Patents

Literature

65results about How to "Small reduction ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

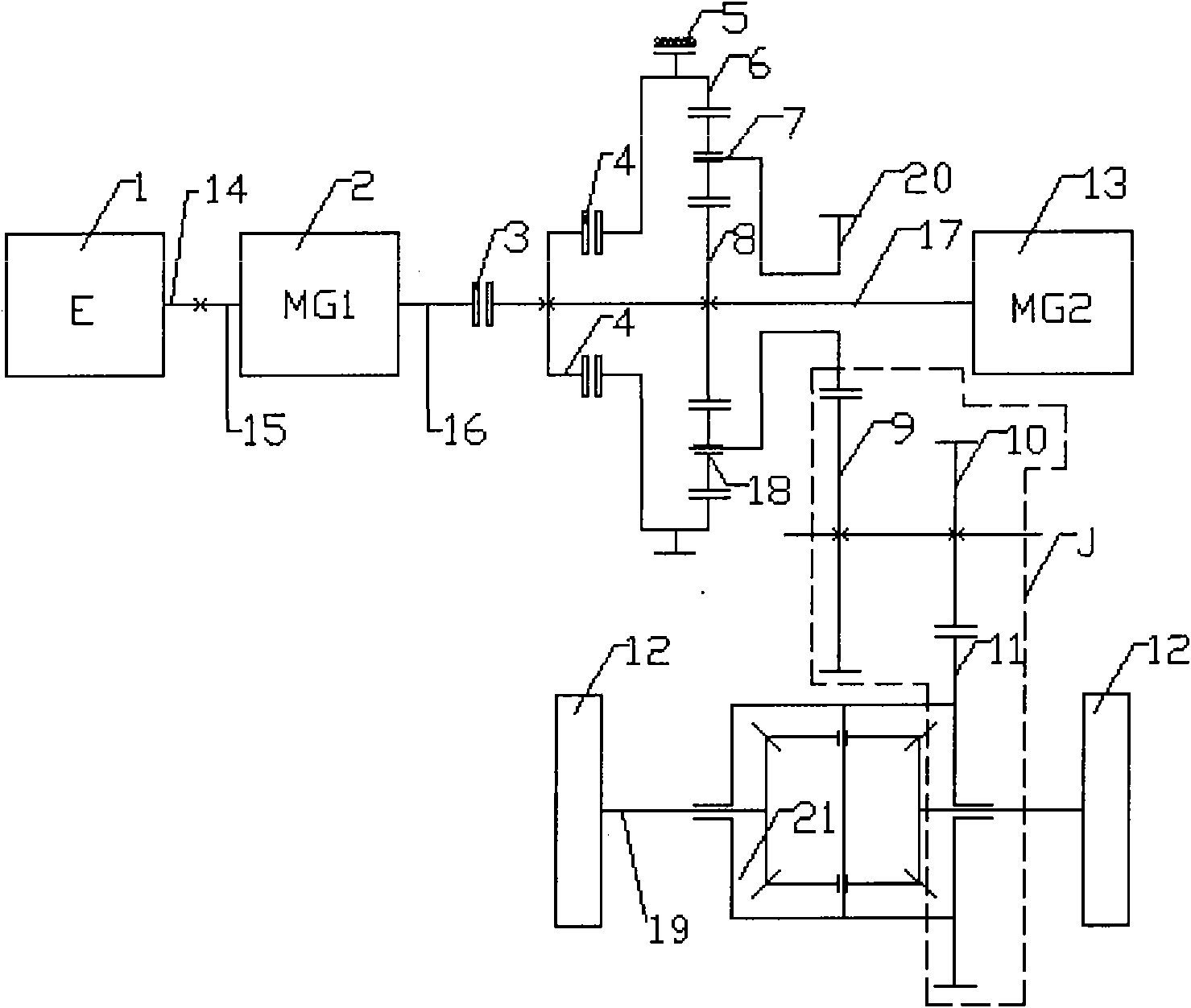

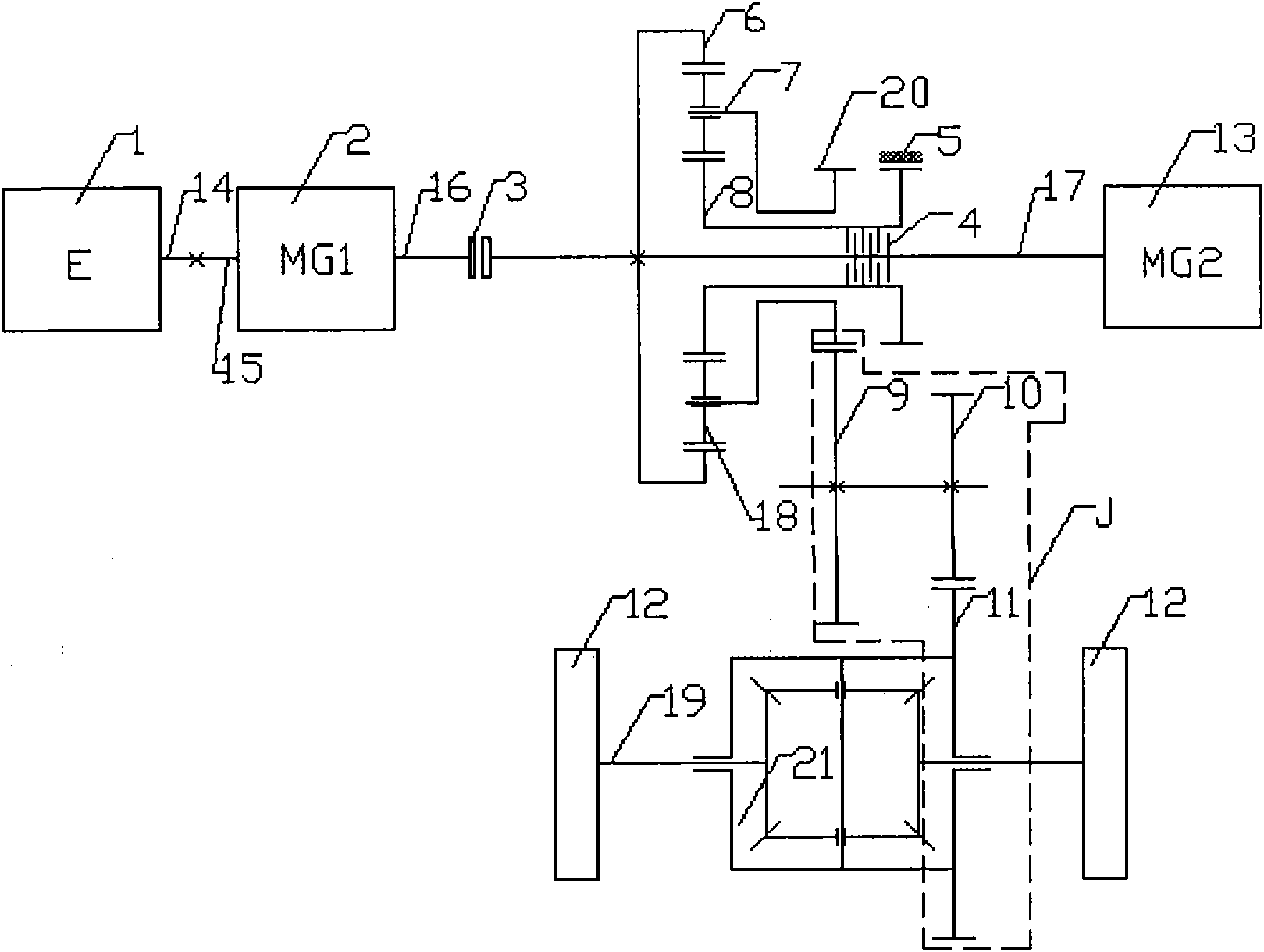

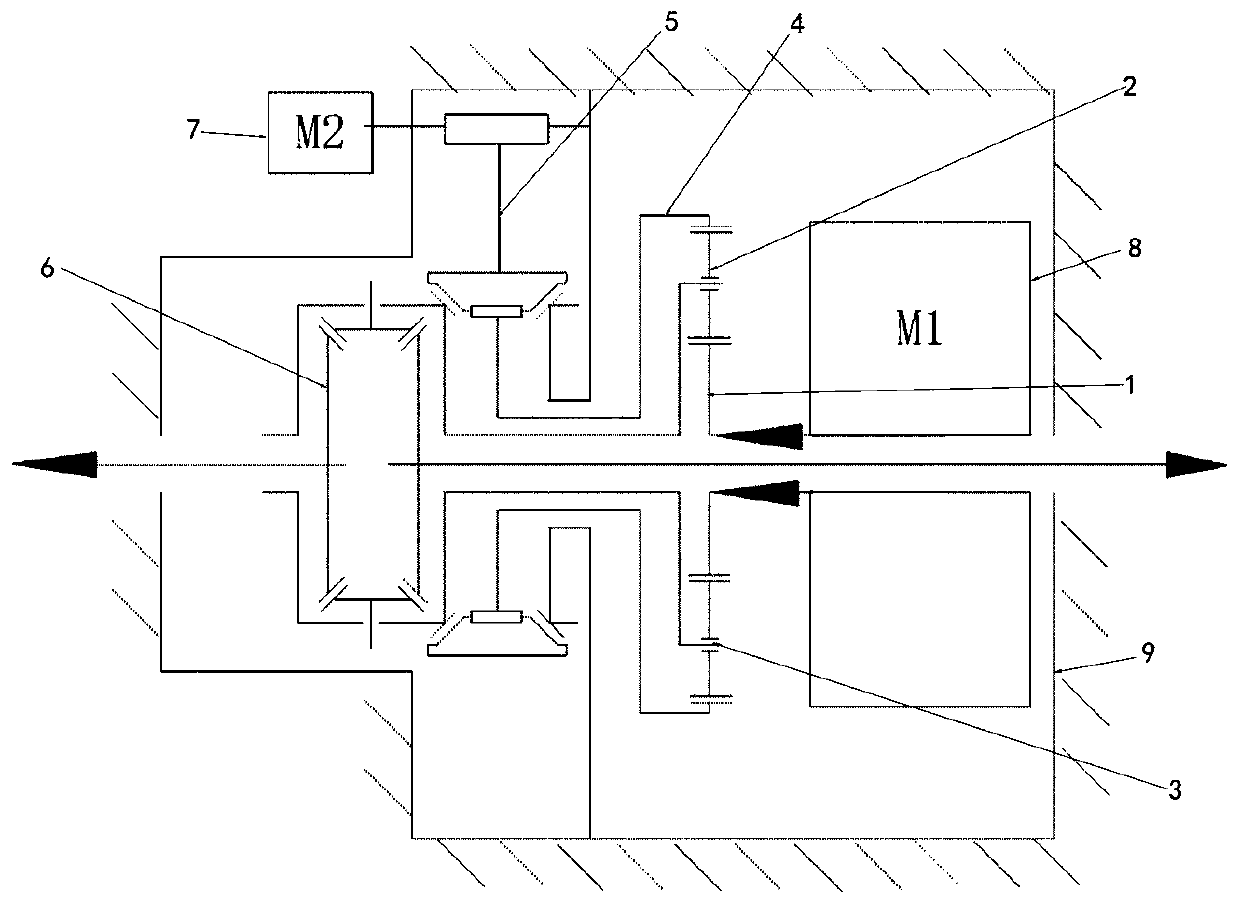

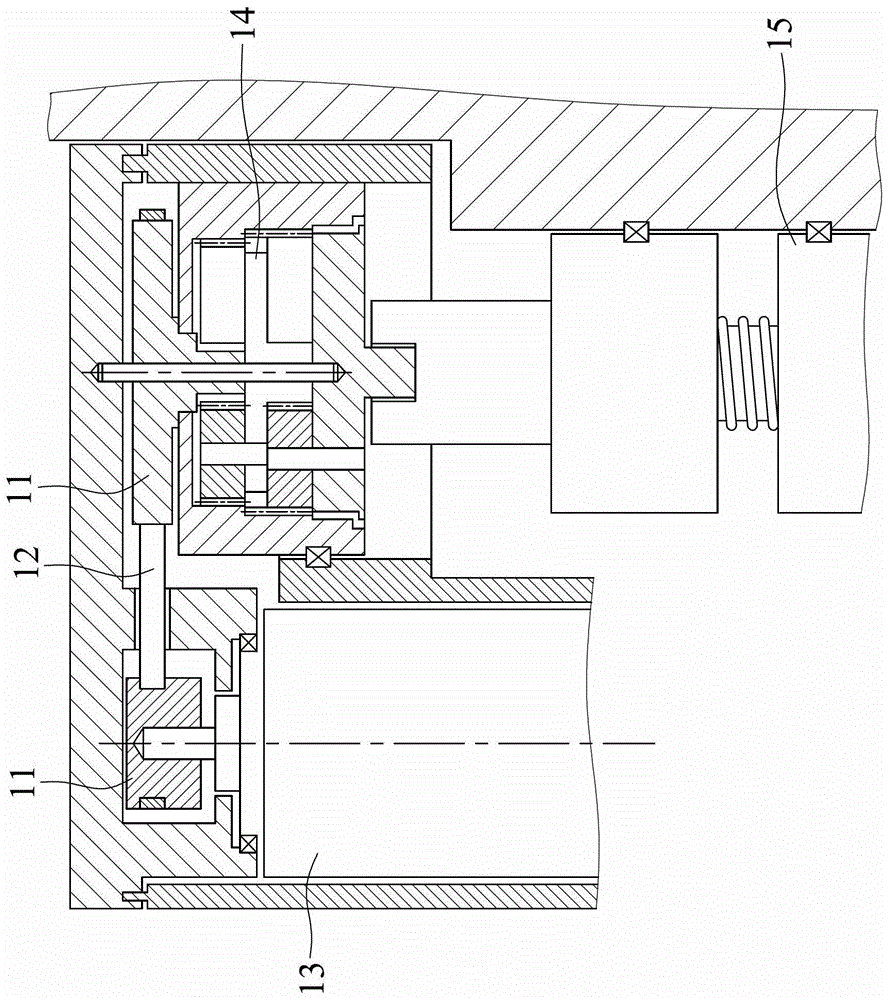

Hybrid driving system for automobile and gear operating method thereof

ActiveCN102107604ASmall reduction ratioReduce in quantityHybrid vehiclesToothed gearingsCouplingInternal combustion engine

The invention relates to a hybrid driving system and a gear operating method thereof. The system comprises an internal-combustion engine, a first motor, a second motor, a planet coupling mechanism, a retarding mechanism and a differential mechanism, wherein an output shaft of the internal-combustion engine is connected with an input shaft of the first motor; an output shaft of the first motor is connected with an output shaft of the second motor by a first clutch; and the output shaft of the second motor is connected with one of a sun wheel and a gear ring of the planet coupling mechanism at the position of the axial direction of the output shaft, and output shaft of the second motor is connected with the other one of the sun wheel with a brake and the gear ring by a second clutch at the other position of the axial direction of the output shaft. In the hybrid driving system, two gear levels of forward gears of an automobile are formed by adjusting the planet coupling mechanism, so that operating modes and corresponding gears are selected flexibly according to different running work conditions of the automobile to achieve the effects of low emission and oil consumption, high kinetic energy and the like of the integral automobile.

Owner:BYD CO LTD

Hollow series-connection mechanical arm

The invention discloses a hollow series-connection mechanical arm. The hollow series-connection mechanical arm comprises a plurality of modularized joints and a base, wherein the rotating end of the first modularized joint is vertically and rotationally connected with the base, the fixed end of the first modularized joint is fixedly connected with the rotating end of the second modularized joint, the fixed end of the second modularized joint is fixedly connected with one end of a first connecting arm, the other end of the first connecting arm is fixedly connected with the fixed end of the third modularized joint, the rotating end of the third modularized joint is fixedly connected with the fixed end of the fourth modularized joint, the rotating end of the fourth modularized joint is fixedly connected with one end of a second connecting arm, the other end of the second connecting arm is fixedly connected with the fixed end of the fifth modularized joint, and the rotating end of the fifth modularized joint is fixedly connected with the fixed end of the sixth modularized joint. The hollow series-connection mechanical arm of the structure is low in self weight, large in weight-power ratio, lower in energy consumption and simple in structure, and the self weight can be reduced easily.

Owner:TIANJIN UNIV

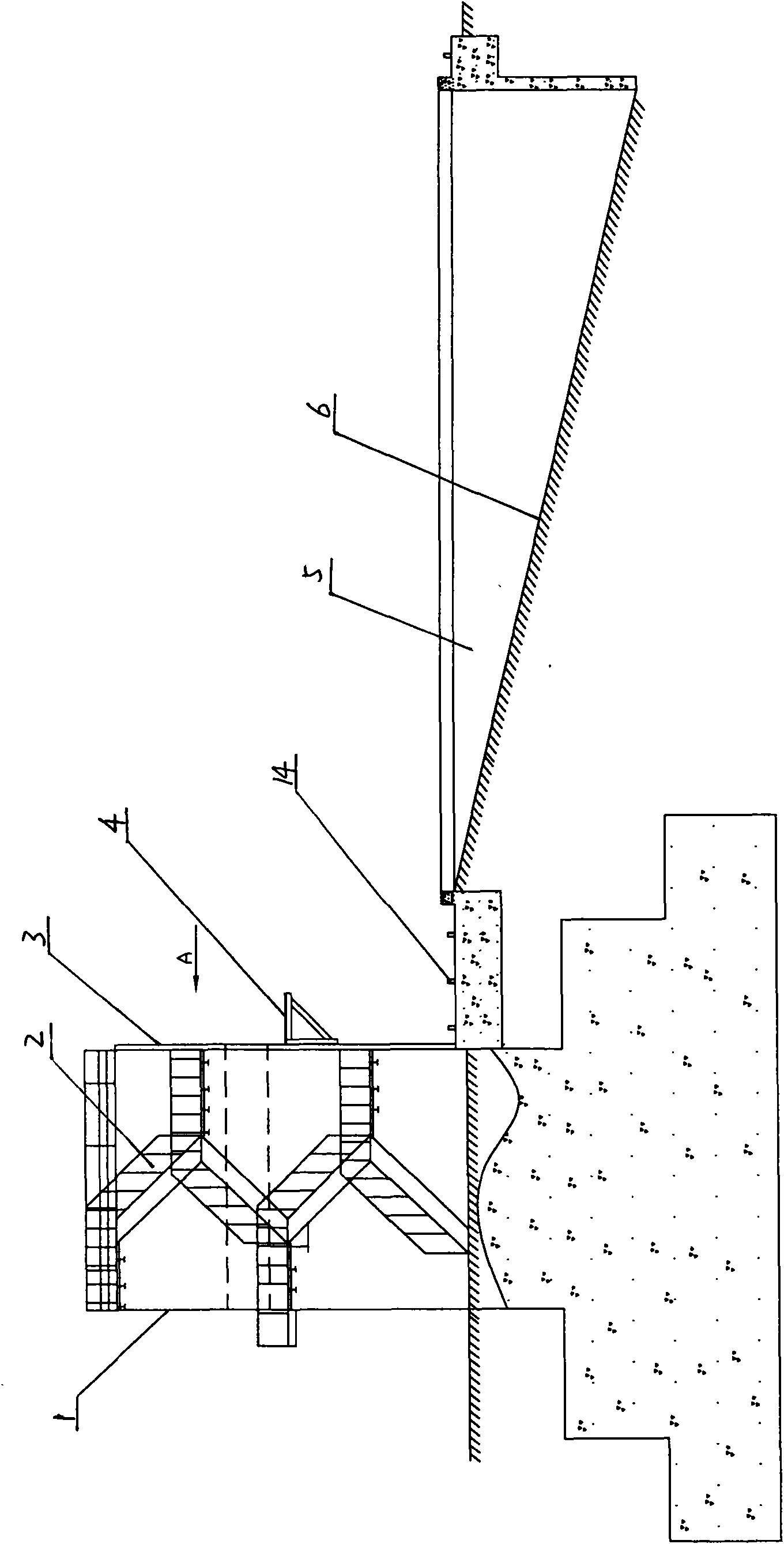

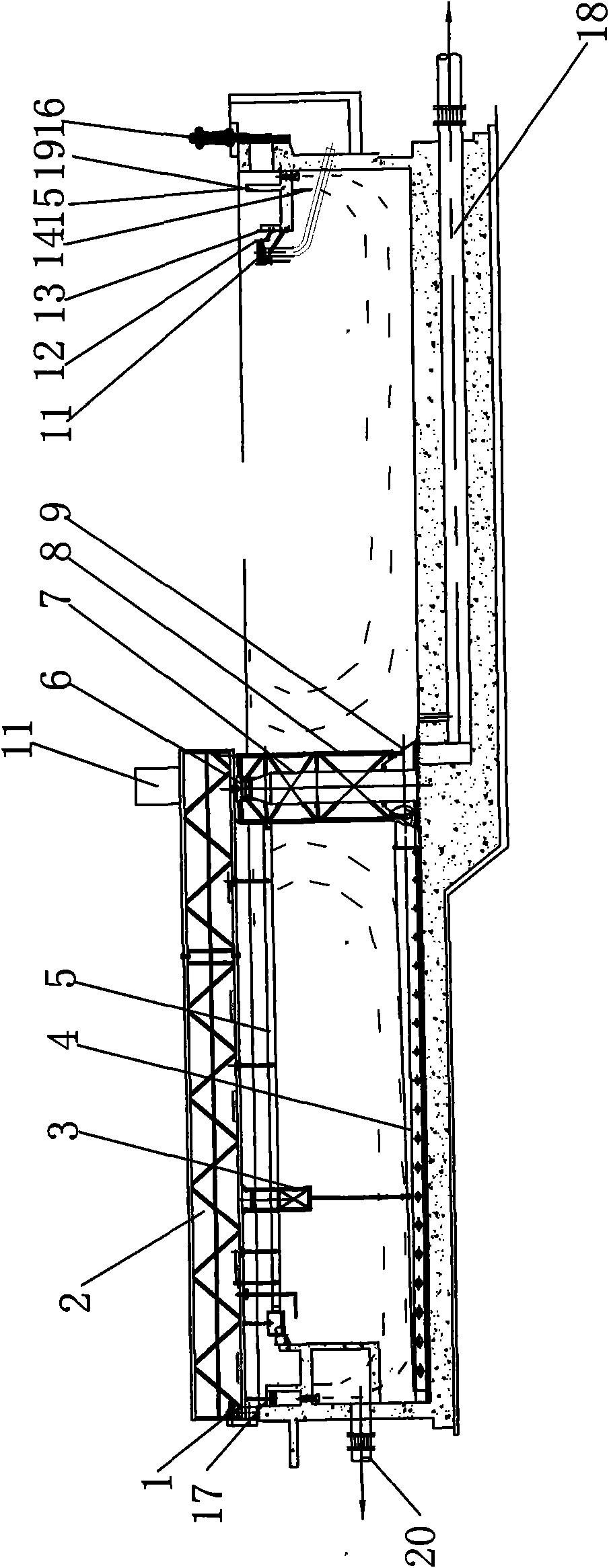

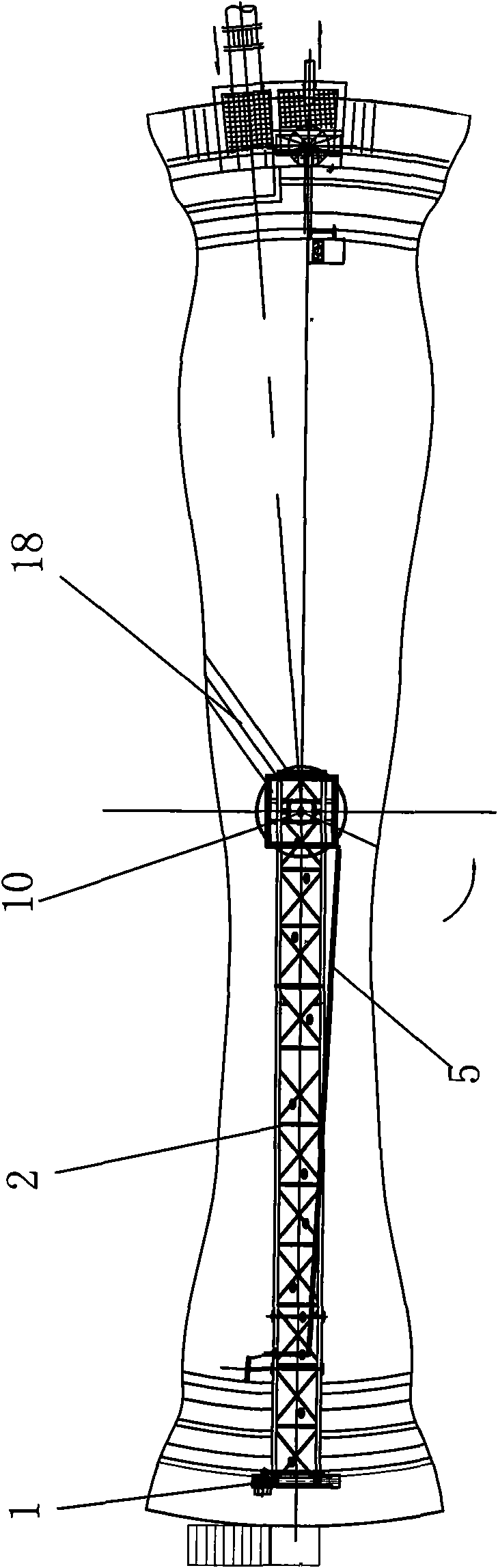

Tester for testing multifunctional vane

InactiveCN101539478AImprove support strengthStable center of gravityMachine part testingMaterial strength using tensile/compressive forcesAbove groundReinforced concrete

The invention discloses a tester for testing a multifunctional vane, which comprises a test bed, a tester for testing static strength and a tester for testing fatigue, wherein the bed body of the test bed is cast by reinforced concrete; the part of the test bed below ground takes the shape of a ladder; and the front end of the part of the test bed above ground is provided with a vane connecting disc fixed by a fixing part. The vane connecting disc and the bed body corresponding to the vane connecting disc are internally provided with a plurality of blind holes which are internally provided with bolt sleeves embedded with the vane connecting disc. The bolt sleeves are fixed by extension reinforcing rods fixed in the bed body. In addition, a test pit is positioned on the ground on which the front end of the bed body of the test bed is arranged; and the test pit is a slope with one end away from the bed body extending below ground. The invention has the advantages of solid structure, strong holding power and long service life. The tester has firm structure, strong supporting force and long service life, and is suitable for installation test of various vanes with different sizes, available for tests of different indexes for vanes. The tester is accurate in test, very convenient in use and wide in application range. In addition, the tester has the advantages of reducing disassembly and assembly of the vane for testing the performance index thereof, saving the testing time and cost, and reducing the damage to the vane.

