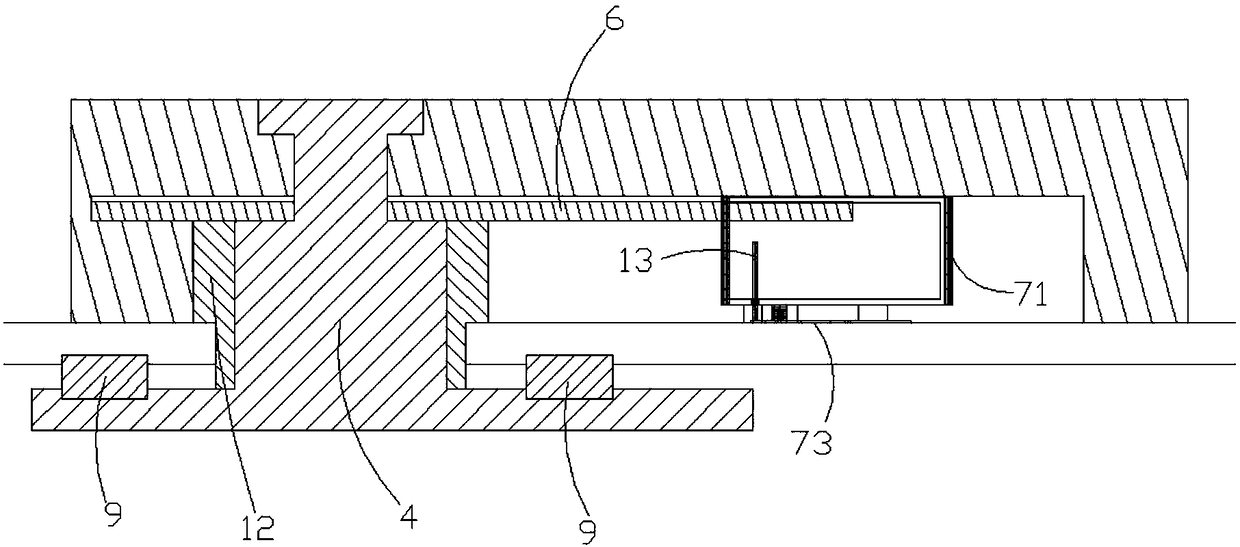

Sound transducer comprising a plurality of single transducers and method for the production thereof

