Transformer tester based on programmable constant current source

A program-controlled constant current source and transformer technology, which is applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problems of unreasonable structural design, slow current adjustment speed, low detection current accuracy, etc., to achieve fast response speed and ensure normal operation. work, the effect of high current accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

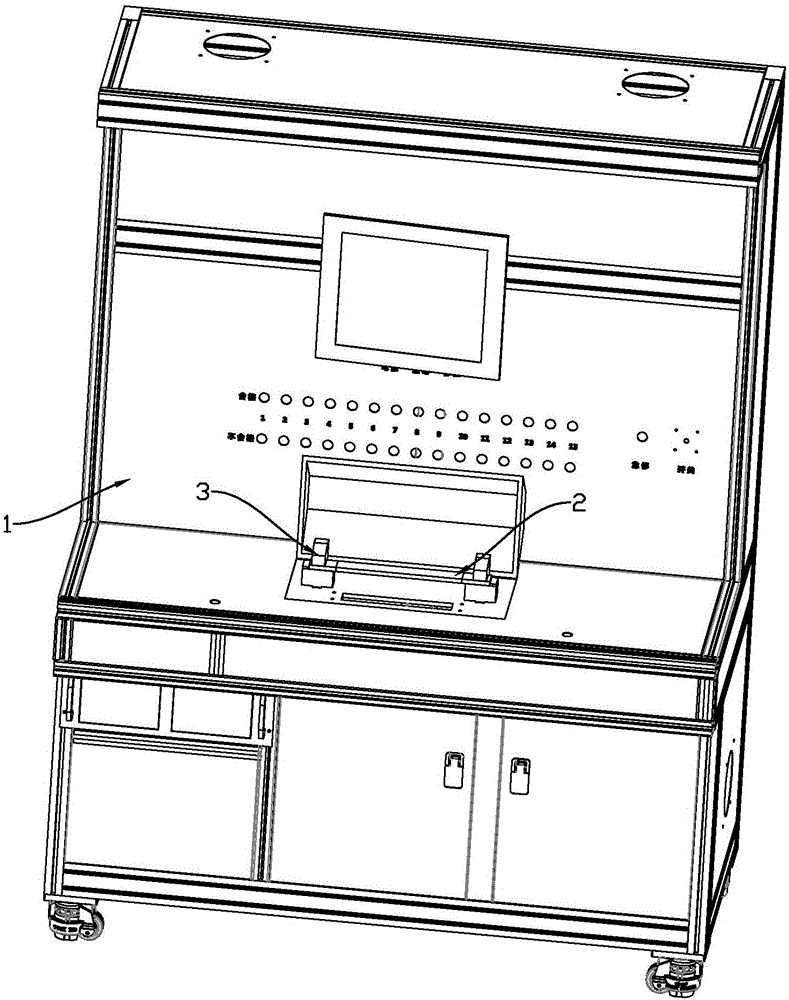

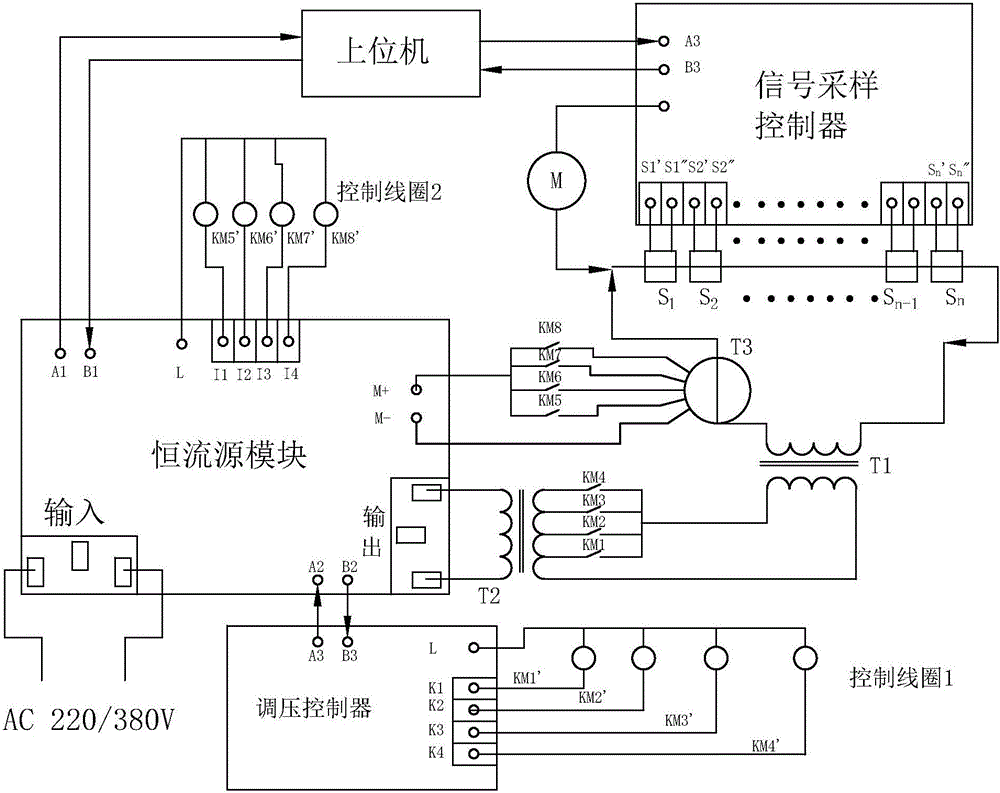

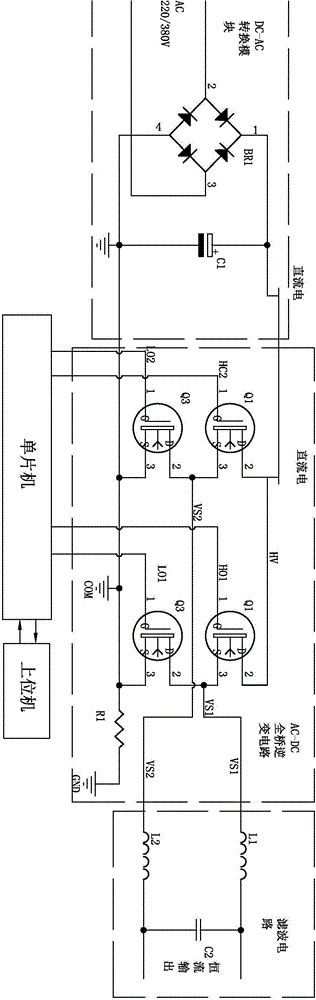

[0036] See attached figure 1 to attach Figure 5 , a transformer testing machine based on a program-controlled constant current source disclosed in the present invention includes a frame 1, a detection device arranged on the frame 1, an AC program-controlled constant current source system, and a host computer. The signal sampling controller for measuring the test signal of the transformer S and the load circuit for detection, the signal sampling controller and the upper computer are connected by communication, and the load circuit for detection is provided with a transformer loading fixture for wearing the transformer. The loading fixture includes a strip-shaped conductive plate 2 connected in series in the load circuit for detection, the two ends of the strip-shaped conductive plate 2 are electrical connection terminals 22, and the middle part of the strip-shaped conductive plate 2 is a transformer loading section 21 covered with an insulating layer; The transformer loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com