Owner:中能风电设备有限公司

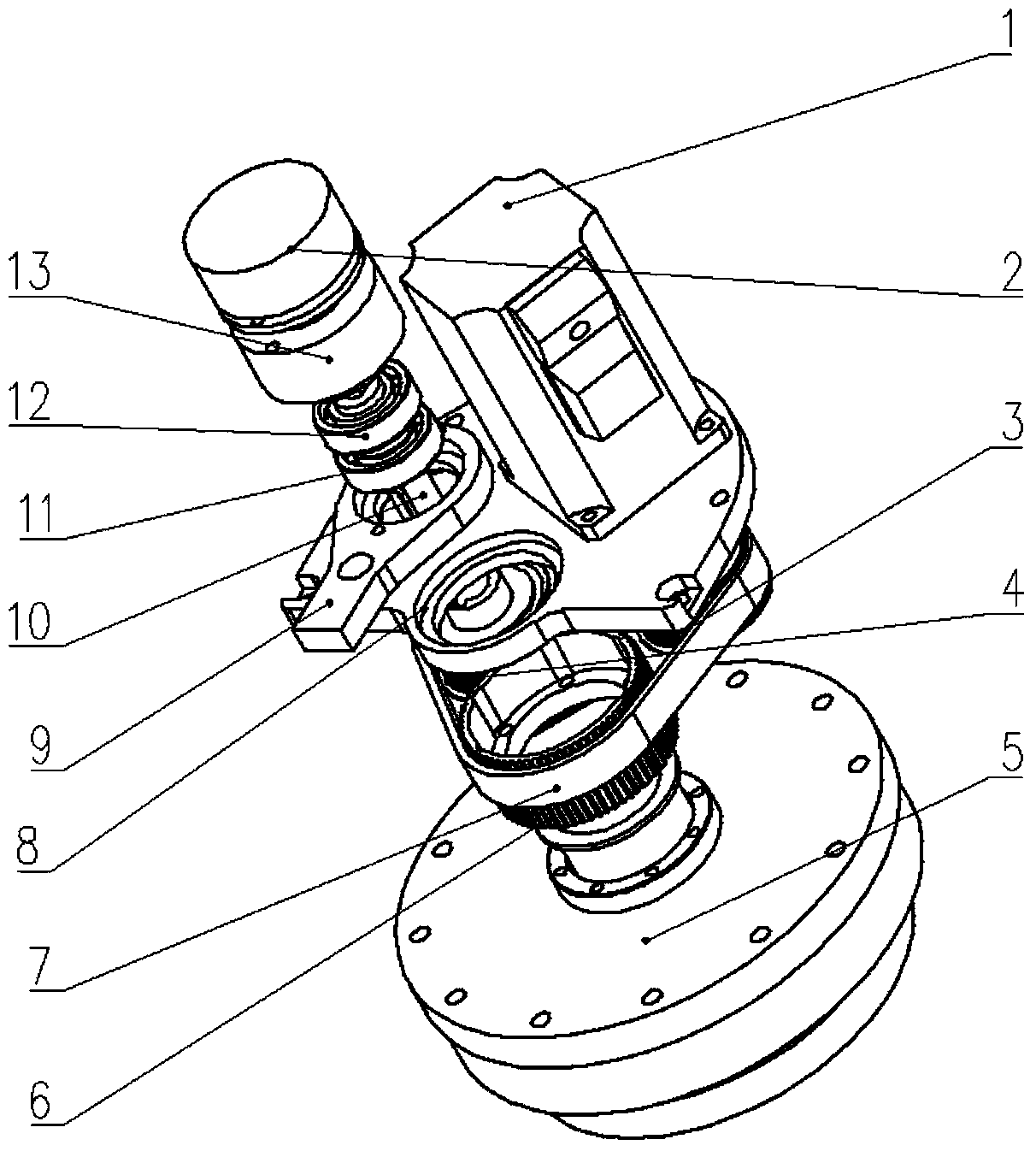

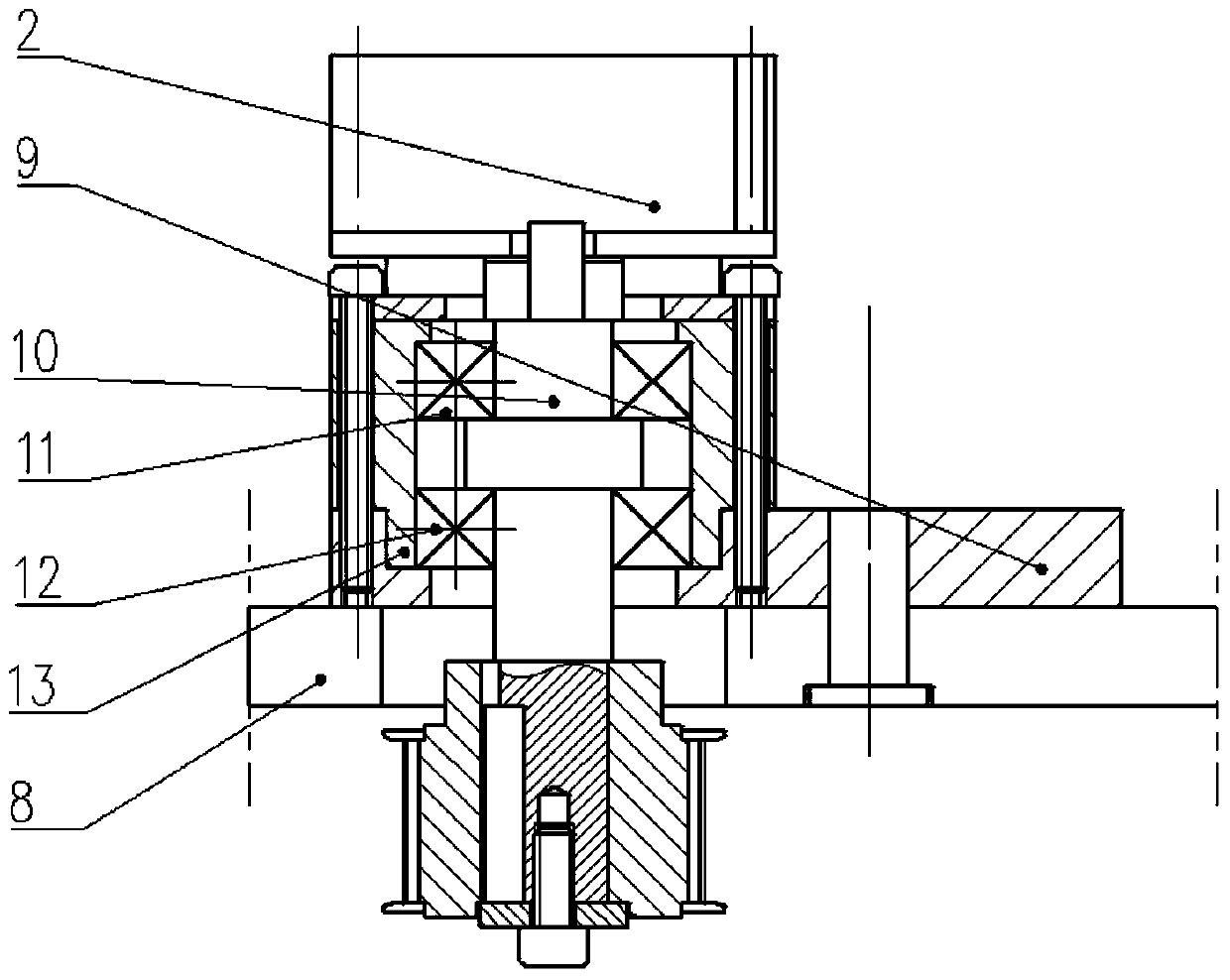

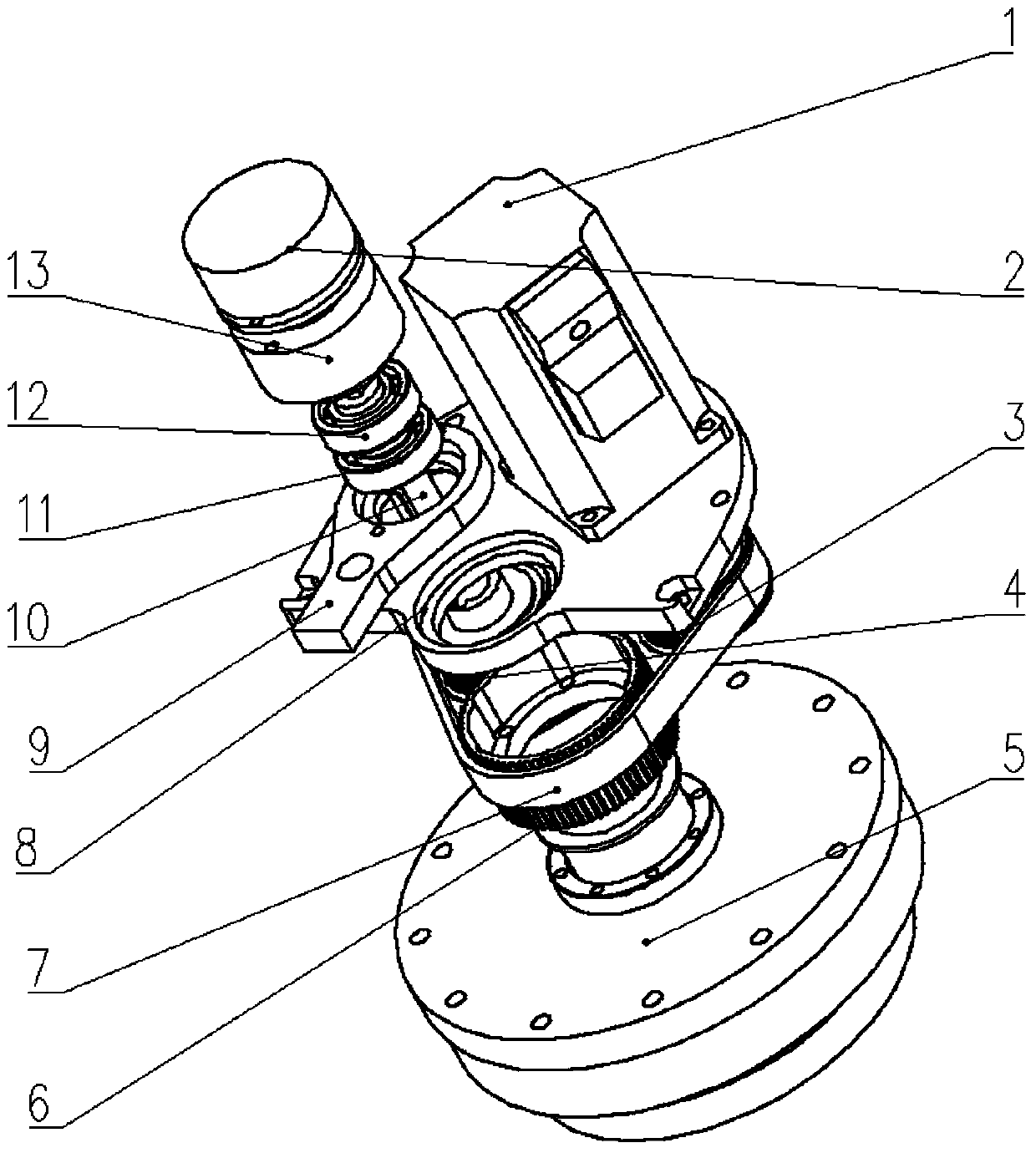

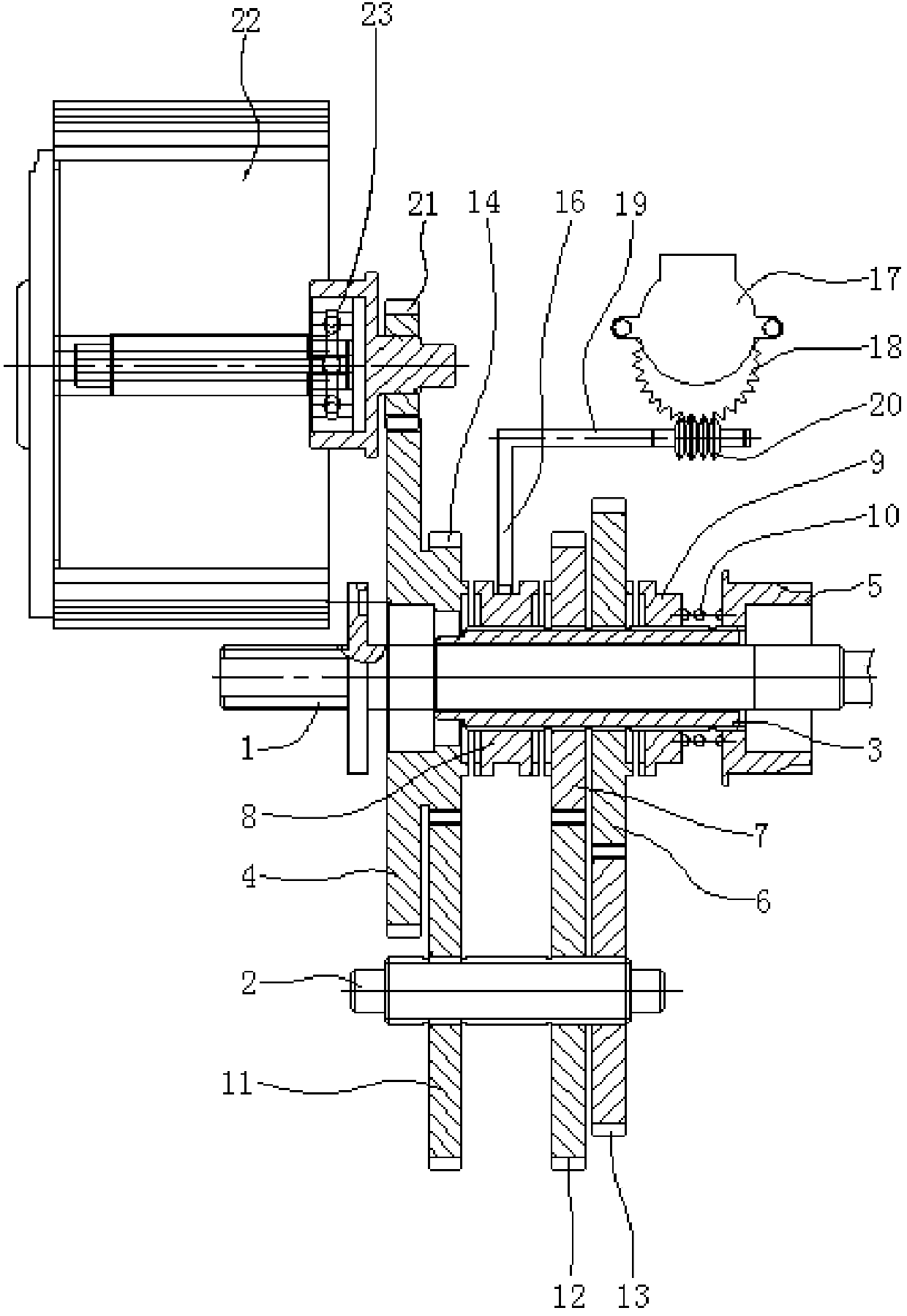

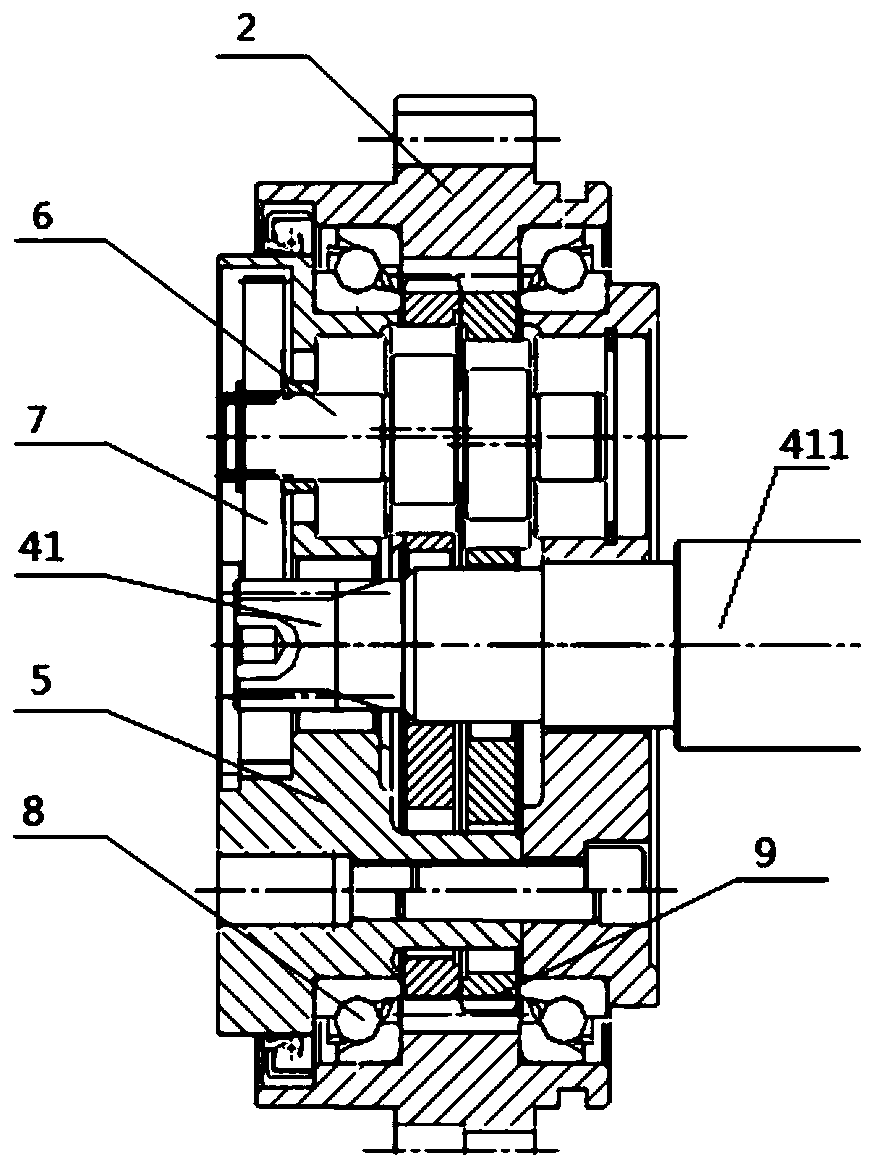

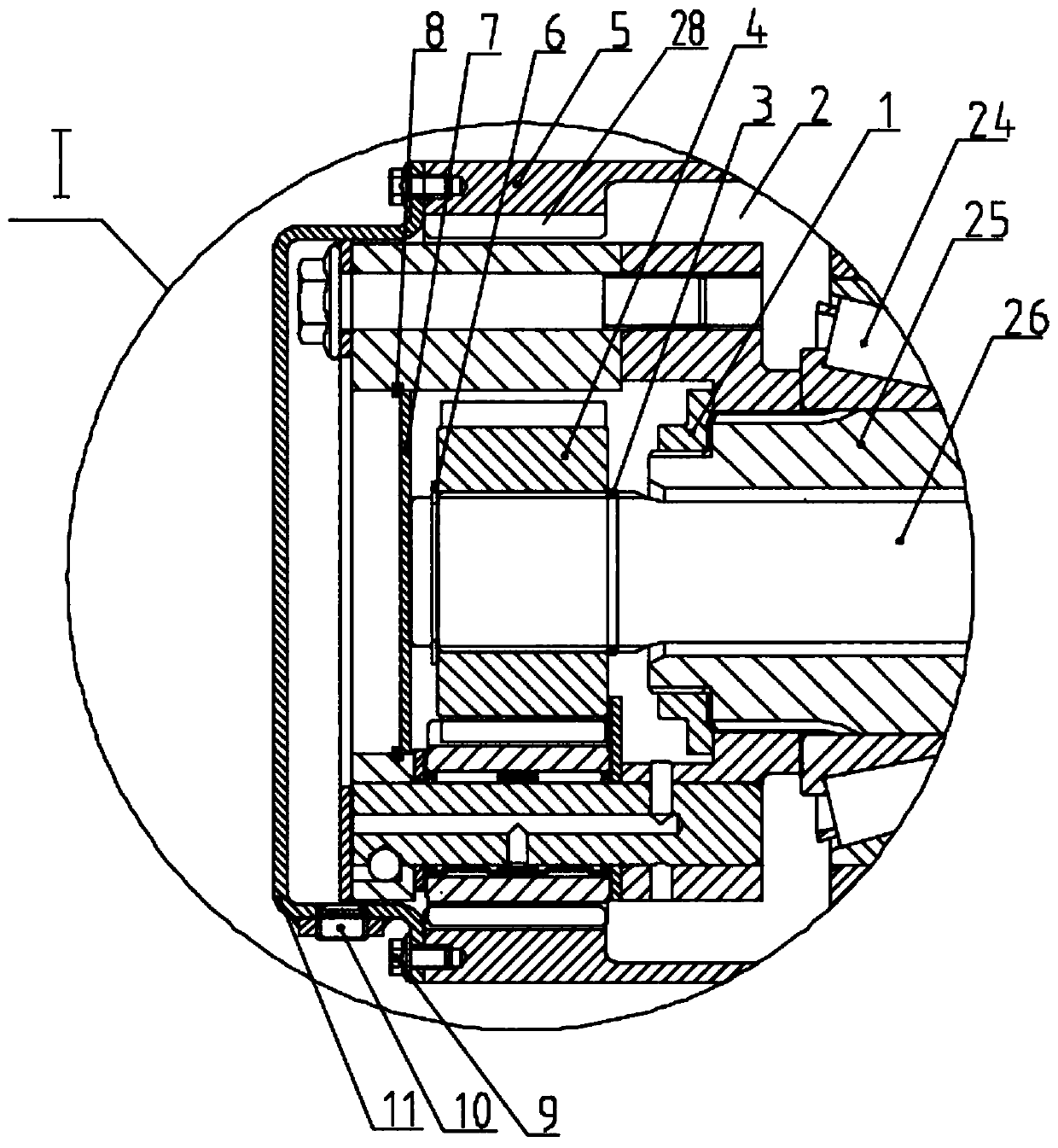

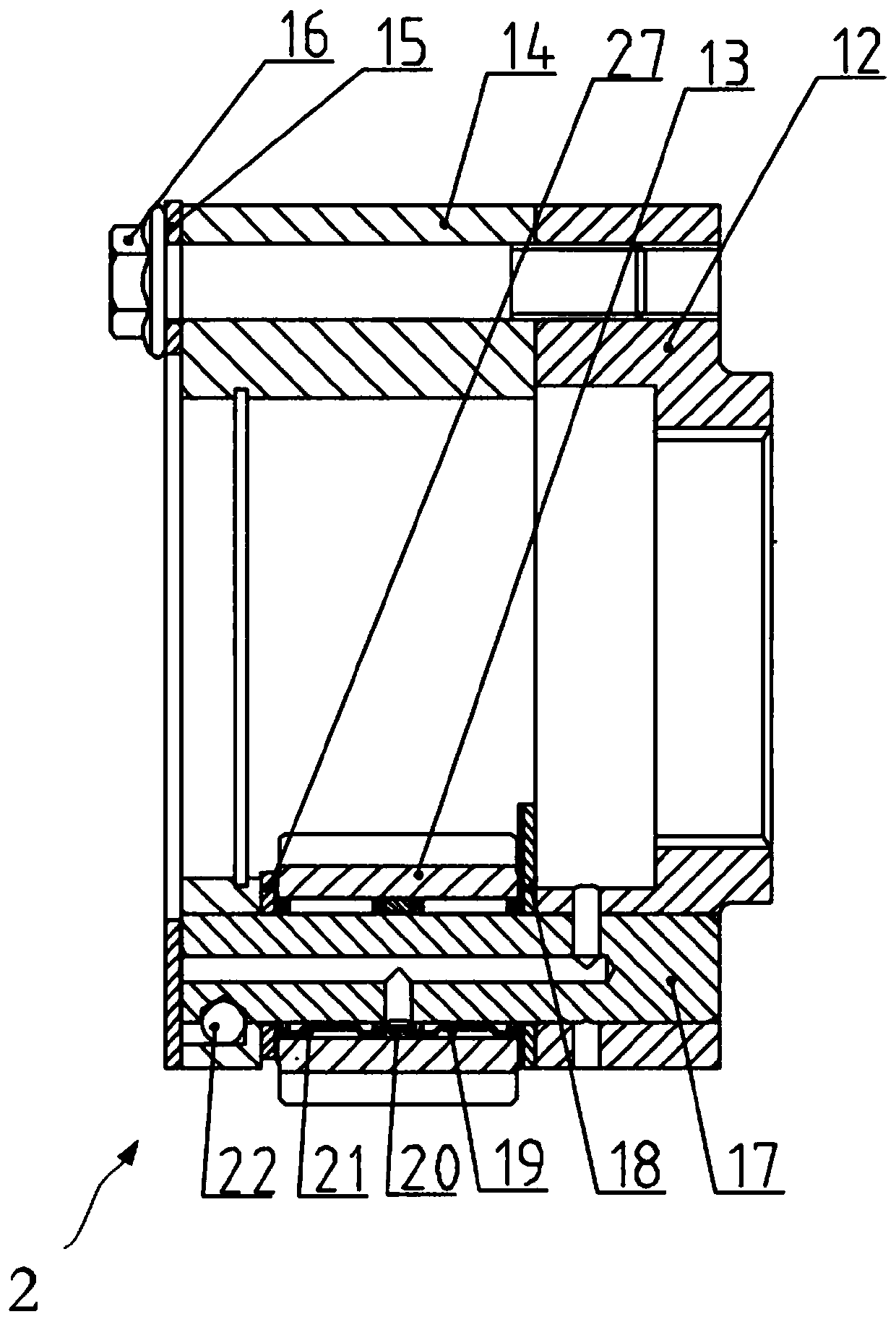

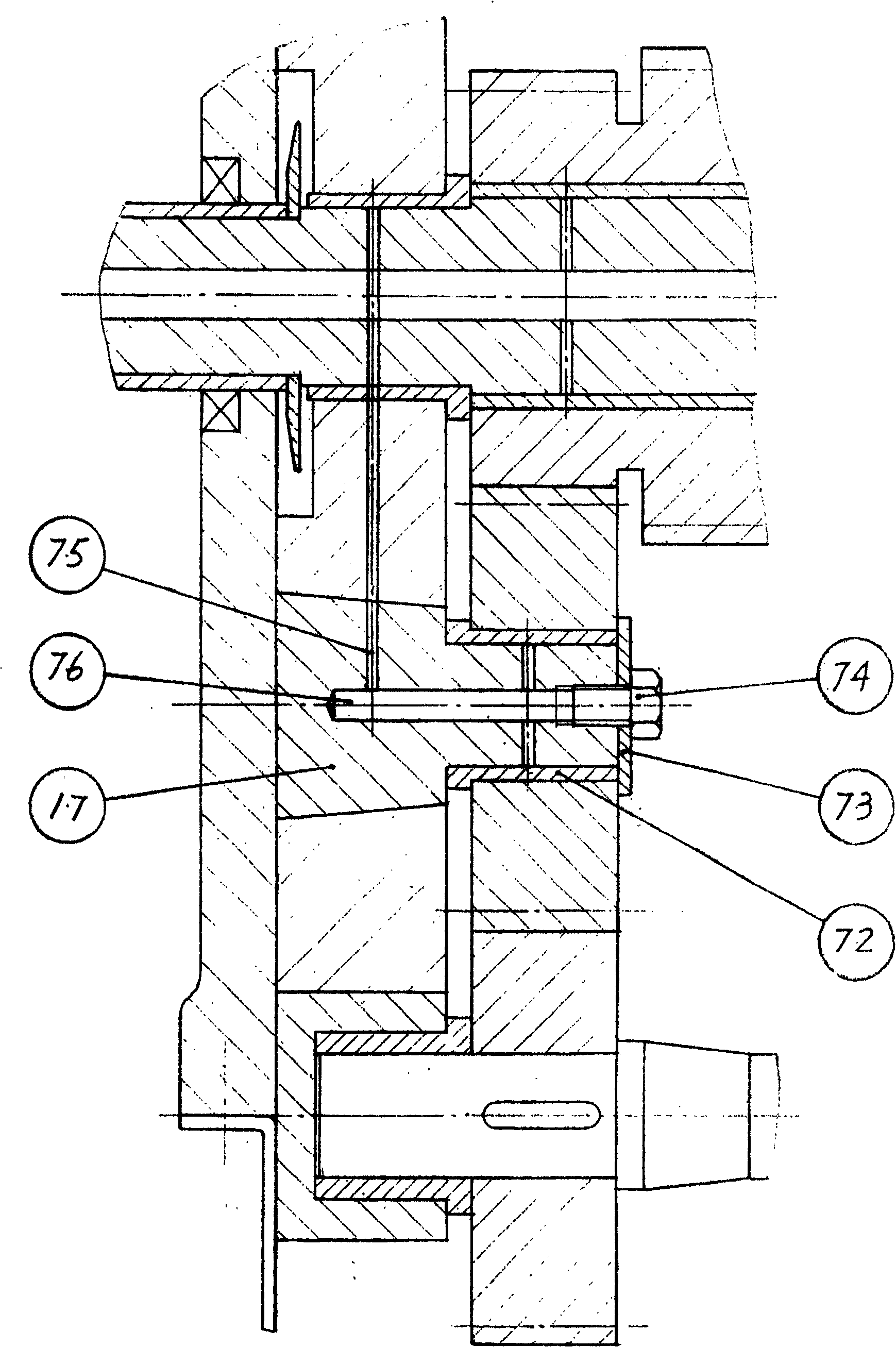

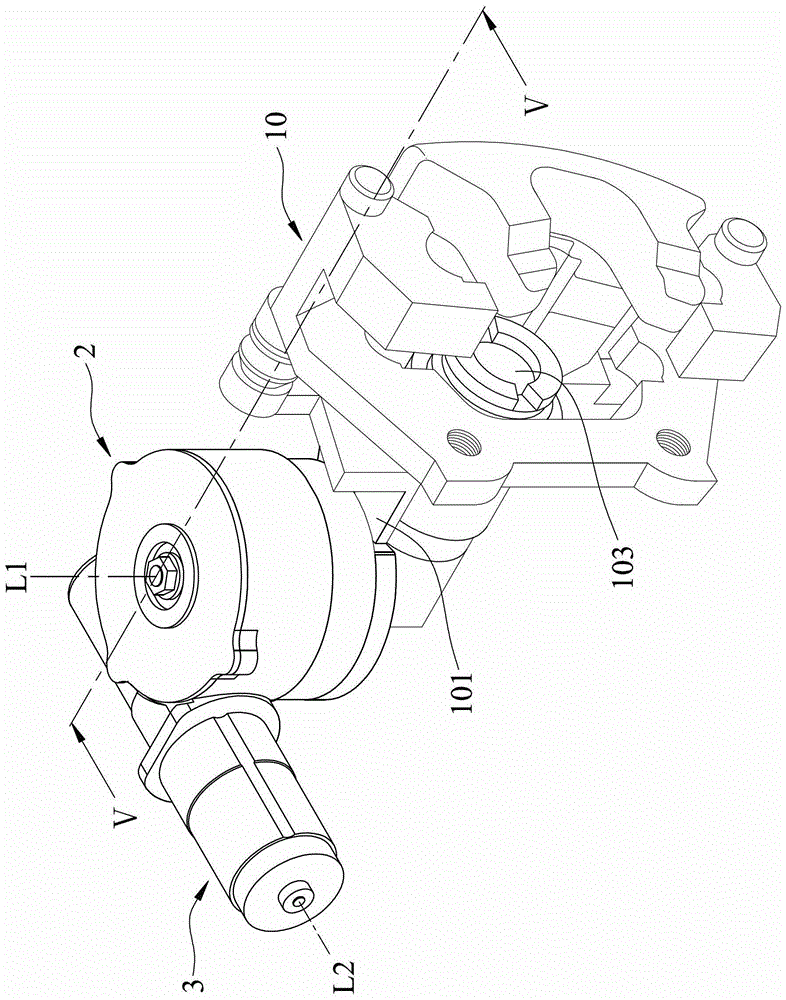

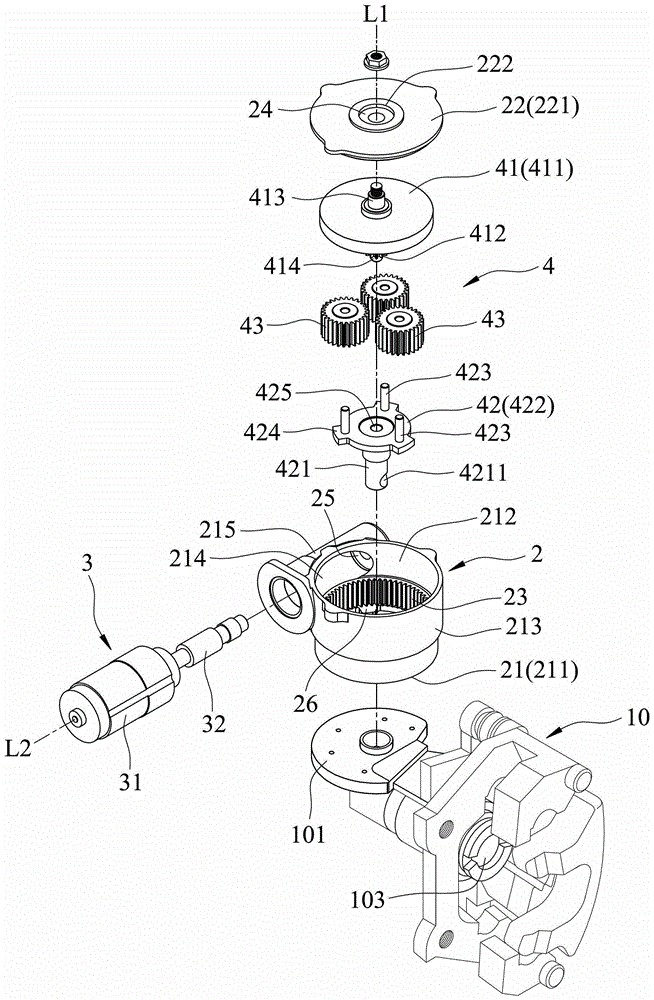

Modularized joint for hollow series-connection mechanical arm

ActiveCN104175329ASimple internal structureCompact internal structureJointsReduction driveGear wheel

The invention discloses a modularized joint for a hollow series-connection mechanical arm. The modularized joint comprises a casing, wherein a rear cover is mounted on the casing; an opening is formed in one side of the casing; a support is mounted in the casing; a servo motor and a tensioning mechanism are mounted on the top surface of the support; a gear reducer is fixed on the casing below the support; the tensioning mechanism comprises a bearing seat; a joint tensioning shaft is mounted in the bearing seat; the bearing seat is supported by and fixed on a belt pulley tensioning swing rod; the belt pulley tensioning swing rod is rotationally connected onto the support through a mounting shaft; a power-loss brake is mounted on the bearing seat; one end of the joint tensioning shaft is fixedly connected with the rotor of the power-loss brake through a rotor hub while the other end of the joint tensioning shaft is connected with a belt pulley B; a belt pulley A is connected with the output shaft of the servo motor; a belt pulley C is mounted at the input end of the gear reducer; the belt pulley A, the belt pulley B and the belt pulley C are rotationally connected through a synchromesh gear belt. By adopting the modularized joint, the accurate positioning is realized, and the positional accuracy of a robot is improved.