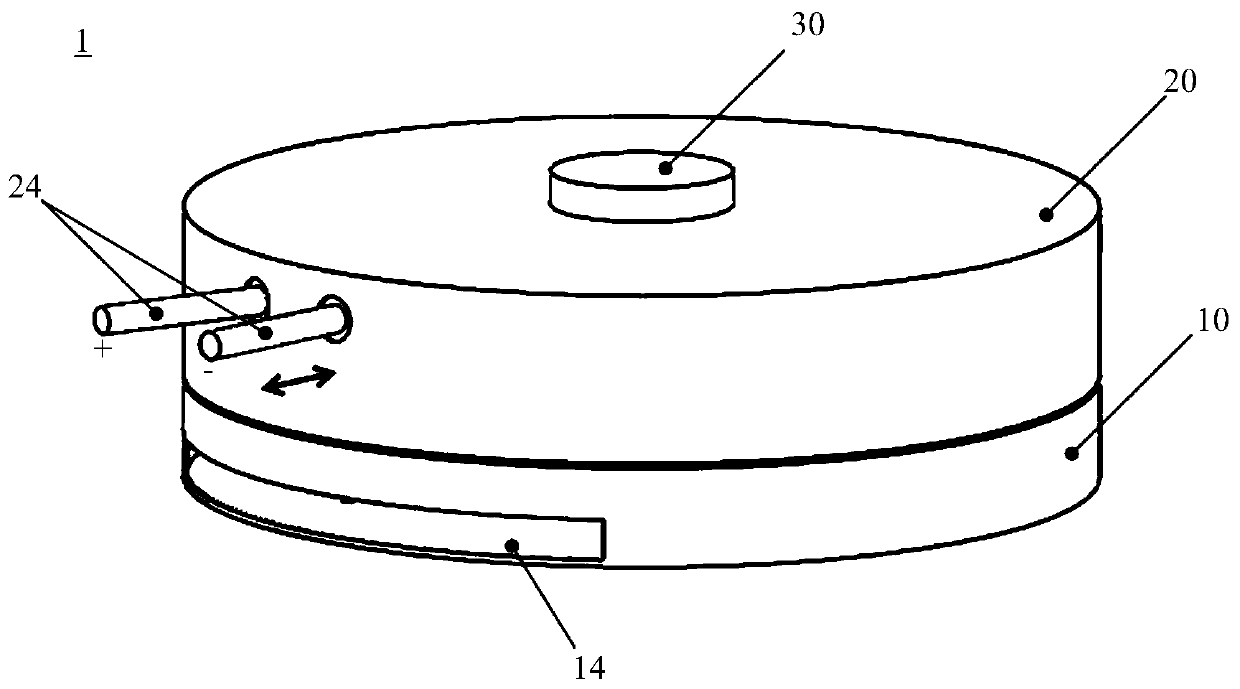

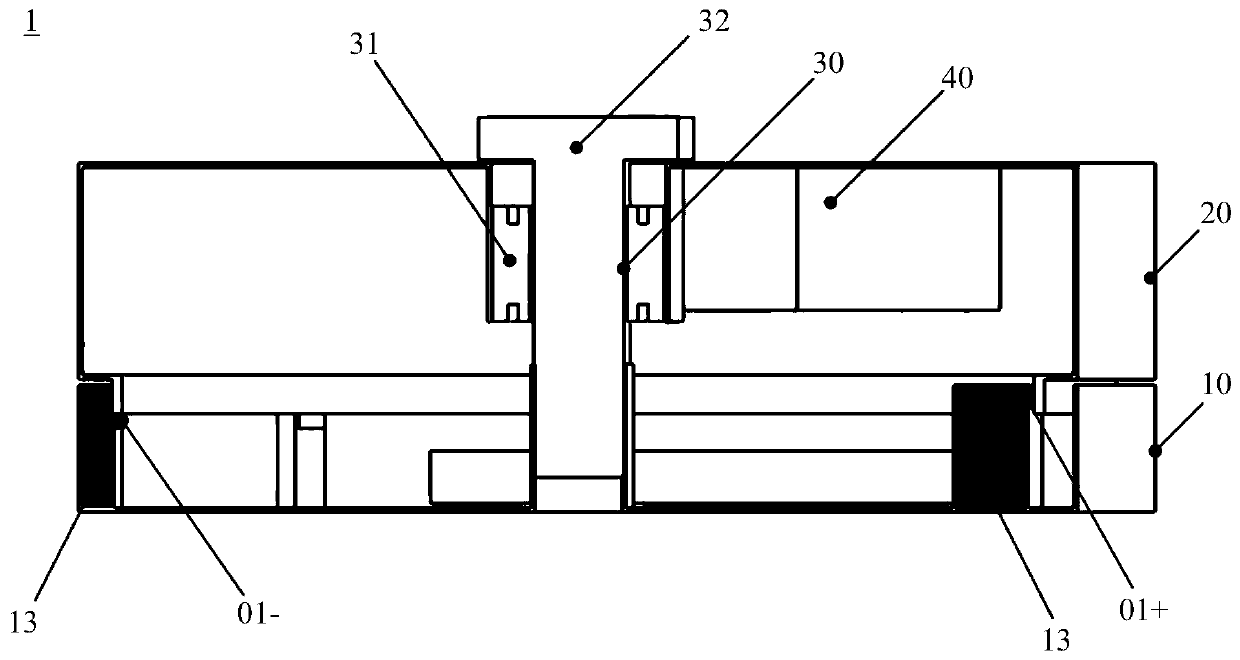

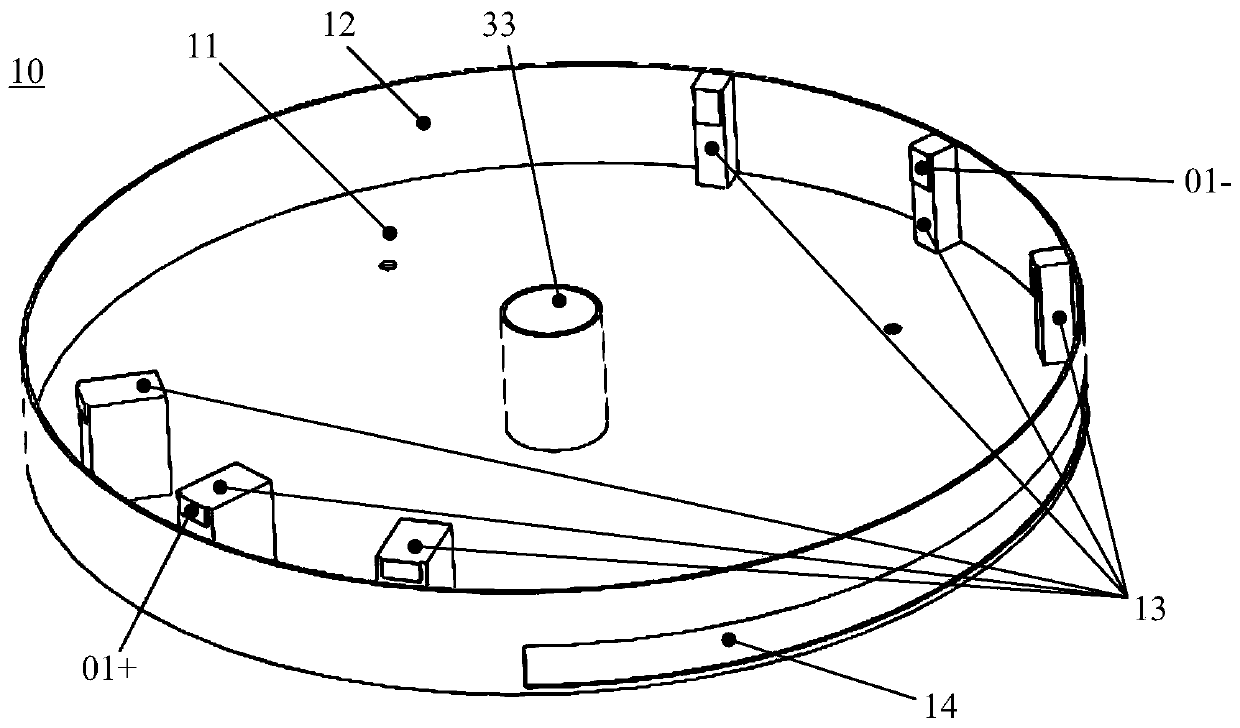

ActiveCN107249763AConductivity disappears or is negligibleTo achieve a conductive connectionMechanical vibrations separationSound producing devicesTransducerElectrode

The invention relates to a sound transducer (1) comprising a plurality of single transducers (10), wherein the single transducers (10) have a carrier (12) and a piezoelectrical element (14) with a first electrode (16) and a second electrode (18). According to the invention, the single transducer (10) is adhered to a flexible film (30) in the form of an array, and the surfaces of the single transducers (10) that are not connected to the flexible film (30) are surrounded by an encapsulation material (60) having vibration damping properties. The invention also relates to a method for producing a sound transducer (1) of this type.

Owner:ROBERT BOSCH GMBH

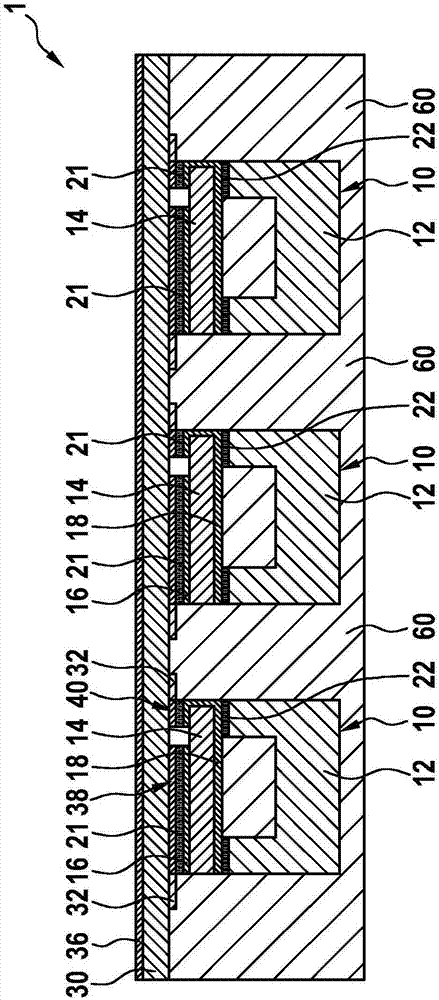

Bus duct connector

InactiveCN110729687ATo achieve a conductive connectionAchieve clamping forceTotally enclosed bus-bar installationsEngineeringStructural engineering

The invention provides a bus duct connector comprising a bracket, a pressing strip, a left inclined block, a right inclined block, a left shell and a right shell. The left shell and the right shell are arranged between the left inclined block and the right inclined block. A plurality of middle shells are arranged in parallel between the left shell and the right shell. Contact pieces and elastic spacers are arranged between the shells. The left side of the lower end of the pressing strip is provided with a first inclined plane. The right side of the lower end of the pressing strip is provided with a second inclined plane. The upper end of the left inclined block is provided with a third inclined plane. The upper end of the right inclined block is provided with a fourth inclined plane. The first inclined plane is in contact with the third inclined plane, and the second inclined plane is in contact with the fourth inclined plane. The left side of the lower end of the bracket and the leftinclined block are connected in a leftward and rightward movement way, and the right side of the lower end and the right inclined block are connected in a leftward and rightward movement way. The upper end of the bracket is provided with a downward pressing locking piece. The pressing strip is arranged between the lower pressing locking piece and the inclined block, and the lower pressing lockingpiece is used for driving the pressing strip to move downward so as to drive the left and right inclined blocks to move in the direction close to each other to compress the elastic spacers and enablethe contact pieces to contact with the bus duct copper bar.

Owner:AMPHENOL PCD SHENZHEN

Integrated connector for battery pack and fuse box circuit breaker module thereof

ActiveCN110212142ATo achieve a conductive connectionAchieve integrationVehicle connectorsCurrent conducting connectionsElectric vehicleEngineering

The invention relates to an integrated connector for a battery pack and a fuse box circuit breaker module thereof. The fuse box circuit breaker module of the integrated connector for the battery packcomprises an insulating shell which is provided with a fuse installing groove and a circuit breaker connecting groove. The sides close to each other of the fuse installing groove and the circuit breaker connecting groove are provided with notches communicated with the groove ports of the fuse installing groove and the circuit breaker connecting groove. The fuse box circuit breaker module furthercomprises a connection bar which passes through the notches and crosses over between the fuse installing groove and the circuit breaker connecting groove to connect the fuse box and the circuit breaker and a spliced insulator which is spliced with an insulating shell to close the notches. The connection bar is clamped between the insulating shell and the spliced insulator. According to the scheme,the problems that the connector structure is not compact and occupies large space and is unfavorable for miniaturization of the electric vehicle caused by separate arrangement of the fuse box and thecircuit breaker of the connector in the prior art can be solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

