Sound transducer comprising a plurality of single transducers and method for the production thereof

An acoustic transducer and transducer technology, which are applied in the directions of instruments, sound-producing instruments, and fluids that utilize vibration, can solve the problem that the acoustic transducer is not covered by vibration-absorbing materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In the following description of exemplary embodiments of the invention, identical or similar parts of elements are provided with the same reference symbols, wherein in individual cases a repeated description of these parts or elements is omitted. The figures show only schematically the object of the invention.

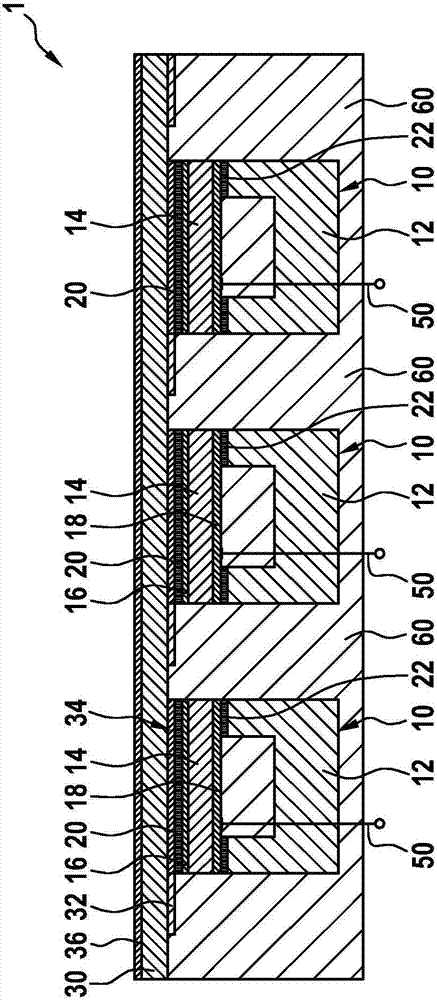

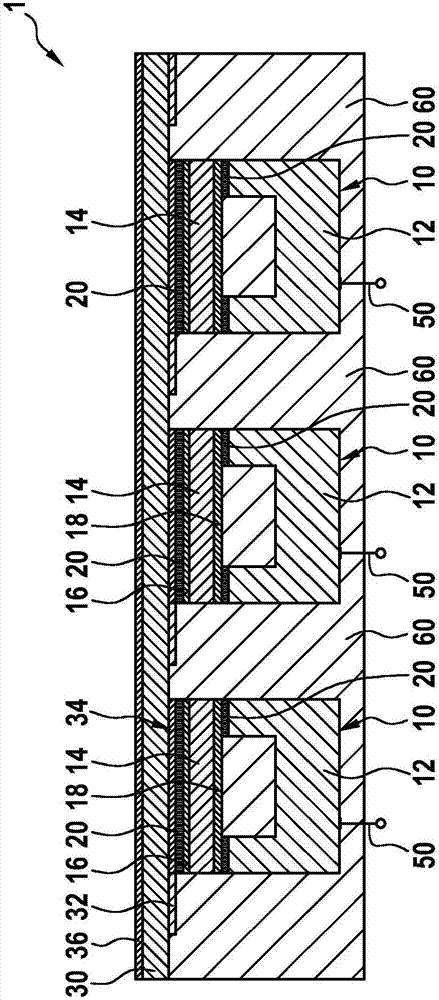

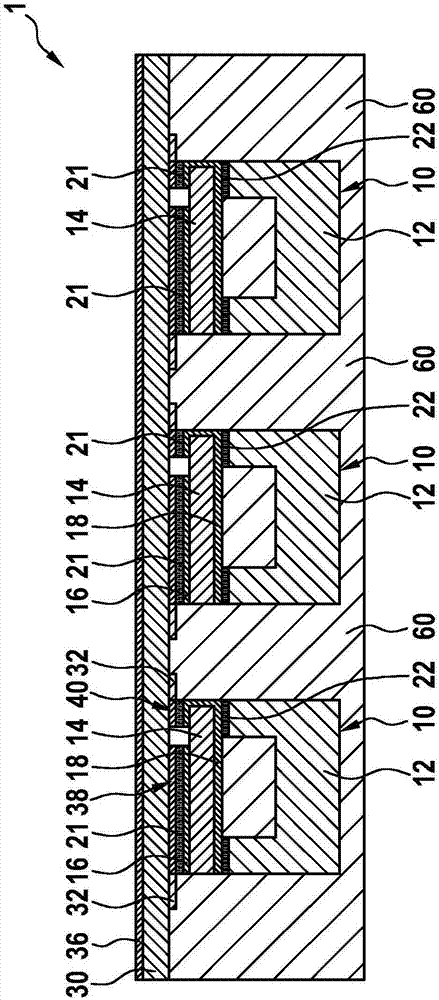

[0048] figure 1 A first embodiment of an acoustic transducer is shown.

[0049] exist figure 1 An acoustic transducer 1 is shown in FIG. 1 , which comprises, for example, three individual transducers 10 . In further embodiment variants, the sound transducer can comprise from two to two hundred and fifty individual transducers 10 .

[0050] Each single transducer 10 includes a carrier 12 and a piezoelectric element 14 . exist figure 1 In an embodiment of the present invention, the piezoelectric element 14 and the carrier 12 are embodied as separate components and are connected to each other by an adhesive 22 . The piezoelectric element 14 comprises a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com