Owner:TIANJIN YANGTIAN TECH CO LTD

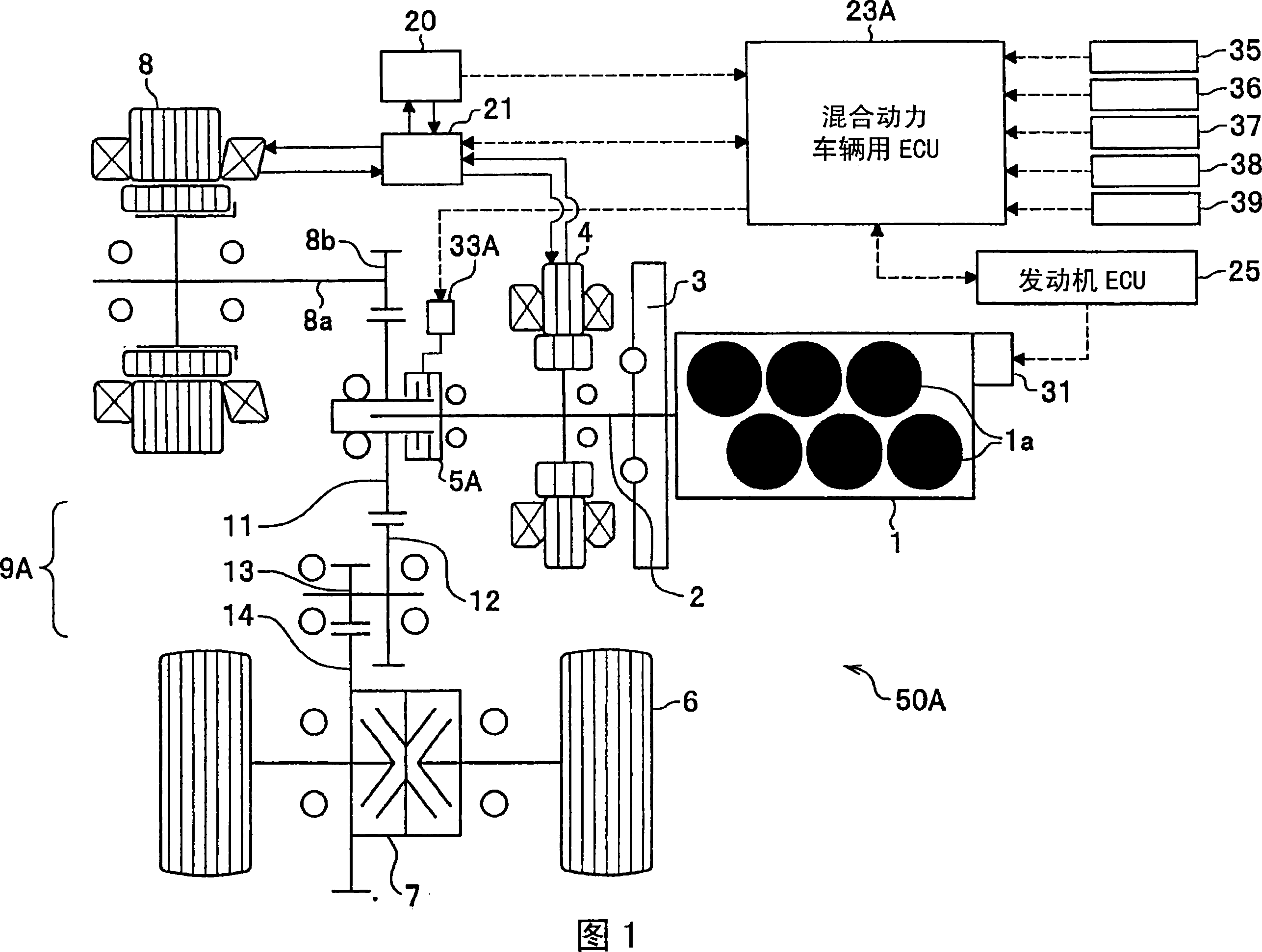

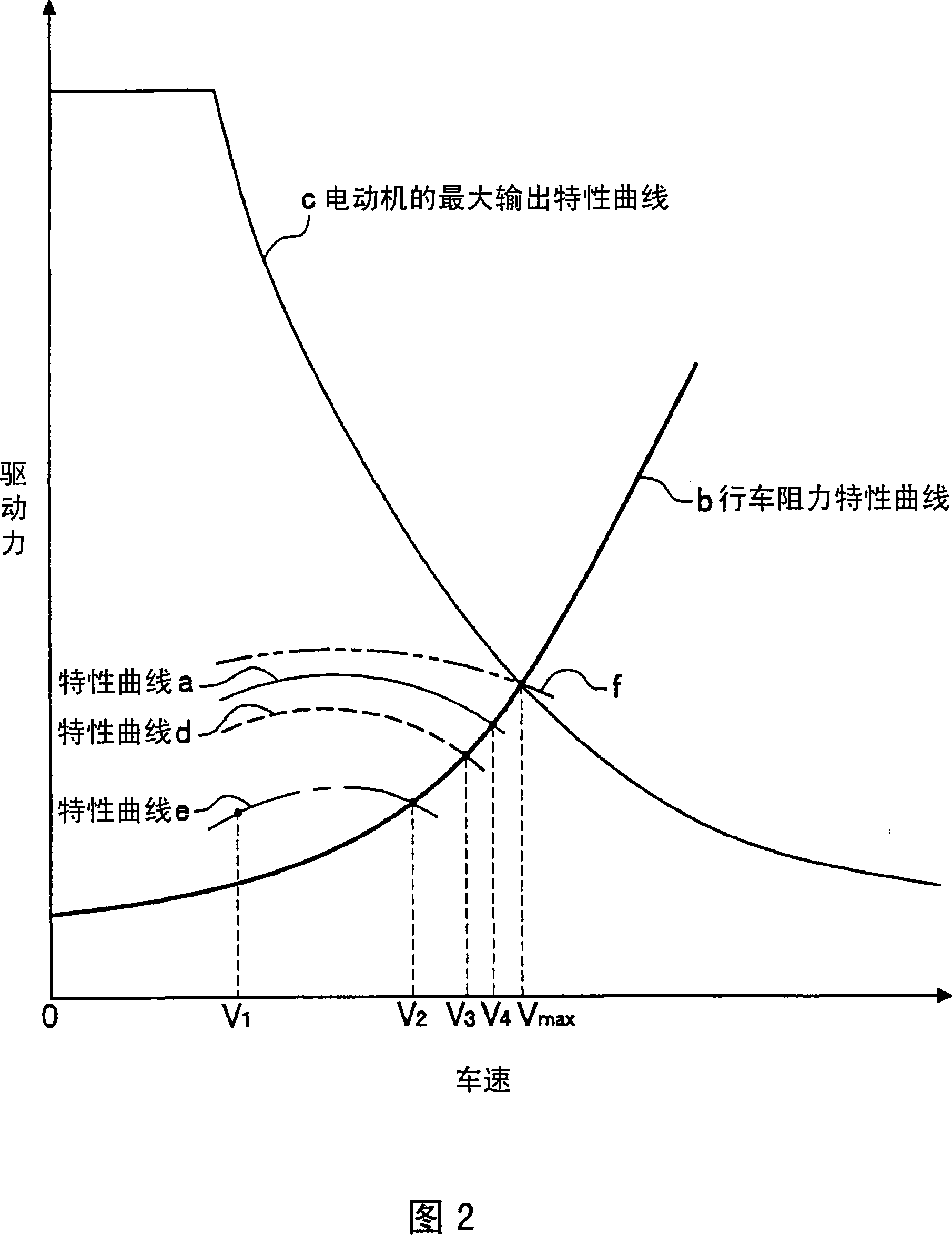

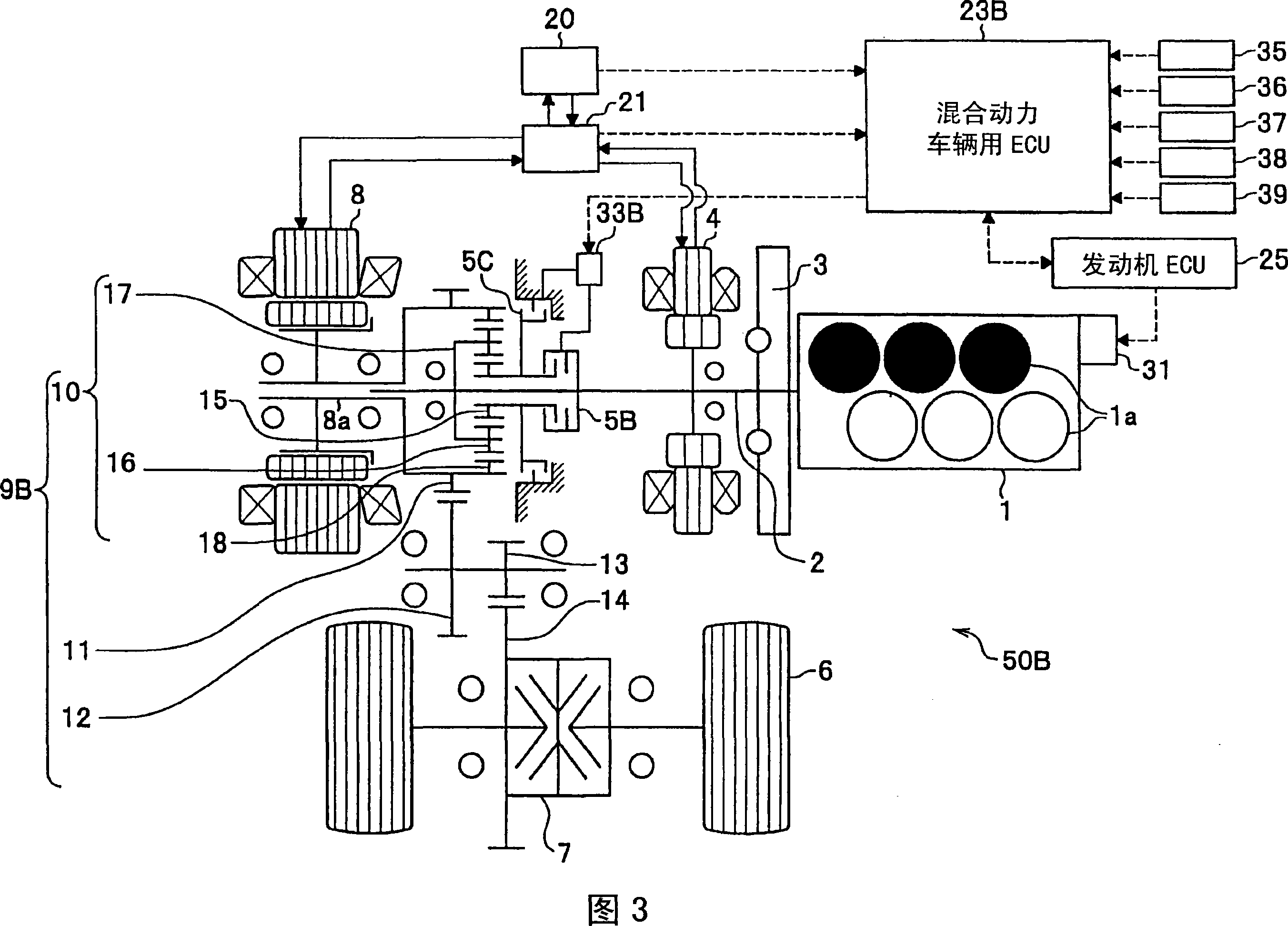

Hybrid vehicle

ActiveCN101108586ASmall reduction ratioHybrid vehiclesGas pressure propulsion mountingHybrid vehicleTravel mode

PROBLEM TO BE SOLVED: To provide a hybrid vehicle which can raise fuel consumption efficiency of a vehicle further at steady traveling time.SOLUTION: In a driving force property of a hybrid vehicle, a speed reduction ratio by engine driving is assumed to be fixed. The speed reduction ratio is set so that it can accelerate only up to the highest vehicle speed V<SB>4< / SB>at maximum output time of the engine at steady traveling time, and cannot accelerate to the highest speed V<SB>max< / SB>of the hybrid vehicle. At steady traveling time where the vehicle speed is V<SB>1< / SB>to V<SB>4< / SB>, it travels with engine driving force in principle. From vehicle speed V<SB>4< / SB>to the maximum speed V<SB>max< / SB>, desired vehicle speed is realized by motor driving. Fuel consumption efficiency can be raised since engine load at steady traveling time is reduced by setting of such a speed reduction ratio and utilization of travel modes. When low output is achieved by an engine output characteristics change mechanism, for example, at cylinder asleep operation of the engine, output becomes as shown by a characteristic curve d which indicates the engine driving force property and the fuel consumption efficiency can be raised further.

Owner:HONDA MOTOR CO LTD

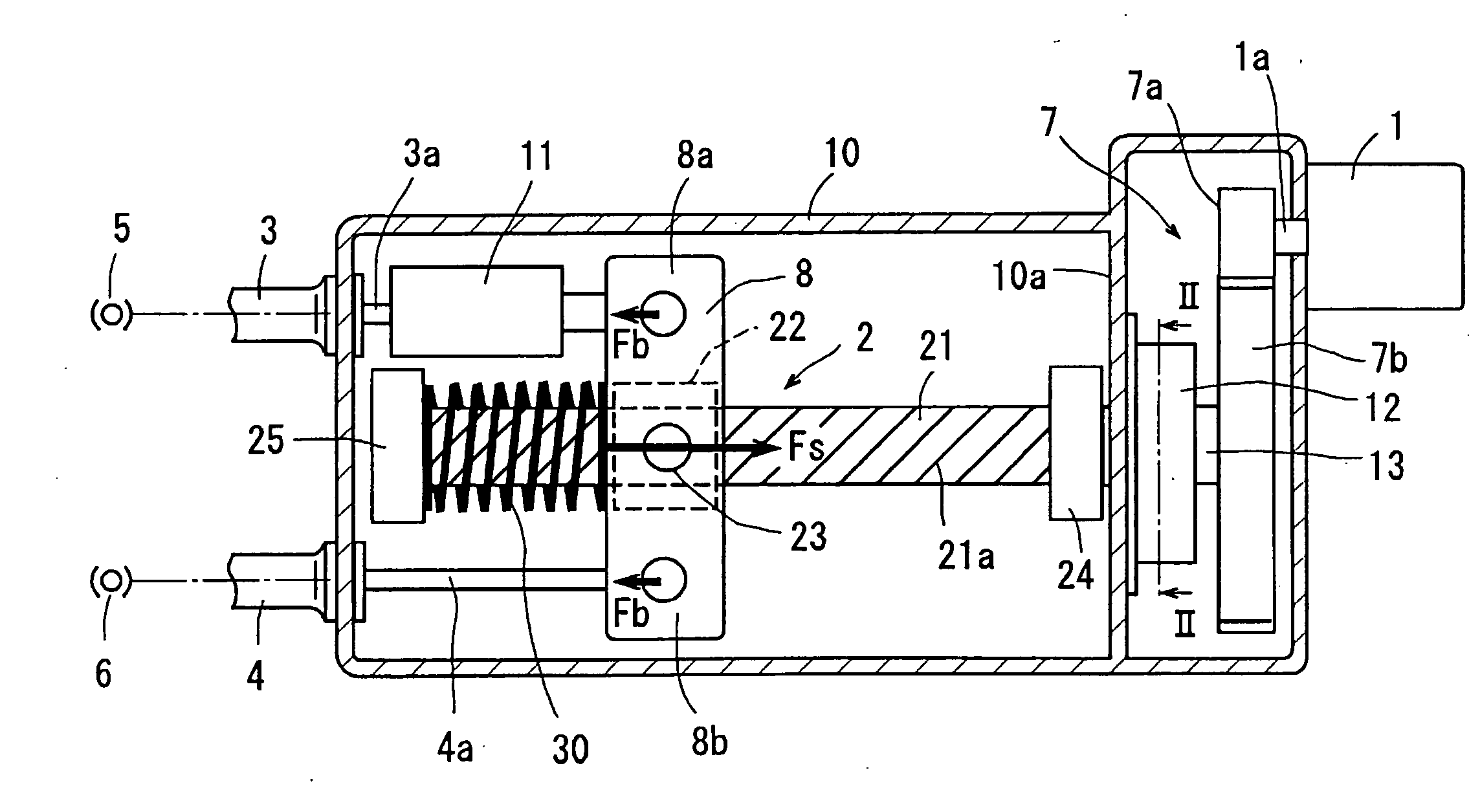

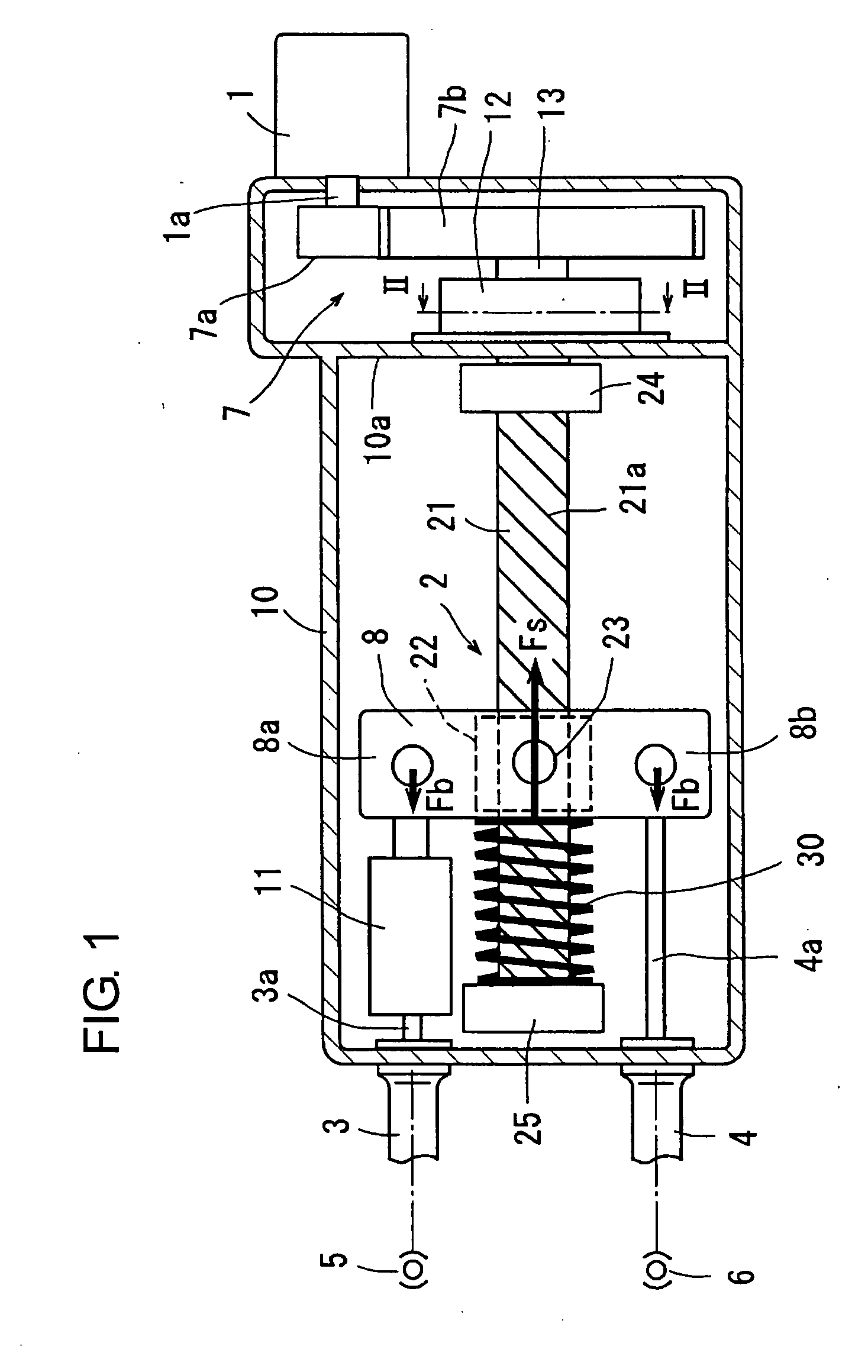

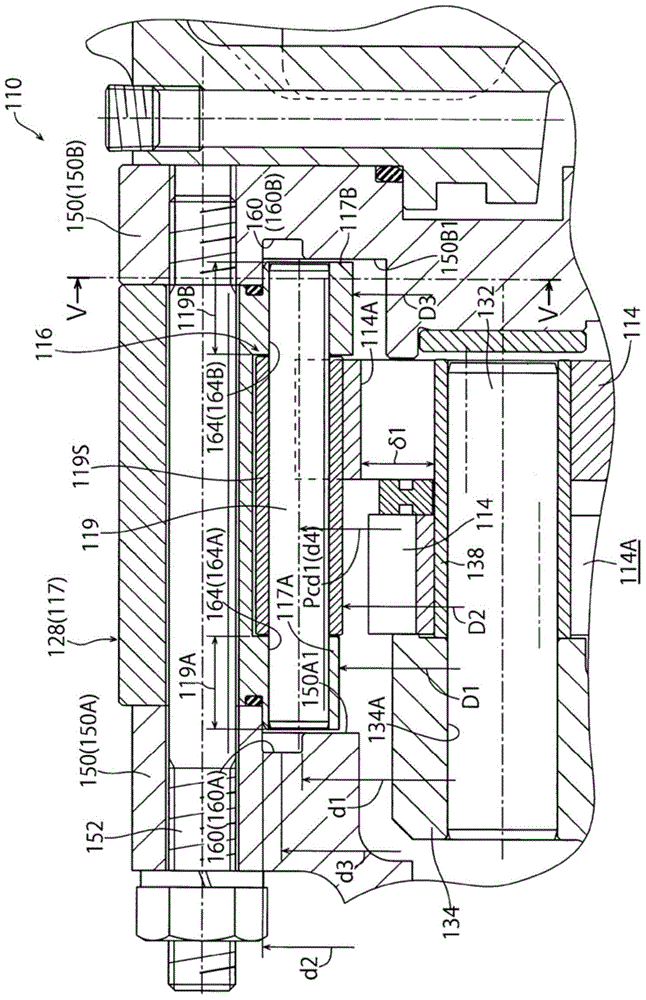

Electric parking brake device

InactiveUS20070272504A1Improve responsivenessSmall loadBraking action transmissionBrake actuating mechanismsElectric parking brakeEngineering

An electric parking brake device comprises an electric motor, a conversion mechanism for converting a rotational drive force given by the electric motor into a linear drive force and a pair of cables (i.e., inner cables) connected to a pair of parking brakes, wherein the parking brakes are brought into a braking state when the cables are drawn in a drawing direction by the operation of the electric motor in a positive-going direction, but are brought into a release state when the cables are returned in a return direction by the operation of the electric motor in a reverse direction. Between the electric motor and the conversion mechanism, a clutch mechanism is provided for transmitting the rotation of the electric motor to the conversion mechanism, but for blocking the rotation transmission from the conversion mechanism toward the electric motor. An auxiliary force applying member comprising any one of a compression spring, a tension spring and a torsion spring is provided for applying an auxiliary force to the conversion mechanism when the same is operated to draw the cables in the braking operation of the cables.

Owner:SAKAI TOMOYASU

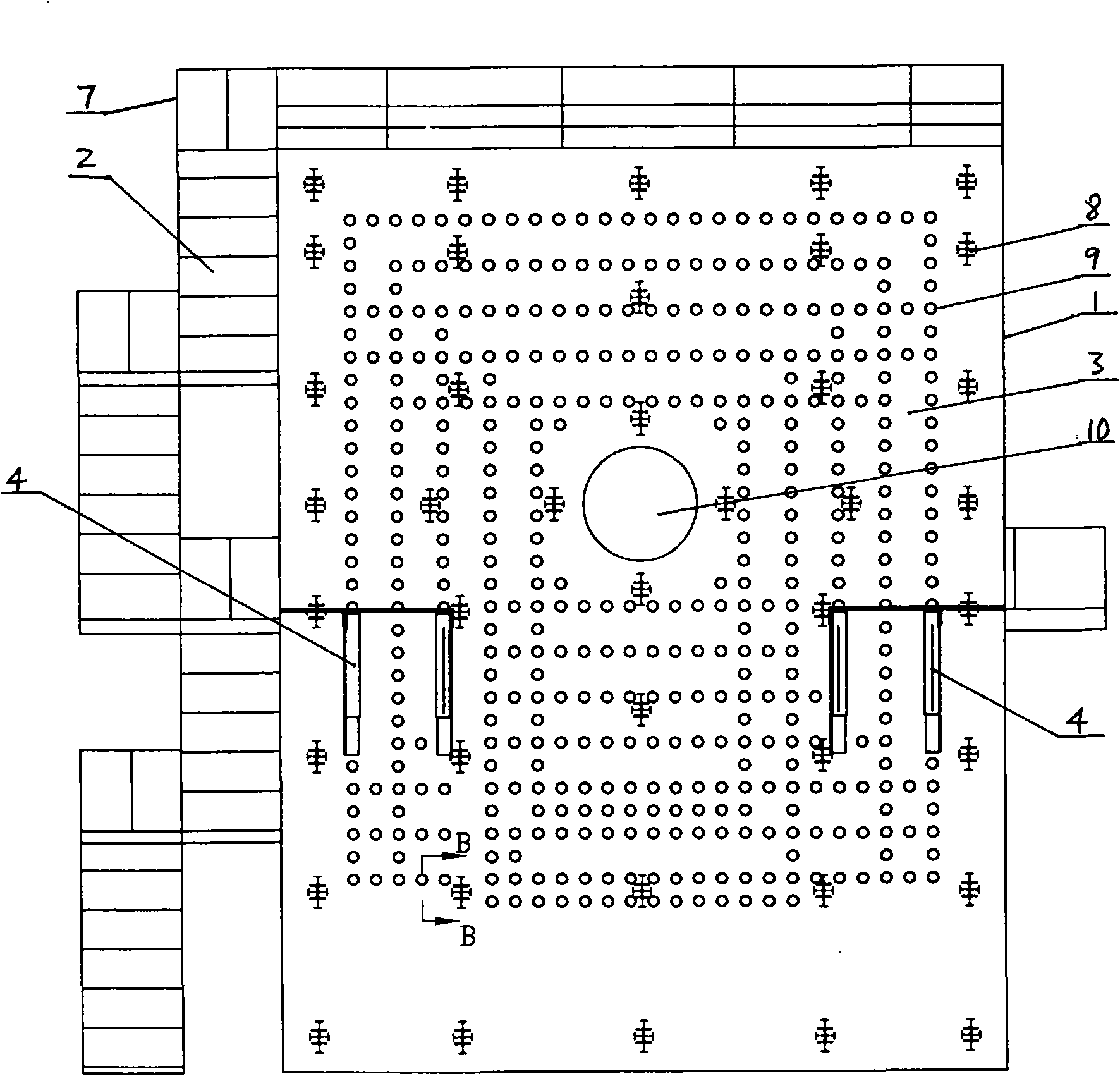

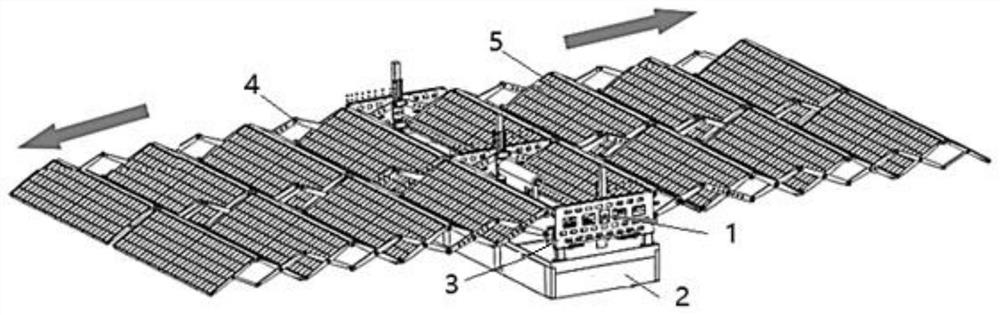

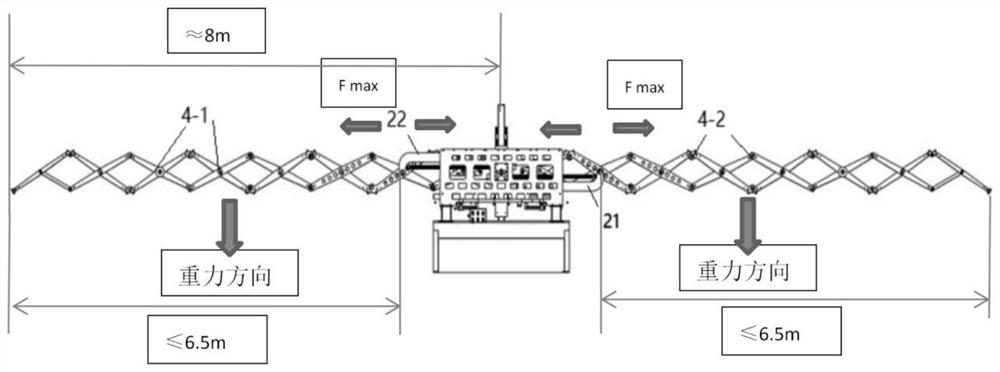

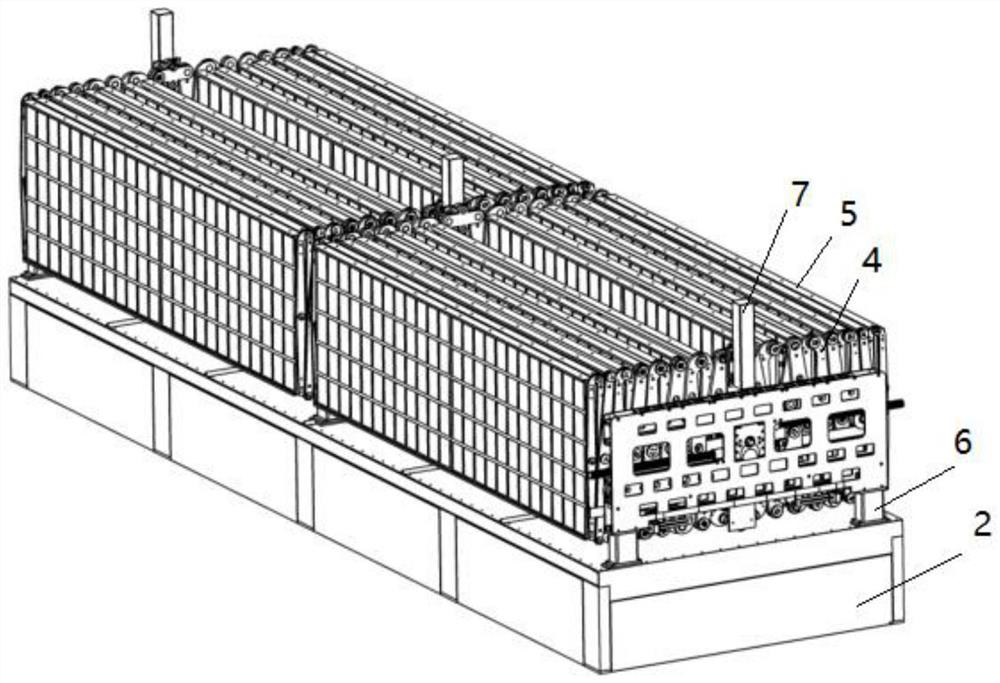

Folding telescopic photovoltaic support

ActiveCN112217462ASave spaceReduce moment armPhotovoltaic supportsSolar heating energyThermal insulationDrive shaft

A folding telescopic photovoltaic support comprises a basic load-bearing welding main body structure frame; a folding and unfolding functional mechanical structure assembly; a telescopic rhombic structure assembly directly bearing the photovoltaic panel; wherein the basic load-bearing structure main body comprises a welding framework; an external coated sheet metal part; and a thermal insulation module. The folding and unfolding functional structure assembly comprises a folding and unfolding functional structure assembly wallboard, a full-length transmission shaft, an auxiliary guide rail groove, a cross-shaped auxiliary guide sliding block, a worm and gear speed reducer, a rhombus support structure main bearing, a synchronous guarantee thrust lead screw, two sets of parallel rails, an L-shaped main bearing sliding block, an L-shaped main bearing sliding block roller and a rhombus support structure fixing joint. The two ends and the center of the structural frame in the length direction are each provided with a retracting and releasing functional structural assembly, a through long shaft penetrates through the length direction of the main body structural frame and the center of a retracting and releasing functional structural assembly wall plate to serve as a power transmission worm shaft, and the turbine worm speed reducer and the transmission worm shaft are meshed in the retracting and releasing functional structural assembly wall plate.

