Single-tube suction dredge

A mud suction machine and single-pipe technology, which is applied to the feeding/discharging device of the sedimentation tank, etc., can solve the problems of difficult absolute balance of the rotating structure, muddy water disturbance in the sedimentation tank, increased energy consumption and wear, etc., and achieves the basic cost. The effect of increasing, less muddy water disturbance, and reducing the total weight of the main engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

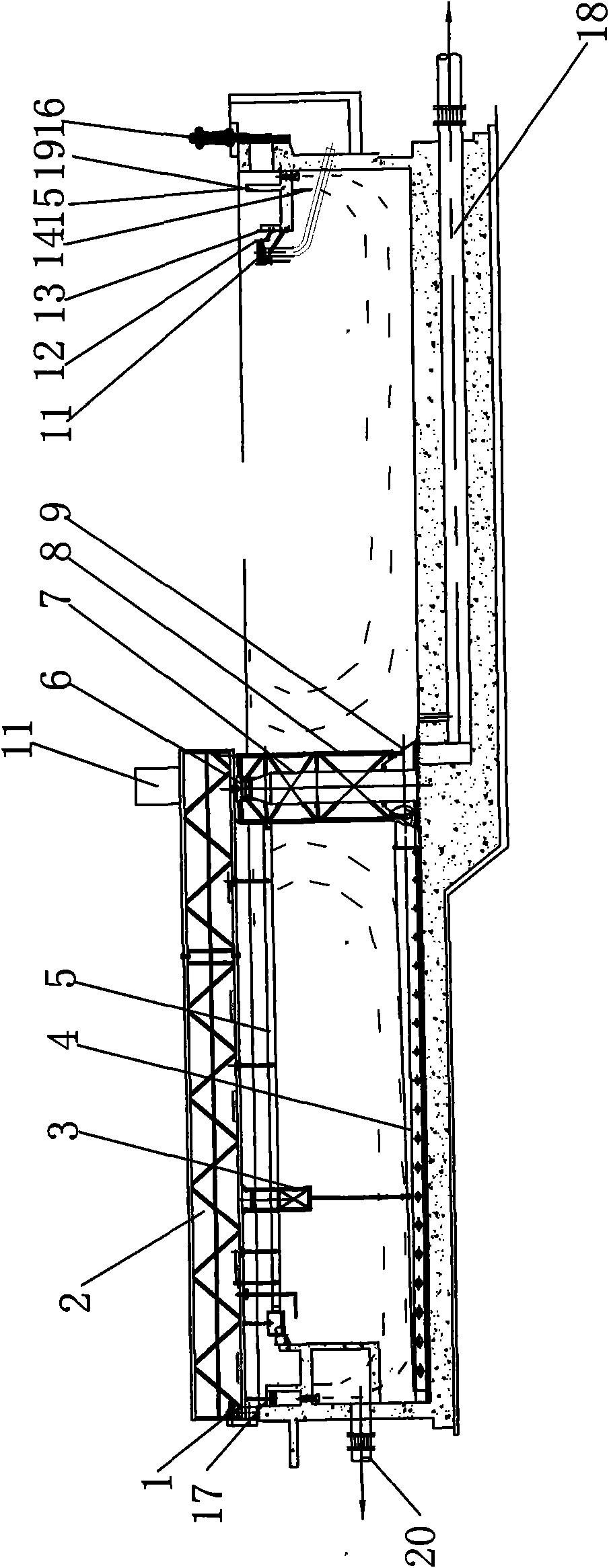

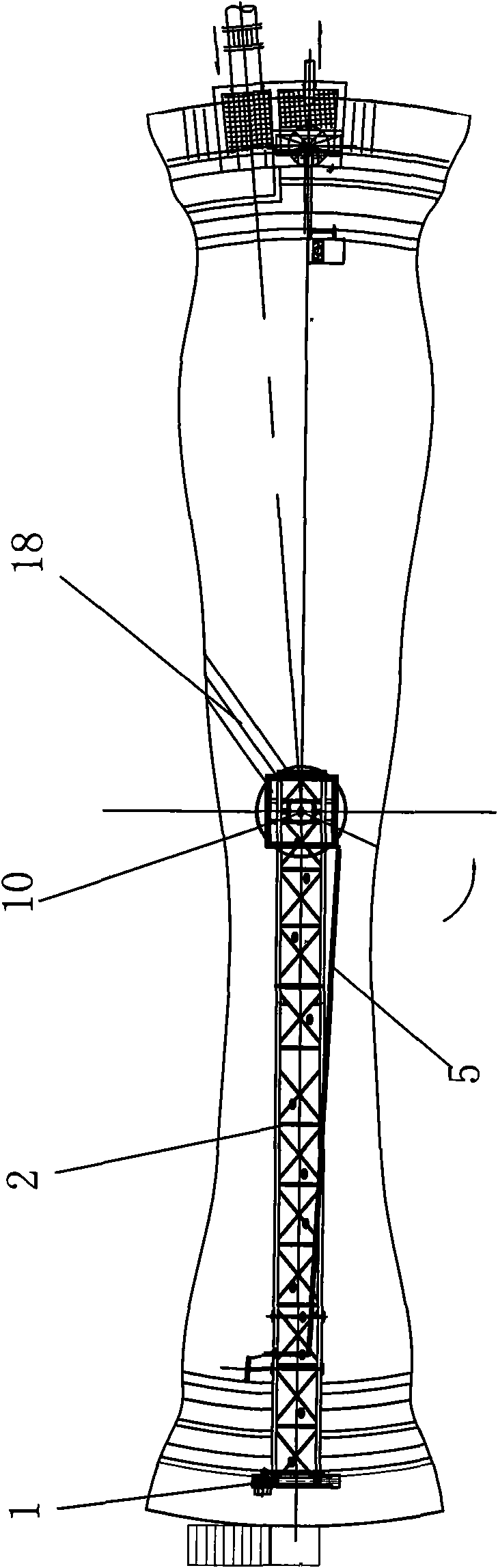

[0026] Example 1, such as figure 1 and figure 2 Shown: a single-pipe dredger, including a dredging pipe 4 arranged inside and outside the bottom of the sedimentation tank through a sealing cylinder 9 movable and sealed connection, a bridge device installed in the sedimentation tank to pull the dredging pipe 4, the sealing cylinder 8 and drive unit 1. The suction pipe 4 rotates around the center of the sedimentation tank at the bottom of the sedimentation tank. The bridge device includes a central column 7 in the fixed sedimentation tank, a central turntable 6, a working bridge 2, a central vertical frame 8, and a suction pipe pull rod 3. The central turntable 6 is movably connected to the center column 7 to form a slewing support, and the turntable is equipped with a current collector, and its upper and lower rings are respectively connected with the poolside motor cable and the central pre-embedded cable. The central turntable 6 is connected to the working bridge 2, and t...

Embodiment 2

[0027] In Embodiment 2, in order to scrape the scum on the pool surface to the scum discharge barrel and discharge it, a bridge hanging scum skimming device 5 is also installed on the working bridge 2, and the bridge hanging scum skimming device is a long baffle. All the other are with embodiment 1.

[0028] Further, the driving device is an electric trolley; the driving device 1 drives the working bridge 2 to rotate around the center column 7, and pulls the bridge hanging skimming device directly connected to the working bridge, the suction pipe pull rod, the suction pipe, and the center vertical frame And the sealing cylinder rotates.

[0029] The liquefaction plate inclined at 45 degrees between the bottom of the suction pipe 4 and the bottom of the pool is parallel to the long beam of the working bridge. There is a liquefaction plate inclined at 45 degrees between the suction pipe and the bottom of the pool, which can completely suck away even the inert sludge with a larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com