Pneumatic brake motor and pneumatic brake method

A technology of pneumatic brake and electric motor, which is applied in the direction of electric components, mechanical energy control, brake type, etc., can solve the problems of high assembly precision, large rectifier power consumption, rectifier burnout, etc., and achieve low assembly precision and low manufacturing cost , The effect of adjustable braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

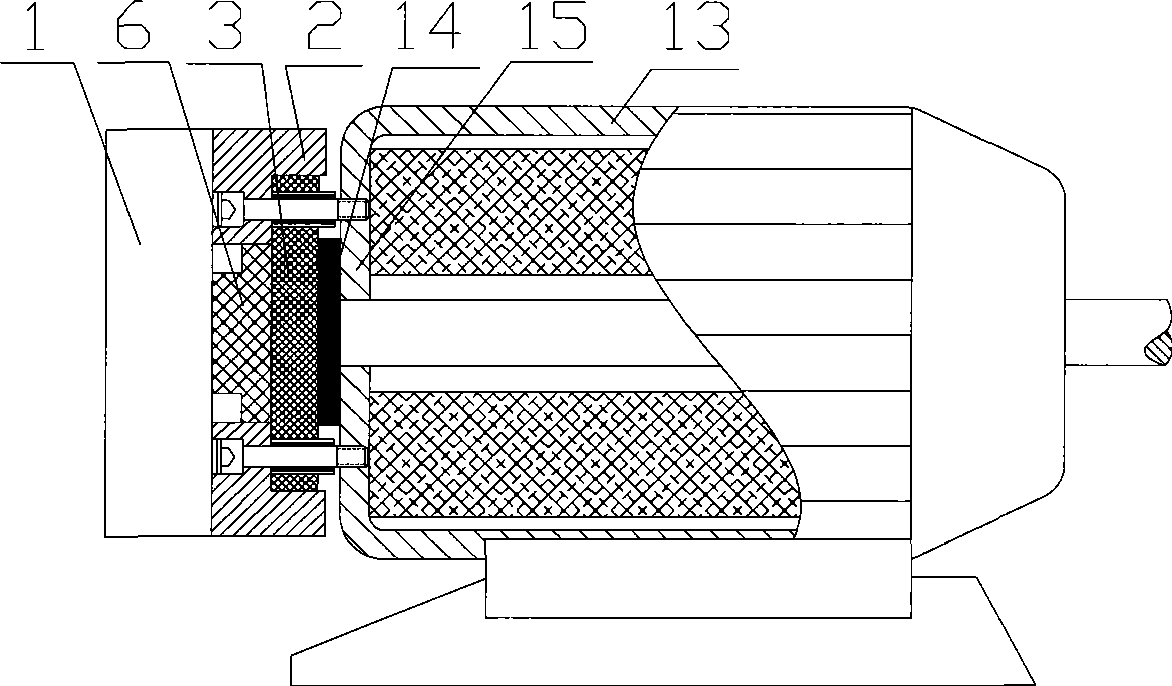

[0010] Embodiment 1: with reference to attached figure 1 and 2 . Pneumatic brake motor, the brake pad 3 is located in the groove on one side of the base 2 and the braking surface of the brake pad 3 and the friction pad 14 in the motor 13 form a brake brake cooperation, the end face of the base 2 and the end face 15 of the motor 13 The other side of the base 2 is connected to the brake cylinder 1 and the piston 6 in the brake cylinder 1 pushes the brake pad 3 to brake. There are 3 or more base countersunk bolt holes on the brake pad 3, and the movable sliding sleeve 3-1 is located in the hole of the brake pad 3 and uses the connecting screw of the base 2 and the motor as a sliding column to form a joint with the brake pad 3. Sliding fit; the base 2 is equipped with 3 or more return spring positioning bolts 2-1 and corresponds to 3 or more through holes on the brake pad 3, and the bolt rods of 3 or more bolts pass through the brake The through hole of the plate 3, the bolt ro...

Embodiment 2

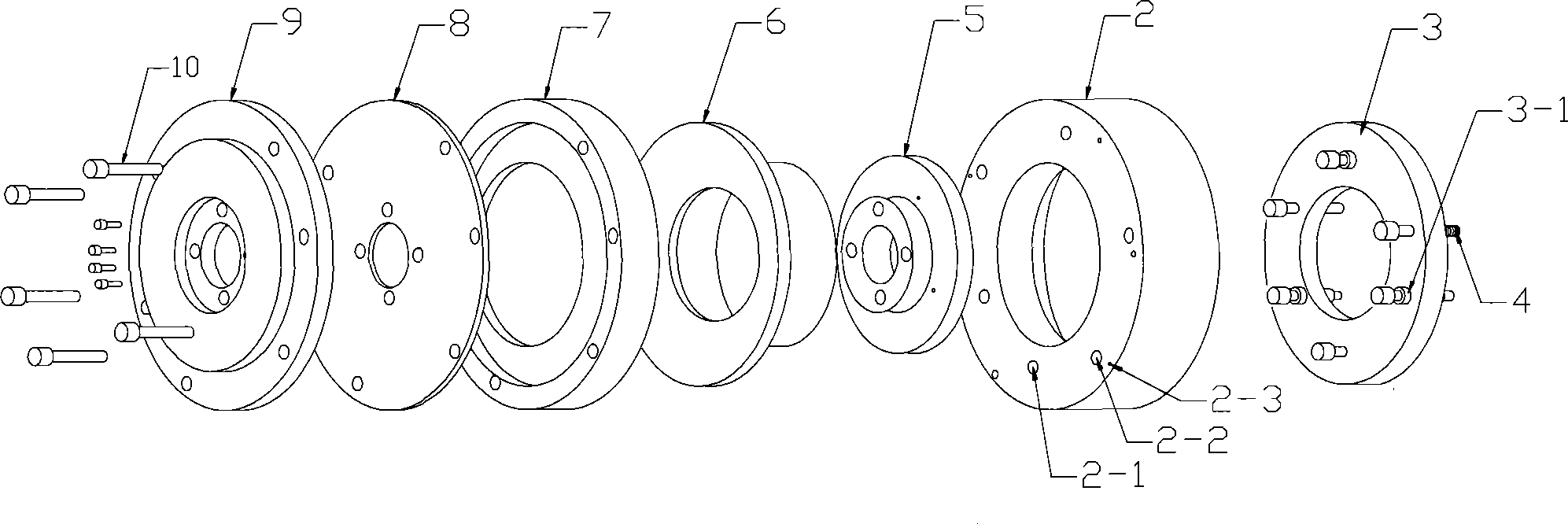

[0011] Embodiment 2: On the basis of Embodiment 1, the brake cylinder 1 is composed of a film cylinder base 9, a film 8, an outer ring flange 7, a piston 6, an inner ring flange 5, a brake pad 3 and one end surface of the base 2 The film 8 is located in the cavity formed by the film cylinder base 9, the outer ring flange 7 and the inner ring flange 5, the piston 6 is located between the outer ring flange 7 and the inner ring flange 5, the inner ring flange 5, the outer ring flange Ring flange 7, film 8 and film cylinder base 9 form a hollow shaft film cylinder through bolts 10 and 11. An annular sealed cavity is formed between them, and the air inlet 12 is arranged on the film cylinder base 9 and is communicated with the air outlet of the compressed air.

Embodiment 3

[0012] Embodiment 3: On the basis of Embodiment 1, the brake cylinder 1 can adopt an electric cylinder, and the structure of the electric cylinder belongs to the prior art, and will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com