Owner:青海黄河上游水电开发有限责任公司西宁太阳能电力分公司 +3

Single-tube suction dredge

InactiveCN101559298ASmall reduction ratioSmall output torqueSettling tanks feed/dischargeSludgeRotating disc

The invention discloses a single-tube suction dredge, comprising a dredging tube which is arranged at the bottom of a sedimentation tank and is movably connected and communicated at the inside and outside thereof by a sealing cylinder in a sealing manner, a traction arranged, a bridging device which is arranged in the sedimentation tank and tows the dredging tube and the sealing cylinder, and a driving device. The bridging device comprises a central column, a central rotating disc, a working bridge, a central vertical frame and a pulling rod of the dredging tube which are fixed in the sedimentation tank; the central rotating disc is movably coupled with the central column to form a revolving support and is coupled with the working bridge and the central vertical frame outside of the central column. A skimming device is coupled below the working bridge; one end of the working bridge is coupled with the central column by the central rotating disc movably and the other end thereof is coupled with the driving device and travels along the edge of the tank; the working bridge is fixedly connected with the dredging tube by the pulling rod of the dredging tube; and the central vertical frame is fixed coupled with the working bridge and the sealing cylinder. As the periphery is adopted to drive the dredging tube, the single-tube suction dredge has simplified structure, less disturbance to muddy water, good skimming effect, light weight for a main machine and low cost, and is particularly applicable to the primary sedimentation tank with larger sewage sludge concentration and the large sedimentation tank of more than 50m.

Owner:广东新环环保产业集团有限公司

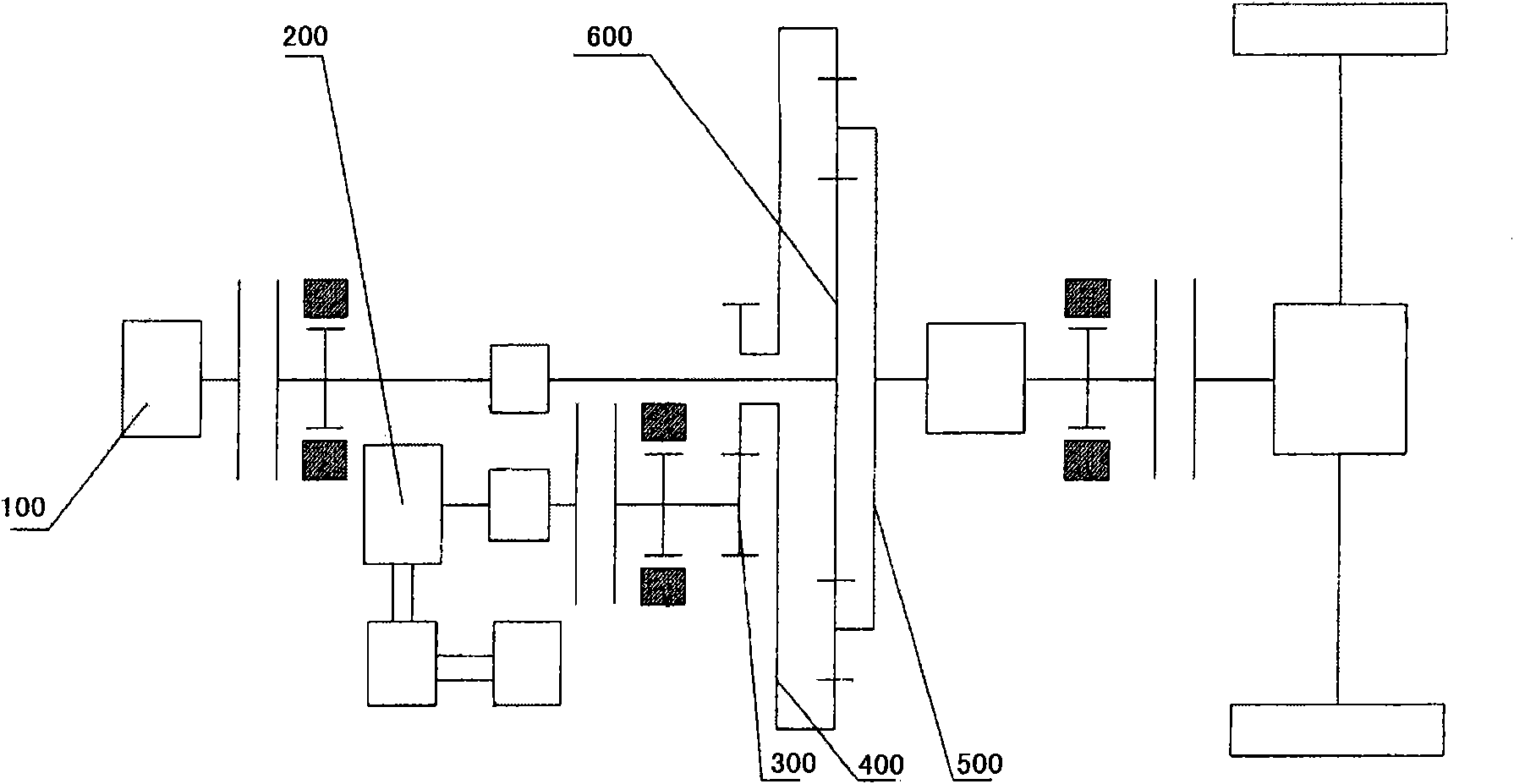

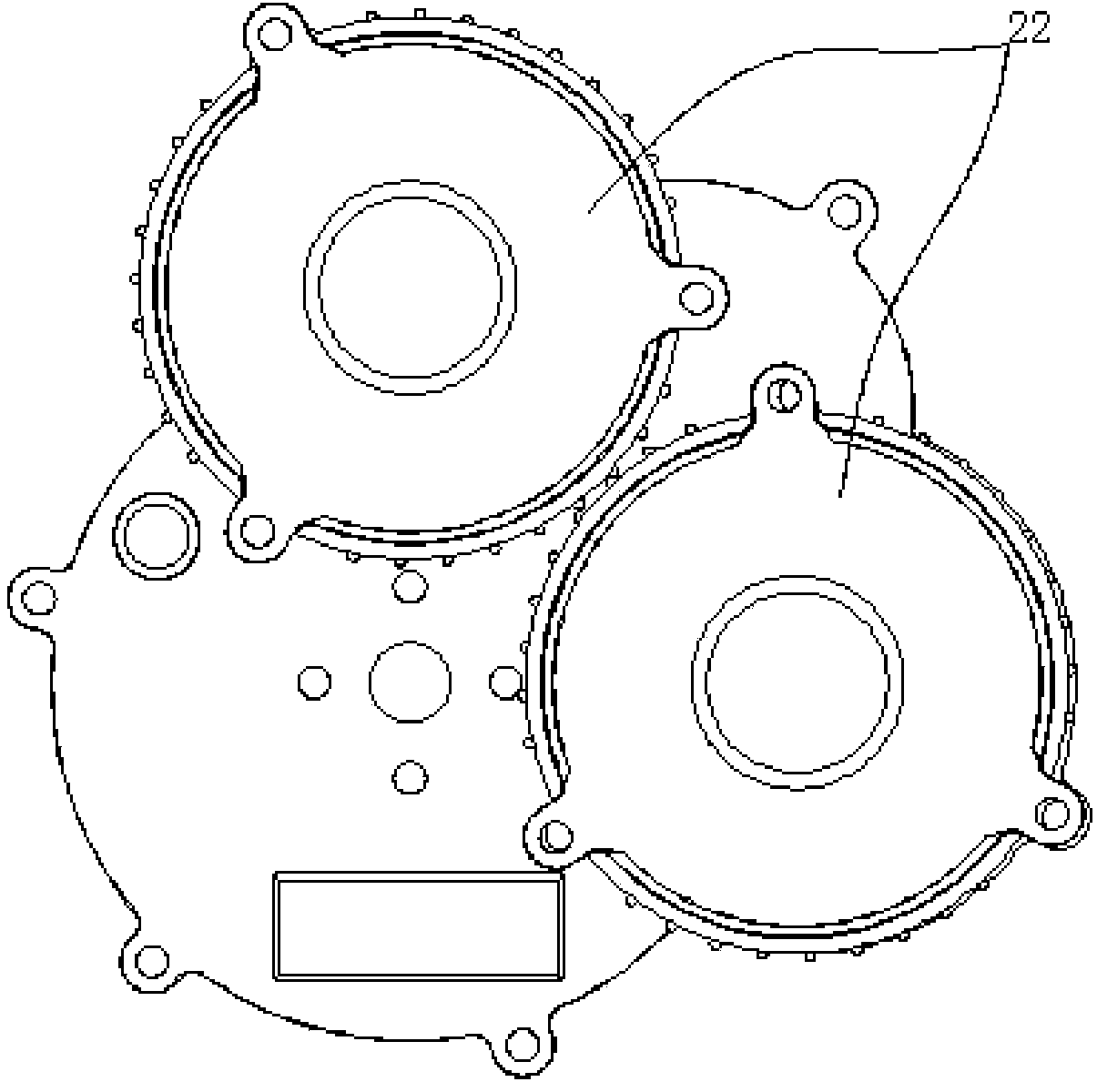

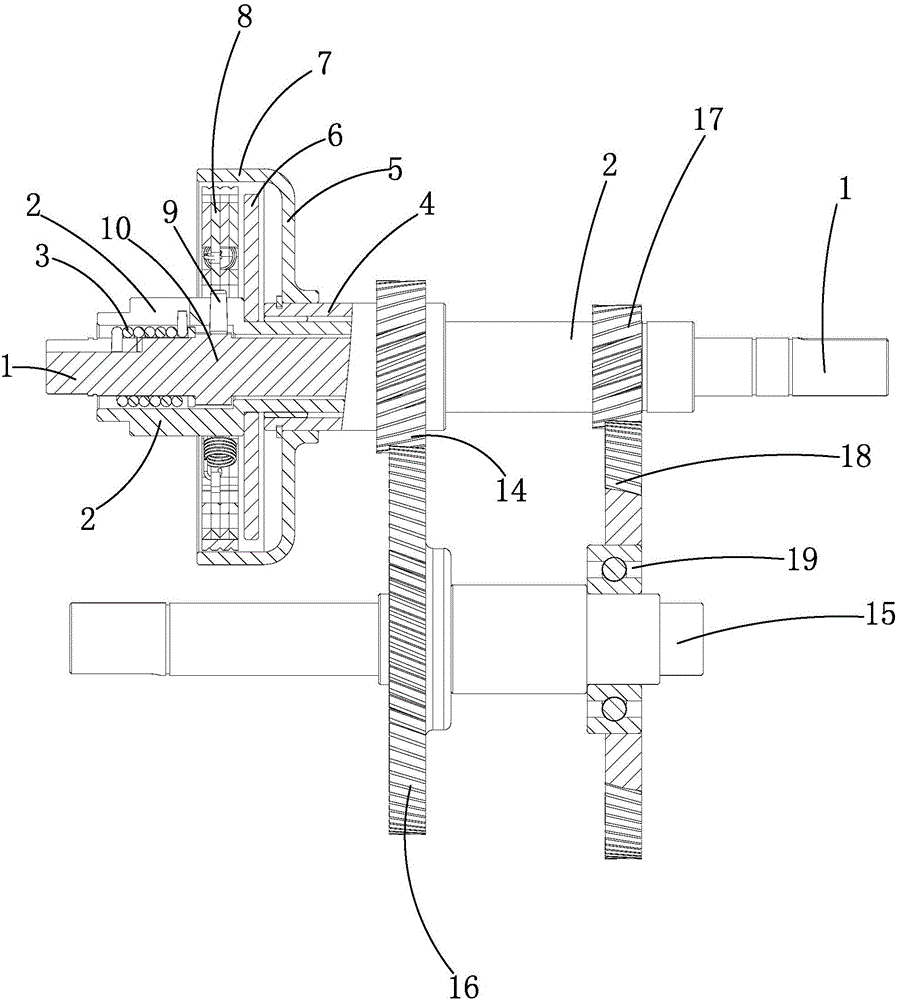

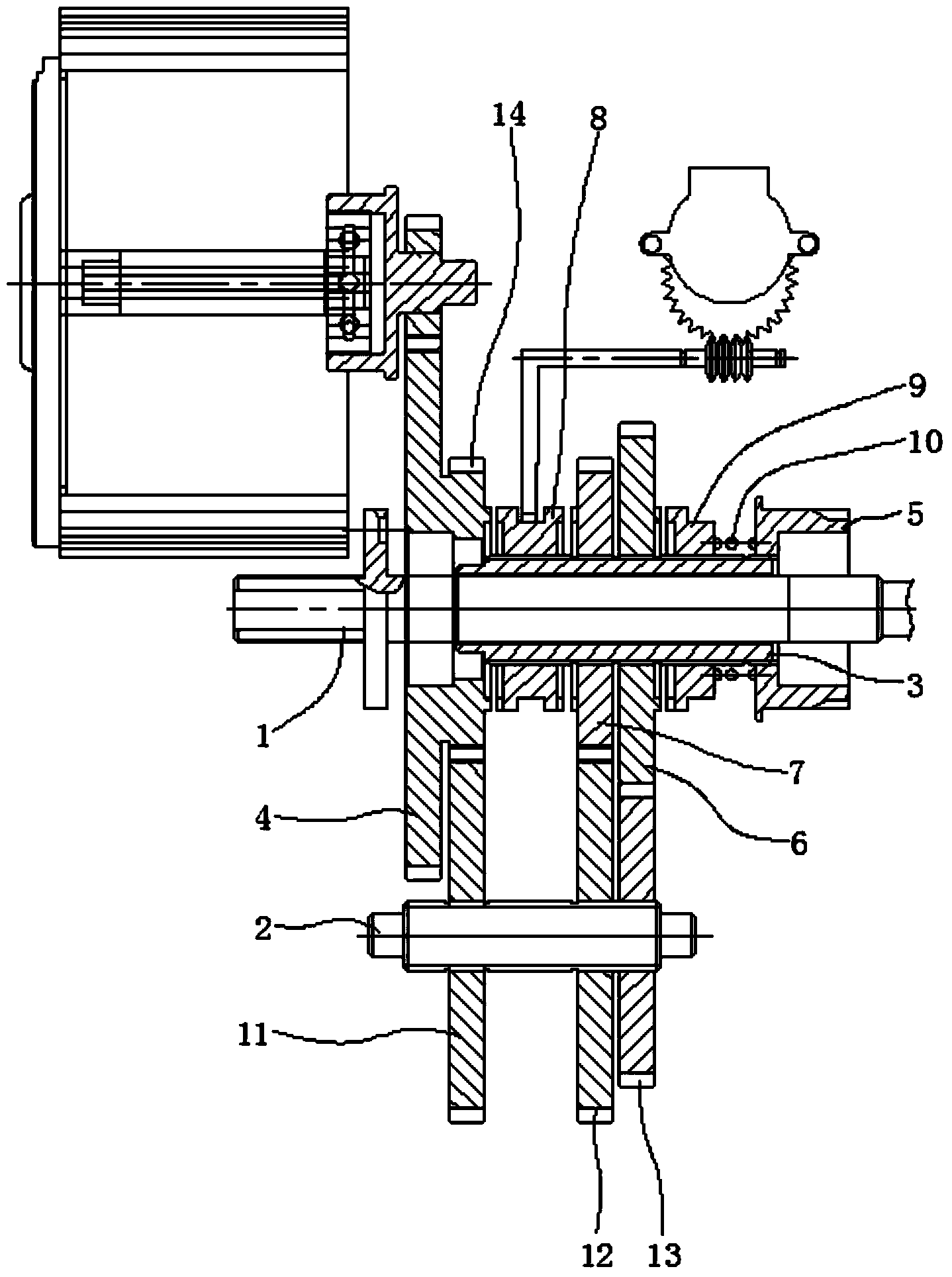

Electromobile three-gear speed changing double-engine-head driving system

InactiveCN103807366AGuaranteed reliabilityEasy to shift gearsToothed gearingsGearing controlMotor shaftEngineering

The invention discloses an electromobile three-gear speed changing double-engine-head driving system. A third-gear gear (4) is provided with a two-stage reduction driving gear (14) and meshed with two input gears (21) at the same time, each input gear (21) corresponds to one motor (22), a transmission shaft sleeve (3) is connected with an output spline housing (5), a second-gear gear (7) and a first-gear gear (6) are arranged in the middle of the transmission shaft sleeve (3) side by side in a freely-sleeved mode, and a double-pawl sliding sleeve (8) is arranged between the second-gear gear (7) and the two-stage reduction driving gear (14). According to the electromobile three-gear speed changing double-engine-head driving system, a stepping motor works when gear shifting is carried out, and the energy can be effectively saved. When the electromobile three-gear speed changing double-engine-head driving system works at a high speed, as only first-stage reduction exists, the efficiency point is higher than that of a traditional gear shifting motor, gear shifting can be rapidly conveniently and stably achieved, and large impact force caused when the gear shifting is carried out can be avoided. The weight of a whole electromobile is borne by a main shaft, the assembly difficulty is reduced, the assembly accuracy is reduced, and a motor shaft can be effectively prevented from being broken.

Owner:重庆绿华电动车有限公司 +1

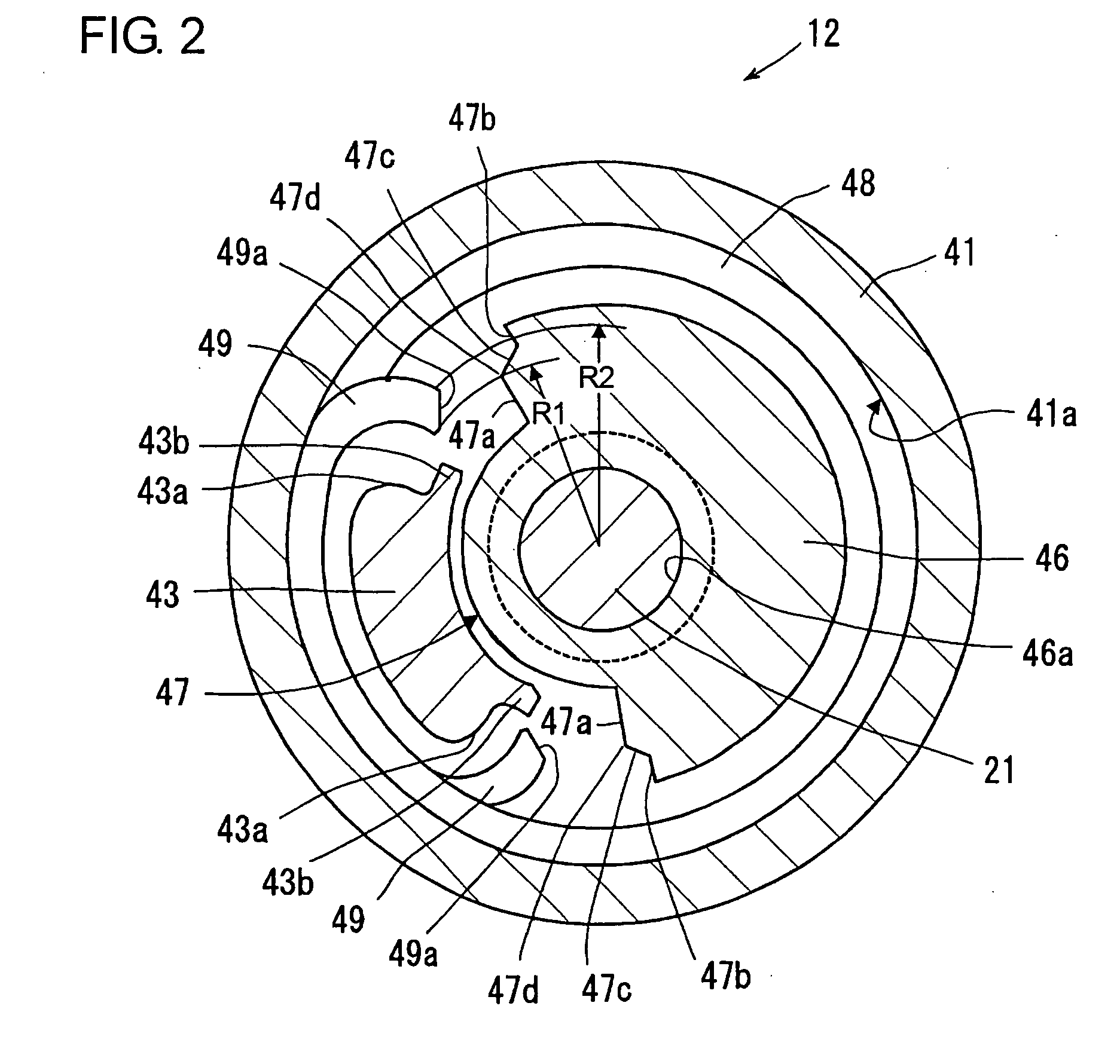

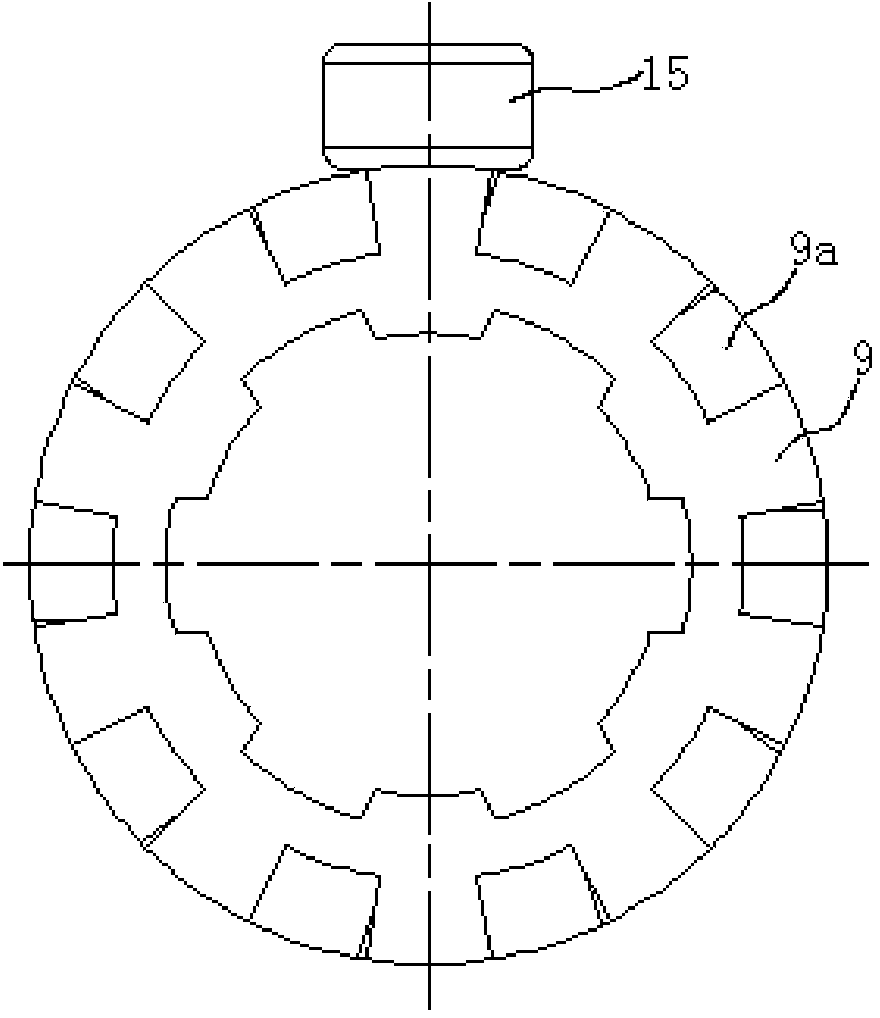

Gear unit series

ActiveCN104565220ALow costSmall reduction ratioToothed gearingsGearing detailsReduction ratioEngineering

The present invention can provide a lower cost to constitute the low reduction ratio high reduction ratio gear unit series gear means comprising a first gear and a second gear unit means, first gear means and second gear means includes: an internal gear, having the gear body and a plurality of pins arranged in the main body of the internal gear member and the inner teeth constituted by a pin member; cover member, the internal gear connected to the main body, wherein the first gear and the second gear means means common cover member, the cover member is provided with a holding tank, the second gear means having means more than the first pin member gear, and the diameter of the pin member is smaller. Body side of the internal gear device having a first gear holding pin member axial part of the entire circumference of the retaining hole, the pin member of the first gear unit is not held in the holding tank cover member, but remains the subject of internal gear retaining hole . In the body of the second gear means is not provided with the gear member retaining pin hole, the second pin member held in the gear unit holding tank cover member.

