Novel electric safety locking device

A safety lock, electric technology, applied in the direction of electric locks, electric car locks, building locks, etc., can solve the problems that the locking action is not in place, can not apply to non-compressed air source, does not have reverse self-locking, etc., to achieve locking maintain reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments.

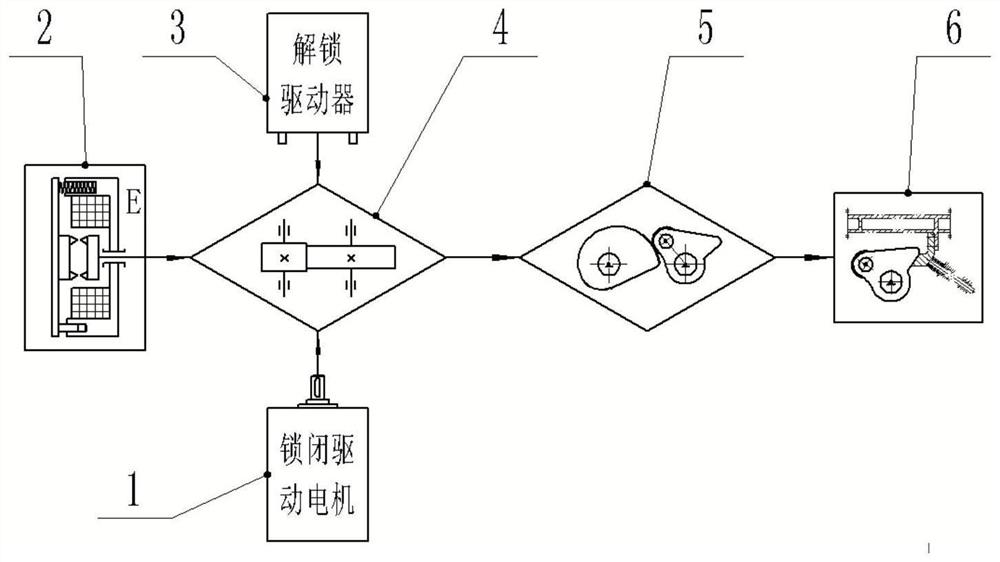

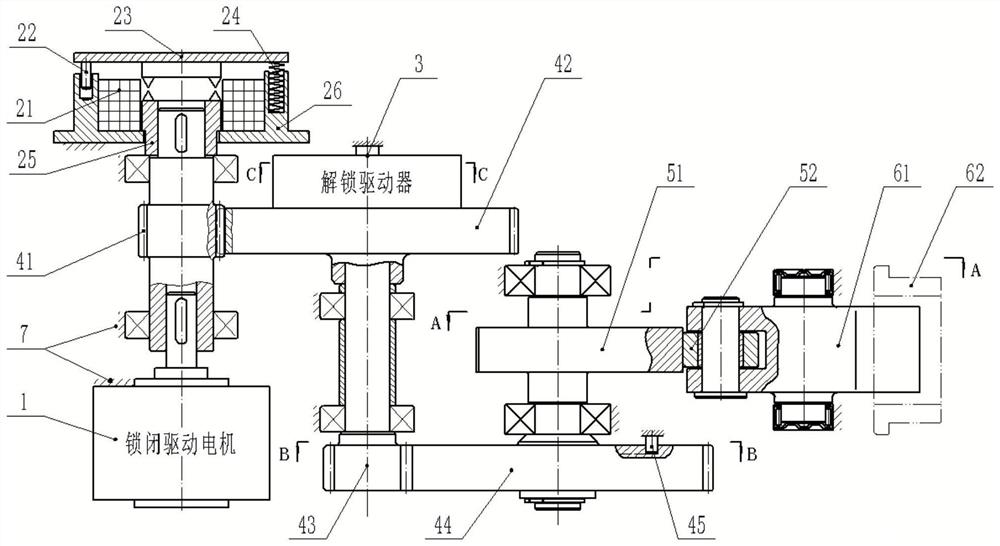

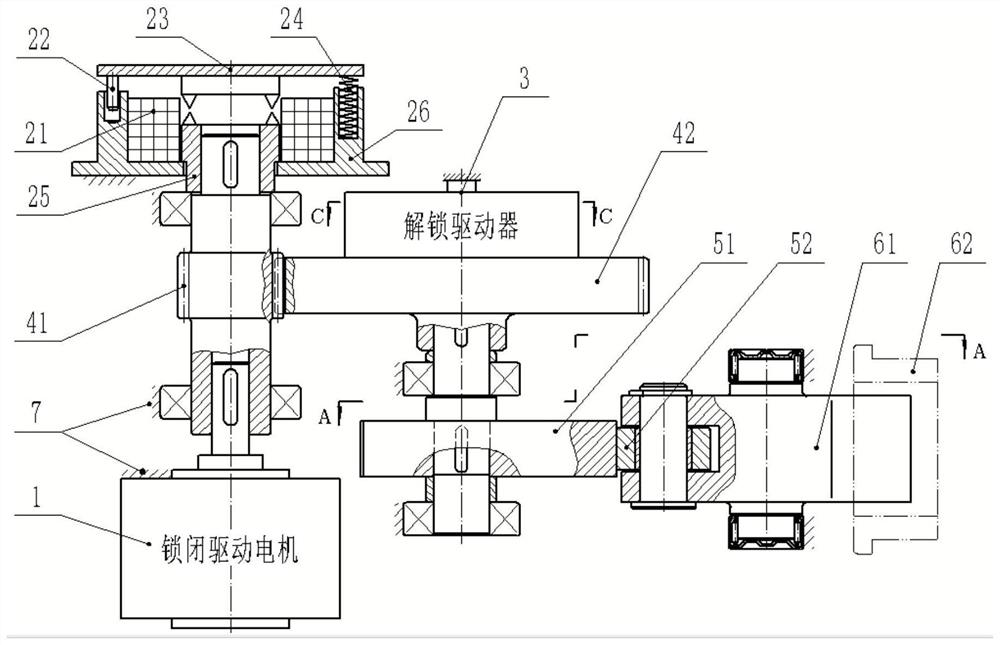

[0035] The first specific example is figure 1 and figure 2 As shown, a new electric safety locking device includes a locking drive motor 1, a locking brake 2, an unlocking driver 3, a fixed speed ratio transmission mechanism 4, a variable speed ratio actuator 5 and an actuator 6;

[0036] like figure 2 As shown, the constant speed ratio transmission mechanism 4 includes a high-speed pinion 41, a high-speed bull gear 42, a low-speed pinion 43 and a low-speed bull gear 44; 61 and its locking operation object lock 62;

[0037]The high-speed pinion 41 is fixedly nested on the output shaft of the locking drive motor 1, the high-speed pinion 41 is engaged with the high-speed bull gear 42 for transmission, and the high-speed bull gear 42 and the low-speed pinion 43 are coaxial Rotate, the low-speed pinion gear 43 and the low-speed bull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com