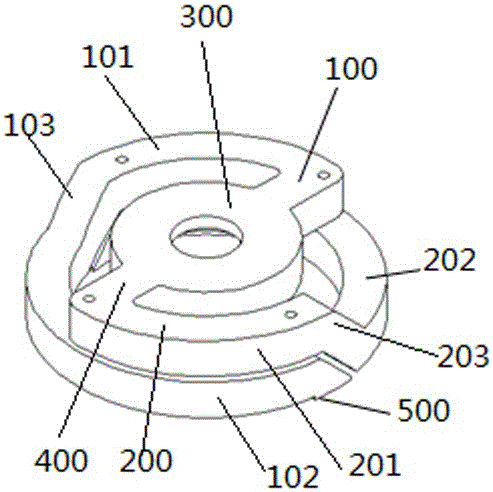

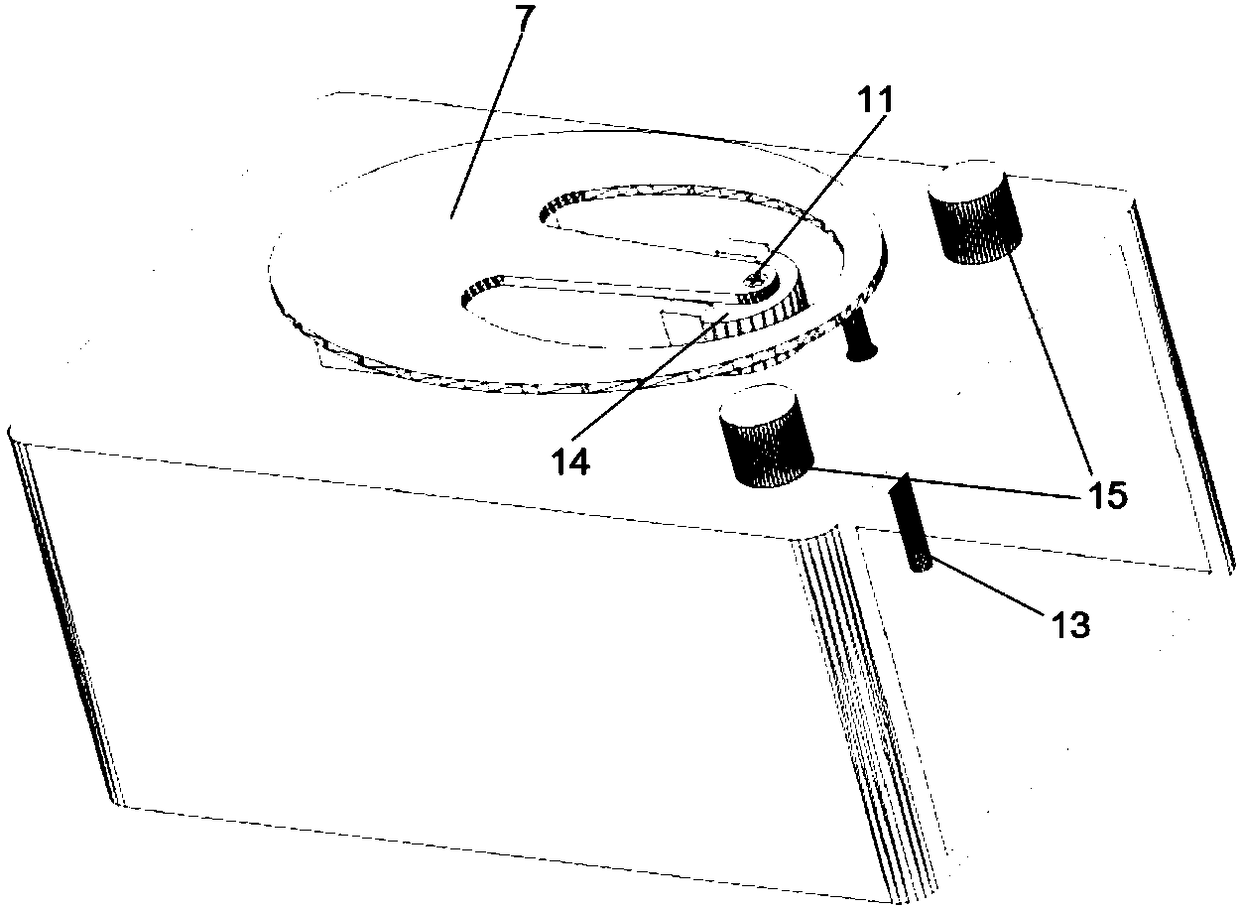

Rotary connection unit, connection channel selection device, and charging equipment

ActiveCN111490381ATo achieve a conductive connectionImprove electrical connection efficiencyBatteries circuit arrangementsCoupling contact membersElectrical connectionStructural engineering

The invention provides a rotary connection unit, a connection channel selection device and charging equipment. The rotary connection unit comprises a pedestal assembly which comprises a bottom plate,a pedestal side wall and a first contact element group, an upper cover assembly which comprises an upper cover plate, an upper cover side wall, a second contact element group and a telescopic contactelement group, a rotating mechanism which is arranged between the base assembly and the upper cover assembly and is used for controlling the upper cover assembly to rotate relative to the base assembly, and a telescopic control mechanism which is arranged in a cavity formed after the pedestal assembly and the upper cover assembly are matched and is used for controlling the telescopic contact element group to extend out of a side wall of the upper cover or retract into the side wall of the upper cover, wherein the pedestal side wall is provided with a wire inlet, and the second contact elementgroup is respectively connected with the first contact element group and the telescopic contact element group. The rotary connection unit is simple in structure and easy to control, the efficiency, flexibility and stability of the electrical connection between a power supply device and a power receiving device can be improved, and the cost can be reduced.

Owner:GUOCHUANG INNOVATION CENTER OF MOBILE ENERGY (JIANGSU) CO.,LTD.