Owner:SUMITOMO HEAVY IND LTD

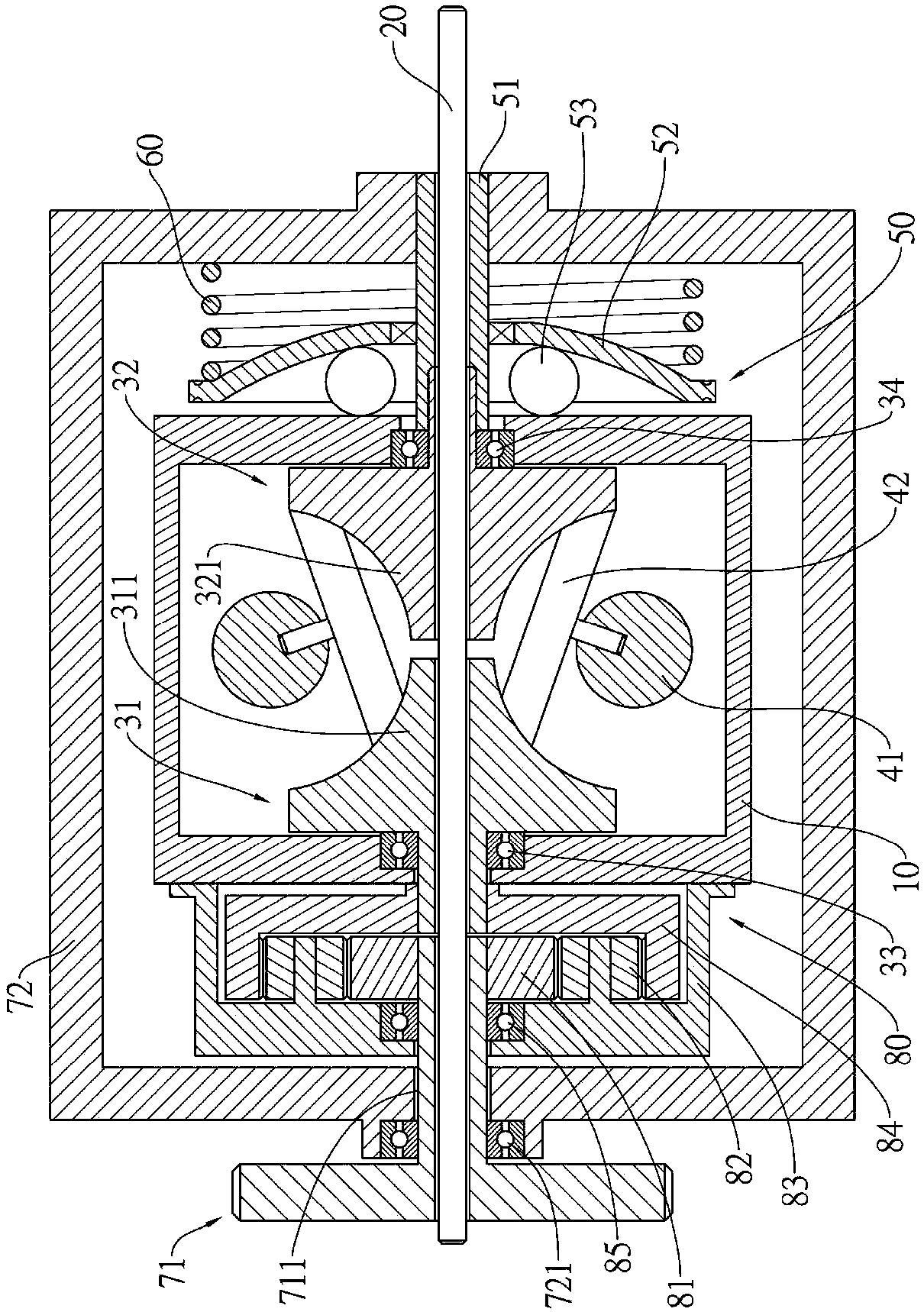

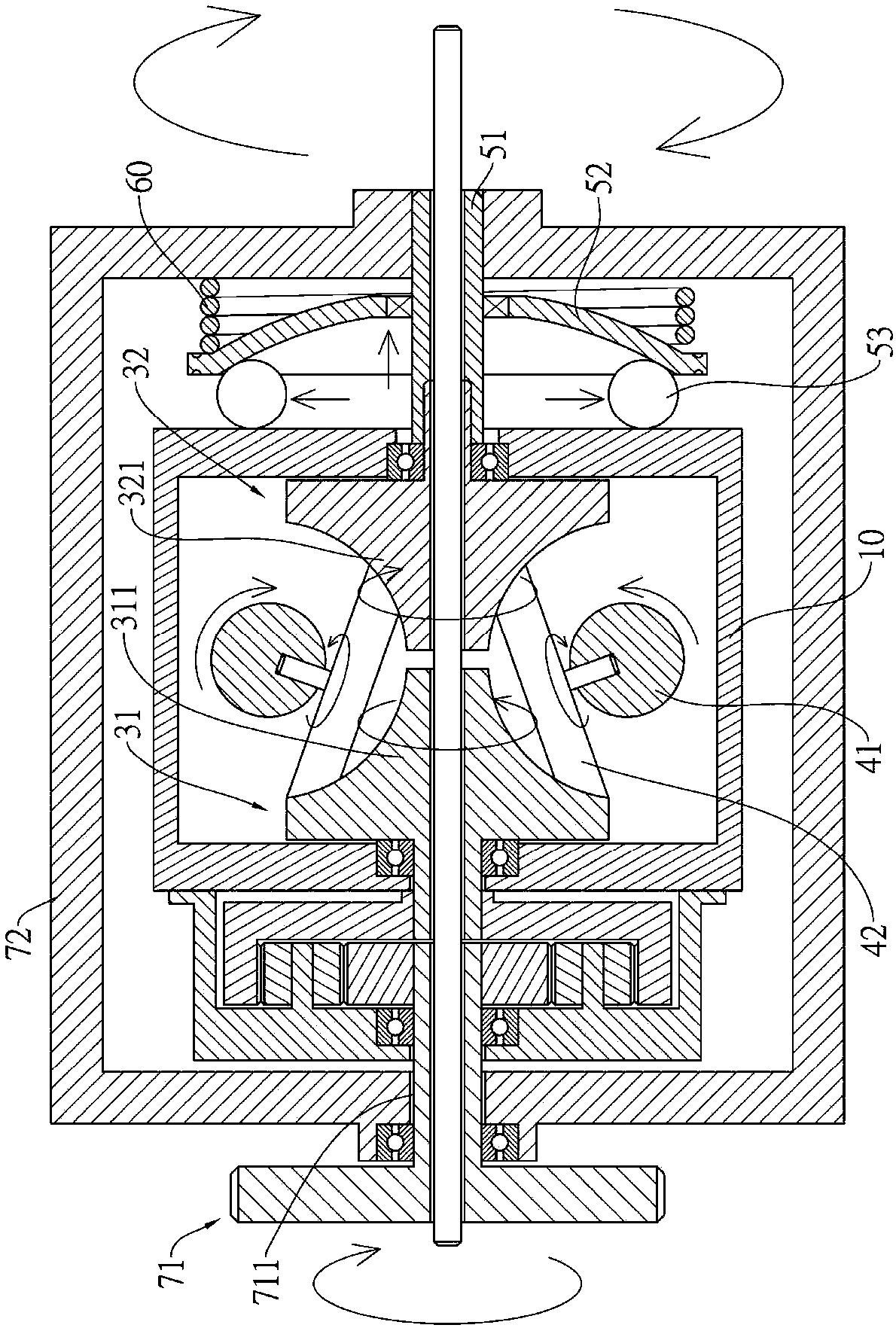

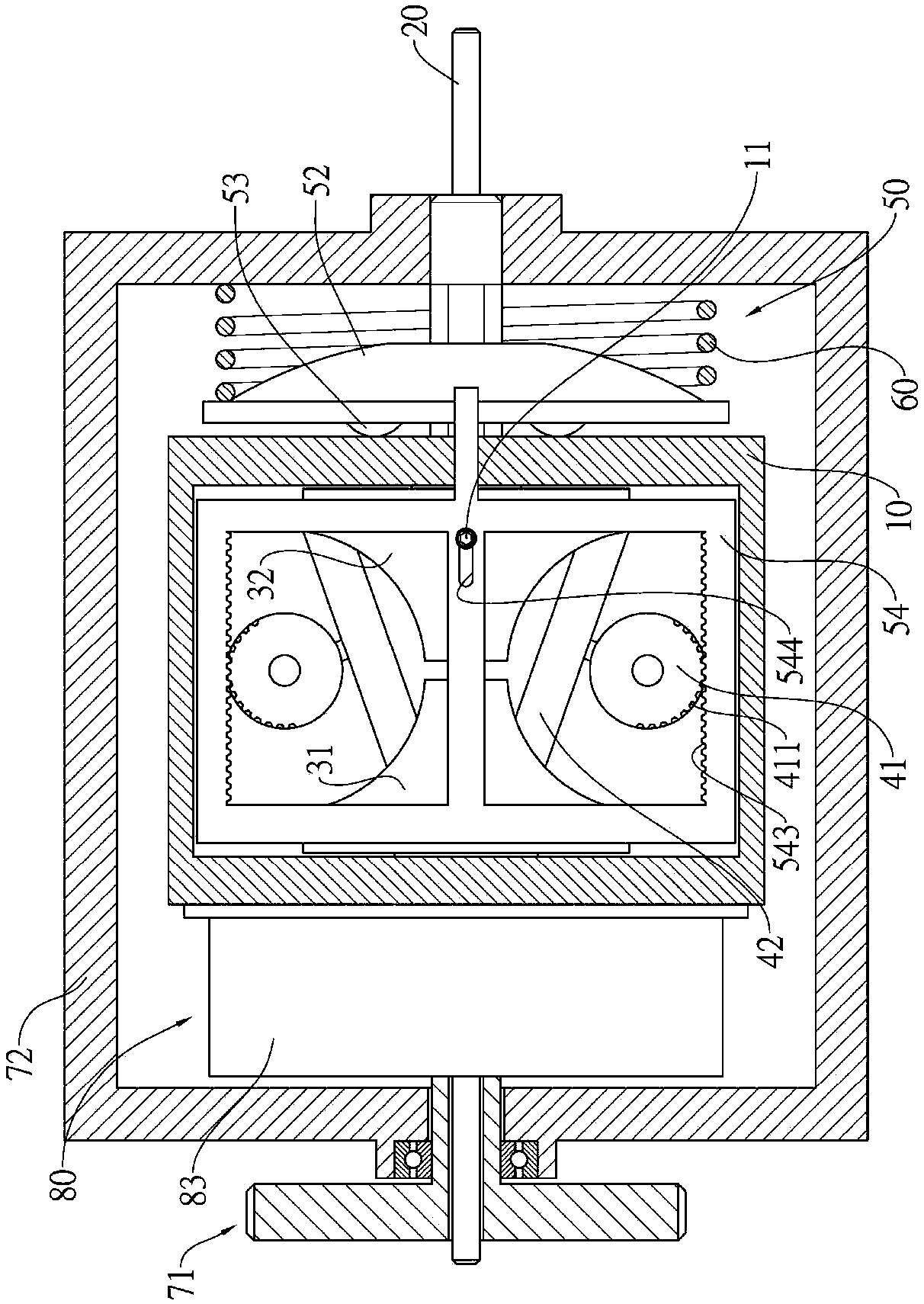

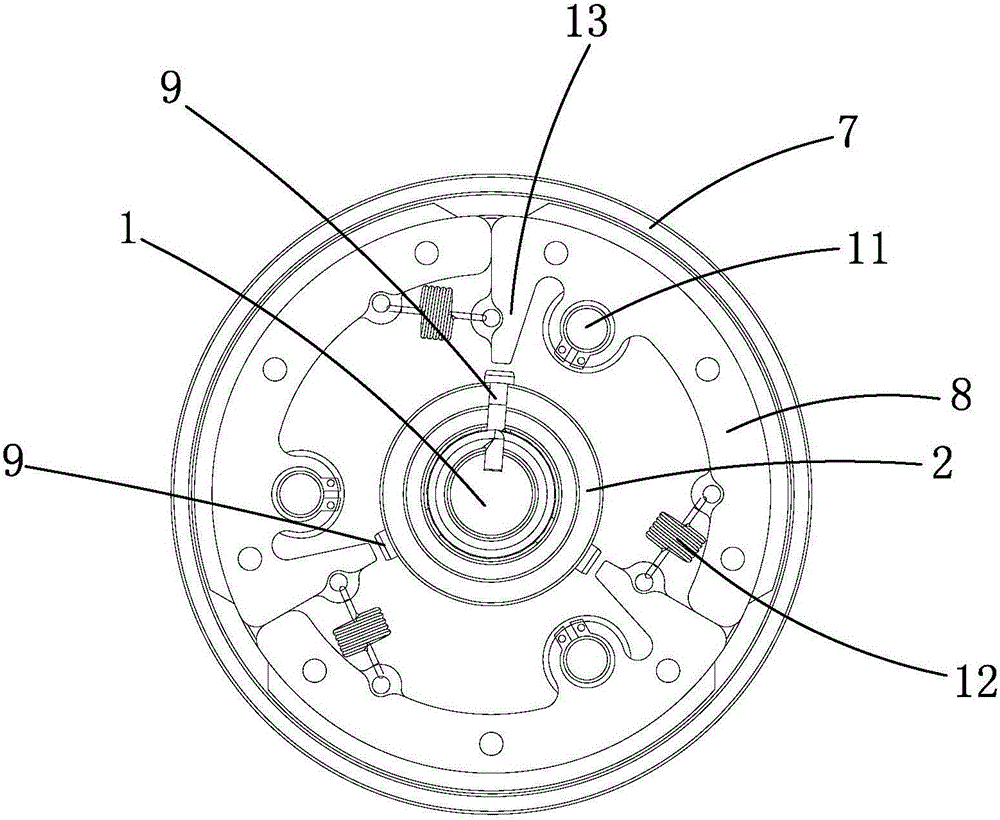

Stepless automatic speed change device for bicycle

ActiveCN109693757ASmall reduction ratioIncrease the reduction ratioWheel based transmissionAutomatic controlReduction ratio

The invention discloses a stepless automatic speed change device for a bicycle. The device comprises a shell, a central shaft, a power input disc, a power output disc, two rotors, two transmission discs, a centrifugal assembly, an elastic element and a reversing assembly; and the centrifugal assembly is connected with and drives the two rotors. When the rotating speed of bicycle wheels is higher,the rotating speed of the centrifugal assembly is higher, and the centrifugal assembly can automatically rotate the two rotors under the action of centrifugal force to gradually reduce the reduction ratio of the power input disc and the power output disc; when the rotating speed of the wheels is reduced, the elastic element can push the centrifugal assembly to reversely rotate the two rotors, so that the reduction ratio of the power input disc and the power output disc is increased. Rotation of the rotors is automatically controlled through centrifugal force generated during rotation of the wheels, and then the reduction ratio is automatically adjusted, so that the purpose of automatic stepless speed change is achieved.

Owner:张占庚 +2

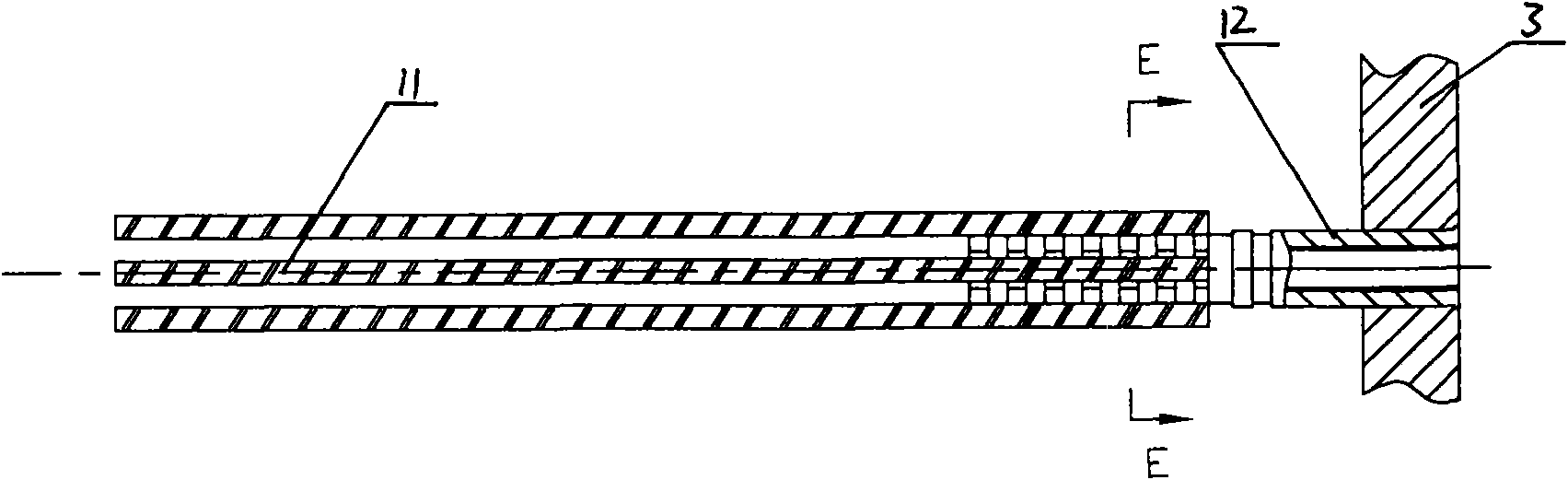

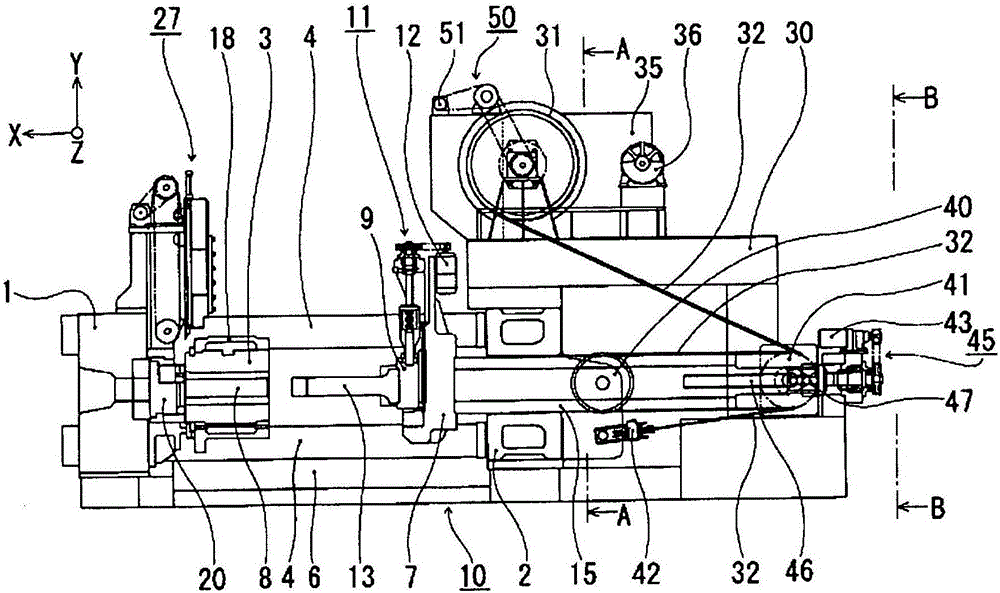

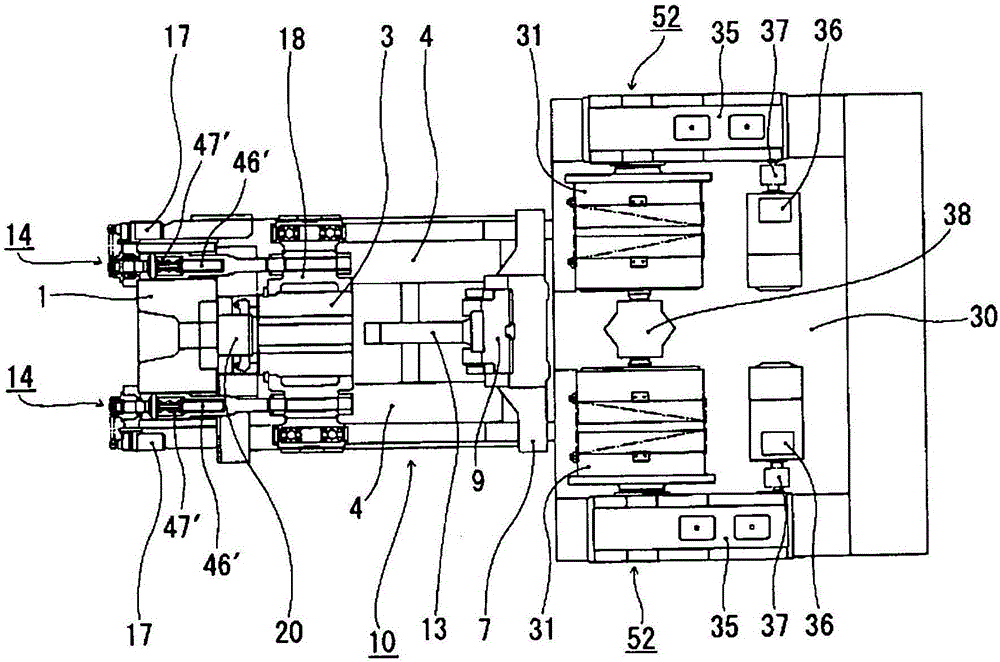

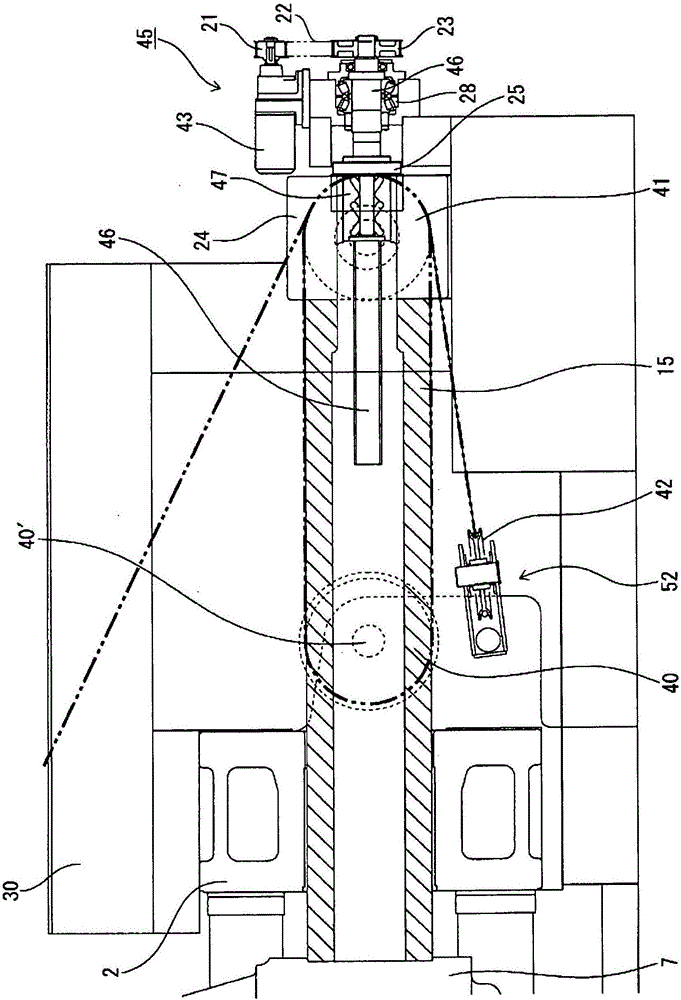

Extrusion press

An electric extrusion press in which an extrusion stem (13) is pressed with an extrusion force produced by an electric drive apparatus, thereby applying pressure to a billet (8) and extrusion-molding a predetermined article through a die (20), wherein the electric drive apparatus comprises one or a plurality of wire drums (31) rotatably provided, and a main motor (36) for electric extrusion rotates the wire drums to wind up wires (32) so as to apply a thrusting force in the extrusion direction to a moving pulley (41) and drive a crosshead (7) and the extrusion stem forward via an extrusion movement part (15).

Owner:UBE MASCH CORP LTD

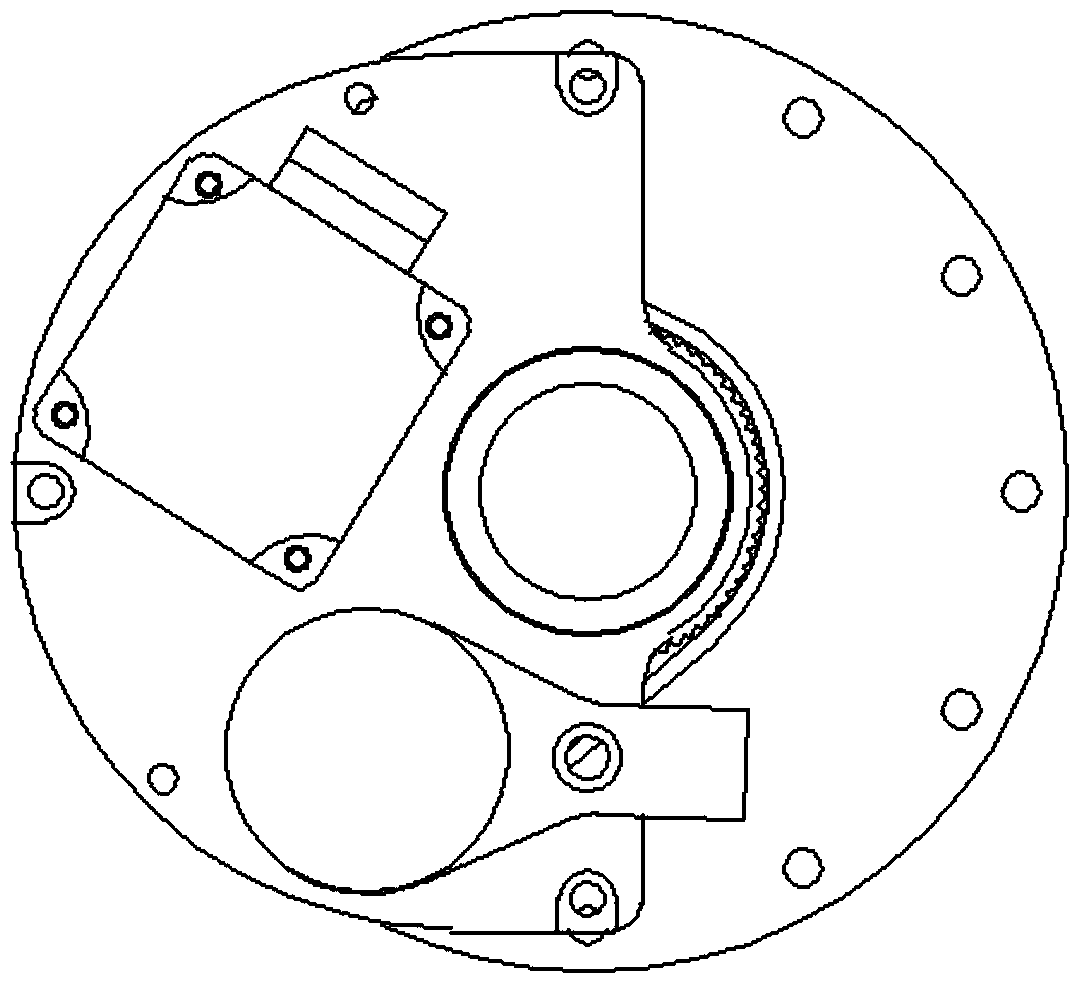

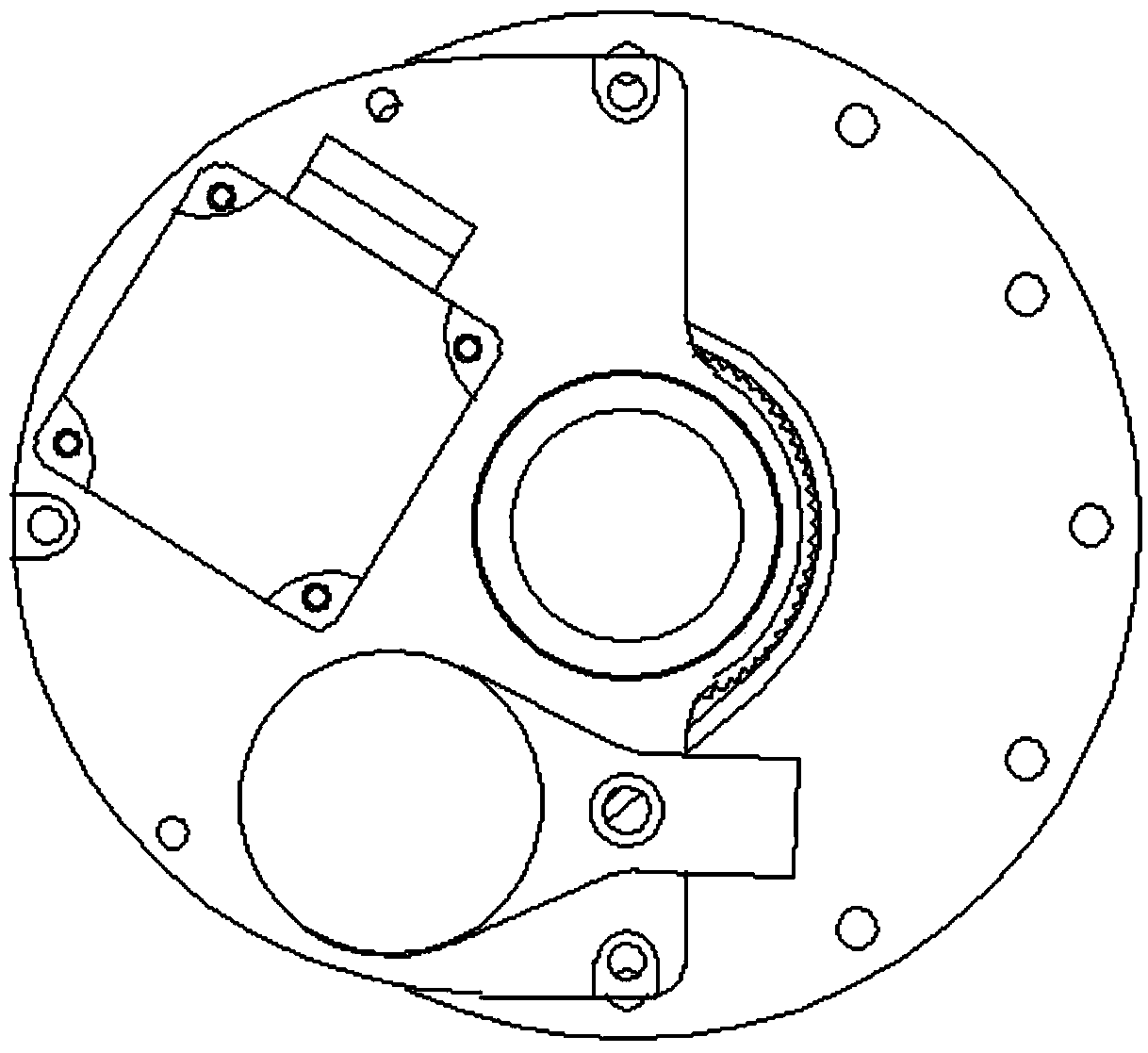

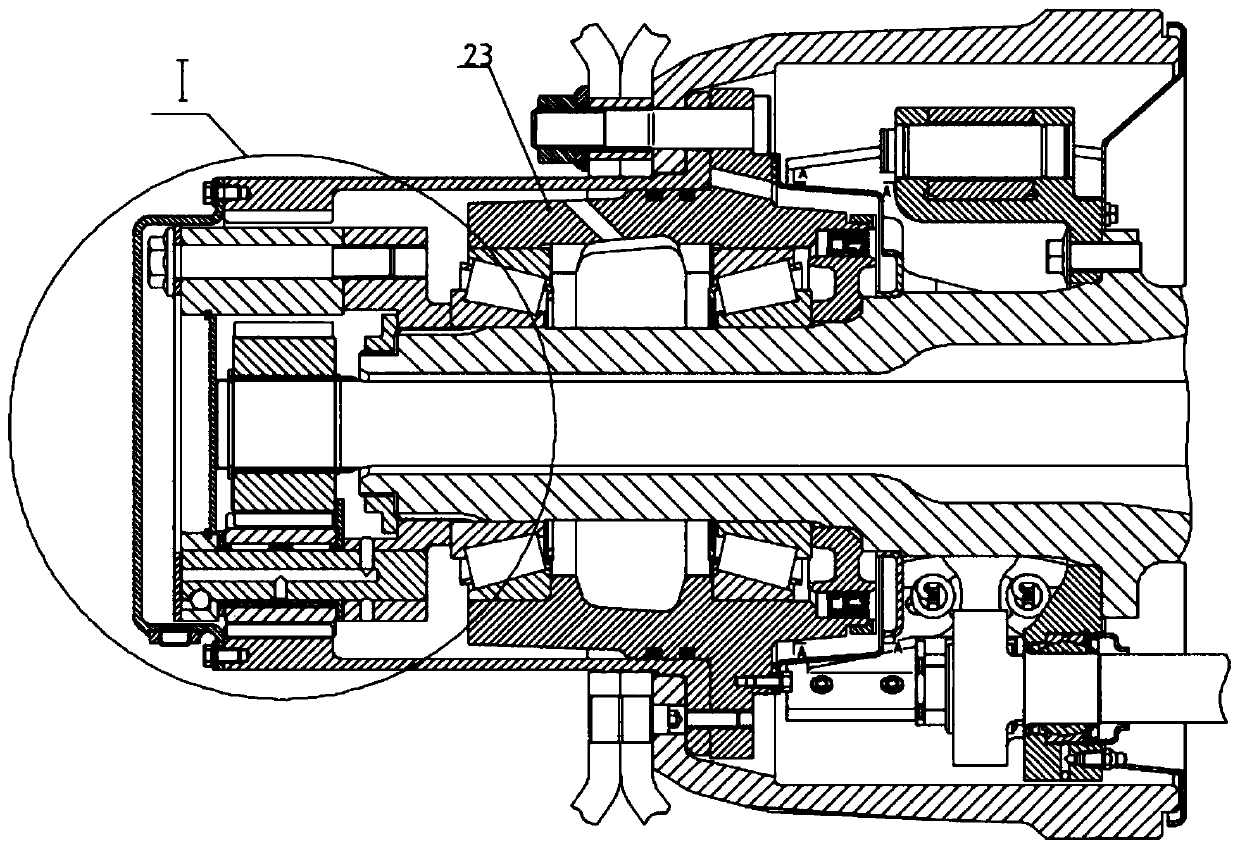

Integrated robot joint structure

The invention provides an integrated robot joint mechanism. The integrated robot joint mechanism comprises an output end body, a pin gear shell of an RV reducer, a fixed end body, an integrated motor,an output disc frame of the RV reducer, an eccentric shaft, a planet wheel, an angular contact ball bearing and a cycloid wheel, wherein the integrated motor comprises a motor main body and an inputshaft connected with the motor; the integrated motor and an RV reducer pin gear shell are combined into an integrated unit; the pin gear shell of the RV reducer of the integrated unit is fixedly connected with the fixed end body; the output disc frame of the RV reducer is connected with the output end body; and the eccentric shaft comprises a cam, an eccentric shaft concentric circle, a tapered roller bearing and a needle roller retainer. In the technical field of RV speed reducers, the problems of large noise, complex debugging and high installation precision requirement of an existing robotjoint structure are solved by adopting the integrated robot joint mechanism.

