Voice coil motor and manufacturing method thereof

A technology of a voice coil motor and a manufacturing method, which is applied in the field of cameras, can solve the problems of increasing solder paste, increasing the consumption of glue consumables, and increasing the huge risk of foreign matter generated by flux, so as to improve production efficiency and cost, avoid consumption of glue consumables, The effect of avoiding the problem of glue cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

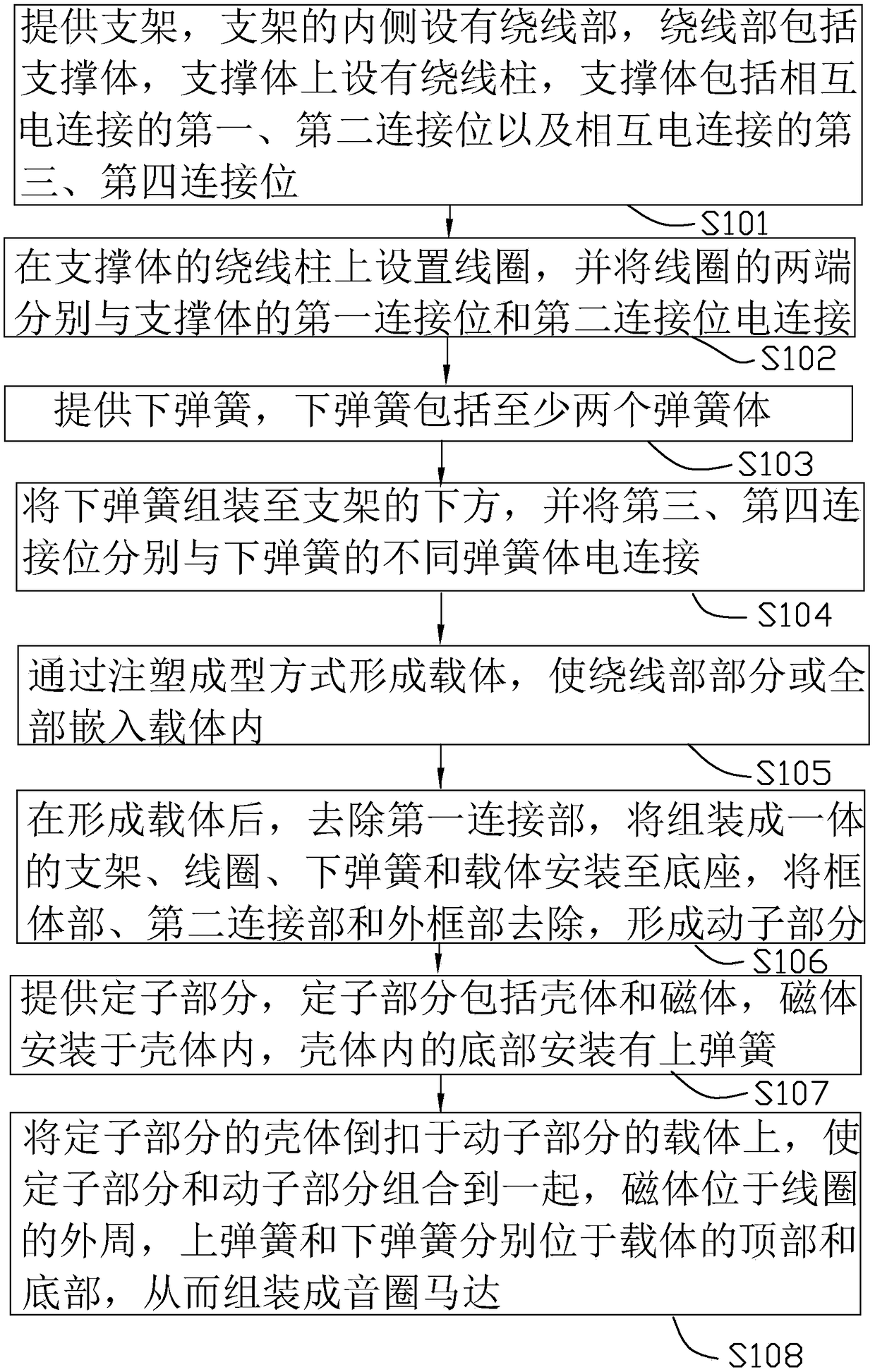

[0072] Such as figure 1 As shown, it is a flowchart of a method for manufacturing a voice coil motor provided in the first embodiment of the present invention. The method for manufacturing a voice coil motor in this embodiment includes the following steps:

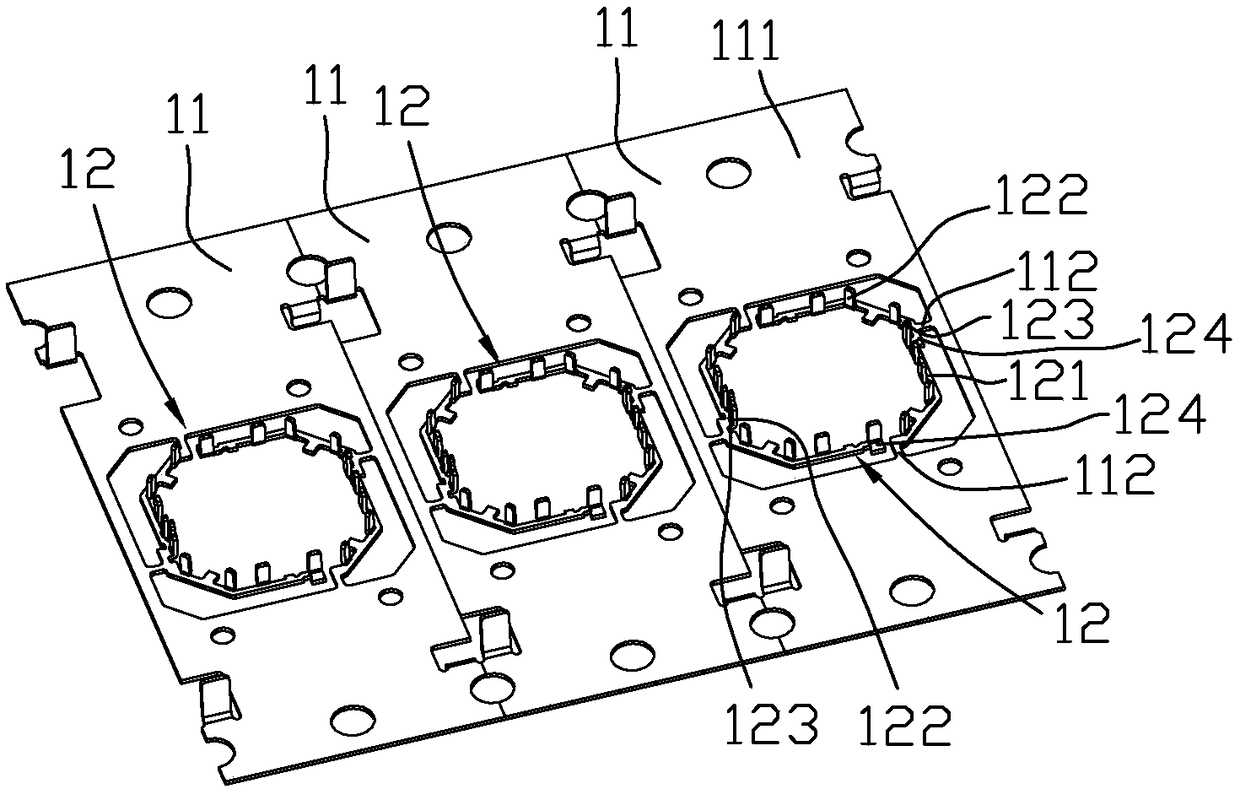

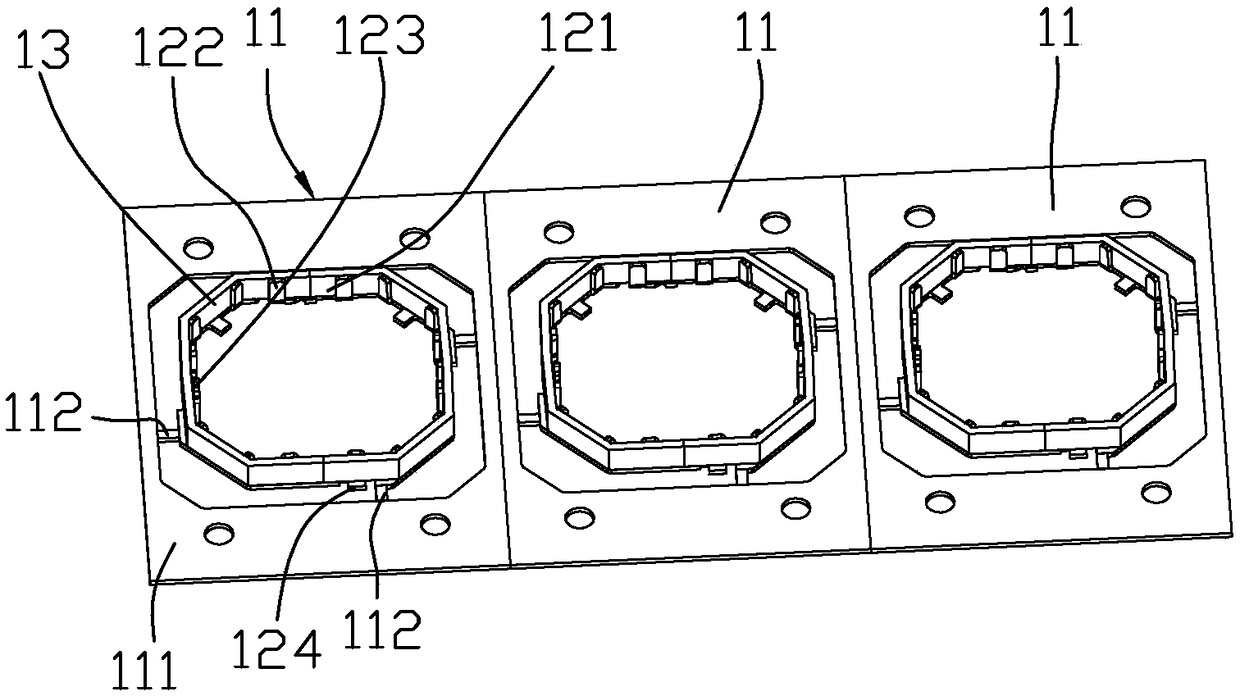

[0073] S101 , provide the bracket 11 , the inner side of the bracket 11 is provided with a winding part 12 , the winding part 12 includes a support body 121 divided into two parts, each part of the support body 121 is provided with a winding post 122 . The support body 121 includes a first connection position and a third connection position electrically connected to each other, and a second connection position and a fourth connection position electrically connected to each other. The first connection position and the second connection position are respectively located in the separated two-part support body 121 on.

[0074] In this example, if figure 2 As shown, the number of brackets 11 is multiple and connected as long...

no. 2 example

[0114] Such as Figure 11 As shown, it is a flowchart of a manufacturing method of a voice coil motor provided by the second embodiment of the present invention. The difference between this embodiment and the above-mentioned first embodiment is that in this embodiment, the winding part 12 and the lower spring 15 The plurality of spring bodies 151 are integrated, that is, the winding part 12 is directly integrated with the plurality of spring bodies 151, but in the above-mentioned first embodiment, the plurality of spring bodies 151 of the winding part 12 and the lower spring 15 are The structure is divided into two parts and the electrical connection is realized by welding between the conductive terminals 154 and 124 .

[0115] The manufacturing method of the voice coil motor of this embodiment includes the following steps:

[0116] S201, such as Figure 12 As shown, a lower spring 15 is provided. The lower spring 15 includes a plurality of spring bodies 151, and a winding p...

no. 3 example

[0147] Such as Figure 2 to Figure 10 and Figure 12-Figure 13 As shown, the third embodiment of the present invention provides a voice coil motor, including:

[0148] The winding part 12, the winding part 12 includes two support bodies 121 spaced apart from each other, and each support body 121 is provided with a winding post 122;

[0149] The coil 13 is arranged on the winding posts 122 of the two supports 121, and the two ends of the coil 13 are respectively electrically connected to the two supports 121;

[0150] The lower spring 15, the lower spring 15 includes a plurality of spring bodies 151 spaced apart from each other, the winding part 12 and the plurality of spring bodies 151 are all made of conductive materials, and the two supporting bodies 121 are different from the different spring bodies 151 of the lower spring 15 respectively. Electrical connection; it can be understood that the number of spring bodies 151 can be at least two.

[0151] The carrier 17 , the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com