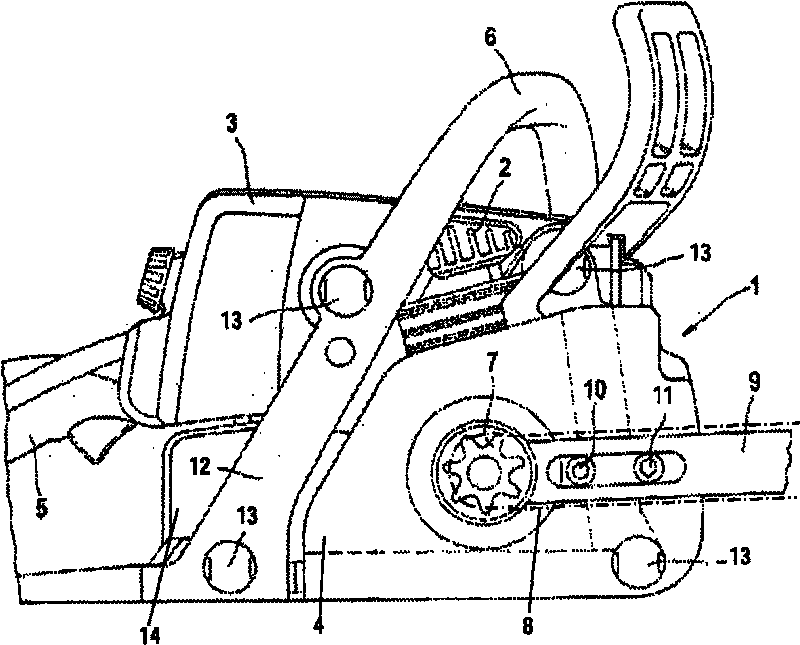

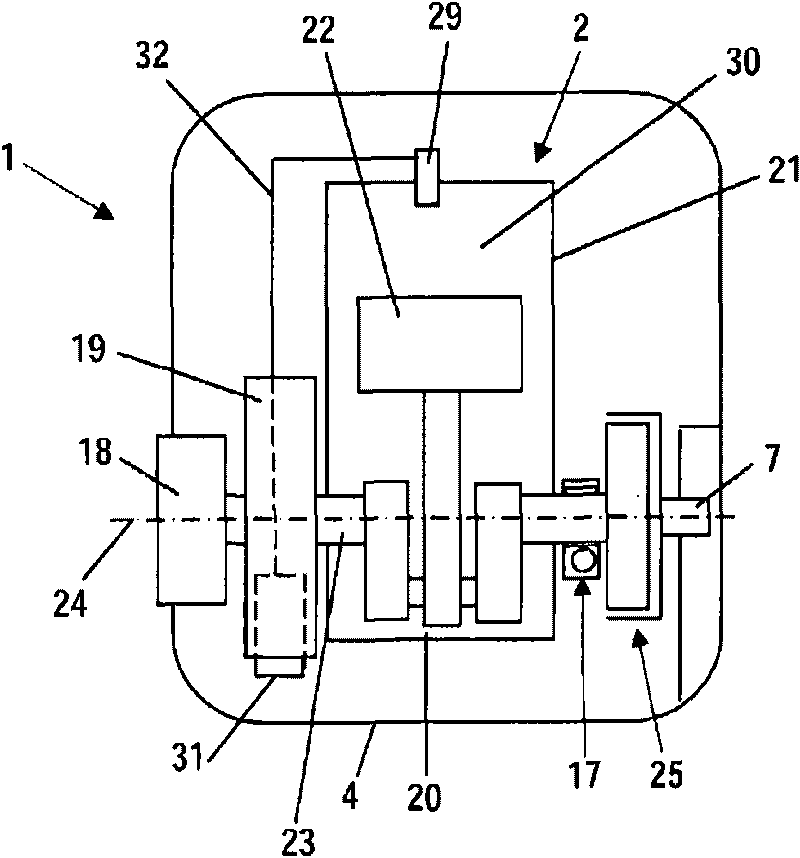

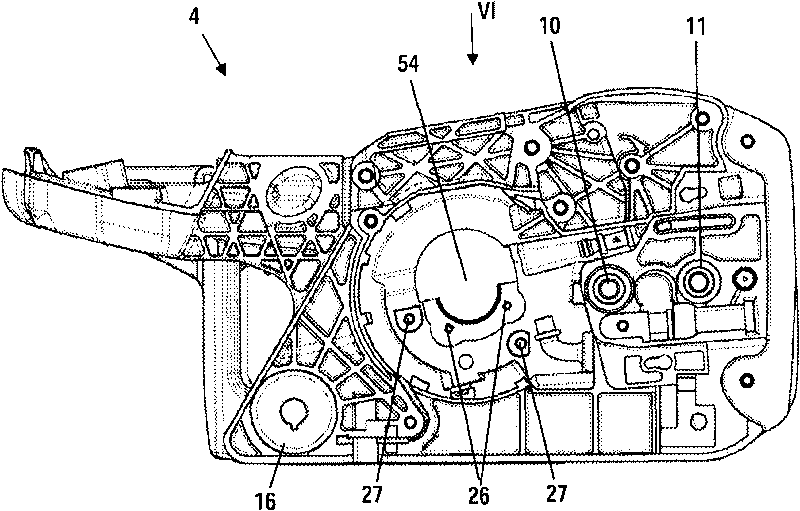

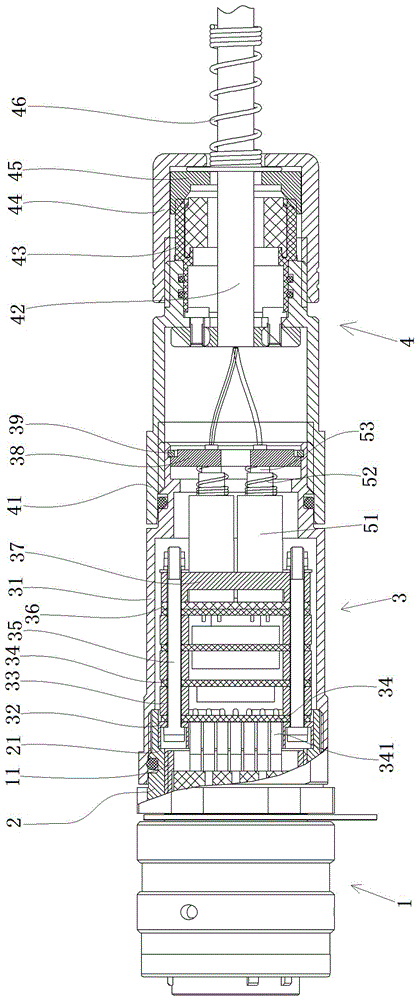

Handheld machine tool and manufacturing method thereof

ActiveCN101745691AEasy to manufactureAchieve precise positioningMetal sawing devicesMachines/enginesExternal combustion engineHand held

The present invention relates to a handheld machine tool which is provided with at least one cutter driven by an internal combustion engine (2), wherein the internal combustion engine (2) is provided with a crankcase (20) which is at least partially composed of an oil pan (28), wherein the machine tool comprises a housing component (4) which is made of plastic; the oil pan (28) is made of metal and is injected into the housing component (4) of the machine tool; the internal combustion engine (2) is provided with an ignition device which is provided with an ignition module (31). If the ignition module (31) is directly and conductively fixed to the oil pan (28) made of metal, a simple structure of the machine tool can be realized. For manufacturing the machine tool, the invention prescribes that: before injection and packing of the material of the housing component (4) are performed to the oil pan (28), at least one fixing component used for fixing the cutter rack is fixed to the oil pan (28).

Owner:ANDREAS STIHL AG & CO KG

A connection structure of soft pack lithium-ion battery modules

ActiveCN105070874BSimplify the assembly processTo achieve a conductive connectionCell component detailsBusbarLithium-ion battery

The invention provides a soft-pack lithium-ion battery module connection structure, which includes at least two battery cells arranged in parallel and a bus bar located above the battery cells and electrically connected to the tabs of the battery cells, and also includes a bus bar arranged below the bus bar and connected to the tabs of the battery cells. The electric core is relatively fixedly assembled with an insulating grid, and the insulating grid is provided with tab perforations corresponding to the tabs of the battery for the tabs to pass through, and the tabs go upward through the top of the tab perforations It has a bent portion that is bent close to the upper side of the insulating grid, and the bus bar has a lower side that is crimped on the bent portion of the tab and welded and fixed to the bent portion of the tab. Since the entire busbar is crimped downwards on the bending part of the tab, in the actual welding assembly, it is only necessary to press down the busbar through the corresponding crimping tool, and the busbar will press down on the bend of the tab part, eliminating the need to configure additional lug press-fitting tooling, effectively simplifying the assembly process of the battery module and reducing production costs.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Conductor electrical connection device

InactiveCN106058535AAssembly accuracy is lowReduce assembly stressCoupling contact membersConnection contact member materialElectrical conductorFinger structure

The invention relates to a conductor electrical connection device comprising a contact finger installing sleeve which extends along a left-and-right direction. The contact finger installing sleeve is provided with a plugging hole segment which sleeves the corresponding end part of a plugging conductor under conductive connection in a clearance way. The contact finger installing sleeve is provided with a conductive contact finger structure. The conductive contact finger structure is provided with an elastic contact finger part which stretches to the plugging hole segment in a suspension way and is arranged in a way of inwardly protruding out of the internal hole wall of the plugging hole segment so as to be conductively contacted with the corresponding plugging conductor. The elastic contact finger part can deform in the radial direction of the contact finger installing sleeve under the abutting effect of the plugging conductor so that the radial position of the plugging conductor in the contact finger installing sleeve can be adjusted, effective conductive contact of the electrical connection device and the plugging conductor can be realized through radial deformation of the elastic contact finger part even deviation exists between the original installing position of the plugging conductor and the design position, and thus the assembling accuracy requirement for the plugging conductor can be reduced and the assembling efficiency can be enhanced.

