Dumping mechanism of welding positioner

A welding positioner and turning mechanism technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor stability, unstable rotation, affecting the use of welding positioner, etc., and achieve stable rotation. , Simple structure, safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

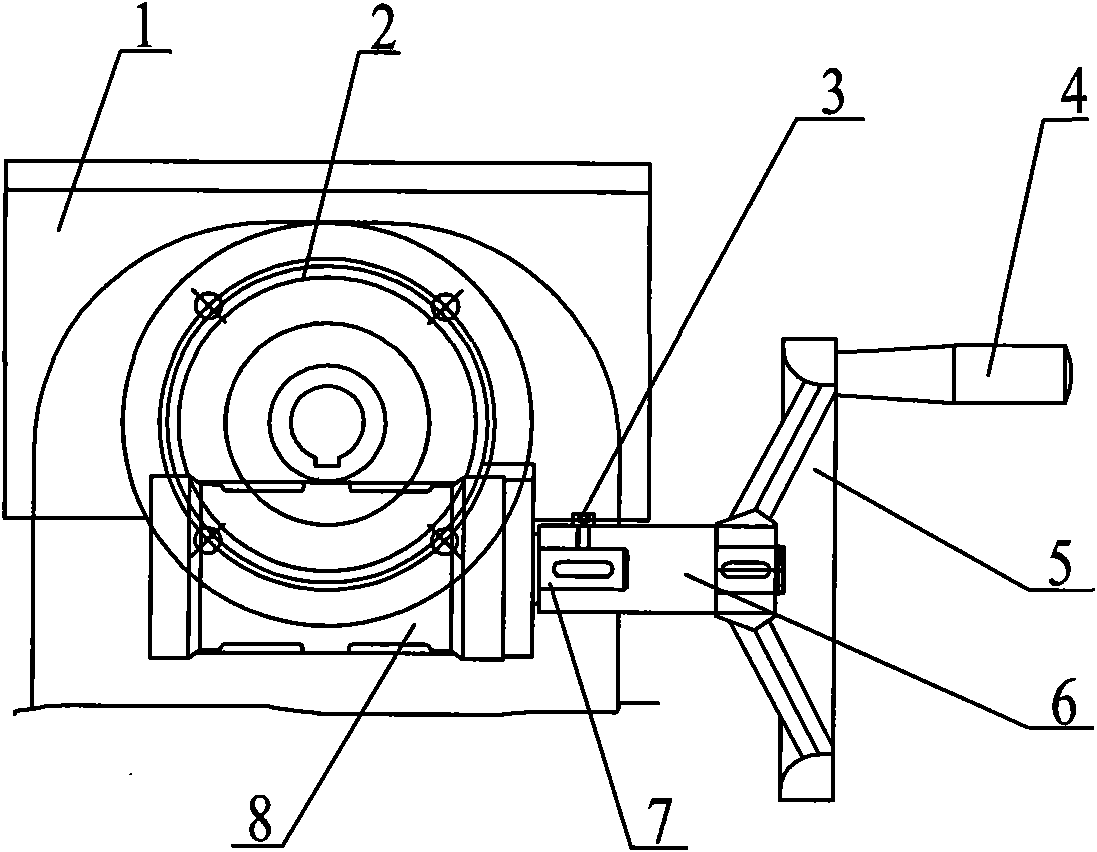

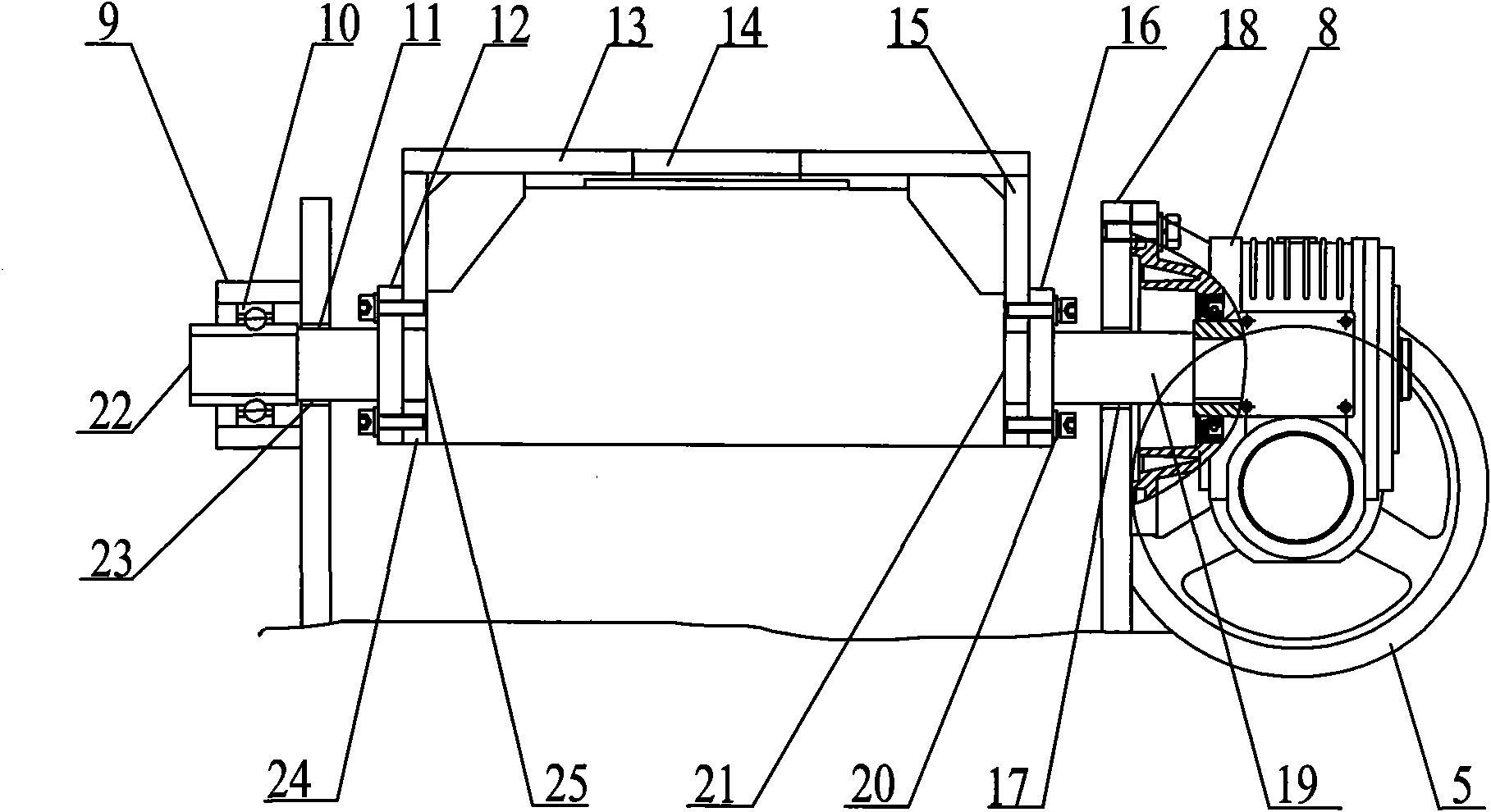

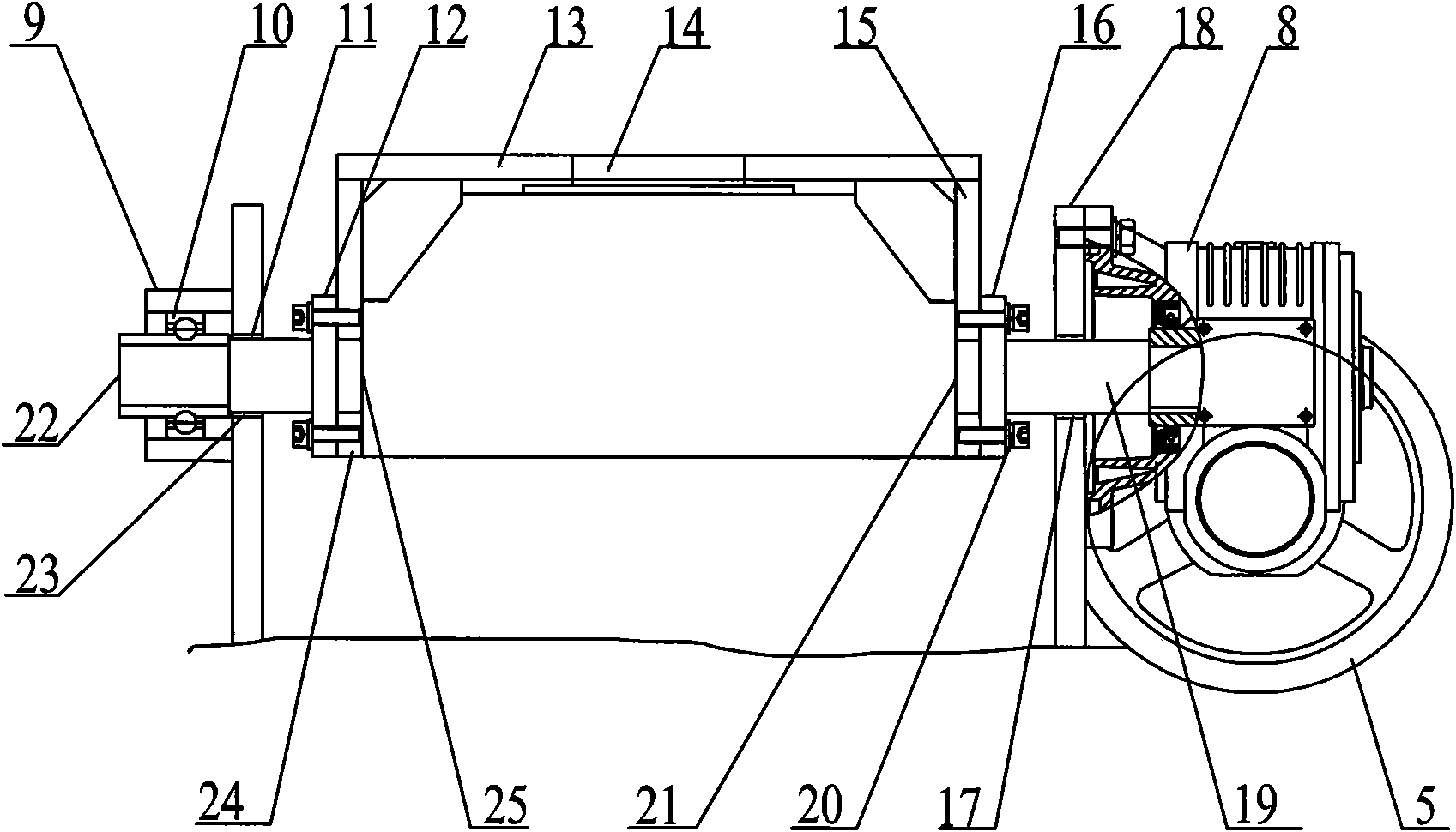

[0011] Such as Figure 1 ~ Figure 2 Shown: The present invention includes a turning seat 1, a work surface 2, a bolt 3, a rotating handle 4, a hand wheel 5, a long shaft 6, an input shaft 7, a reducer 8, a bearing seat 9, a bearing 10, a second turning shaft 11, The second fixing plate 12, the side plate 13, the positioning hole 14, the first end plate 15, the first fixing plate 16, the first connecting hole 17, the frame 18, the first turning shaft 19, the screw 20, the first installation The hole 21, the connecting body 22, the second connecting hole 23, the second end plate 24 and the second mounting hole 25.

[0012] Such as figure 1 with figure 2 As shown: the turning base 1 is located in the frame 18, and the turning base 1 can be turned relative to the inside of the frame 18. The turning base 1 includes two side plates 13 and two end plates. The end plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com