Control method of printer and printer thereof

A control method and a printer technology, which are applied in printing, transfer materials, and letter-spacing mechanisms, etc., and can solve problems such as fading printed characters and insufficient ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

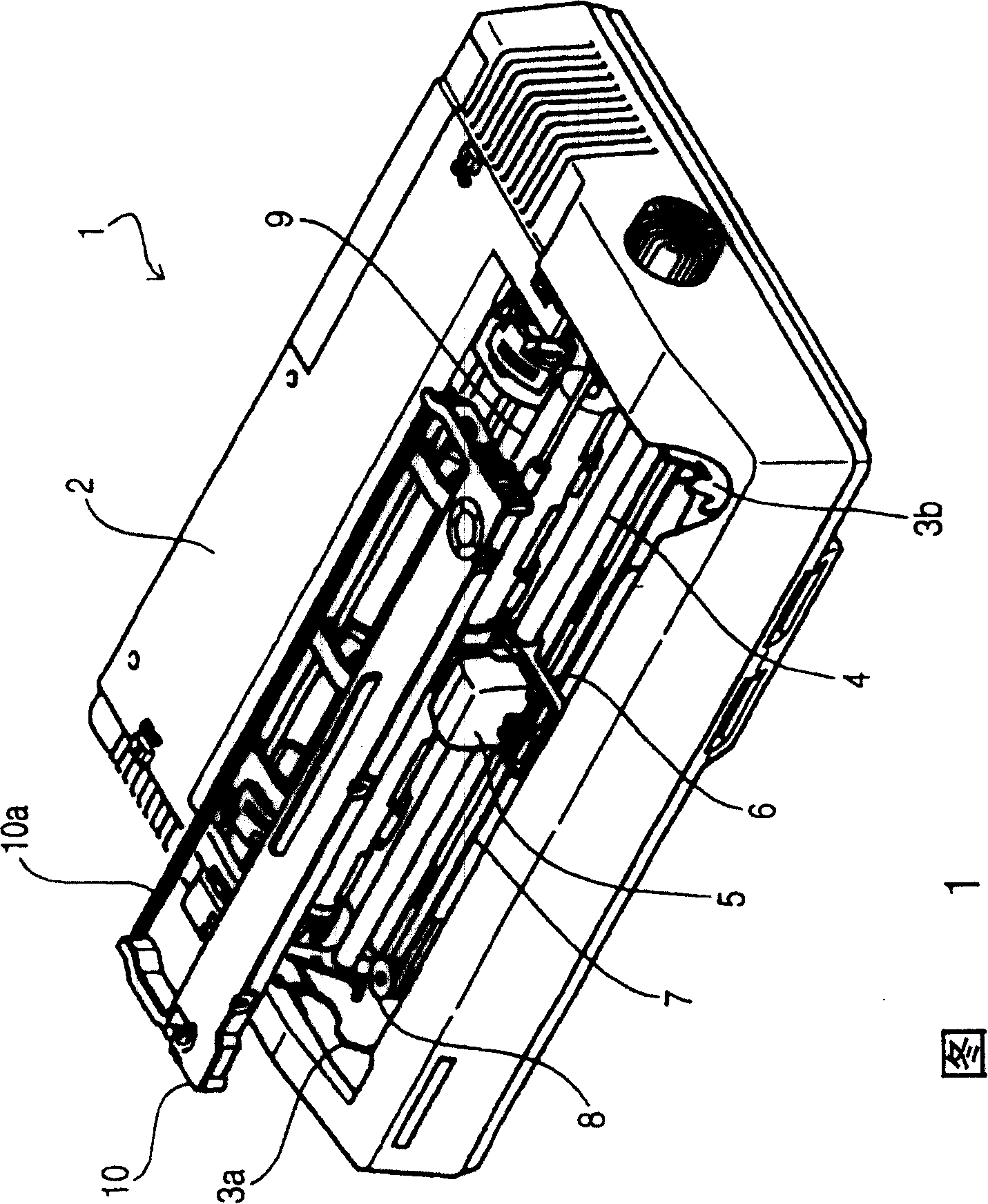

[0022] FIG. 1 shows an overall schematic diagram of a printer 1 related to this embodiment, in which reference numeral 2 denotes a casing, and 3a, 3b denote machine frames. The carriage guide 4 is supported by the machine frames 3a and 3b, and along the carriage guide 4, the carriage 6 on which the printing head 5 is mounted is supported and can freely move back and forth. The carriage 6 is fixed on a section of synchronous belt 7 arranged below it, and will also move back and forth following the back and forth movement of the synchronous belt 7 . The timing belt 7 is wound around a driven pulley 8 and a driving pulley (not shown), and the carriage 6 is driven by a carriage driving motor 41 (see FIG. 5 ) that rotates the driving pulley. The carriage drive motor 41 and the timing belt 7 are the carriage drive mechanism at this time.