Owner:平高集团威海高压电器有限公司 +2

Active cable assembly and active cable connector thereof

ActiveCN106873098AImprove adaptabilityTo achieve a conductive connectionCoupling light guidesElectricityPhotoelectric conversion

The invention relates to an active cable assembly and an active cable connector thereof. The active cable assembly comprises an active cable and active cable connectors arranged at the two ends of the active cable. The active cable connectors consist of electric plugs and photoelectric conversion units in conductive connection with a contact piece of the electric plug; and the electric plugs include electric plug shells extending from front to back. The active cable connectors also include connector shells; and the photoelectric conversion units are arranged in the rear of the electric plug shells and are installed in the inner cavities of the connector shells. Because the photoelectric conversion units are installed in the inner cavities of the connector shells, the dimensions of the photoelectric conversion units are not limited by the electric plugs, so that the photoelectric conversion units with proper dimensions can be set based on practical demands and thus adaptability of the active cable connector can be enhanced.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Connecting materials

InactiveCN1510092AImprove heat resistanceTo achieve a conductive connectionPrinted circuit assemblingNon-macromolecular adhesive additivesHigh resistanceHigh humidity

A connecting material for bonding and connecting elements each having electrodes thereon in a correpondingly confronted relation to each other, while attaining electroconductive connection between the corresponding electrodes, which material has a high heat resistance and can avoid occurrence of faulty electric conductance even in the case of bonding such elements as having a large number of electrodes arranged, thus, at a considerable small interval under such a condition that the bonded assembly is exposed to a service environment of high temperature or of high temperature and high humidity, wherein the said connecting material comprises a thermosetting resin and an inorganic filler and has, after having been cured, characteristic features comprising a modulus of elasticity of 1 - 12 GPa, a glass transition temperature Tg of 120 - 200 DEG C, a coefficient of linear expansion ( alpha 1) of 50 ppm / DEG C or less at temperatures below the Tg and a coefficient of linear expansion ( alpha 2) of 110 ppm / DEG C or less at temperatures above the Tg, wherein the difference ( alpha 2 - alpha 1) does not exceed over 60 ppm / DEG C.

Owner:DEXERIALS CORP

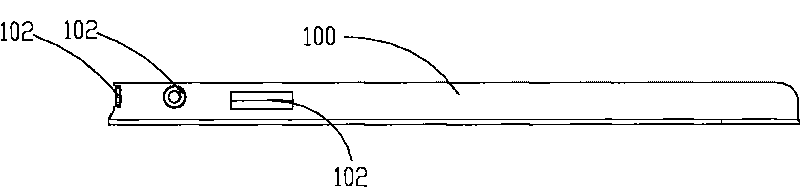

Portable electronic equipment

ActiveCN101715276AGuaranteed aestheticsIntegrity guaranteedRotary current collectorDigital data processing detailsEngineeringElectronic equipment

The invention discloses portable electronic equipment comprising a main body with a notch, a rotating shaft fixedly arranged on at least one wall of a cavity, a rotating body rotatably arranged on the rotating shaft and an input / output interface, wherein the notch extends inwards to form the cavity; the distance from the axes of the rotating shaft to the outer surface of the rotating body is equal to the distance from the axes to the surface of the body with the notch; the input / output interface is arranged on the outer surface of the rotating body; through rotating the rotating body to be in the first state, the input / output interface is hidden at the notch of the main body, and through rotating the rotating body to be in the second state, the input / output interface is exposed at the notch of the main body. Therefore, the input / output interface can be hidden so as to ensure the appearance to be attractive and integral or can be exposed, and thereby, the communication with other electronic equipment can be realized.

