Guide rail type LED light bar socket and guide rail type LED light bar extension socket connector

An LED light bar, rail type technology, applied in the direction of conductive connection, connection, connection component installation, etc., can solve the problems of time-consuming, inconvenient power supply wiring, and different luminous brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

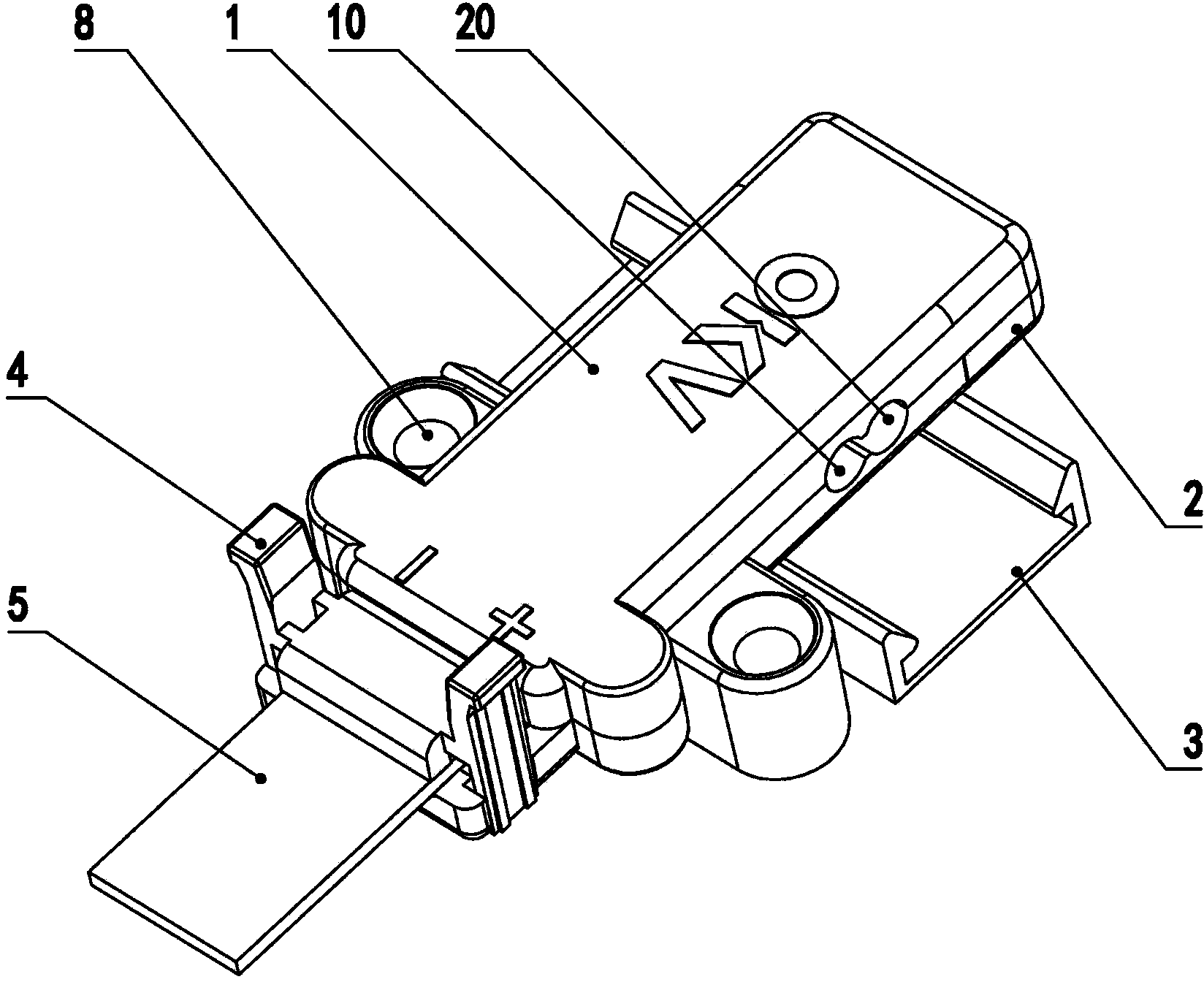

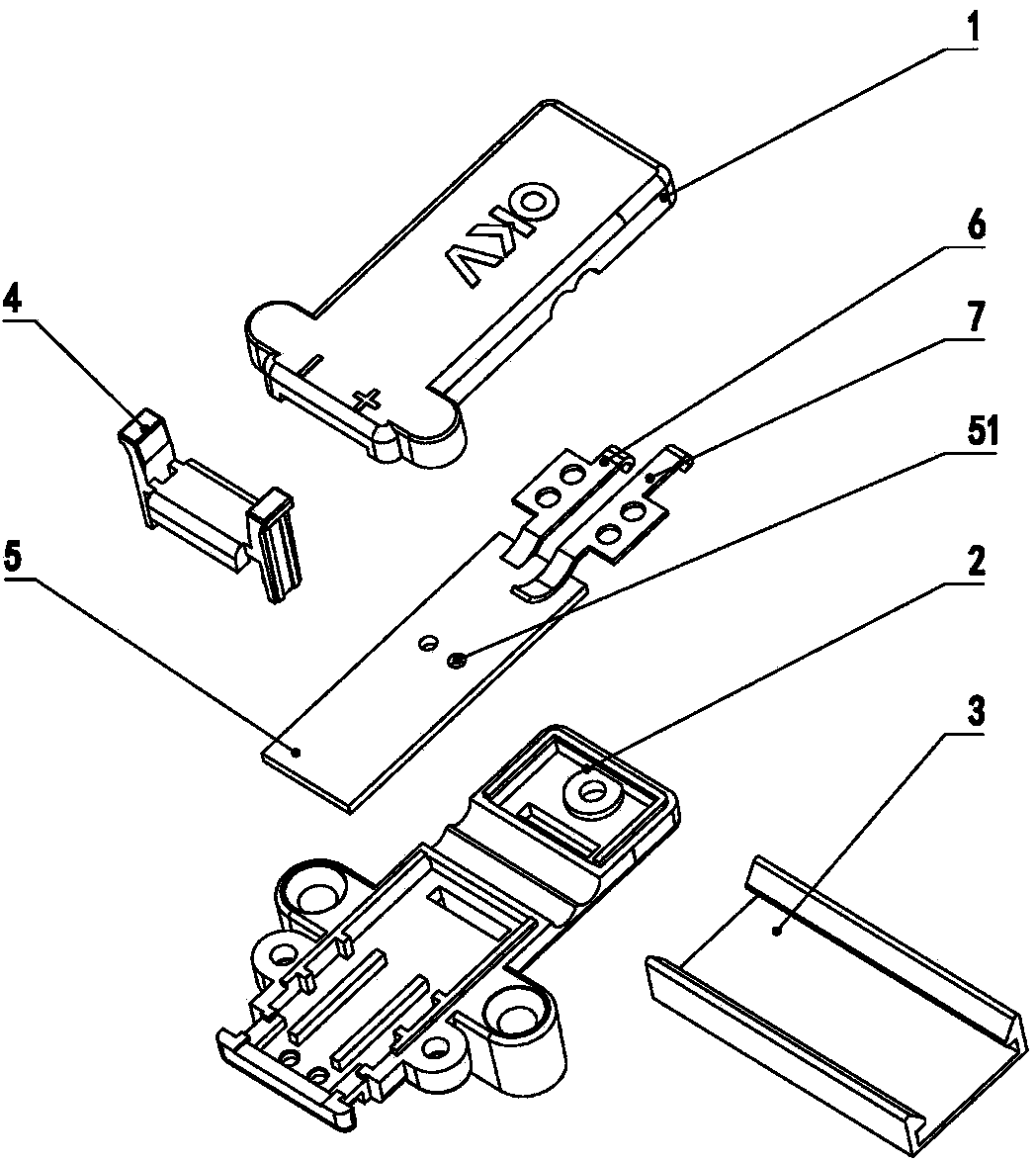