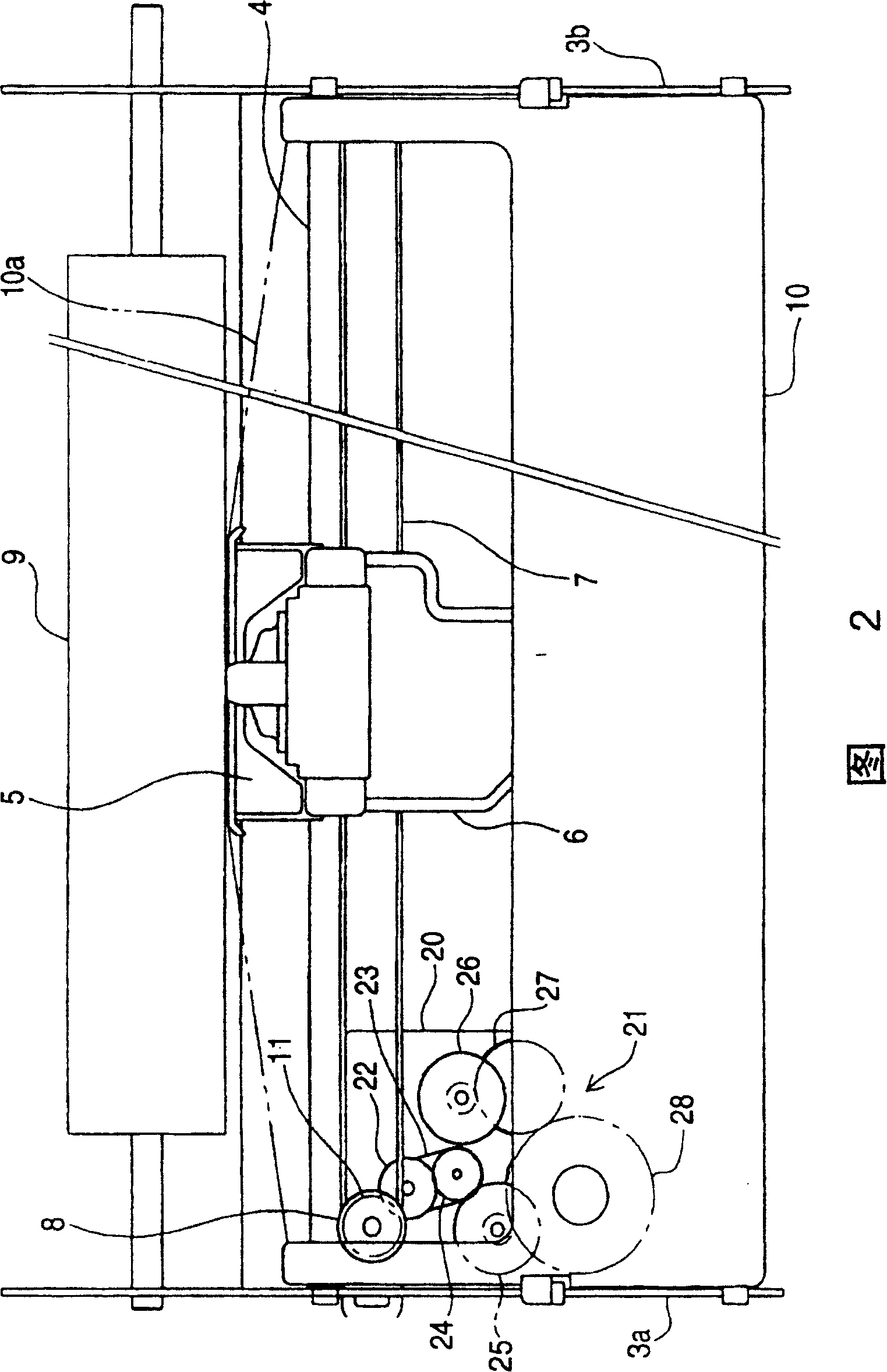

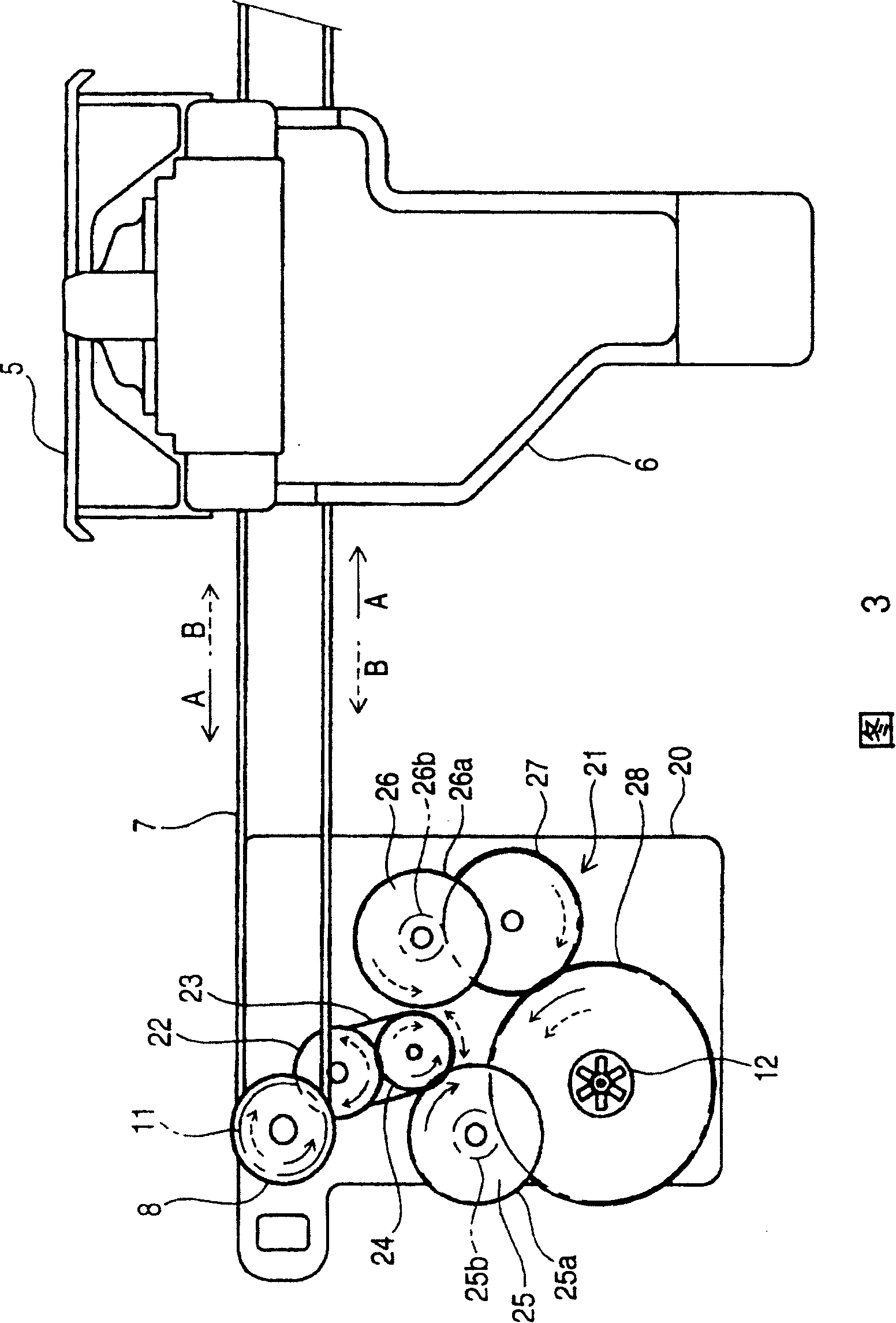

[0023] FIG. 2 is a plan view sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com