Owner:LENOVO (BEIJING) CO LTD

Welding torch cable self-rototing device

InactiveCN1986366AGuaranteed rotating contactTo achieve a conductive connectionEngineeringLower face

The welding torch cable self-rotating device set between the welding torch tail and the cable consists of one rotation body, one conducting connector and one elastic conducting ring. The rotation body has upper end fixed to the cable and upper axial hole for leading out the upper wire feeding hose; the conducting connector has the upper face contacting with the lower face of the rotation body, lower end connected electrically to the welding torch and lower axial hole for leading out the lower wire feeding hose; and the elastic conducting ring connected between the rotation body and the conducting connector. The rotation body may be rotated relatively to the elastic conducting ring to avoid cable twisting for normal welding.

Owner:HUAHENG WELDING

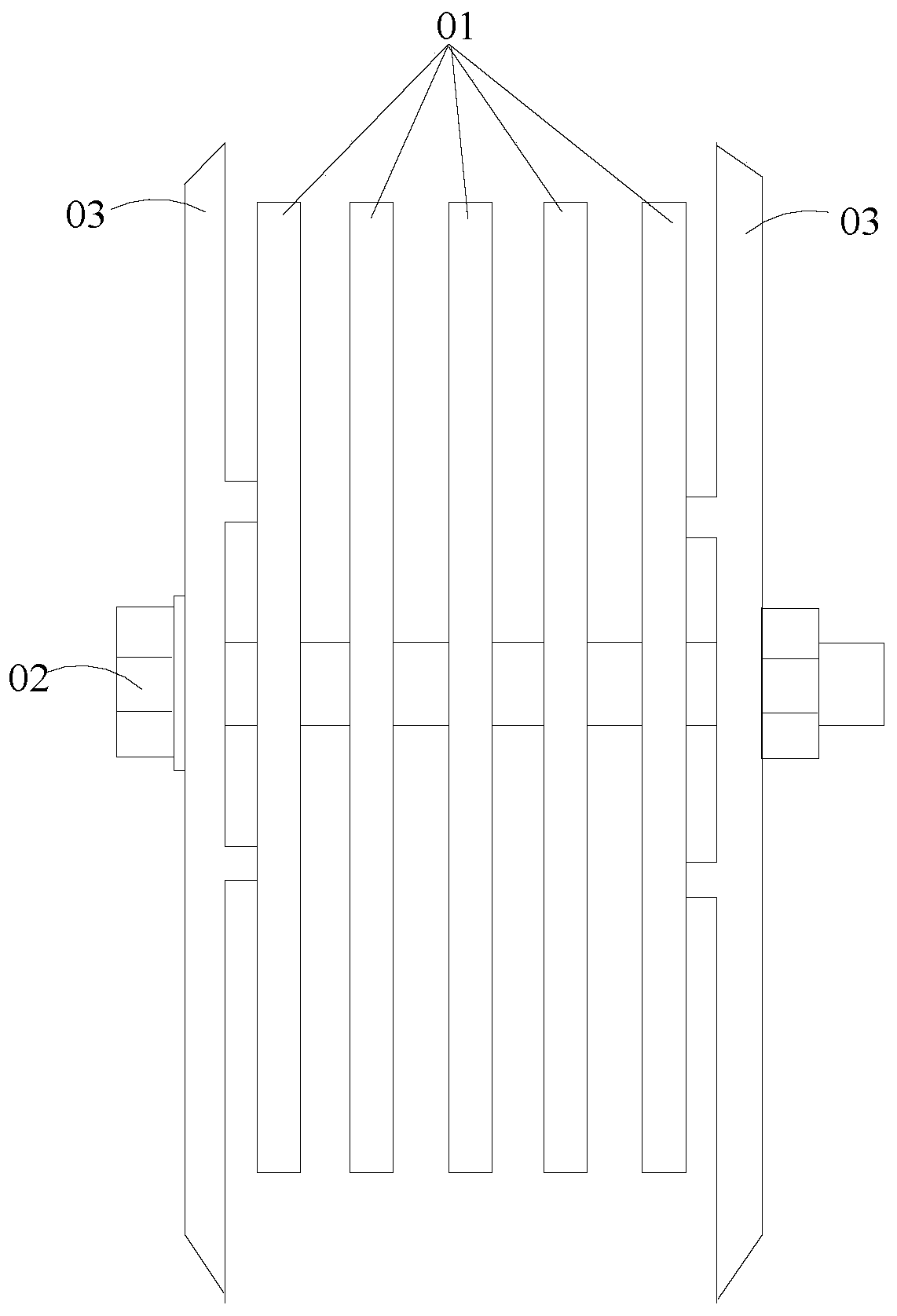

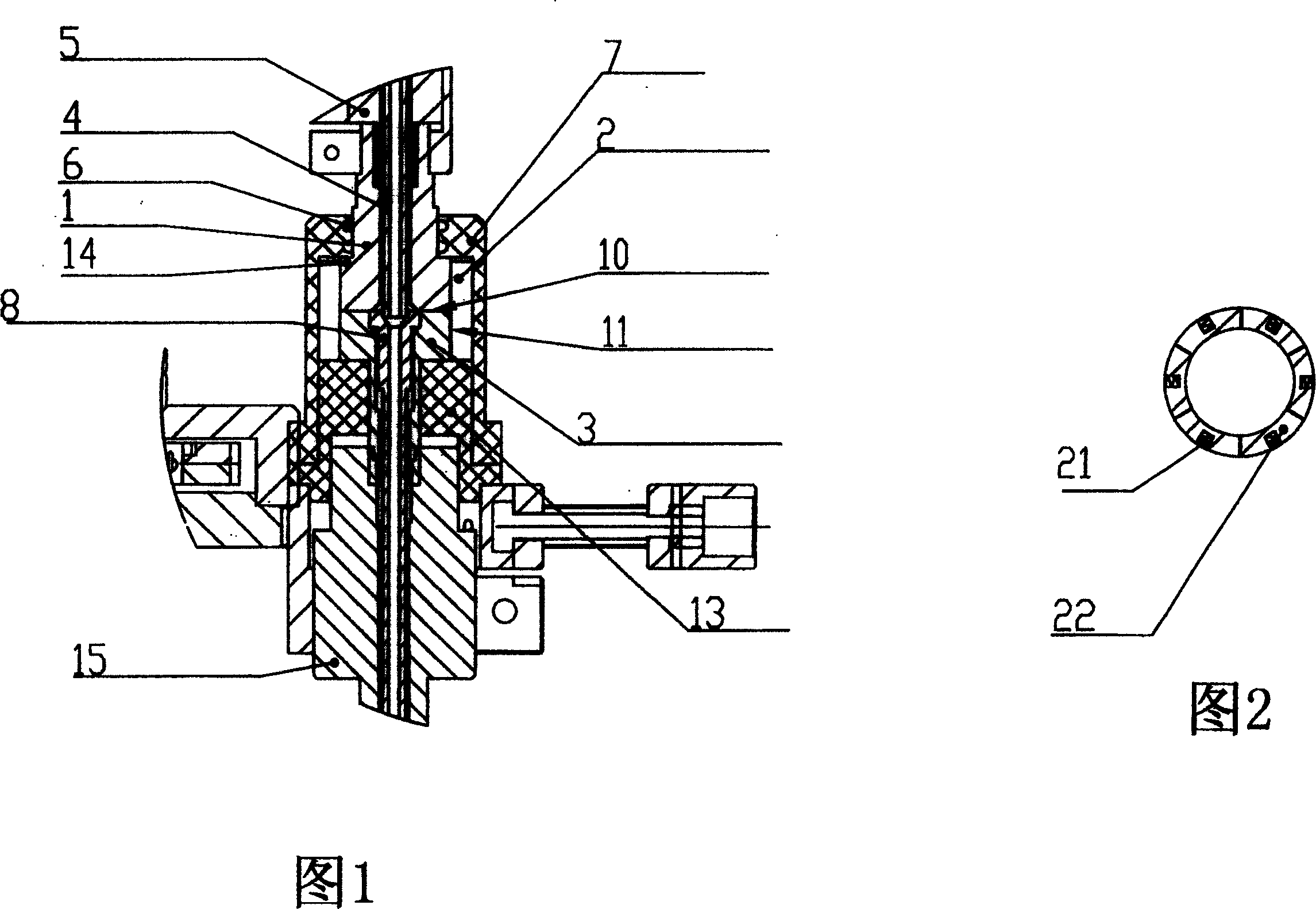

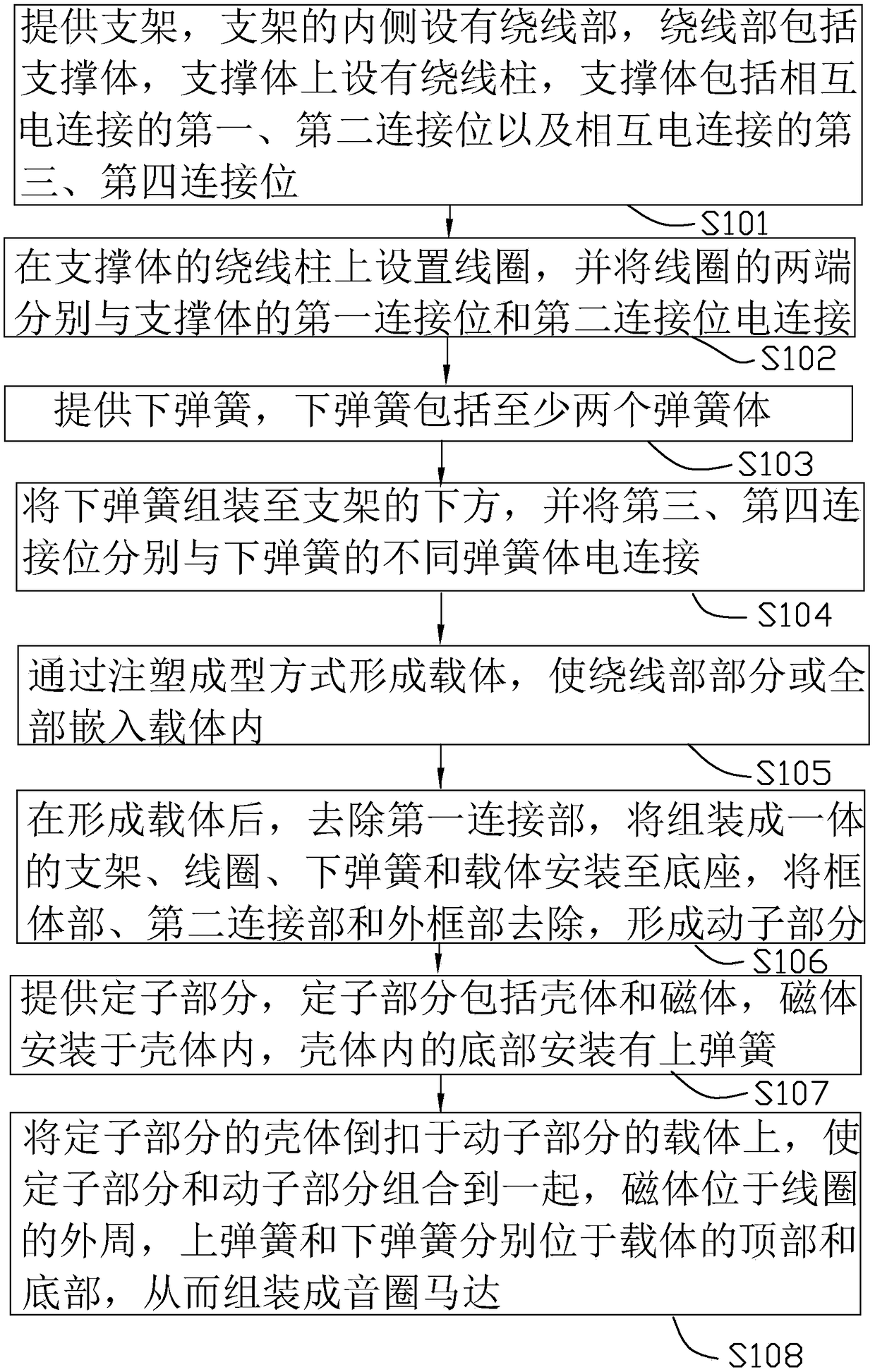

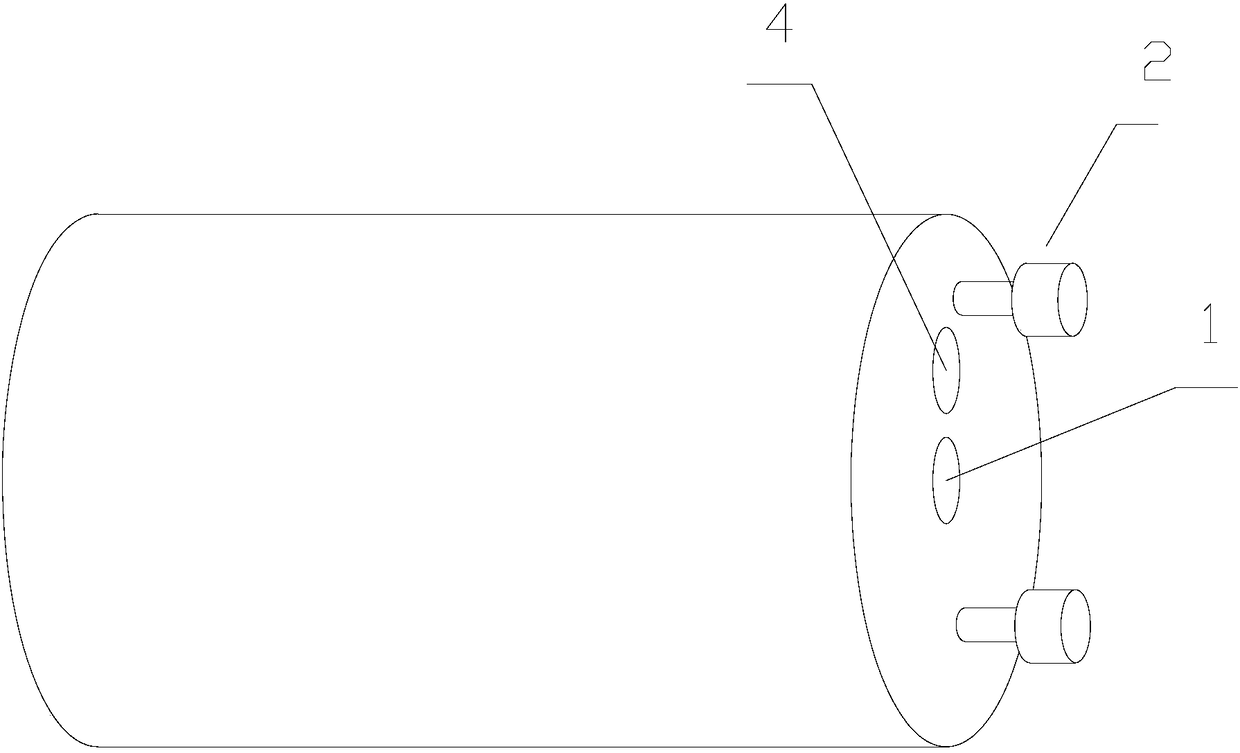

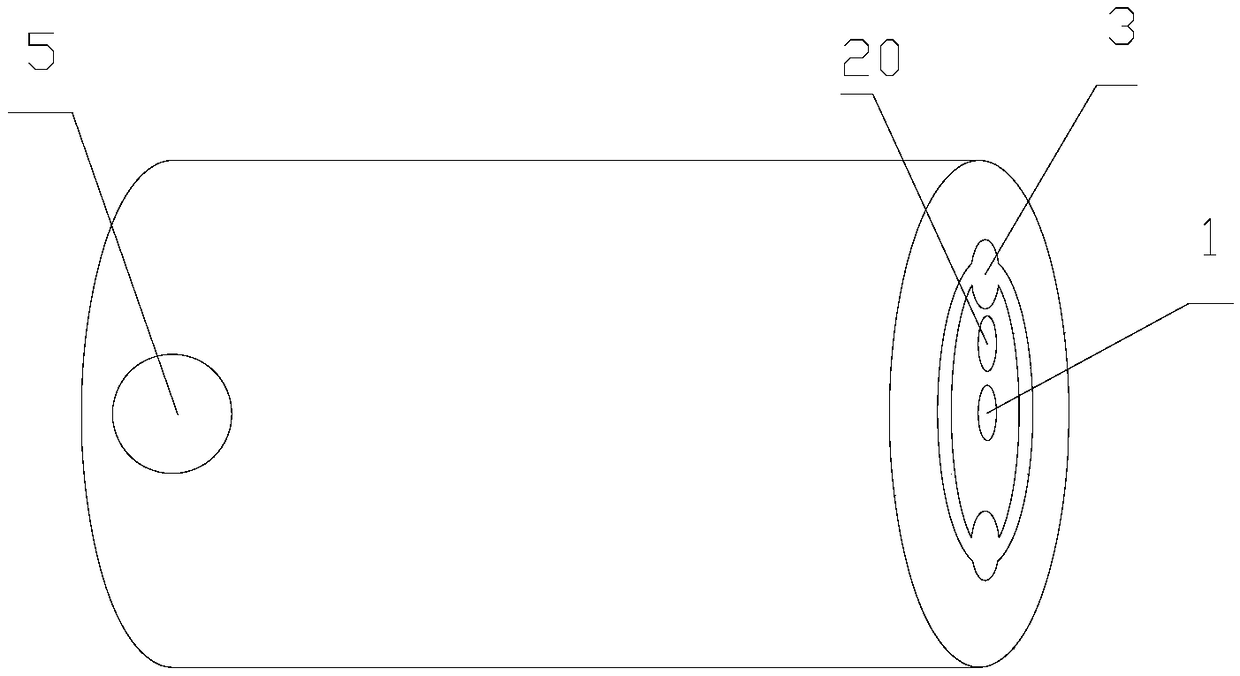

Voice coil motor and manufacturing method thereof

The invention discloses a voice coil motor and a manufacturing method thereof. The manufacturing method of the voice coil motor comprises the steps of providing winding parts, wherein each winding part comprises a support body, and winding columns are arranged on the support body; providing a lower spring, wherein the lower spring comprises at least two spring bodies, and the third connecting position and the fourth connecting position of the support body are electrically connected with different spring bodies of the lower spring respectively; setting a coil on the winding columns of the support body, and enabling the two ends of the coil to be electrically connected with the first connecting position and the second connecting position of the support body respectively; and forming a carrier in an injection molding manner. According to the voice coil motor and the manufacturing method thereof, the coil is electrically connected with the winding parts, and then the winding parts are electrically connected with the lower spring, so that conduction connection between the coil and the lower spring is realized, removal of a varnished wire of the coil is not needed, wire end arrangement by the working staff is avoided, production efficiency is improved and cost is lowered, the problem of exposure of a welding point is avoided, long lasting and firmness of the welding point can be ensured, process difficulty is lowered, and consumption of glue consumable material caused by rubber coating processing can be avoided.

Owner:深圳市丘钛微电子科技有限公司

Connector capable of performing power-on identification

InactiveCN108598748AAchieve seamless connectionAchieve rotationIncorrect coupling preventionCoupling contact membersState of artCopper wire