Owner:南通振康机械有限公司 +1

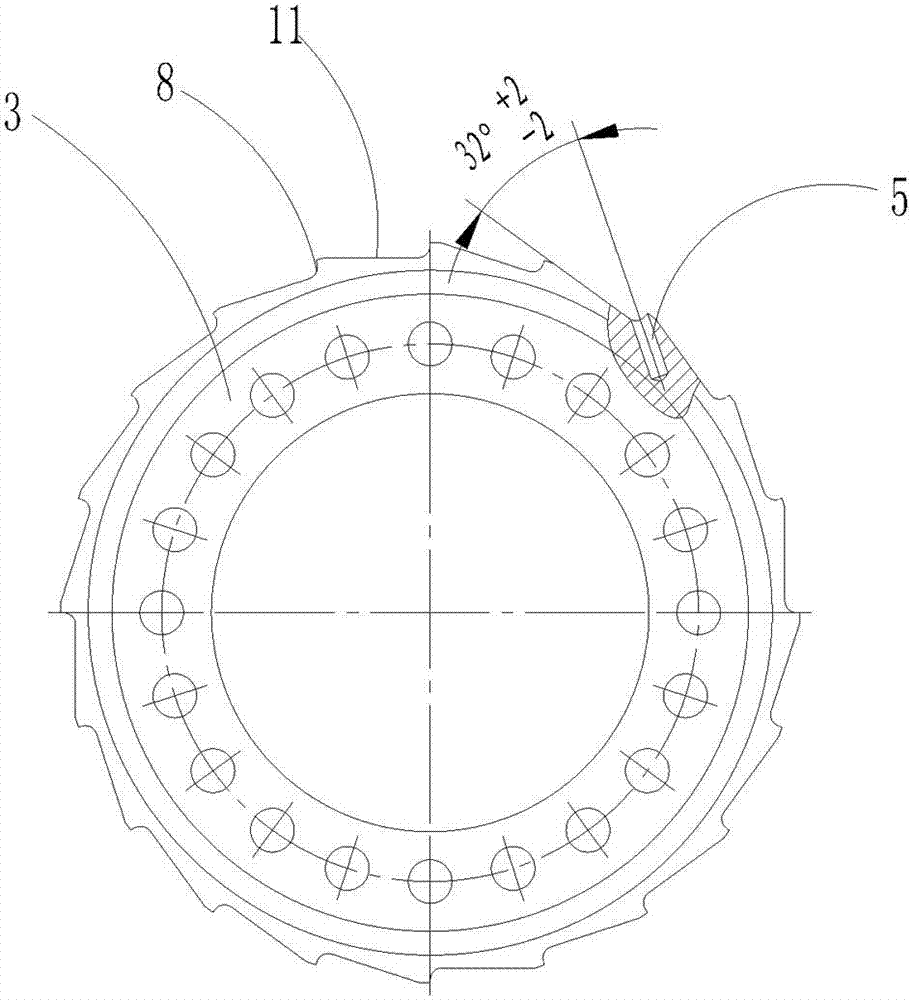

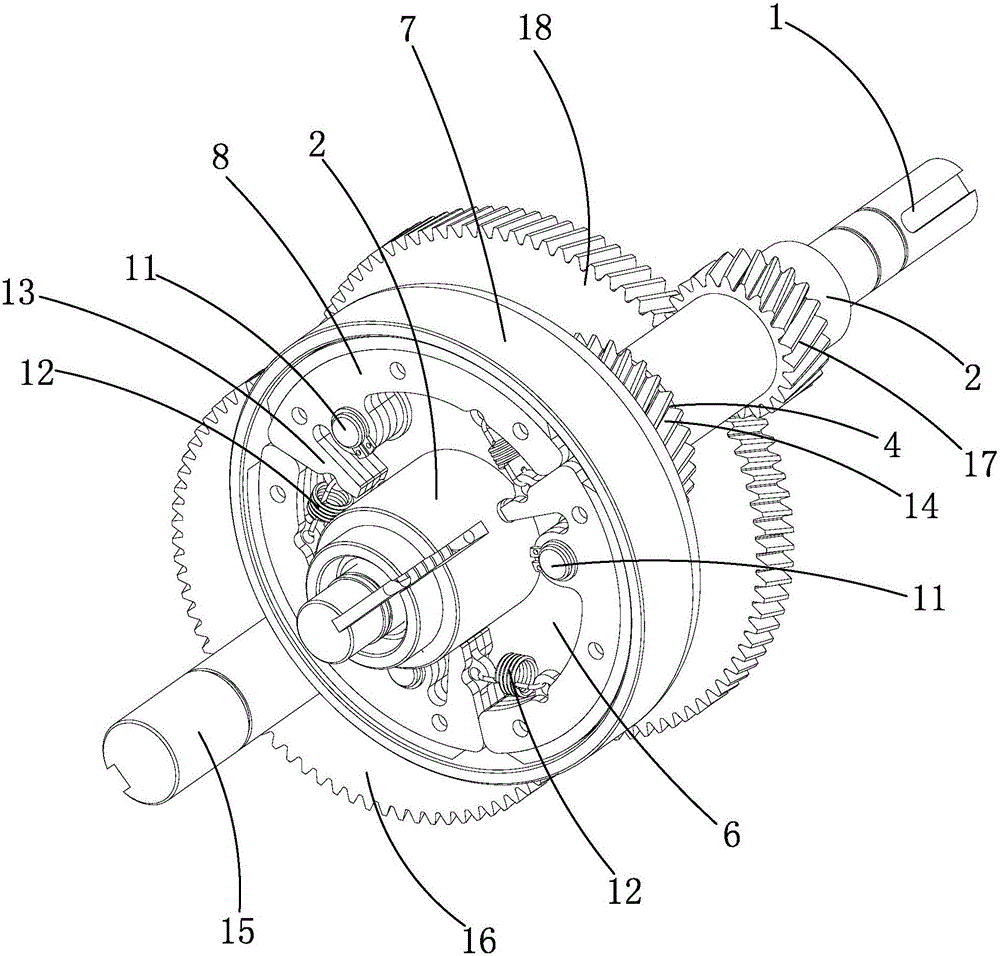

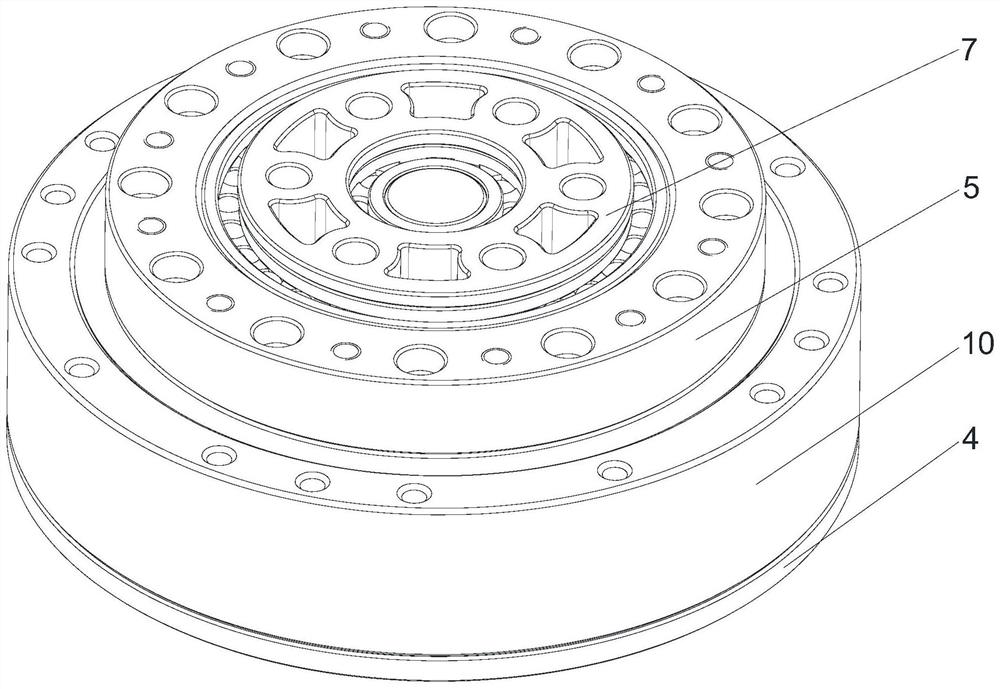

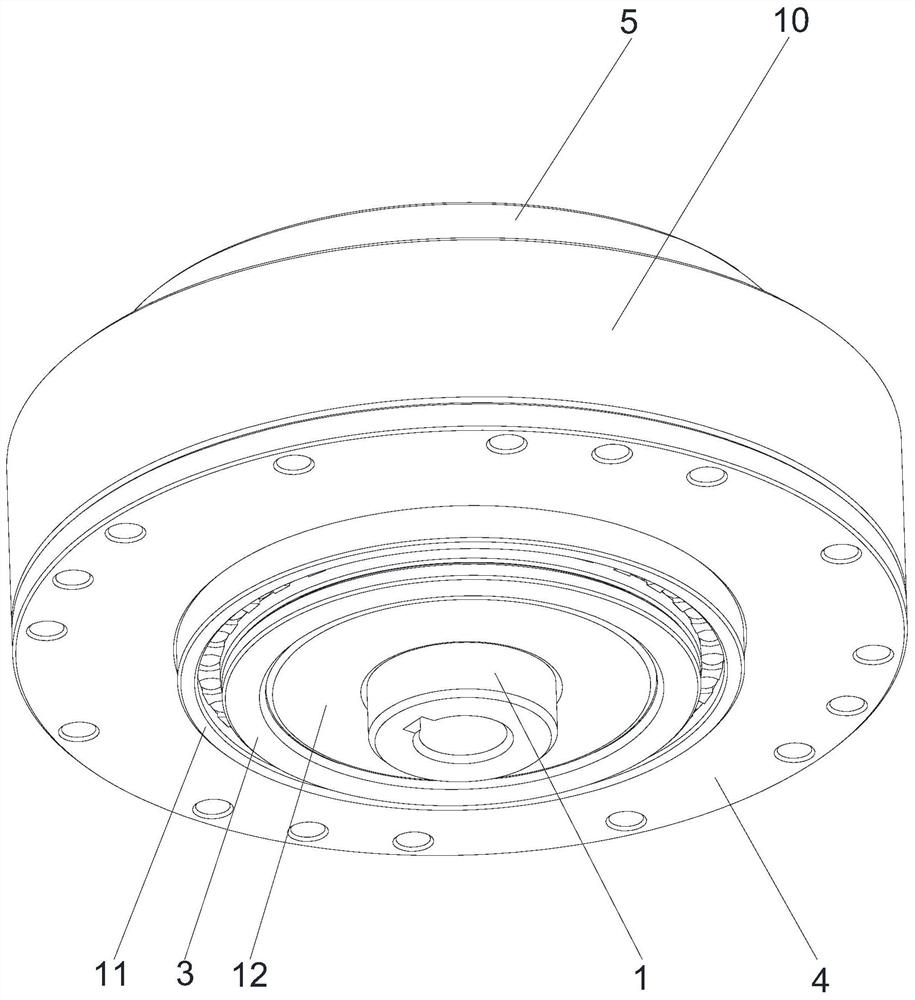

Spring resetting type overrunning clutch for energy-conservation type loader

The invention relates to the technical field of engineering machinery transmission, in particular to a spring resetting type overrunning clutch for an energy-conservation type loader with low rotating speed. An inclined angle between a spring resetting hole and an inner ring cam ranges from 30 degrees to 34 degrees; the diameter of the spring resetting hole ranges from 4.49mm to 4.538mm, and the depth of the spring resetting hole ranges from 15mm to 15.1mm; and the cross section of a roller path wall is circular arc-shaped. The spring resetting type overrunning clutch has a simple structure, a low reduction ratio, large transmission torque, good overloading performance and long service life, is stable in working and safe and reliable, and is beneficial to realizing energy conservation and emission reduction of the domestic loader and improving the performances of the whole loader.

Owner:HANGZHOU ZONGXING GEAR

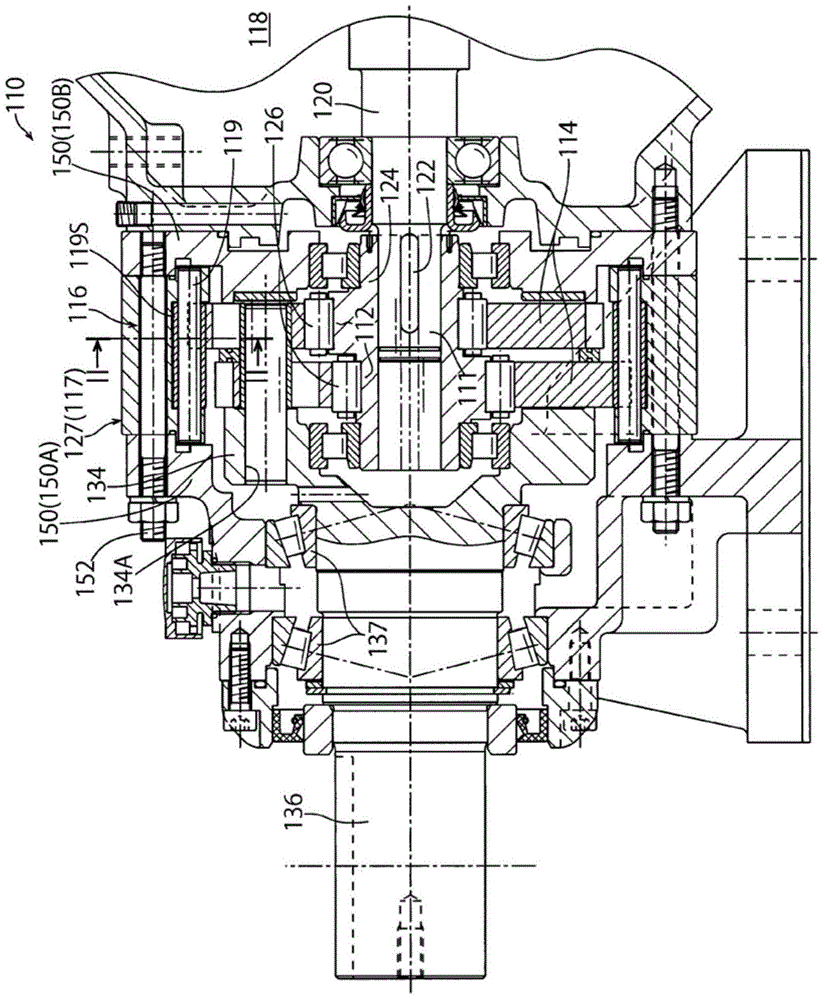

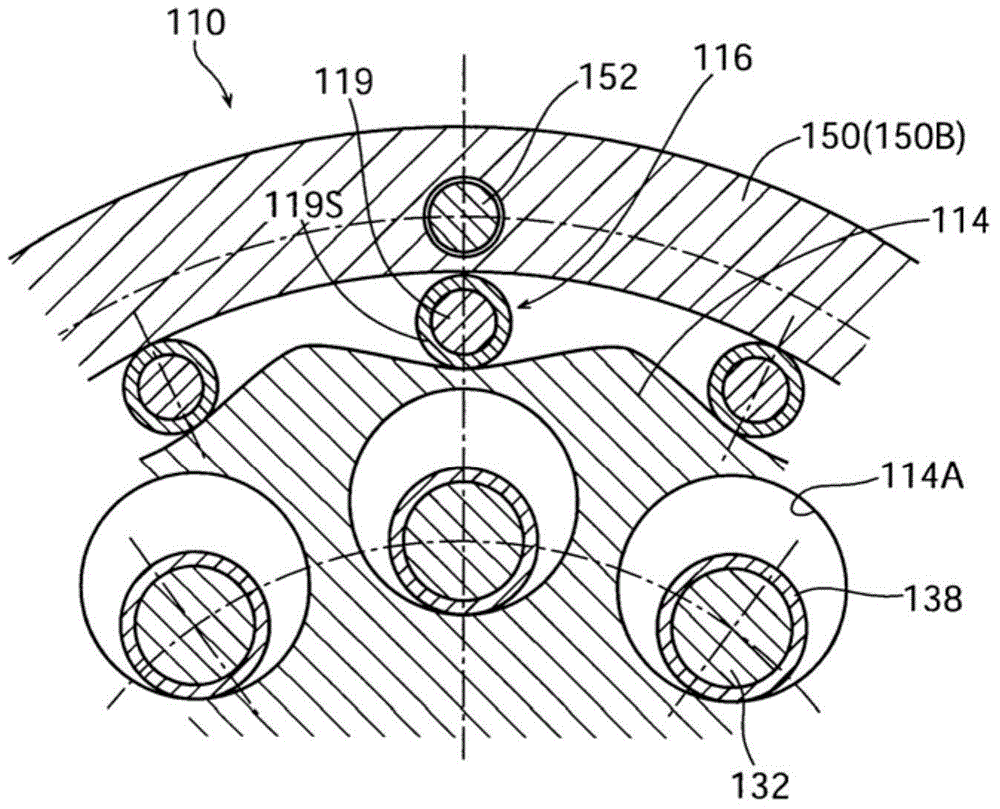

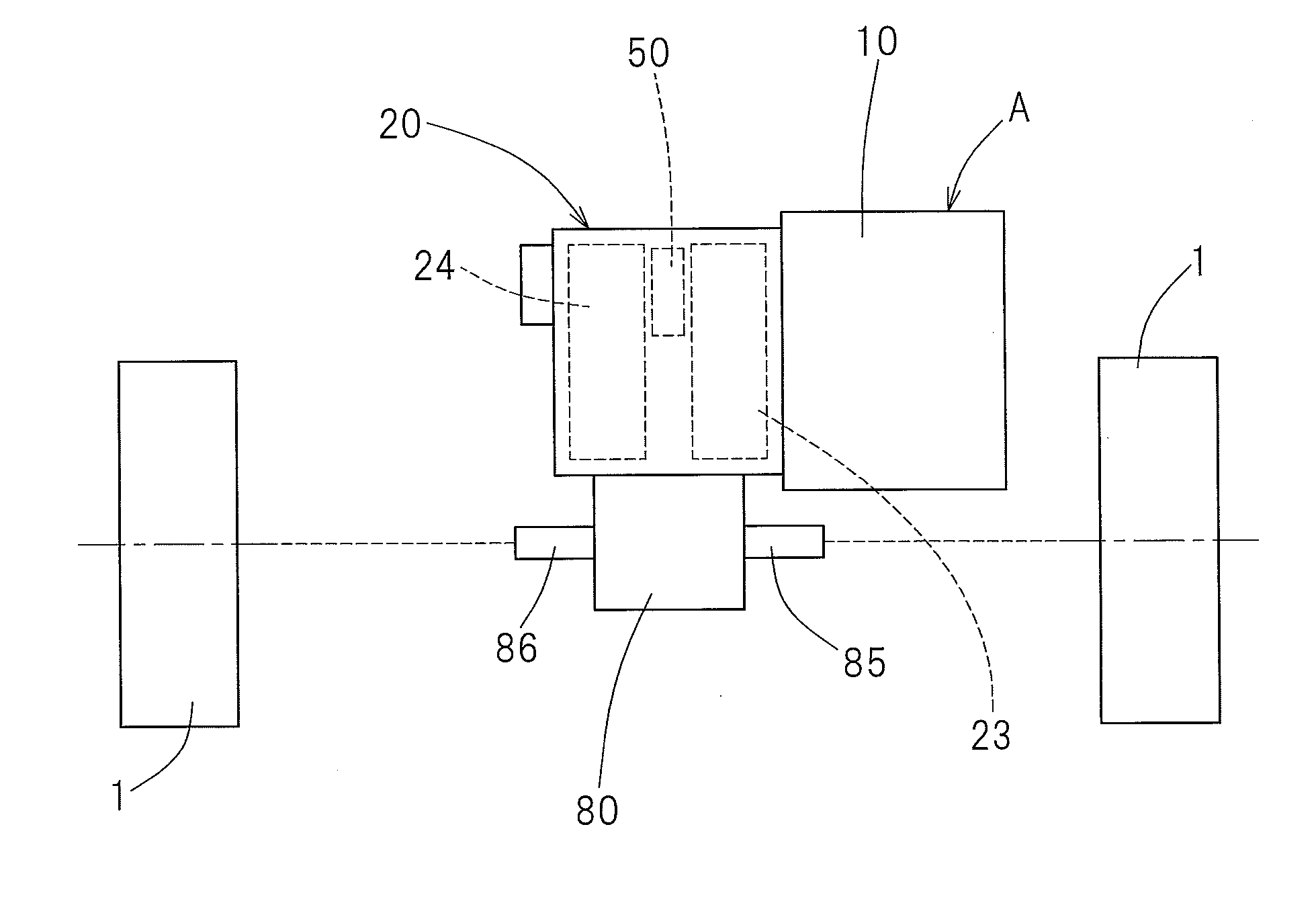

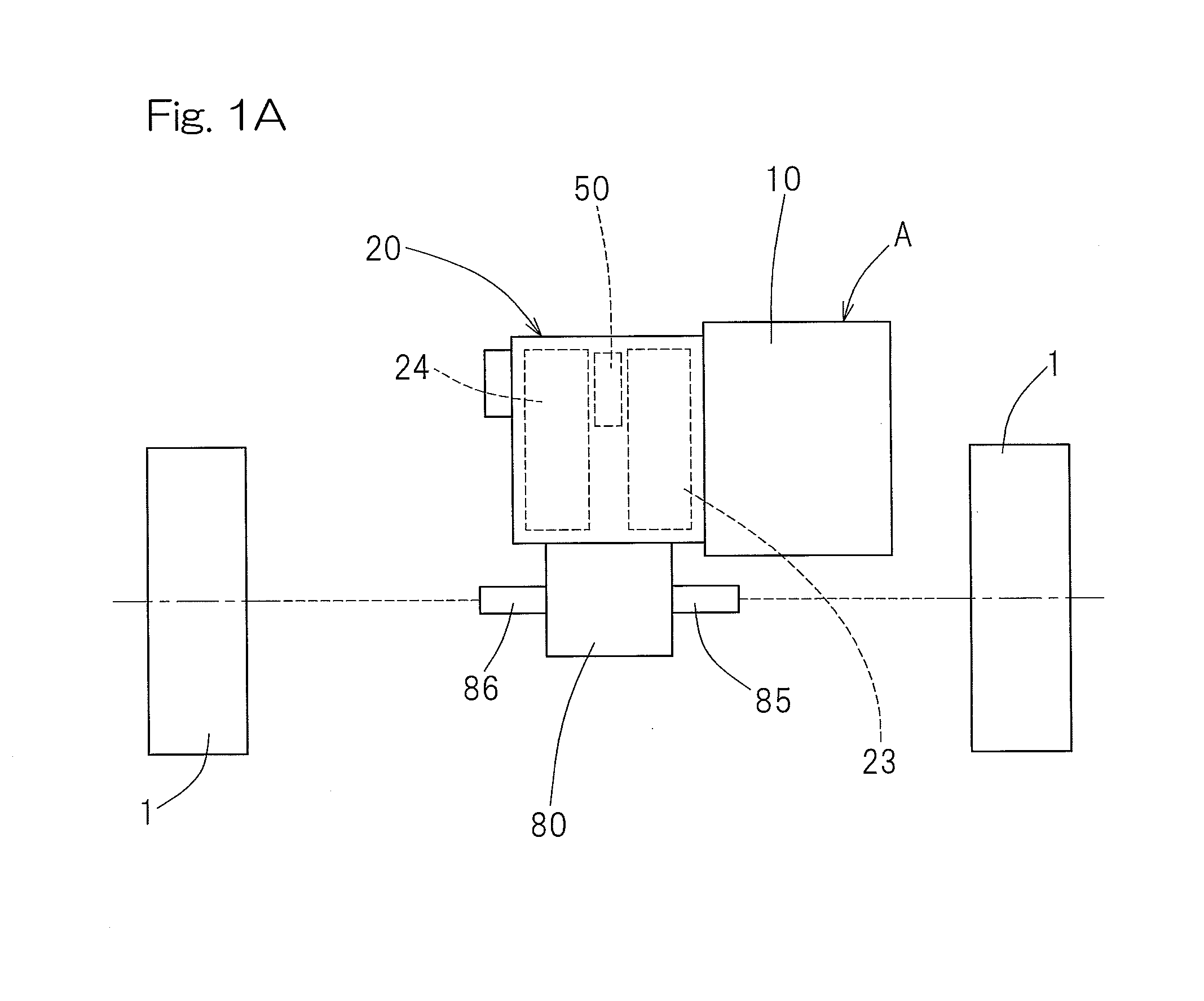

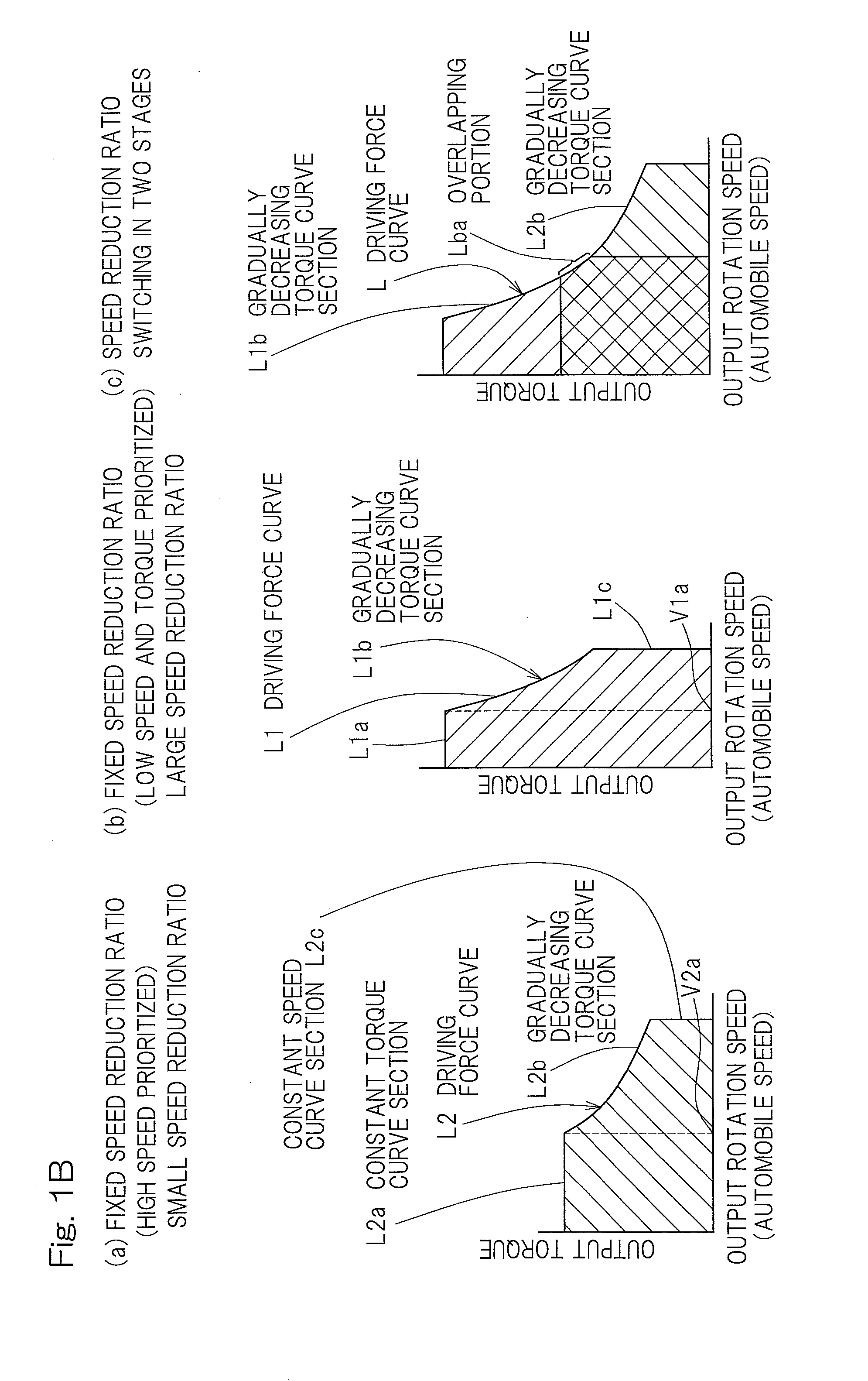

Vehicular motor drive device and automobile

InactiveUS20140209398A1Light weightSmall sizeHybrid vehiclesGearing controlMotor driveReduction drive

A vehicular motor drive device is provided with an electric motor and a speed reducer having two gear trains capable of switching a fixed gear ratio. Driving force curves, which are determined depending on an output characteristic of the motor and represent a relationship between an output rotation speed in the respective gear train and an output torque, which is obtainable maximally at such output rotation speed, have a constant torque curve section, a gradually decreasing torque curve section and a constant speed curve section. The gear trains have respective speed reduction ratios such that the driving force curve of a gear train having a larger speed reduction ratio and the driving force curve of a gear train having a smaller speed reduction ratio continue to and partially overlap with each other in the gradually decreasing torque curve sections.

