Horizontal thin type numeral control panoramic table for point gearing cambered surface cam mechanism

An arc cam and point meshing technology, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of affecting the service life of the workbench, the size limitation of the processed workpiece, and the low positioning accuracy, so as to eliminate the gap Convenience, low processing and assembly accuracy requirements, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

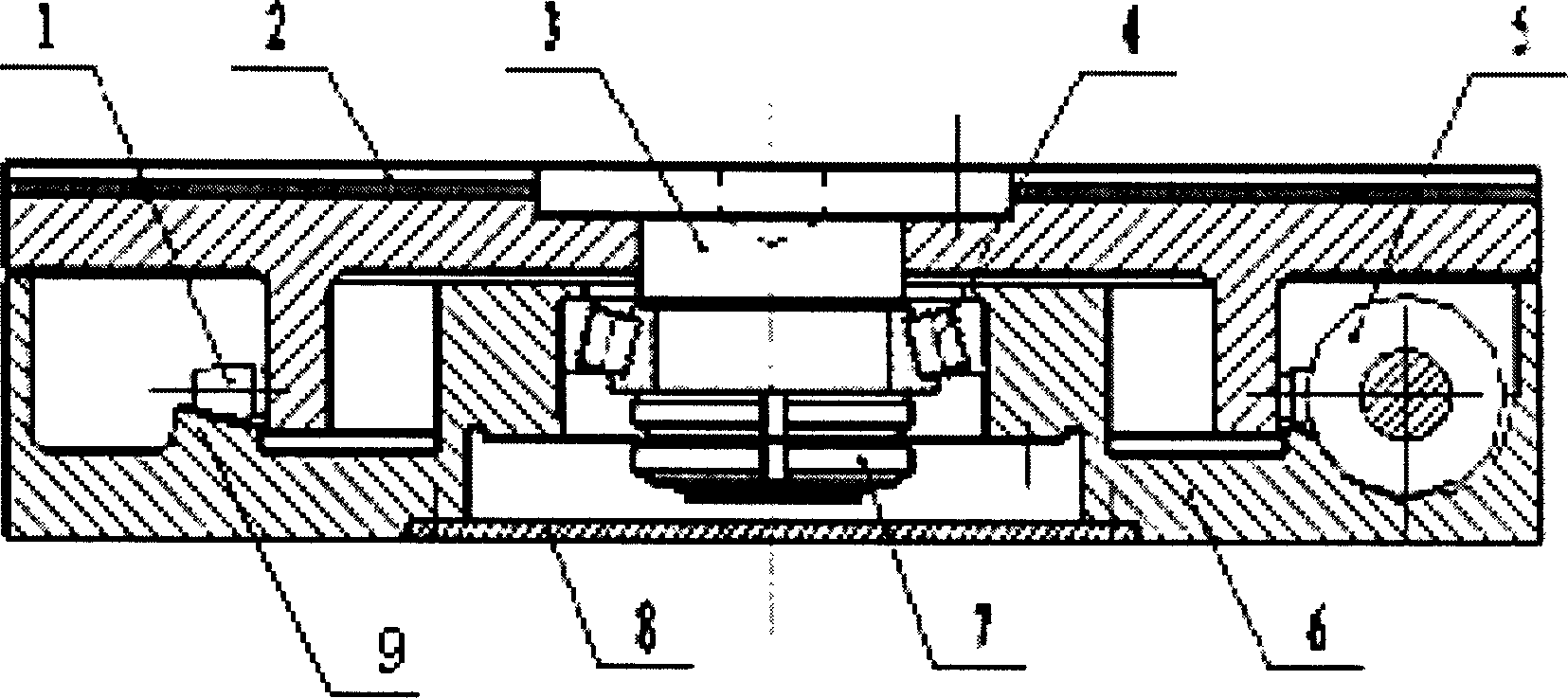

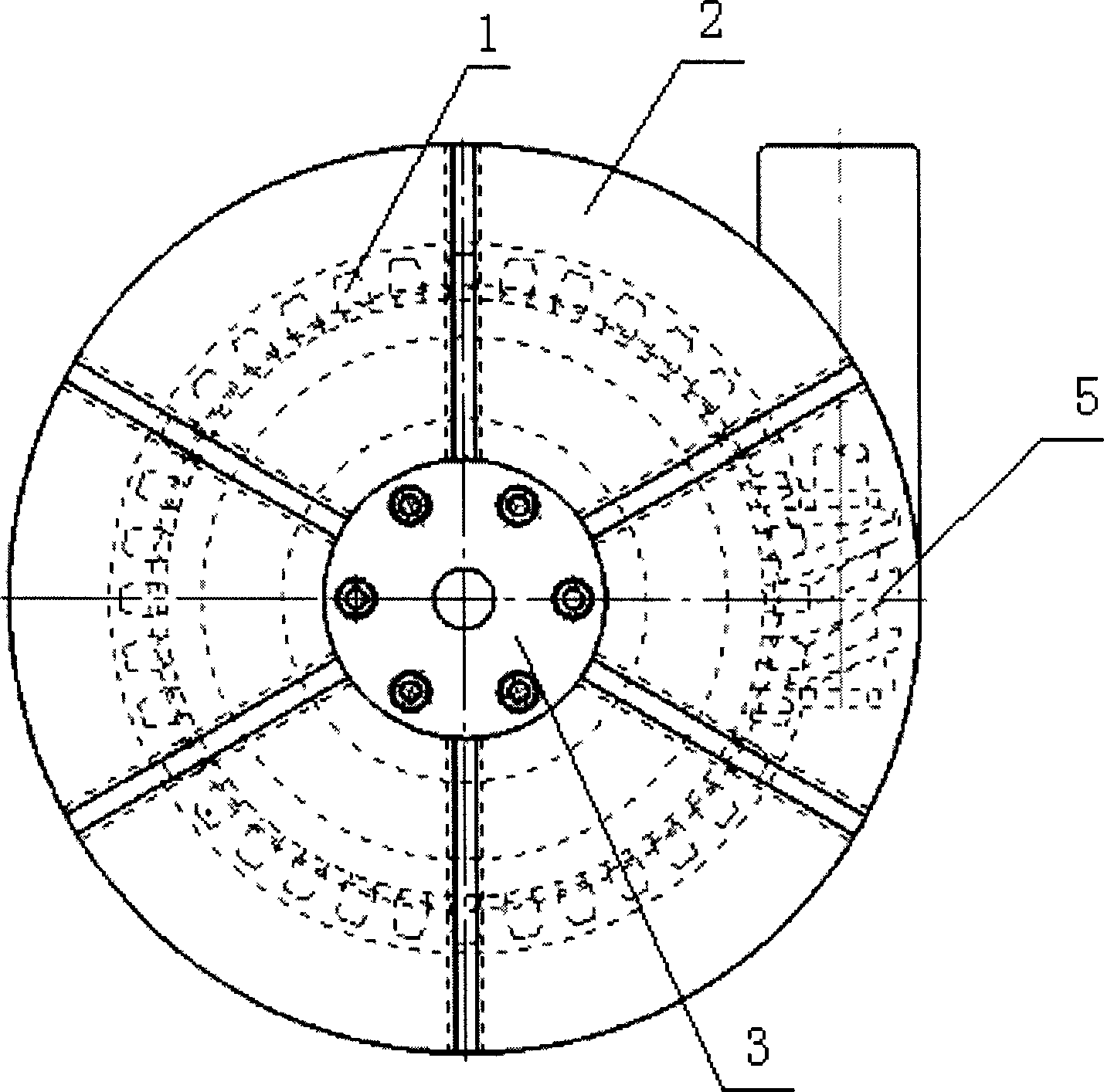

[0010] see figure 1 , 2, the present invention includes a base 6 and an indexing shaft 3 with a bearing 4, the indexing shaft 3 is set on the base 6 through the bearing 4, and a lock nut for preloading is provided at the lower end of the indexing shaft 3 7, and at the lower end of the base 6 is also provided with a baffle 8 that closes the index shaft 3, on the base 6 is provided with an index disc 2 connected with the index shaft 3, and the lower part of the index disc 2 radiates radially Uniformly distributed spherical tapered rollers 1, the spherical tapered rollers 1 mesh with the arc cam 5 set in the base 6, an incomplete inner conical table 9 is also provided on the base 6, and the spherical tapered rollers 1 are set On the inner conical table surface 9 , the inner conical table surface 9 is disconnecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com