The present invention relates to the field of wires and cables and discloses a connector capable of performing power-on identification, which comprises a first section of connector and a second section of connector, wherein the central positions of the first section of connector and the second section of connector are provided with a through hole capable of penetrating a copper wire; a clamping joint is disposed on the first section of connector; a clamping slot is arranged on the second section of connector; the clamping joint can be inserted to the clamping slot to be fixed; a wire insertingslot is respectively arranged on the end surface where the clamping joint of the first section of connector is located and the end surface where the clamping slot of the second section of connector is located; and the wire inserting slot is used for fixing a copper wire. The connector capable of performing the power-on identification overcomes the problem that the cable connection in the prior art is unsafe and the connection portion is easily detached, avoids the safety hazard at the connection, achieves a seamless connection and prevents electric leakage.

Owner:安徽易恒云创科技有限公司

Vacuum arc-extinguishing chamber with composite contact structure

ActiveCN112735901AReduce movement distanceReduce overtravelHigh-tension/heavy-dress switchesAir-break switchesEngineeringLow vacuum

The invention relates to a vacuum arc-extinguishing chamber with a composite contact structure. The vacuum arc-extinguishing chamber comprises: a static contact structure which comprises a static main contact, a static arc contact and a static end corrugated pipe, wherein the static arc contact is movably assembled in the static main contact, and the static end corrugated pipe applies an elastic reset acting force to the static arc contact; and a moving contact structure which comprises a moving main contact, a moving arc contact and a moving end corrugated pipe. The moving arc contact is movably assembled in the moving main contact; and the moving end corrugated pipe applies an elastic reset acting force to the moving arc contact to force the moving arc contact to move towards the static arc contact. The static end corrugated pipe and the moving end corrugated pipe are utilized to enable the static arc contact and the moving arc contact to move relative to the corresponding main contacts, and the protruding amount of the two arc contacts relative to the main contacts is offset by the two arc contacts, so compared with a scheme for offsetting only depending on the movement of the static arc contact, the scheme using the two arc contacts to act can effectively reduce the moving distance of the static arc contact, reduce the overtravel condition of the vacuum arc-extinguishing chamber and lower the requirement for the installation place of the vacuum arc-extinguishing chamber.