Owner:NTN CORP

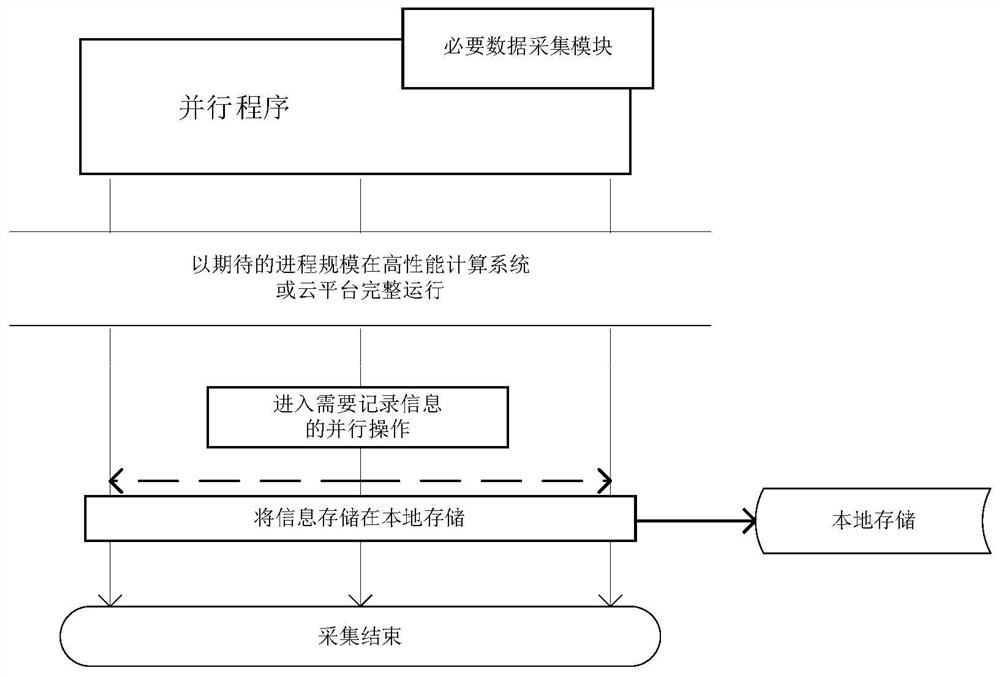

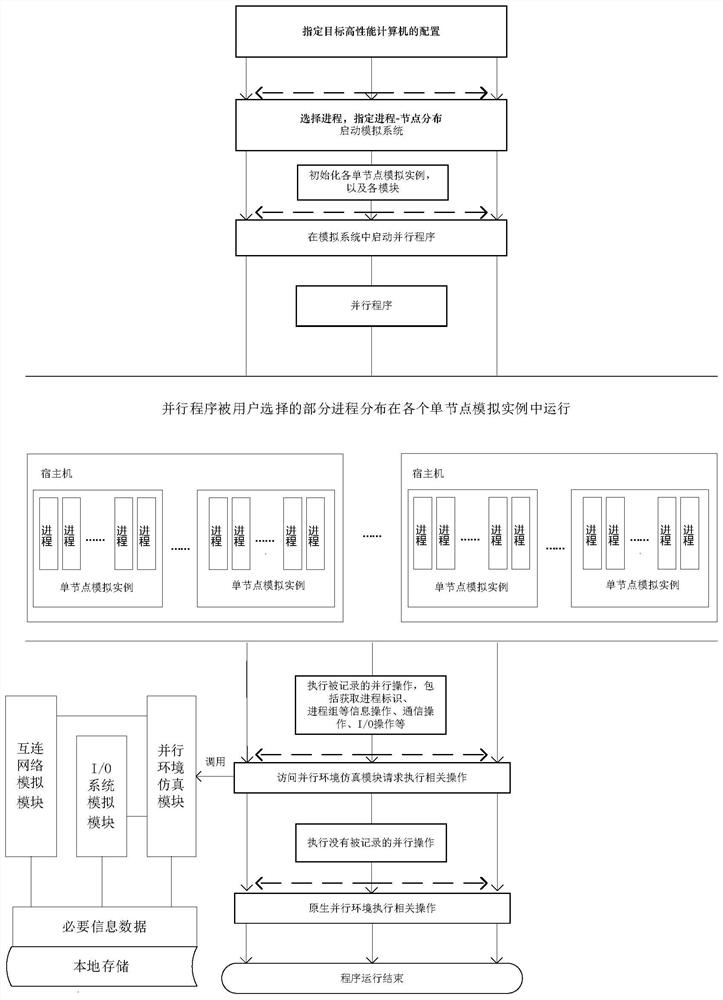

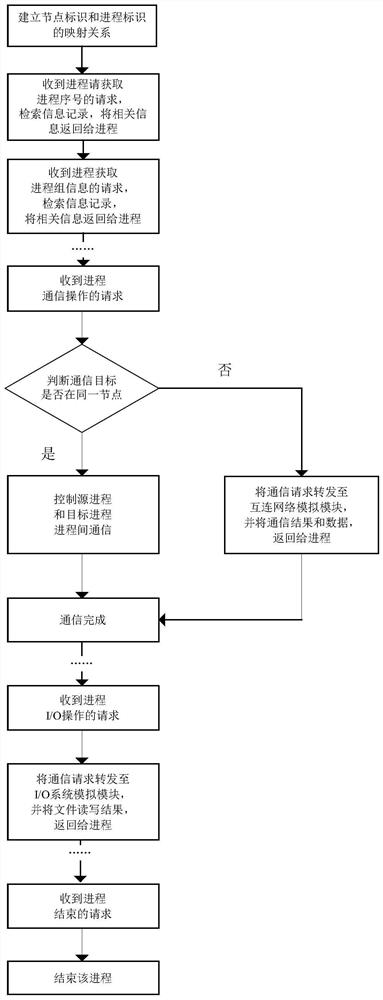

Large-scale parallel system simulation method based on single-node simulation

ActiveCN112068942AVersatilityFlexibleProgram initiation/switchingResource allocationComputation processProcess scaling

The invention provides a large-scale parallel system simulation method based on single-node simulation, wherein the method comprises the following steps: step 1, firstly, a large-scale parallel program runs in an existing computing system or a cloud platform according to an expected process scale and problem scale, and running information is acquired in a program running process; step 2, after necessary information supporting operation of a single process is collected, a user specifies configuration of a target high-performance computer to be simulated; step 3, the user selects a part of processes to be simulated, specifies process-node distribution, inputs the processes and node information into configuration, and starts a parallel system simulation system in a local host machine cluster;and step 4, the user starts the parallel program in the parallel system simulation system, and in the execution process, the calculation process, process scheduling and process-to-resource competition of the processes executed in the same node are accurately simulated by the single-node whole system simulation instance.

Owner:BEIHANG UNIV

Transmission with torque control mechanism

ActiveCN105909693ALarge reduction ratioLarge tooth radius and low speed small reduction ratioToothed gearingsAutomatic clutchesClutch controlControl theory

The invention relates to a transmission with a torque control mechanism. A traditional transmission cannot shift a gear according to a torque, so that a power source is easy to damage. The transmission comprises an input shaft linked with the power source, an output shaft, a clutch mechanism and a gear set; the transmission is provided with the torque control mechanism; the torque control mechanism includes an inner transmission sleeve, an elastic element and a clutch control module; the inner transmission sleeve is coated with an outer transmission sleeve, and realizes switching with the outer transmission sleeve between a linkage state and a cutoff state through the clutch mechanism; the input shaft and the inner transmission sleeve urge deformation of an elastic element due to a torque difference value; and the clutch mechanism is controlled through triggering the clutch control module. The elastic element is additionally arranged on a traditional clutch mechanism structure, so that the elastic element is deformed to trigger the clutch control module to interfere actions of the clutch module; the gear is adjusted according to the rotating speed and the torque; and the power is limited in a set range, so that various failures or performance reduction caused by insufficient power can be prevented, and the safety of the power source is guaranteed.

Owner:ZHEJIANG UNITE MOTOR

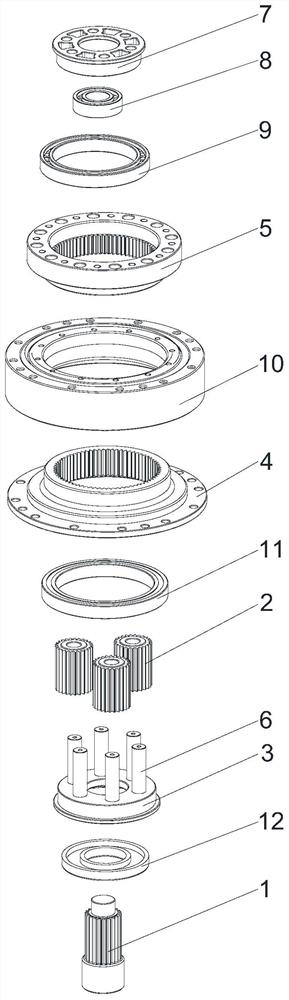

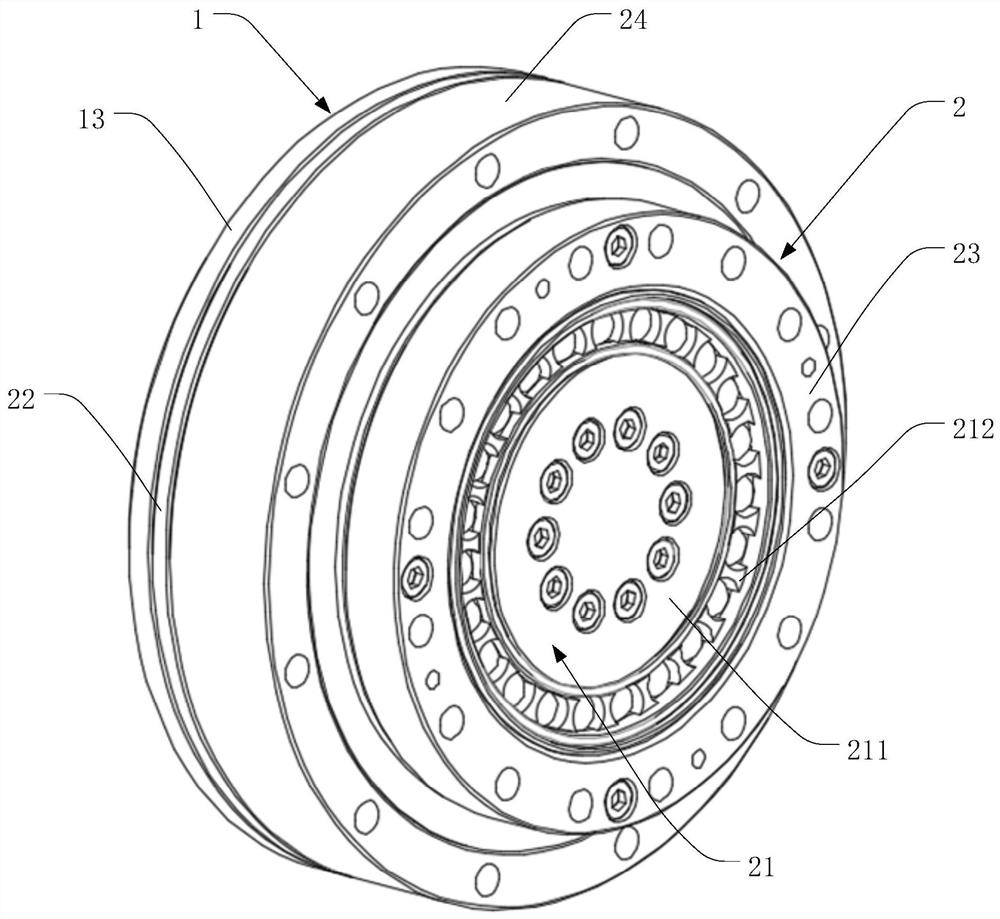

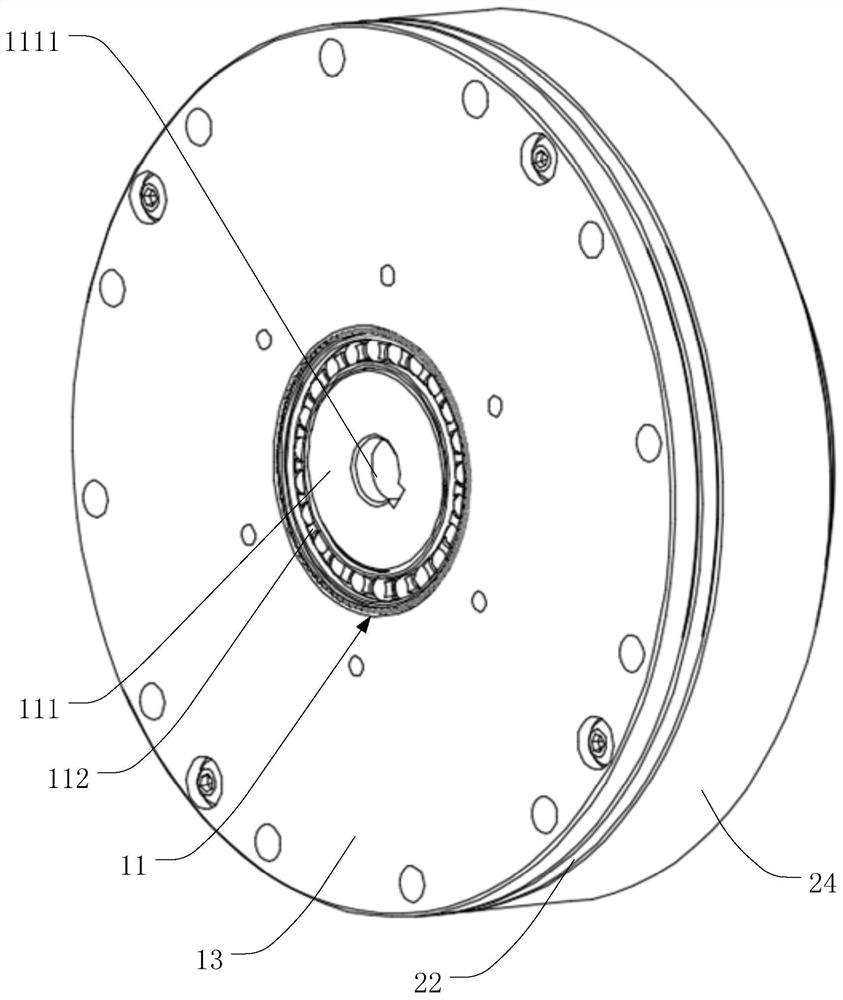

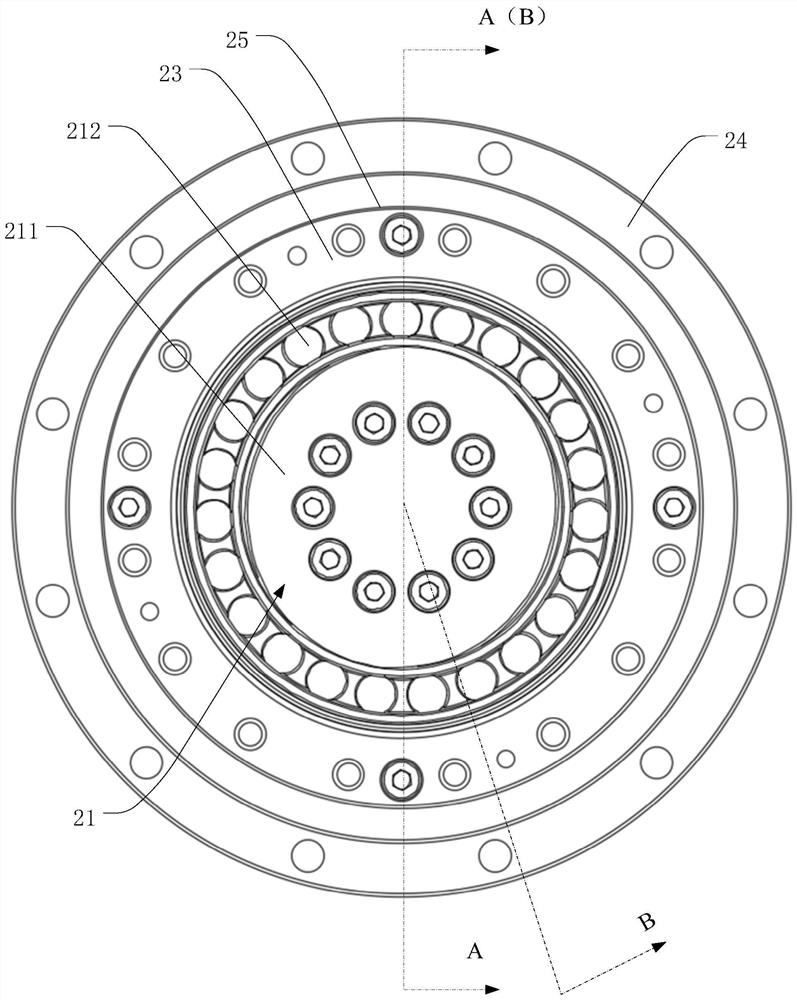

Self-locking planetary reducer

InactiveCN111795120AHigh modulusSimple structureToothed gearingsGearing detailsGear driveReduction drive

The invention discloses a self-locking planetary reducer. The self-locking planetary reducer comprises an inner gear ring, a sun gear, a planet wheel and a planet carrier. The inner gear ring comprises a fixed inner gear ring body and an output inner gear ring body used for power output and located above the fixed inner gear ring body. The number of gear teeth of the fixed inner gear ring body isgreater than or smaller than the number of gear teeth of the output inner gear ring body. The planet wheel is mounted on the planet carrier and the outer side of the planet wheel is engaged with the fixed inner gear ring body and the output inner gear ring body. The sun gear is fixed to the center of the inner gear ring body and is engaged with the inner side of the planet wheel. One end of the sun gear is used for being connected with a power source, so that the sun gear drives the planet wheel to rotate along the inner rings of the fixed inner gear ring body and the output inner gear ring body when rotating, and the output inner gear ring body is synchronously driven to rotate and output power. The self-locking planetary reducer has the beneficial effects that the structure is simple, the gear modulus of the self-locking planetary reducer can be made larger compared with other reducers under the same deceleration ration and the same size, the impact force is strong, the service lifeis long, the torque is large, the positioning precision is high, the vibration is small, the reduction ratio is larger, and the repeated positioning precision is high.

Owner:何金仙

Two-stage harmonic speed reduction equipment

The invention belongs to the technical field of speed reducers, and particularly relates to two-stage harmonic speed reduction equipment. The two-stage harmonic speed reduction equipment comprises a first-stage harmonic speed reducer and a second-stage harmonic speed reducer, wherein the first-stage harmonic speed reducer comprises a first-stage wave generator, a first-stage flex spline and a first-stage circular spline connected to the first-stage flex spline in a sleeving manner; the first-stage flex spline is connected to the first-stage wave generator in a sleeving manner; the second-stage harmonic speed reducer comprises a second-stage wave generator, a second-stage flex spline and a second-stage circular spline connected to the second-stage flex spline in a sleeving manner; the second-stage flex spline is connected to the second-stage wave generator in a sleeving manner; the first-stage circular spline is connected to the second-stage flex spline; and the first-stage circular spline is connected to the second-stage wave generator. The two-stage harmonic speed reduction equipment has the advantages of being relatively large in speed reduction ratio, small in axial size, light in weight and the like, and the practicability and applicability of the two-stage harmonic speed reduction equipment are improved.

Owner:深圳市大族精密传动科技有限公司

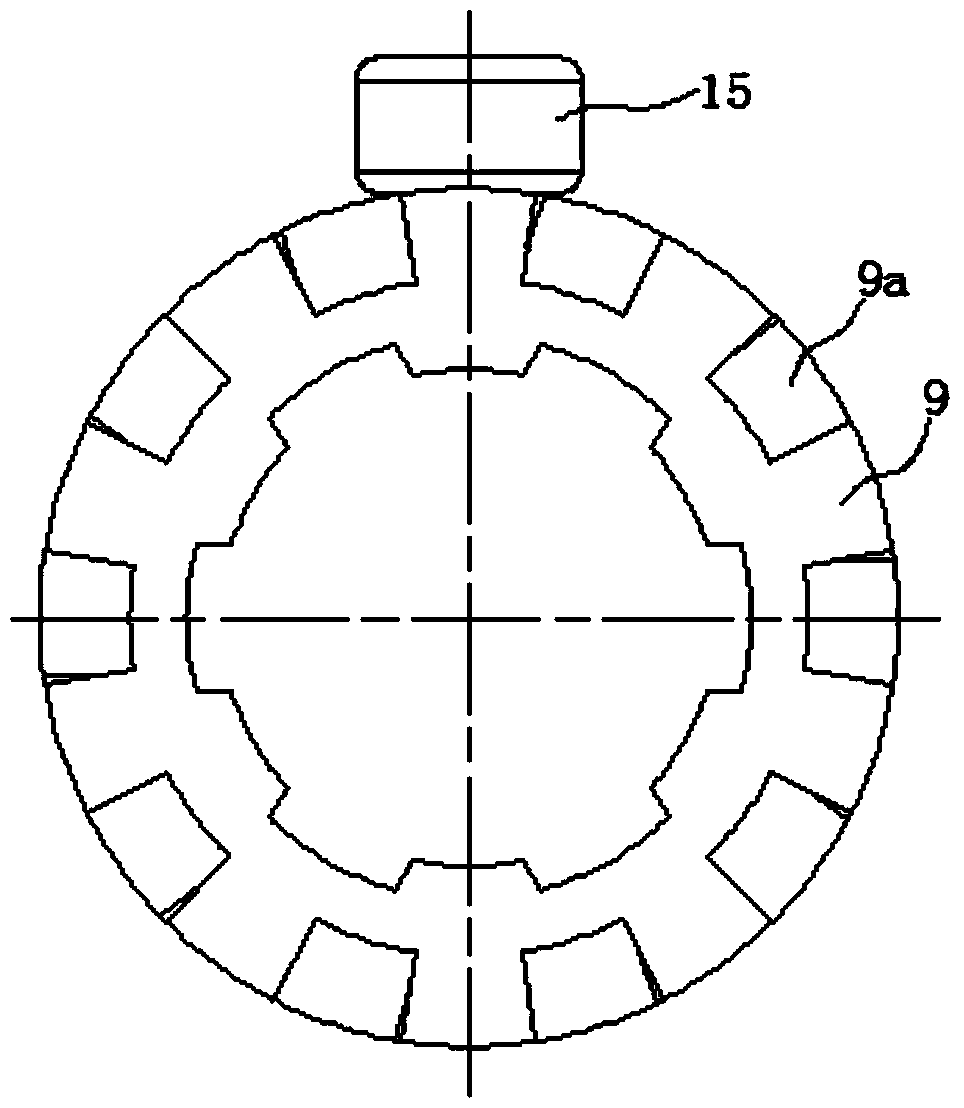

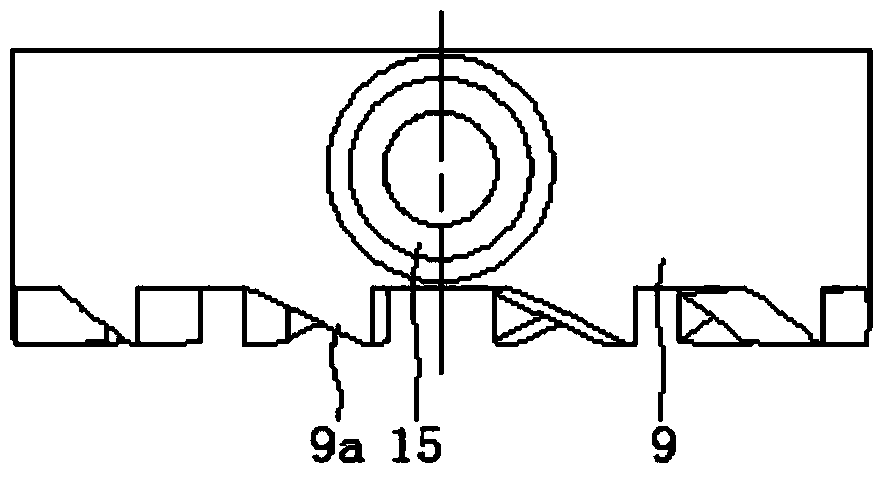

Three-gear variable speed transmission mechanism of electrocar

InactiveCN103836128AEliminate the ills of damageAvoid breakingToothed gearingsGearing controlDrive shaftEngineering

The invention discloses a three-gear variable speed transmission mechanism of an electrocar. A transmission sleeve (3) sleeves a spindle hollowly, a three-gear gear (4) sleeves on the periphery of one end of the transmission sleeve (3) hollowly, a two-grade driving reduction gear (14) is arranged on the three-gear gear (4), the other end of the transmission sleeve (3) is connected with an output spline sleeve (5), a two-gear gear (7) and a one-gear gear (6) sleeve a middle portion of the transmission sleeve (3) side by side hollowly, a double-pawl sliding sleeve (8) is arranged between the two-gear gear (7) and the two-grade driving reduction gear (14), and a single-pawl sliding sleeve (9) is arranged between the one-gear gear (6) and the output spline sleeve (5). When the three-gear variable speed transmission mechanism runs at a high speed, efficiency of the three-gear variable speed transmission mechanism is higher than that of other gear-shifting motors since only one reduction grade is provided, gear shifting is convenient and stable, and large impact force during gear shifting can be avoided. The spindle bears the overall weight of the electrocar, so that assembling difficulty and precision are lowered, and fracture of a motor shaft can be avoided effectively.