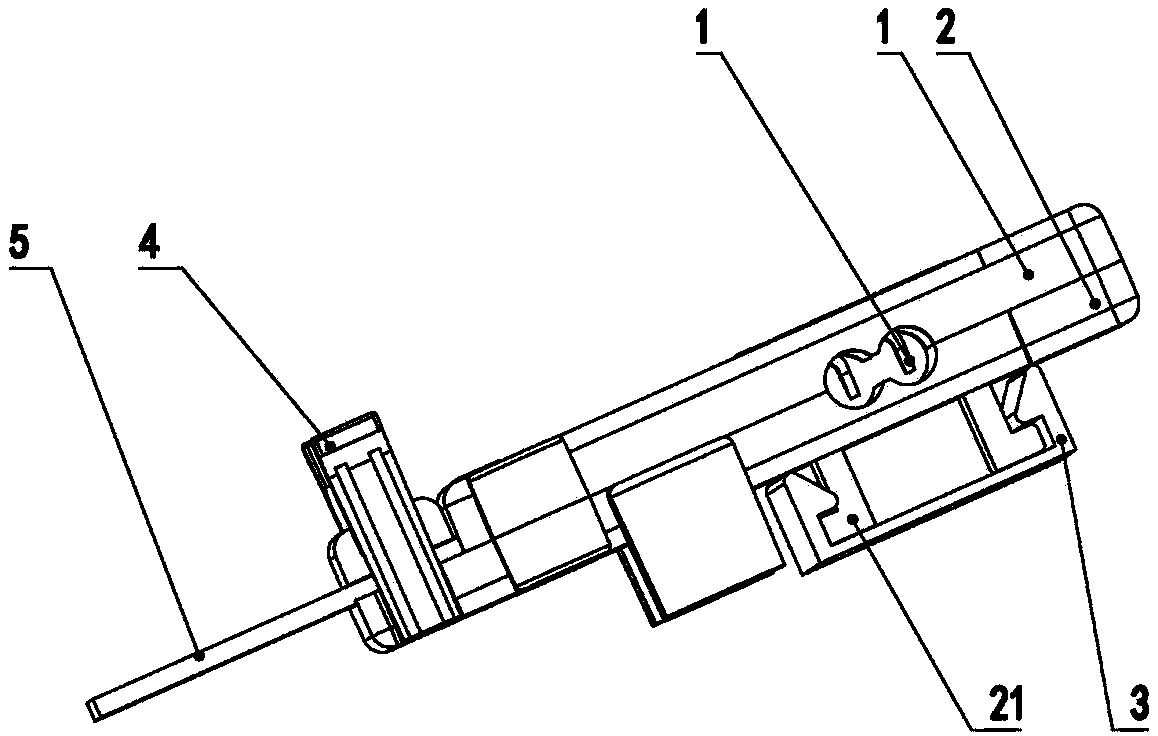

[0025] Figure 1 to Figure 8 The reference numerals in the figure are: guide rail type LED light bar socket 100; upper housing 1; lower housing 2; guide rail sliding feet 21; 4. Buckle pin 41; loose buckle wrench clip 42; fixing column 43; LED light bar 5; fixing hole 51; negative terminal 6; negative piercing protrusion 61; negative contact spring 62; positive terminal 7; positive The piercing protrusion 71 ; the positive electrode contact spring 72 ; the mounting screw hole 8 ; the wire 9 ; the negative electrode threading hole 10 ; the positive electrode threading hole 20 .

[0026] Such as Figure 1 to Figure 6 As shown, a rail-type LED light bar socket 100 includes an upper case 1, a lower case 2, a negative terminal 6 and a positive terminal 7, wherein a power supply is provided between the upper case 1 and the lower case 2. The negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com