Owner:PINGGAO GRP +2

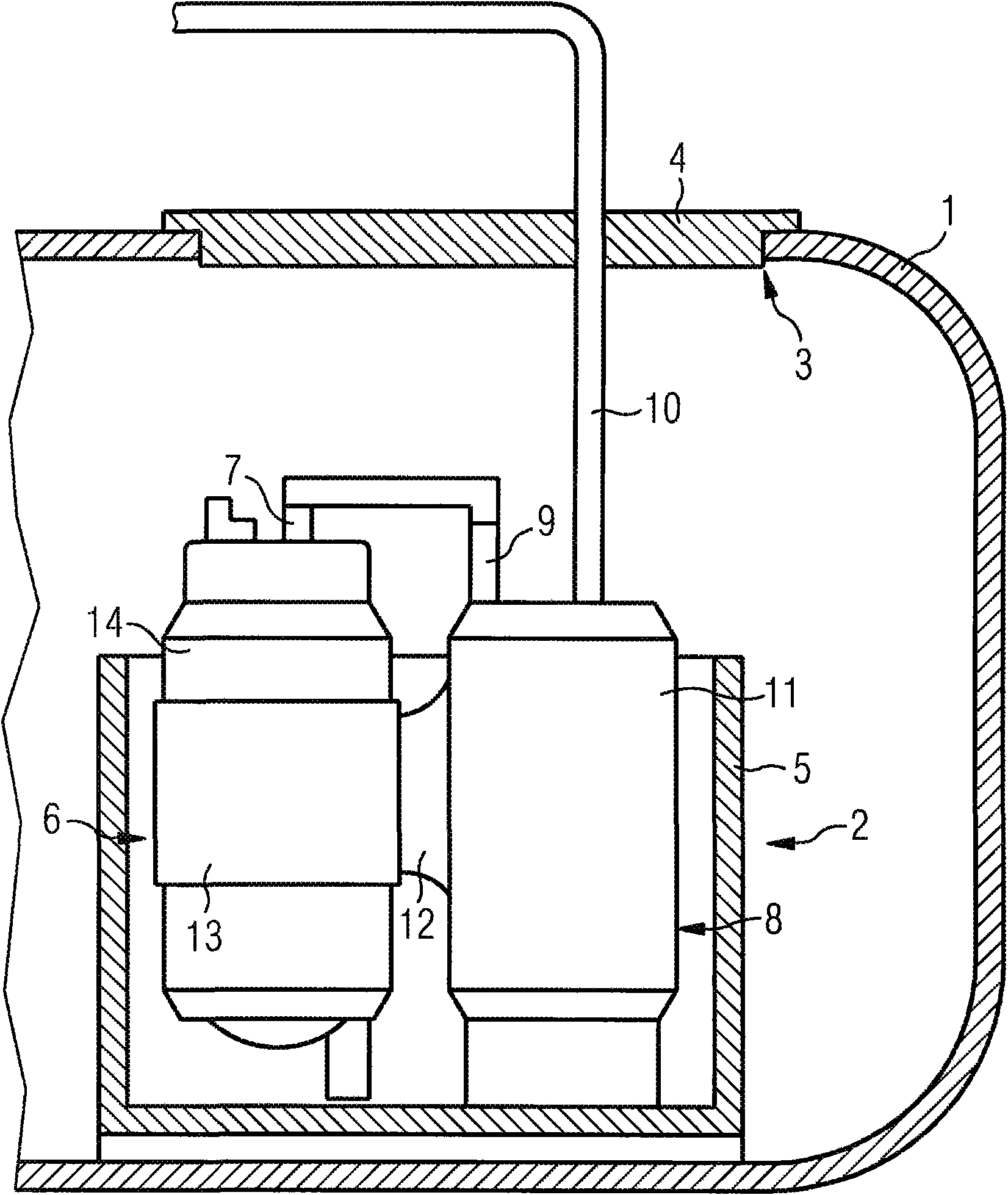

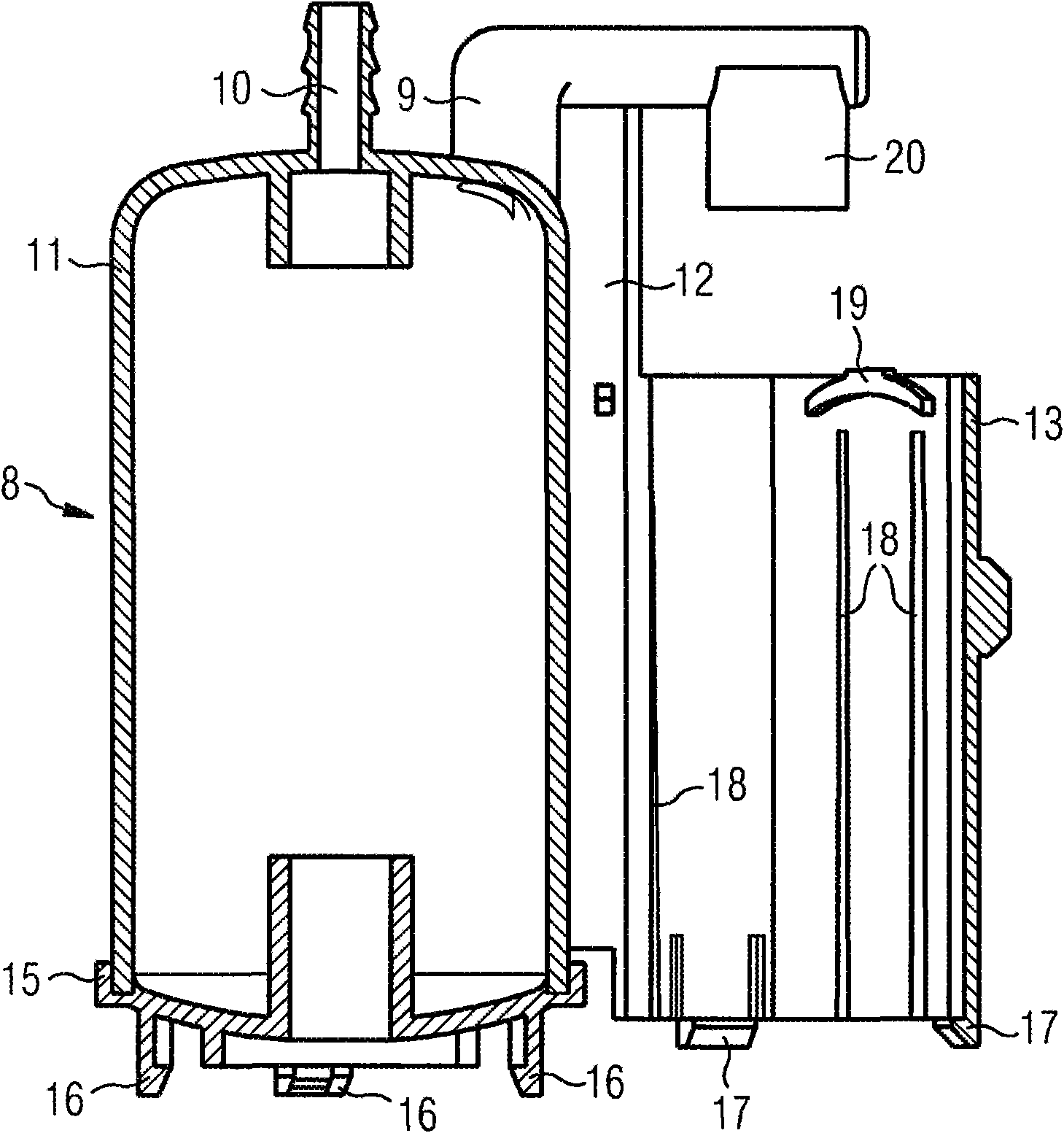

Pump unit

ActiveCN101605980ALarge design possibilitiesImprove conductivityEngine controllersMachines/enginesExternal combustion engineFuel filter

The invention relates to a pump unit for pumping fuel from a fuel reservoir to an internal combustion engine of a motor vehicle, comprising a fuel pump, which is disposed in a swirl pot and has a housing made of metal, and a fuel filter, which is disposed downstream of the fuel pump. The housing of the fuel filter is connected to the housing of the fuel pump in an electrically conductive manner.

Owner:VTESCO TECH GMBH

Top cover structure of power lithium ion battery

ActiveCN108598298APrevent overchargingIncrease internal resistanceSmall-sized cells cases/jacketsCells structural combinationElectrical connectionEngineering

The invention relates to a top cover structure of a power lithium ion battery. The top cover structure comprises a top cover plate, a liquid injection hole arranged on the top cover plate, an explosion-proof hole, a first electrode column and a second electrode column, wherein the first electrode column and the second electrode column respectively penetrate through the top cover plate and fixed onthe top cover plate, the first electrode column is electrically connected to the top cover plate, the second electrode column and the top cover plate form insulating connection, the second electrodecolumn is provided with an electrical connection sheet electrically connected to the second electrode column, the top cover plate is further provided with a temperature sensitive switch, the temperature sensitive switch is electrically connected to the top cover plate, the temperature sensitive switch is electrically connected to the electrical connection sheet when the temperature of the top cover plate is equal to or higher than a preset temperature, and the temperature sensitive switch and the electrical connection sheet form broken circuit assembly when the temperature of the top cover plate is lower than the preset temperature.

Owner:江苏科达利精密工业有限公司

Active optical cable connector and active optical cable assembly using same

ActiveCN106842446AImprove reliabilityCause non-removable problemsCoupling light guidesPhotoelectric conversionEngineering

The invention relates to an active optical cable connector and an active optical cable assembly using the same. The active optical cable connector comprises a connector shell assembly and a photoelectric conversion unit arranged in an inner cavity of the connector shell assembly, wherein a stop structure is arranged in the inner cavity of the connector shell assembly in front of the photoelectric conversion unit; a pressing structure for elastically pressing the photoelectric conversion unit against the stop structure is arranged in the inner cavity of the connector shell assembly behind the photoelectric conversion unit; and the photoelectric conversion unit is elastically pressed in the inner cavity of the connector shell assembly by the pressing structure. According to the connector, the problem that the photoelectric conversion unit cannot be dismantled due to use of mucilage glue is solved; and the photoelectric conversion unit is elastically pressed, and elastic floating force can be provided when the connector is vibrated and the photoelectric conversion unit moves in the inner cavity of the connector shell assembly, so that impact and collision of the photoelectric conversion unit and the connector shell assembly are avoided and the reliability of the connector is improved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

LED(light emitting diode) lamp utilizing recycling metal beverage can as radiating substrate

InactiveCN102011956AImprove cooling effectControl heating temperaturePoint-like light sourceLighting heating/cooling arrangementsCopper foilEngineering

The invention discloses an LED (light emitting diode) lamp utilizing a recycling metal beverage can as a radiating substrate. The LED lamp comprises a lamp head, a lamp cup body, a circuit board on which an LED and a lamp shade are arranged, wherein the lamp head is fixedly connected with one end of the lamp cup body through an insulated plastic shell; the lamp shade is fixedly connected with the other end of the lamp cup body; and the circuit board is connected to the lamp cup body and is accommodated in a cavity surrounded by the lamp cup body and lamp shade; and the recycled metal beverage is directly taken as the lamp body, one end of the metal beverage can serve as a metal installation face connected with the circuit board, the circuit board is copper base plate, and a copper foil layer of a circuit board substrate is fixedly connected with the metal installation face of the metal beverage can through adhesion agent. The recycled metal beverage serves as the lamp cup body, thus the complete metallization structure of an LED is realized, the radiating performance of the LED is improved greatly, the metal beverage can is recycled, and the requirements of low carbon, environmental friendliness and economical efficiency are reached.

Owner:XIAMEN HUIGENG ELECTRONICS IND

Guide rail type LED light bar socket and guide rail type LED light bar extension socket connector

InactiveCN104377475AReduce lossTo achieve a conductive connectionCoupling contact membersContact members penetrating/cutting insulation/cable strandsEngineeringLED lamp

The invention provides a guide rail type LED light bar socket. The guide rail type LED light bar socket comprises an upper shell, a lower shell, a negative terminal and a positive terminal, wherein the upper shell is connected with the lower shell, a negative wire passing hole allowing a negative wire to pass through and a positive wire passing hole allowing a positive wire to pass through are formed between the upper shell and the lower shell, an installation cavity is defined between the upper shell and the lower shell, both the negative terminal and the positive terminal are arranged in the installation cavity, a negative impaling protrusion part is arranged at one end of the negative terminal, and a negative contact spring is arranged at the other end of the negative terminal. The invention further provides a guide rail type LED light bar extension socket connector. The guide rail type LED light bar socket and the guide rail type LED light bar extension socket connector have the advantages that the negative wire and the positive wire do not need to be cut into sections, operation such as welding is not needed, loss is small, consistent power supply on the head and on the tail can be achieved, luminance consistency is high, wiring management is convenient, installation is easy, insertion is convenient, and plug and play of an LED light bar is achieved.

Owner:樊健平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com