Conductor electrical connection device

An electrical connection and conductor technology, which is applied to the parts, coupling devices, circuits and other directions of the connection device, can solve the problems of high requirements on the conductor assembly process, small error tolerance rate of assembly errors, etc., to improve assembly quality, reduce assembly stress, and reduce The effect of assembly accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

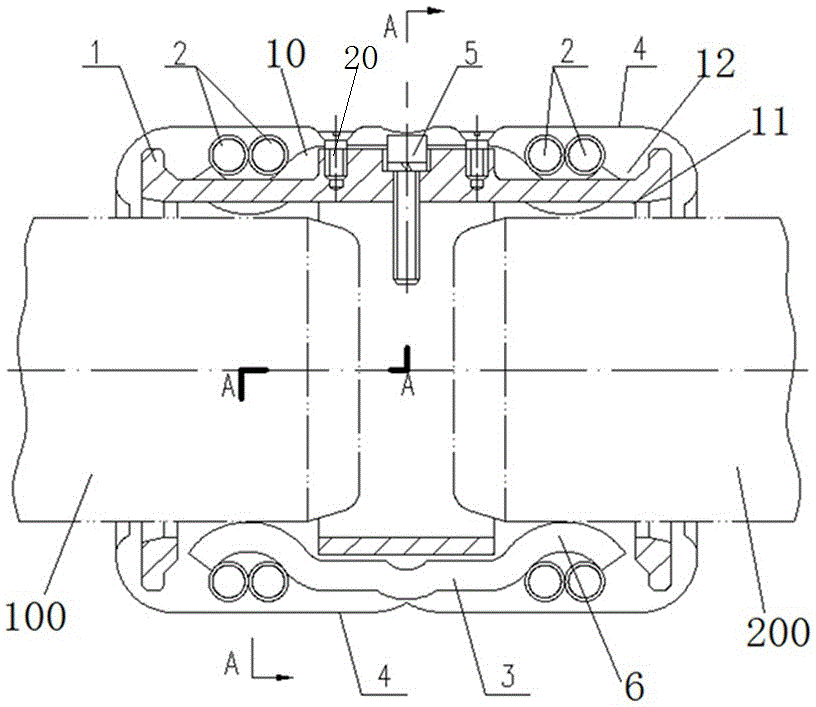

[0032] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

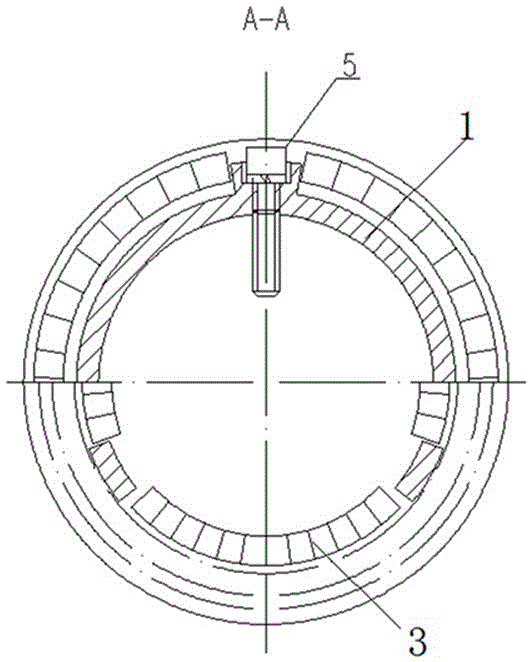

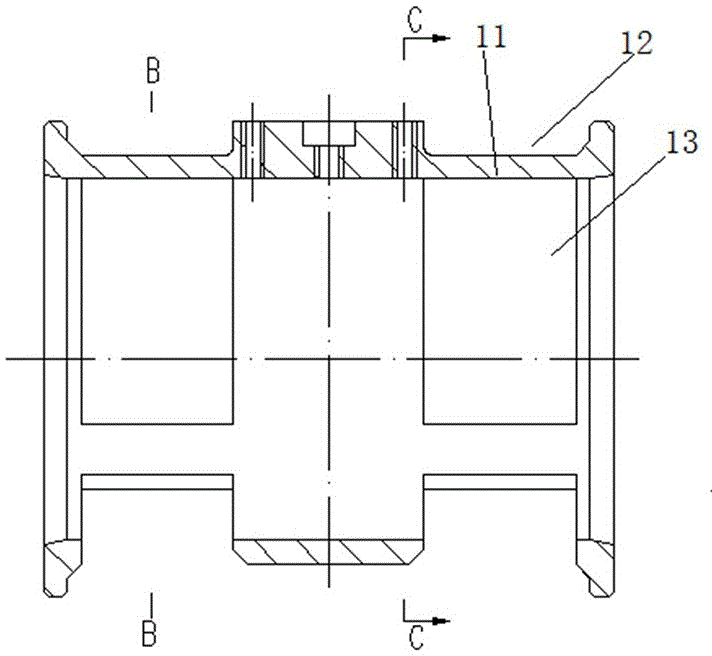

[0033] Specific embodiments of the conductor electrical connection device provided by the present invention, such as Figure 1 to Figure 9 As shown, the electrical connection device in this embodiment includes contact finger installation sleeves 1 extending in the left and right directions, and the left and right sides of the contact finger installation sleeve 1 respectively have a plug hole section 11 for connecting with two plug holes to be electrically connected. The corresponding ends of the conductors are fitted with gap plugs.

[0034] The contact finger mounting sleeve 1 is provided with conductive contact finger structures 10, and three conductive contact finger structures 10 are evenly distributed along the circumferential direction, and each conductive contact finger structure 10 has two elastic contact finger parts arranged at intervals along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com