Owner:重庆绿华电动车有限公司 +1

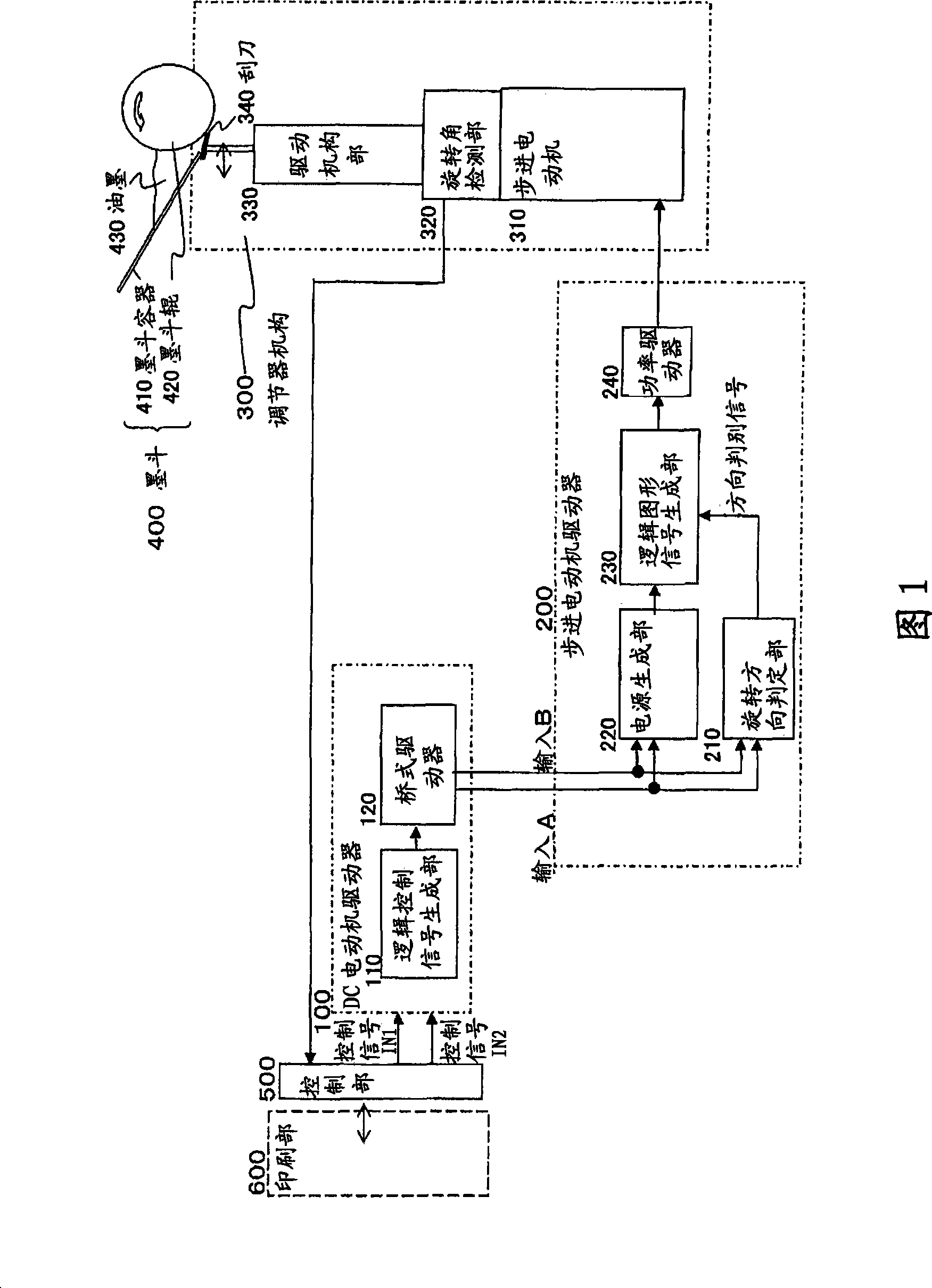

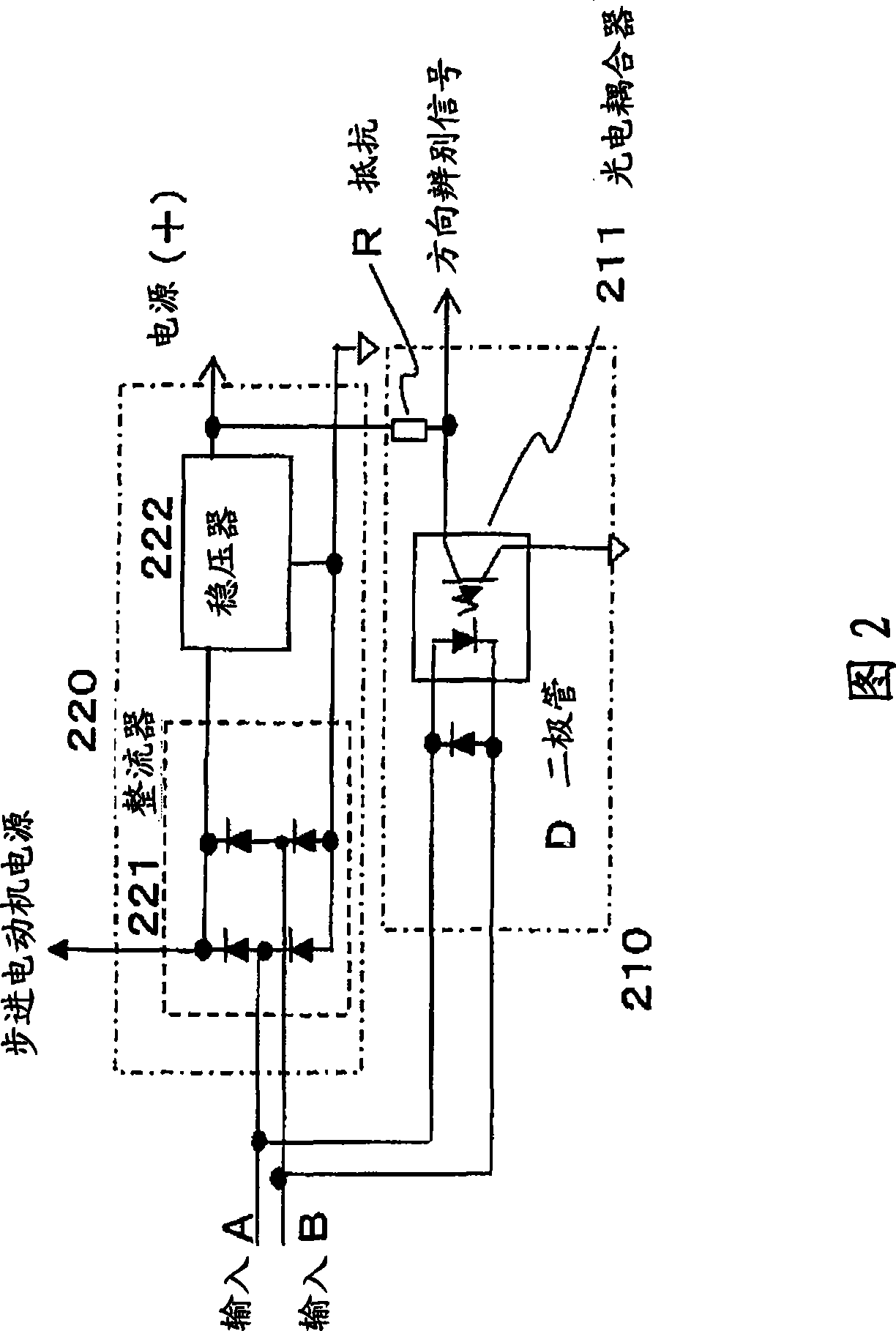

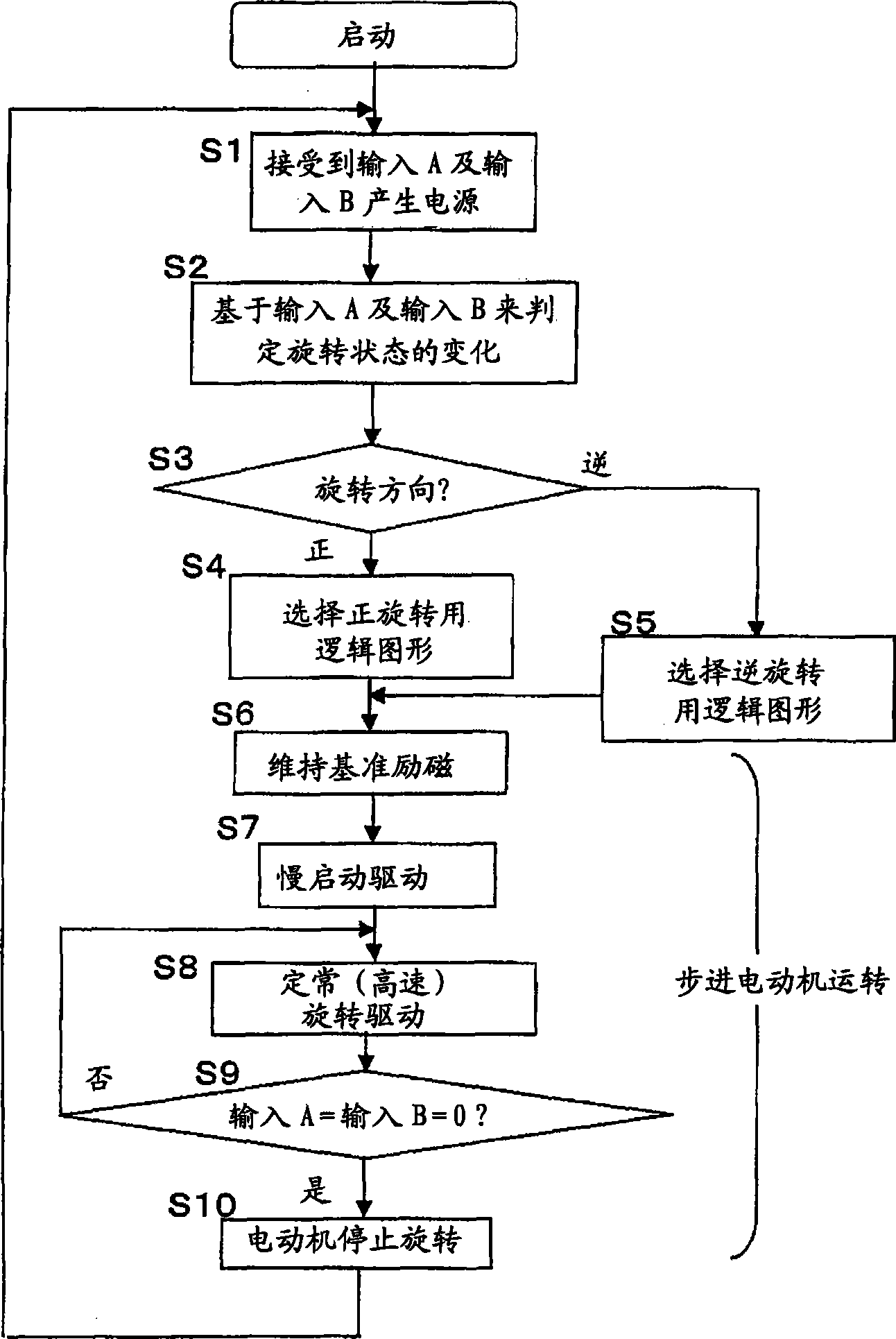

Ink supply mechanism and stepping motor driver therefor

In the invention, the DC motor for driving printing ink supplying quantity regulating scraper can be replaced by a step motor, and the step motor can be driven by the same control signal with the DC motor. The DC motor is replaced by the step motor (310); and the DC motor driver (100) as driving unit for providing analog voltage is remained; the analog voltage is used for driving the DC motor to rotate, reversely rotate or stop; a step motor driver (200) is disposed between the DC motor driver (100) and the step motor for generating power source from the analog voltage used for driving the DC motor and generating logic figure signal to drive the step motor.

Owner:COPAL ELECTRON CO LTD

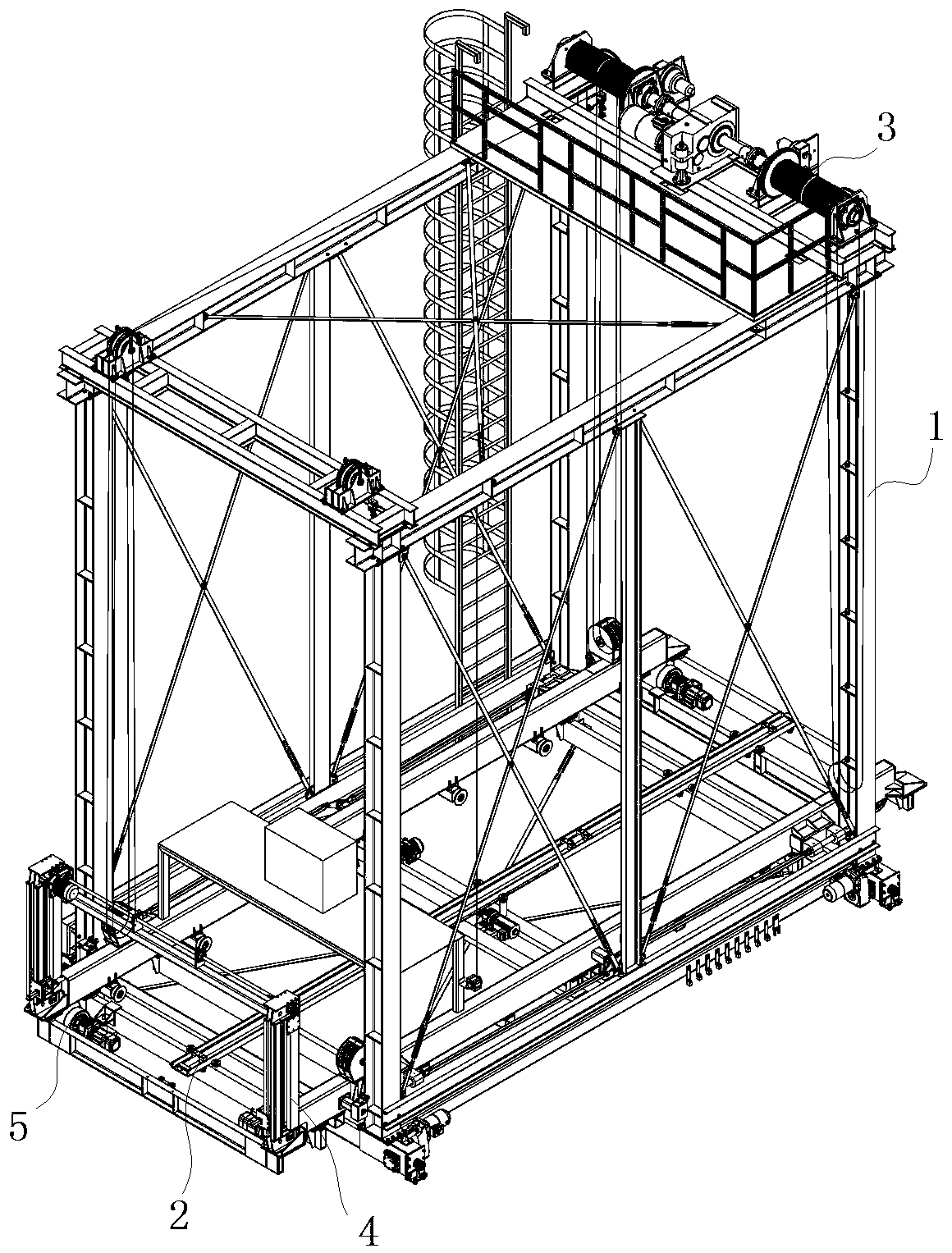

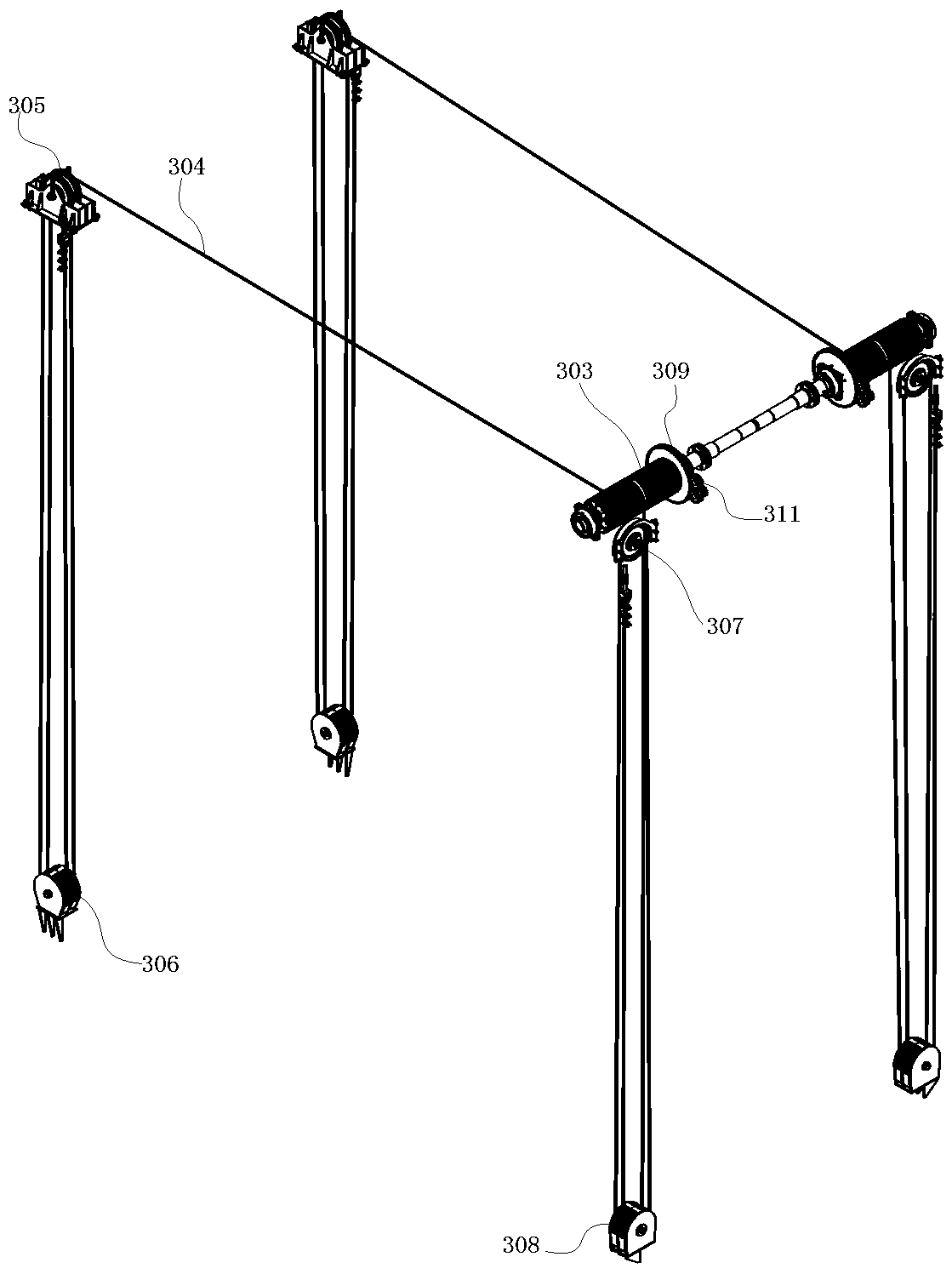

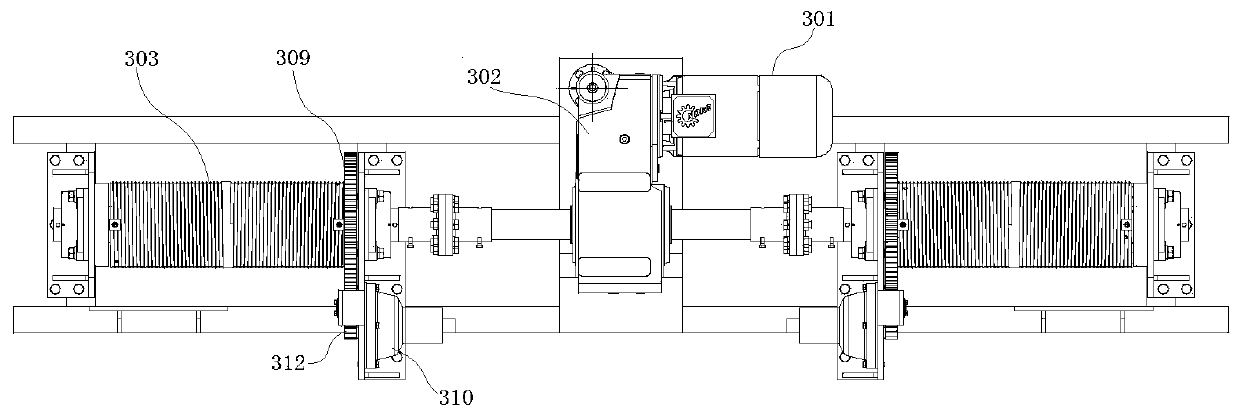

Shallow foundation pit stacking truck

PendingCN107827011ASmall reduction ratioPrevent deviationAuxillary shaping apparatusWinding mechanismsArchitectural engineeringEngineering

The invention relates to a shallow foundation pit stacking truck, and belongs to the technical field of construction machinery. The shallow foundation pit stacking truck comprises a rack, a bracket, alifting device, a pushing device and a die table support device, wherein the bracket is installed on the rack, the lifting device is installed on the rack, the pushing device and the die table support device are installed at the bottom of the bracket, and walking wheels at the bottom of the rack are arranged on a guide rail on the ground. According to the stacking truck, the positions of a driving roller and a support roller on the bracket are lowered to the bottom of the bracket from the top surface, so that the position of the bottom surface of a die table is greatly lowered, and the stacking truck achieves the effect of shallow foundation pits even without a pit. The shallow foundation pit stacking truck has the advantages of high stability, safety and reliability and can be widely popularized and applied in concrete component assembly construction.

Owner:HEBEI XINDADI ELECTROMECHANICAL MFG

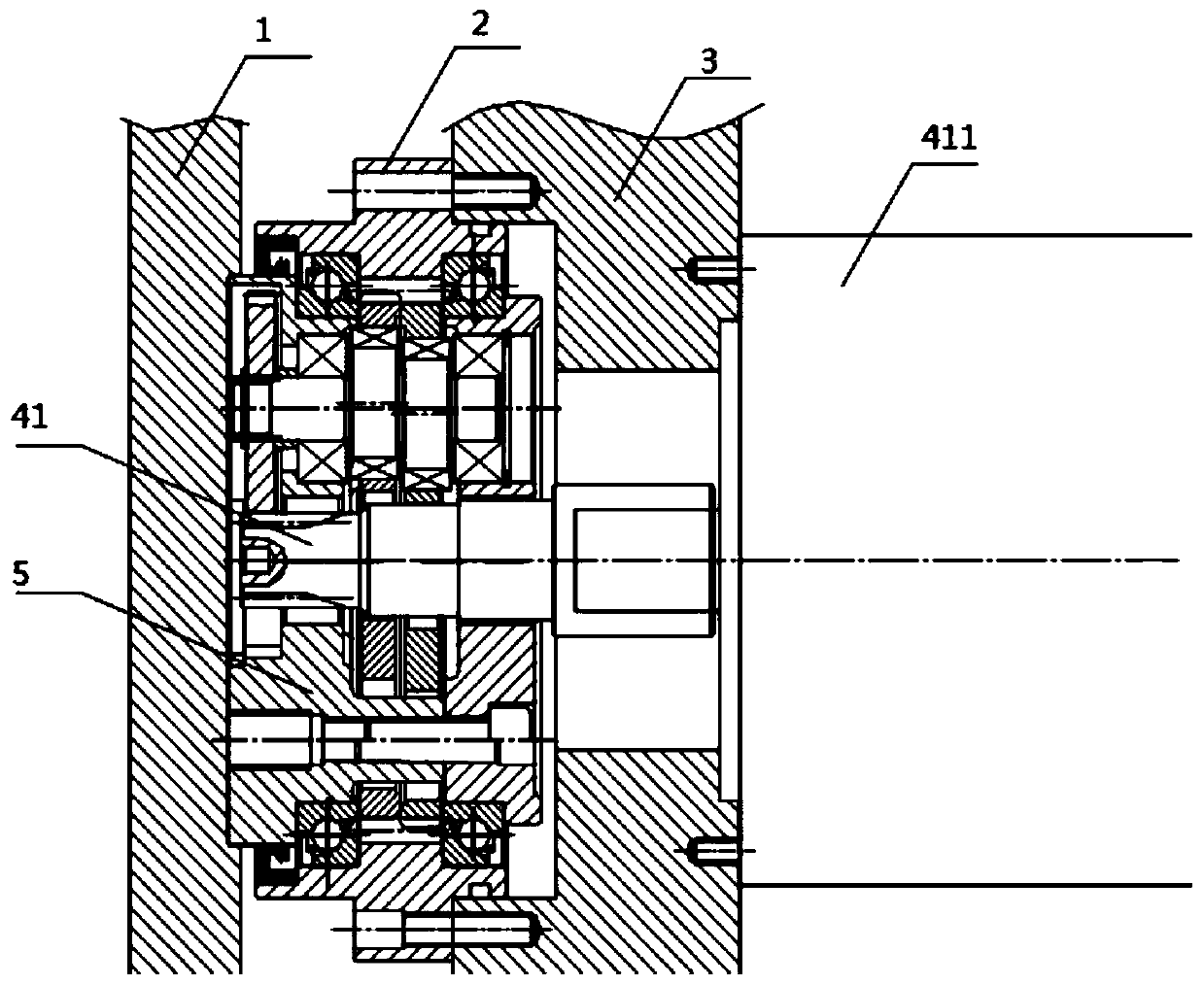

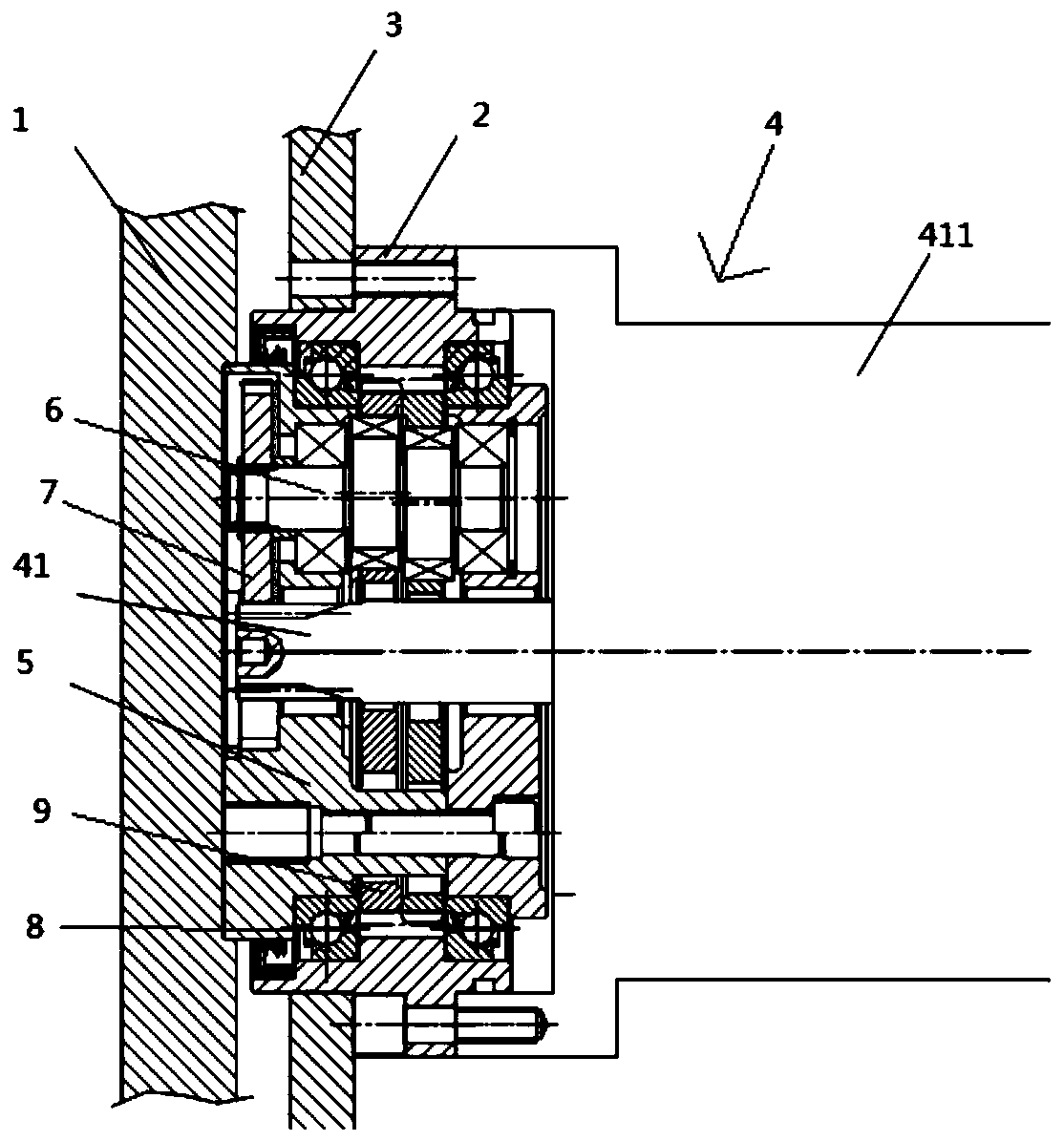

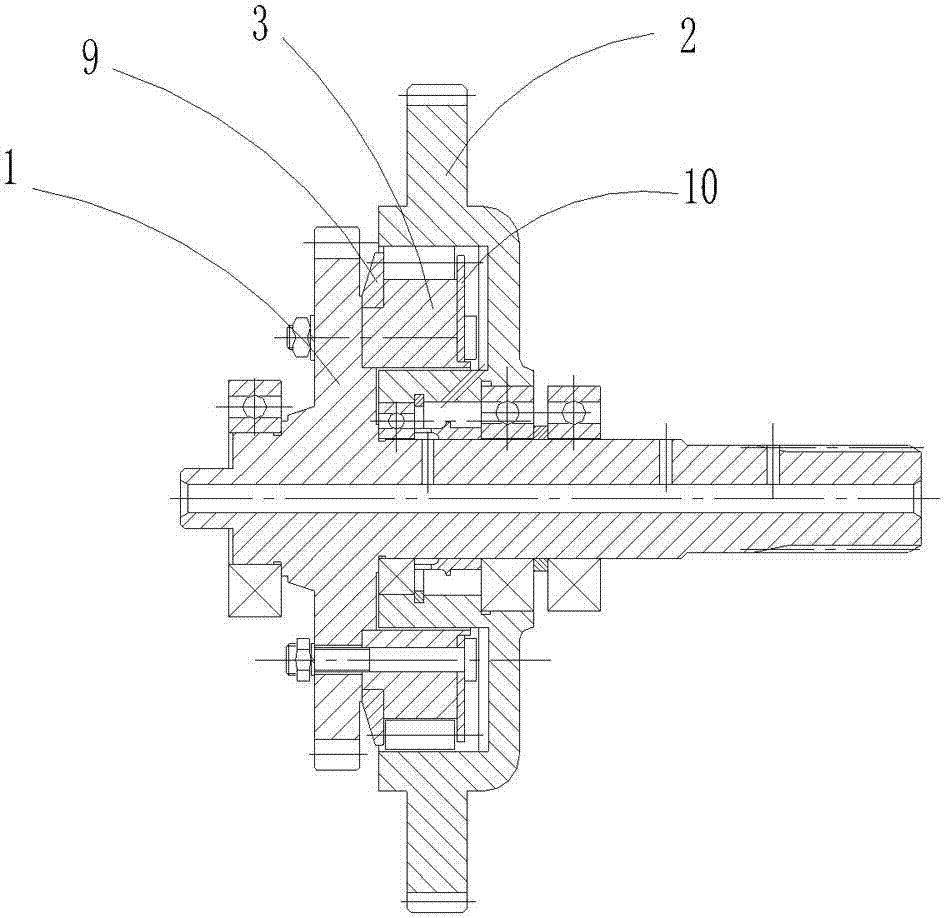

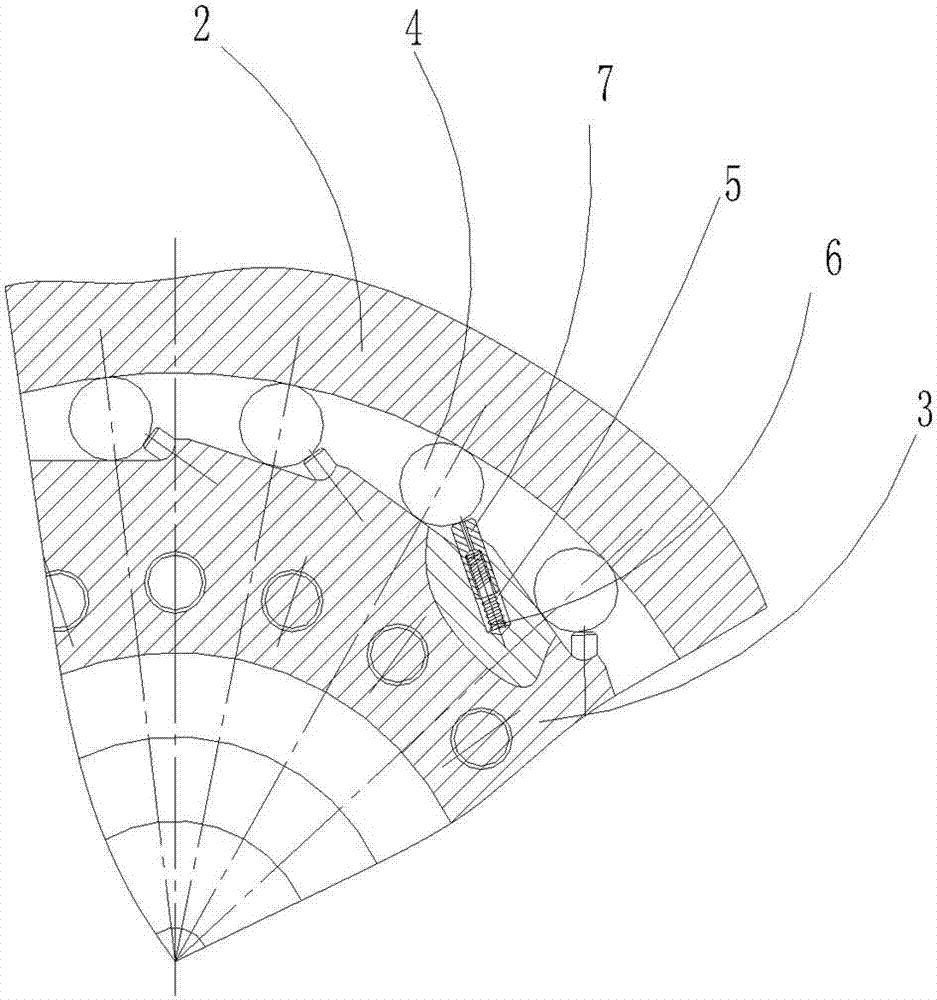

Wheel reductor structure

ActiveCN110529560AReduce weightSmall reduction ratioGear lubrication/coolingToothed gearingsReduction ratioEngineering

The invention belongs to the technical field of automobiles. The invention discloses a wheel reductor structure. The structure comprises a sun gear, a plurality of planet gears, a half shaft, an end cover, a wheel reductor shell, a hub, a planet carrier and a gear ring, and also comprises a shaft sleeve and a bracket fixed to the planet carrier, wherein the half shaft penetrates through the shaftsleeve from the middle part and can freely rotate in the shaft sleeve; the bracket is fixed on the shaft sleeve; the sun gear is fixed on the half shaft to be used as power input; and the gear ring isfixed on the wheel reductor shell to be used as power output. The wheel reductor structure has the beneficial effects that the planet carrier is fixed, the sun gear is adopted as power input, and thegear ring is adopted as power output, so that the reduction ratio is reduced, the transmission efficiency is improved, and market requirements are better met; meanwhile, the gear ring is integrated on the wheel reductor shell so that the weight of the wheel reductor is reduced than that in an existing structure that the gear ring and the wheel reductor shell are arranged separately.

Owner:FAW JIEFANG AUTOMOTIVE CO

Wind guiding mechanism and air conditioner

InactiveCN104296352ANot easy to swingNot easy to produce empty noiseLighting and heating apparatusAir-flow control membersStable stateReciprocating motion

The invention provides a wind guiding mechanism and an air conditioner. The wind guiding mechanism comprises wind guiding blades and a wind guiding movement mechanism; the wind guiding movement mechanism comprises a wind guiding motor and a multi-gear movement mechanism; an output shaft of the wind guiding motor is connected with the multi-gear movement mechanism; the wind guiding blades are driven to perform reciprocating motion through the multi-gear movement mechanism. The air conditioner comprises a base casing, a panel and the above wind guiding mechanism. The wind guiding mechanism of the air conditioner has the advantages of keeping a stable state during the operation process and being not easy to generate swing; being small in friction and not easy to generate empty sound due to the fact that a movement contact mode of the multi-gear movement mechanism is wire to wire; saving space, being reliable and durable, high in overload bearing capacity and low in energy consumption and enabling the reducer efficiency to be higher than 95% due to a rear reducer; being small in vibration and low in noise due to a seal structure.

Owner:GREE ELECTRIC APPLIANCES INC

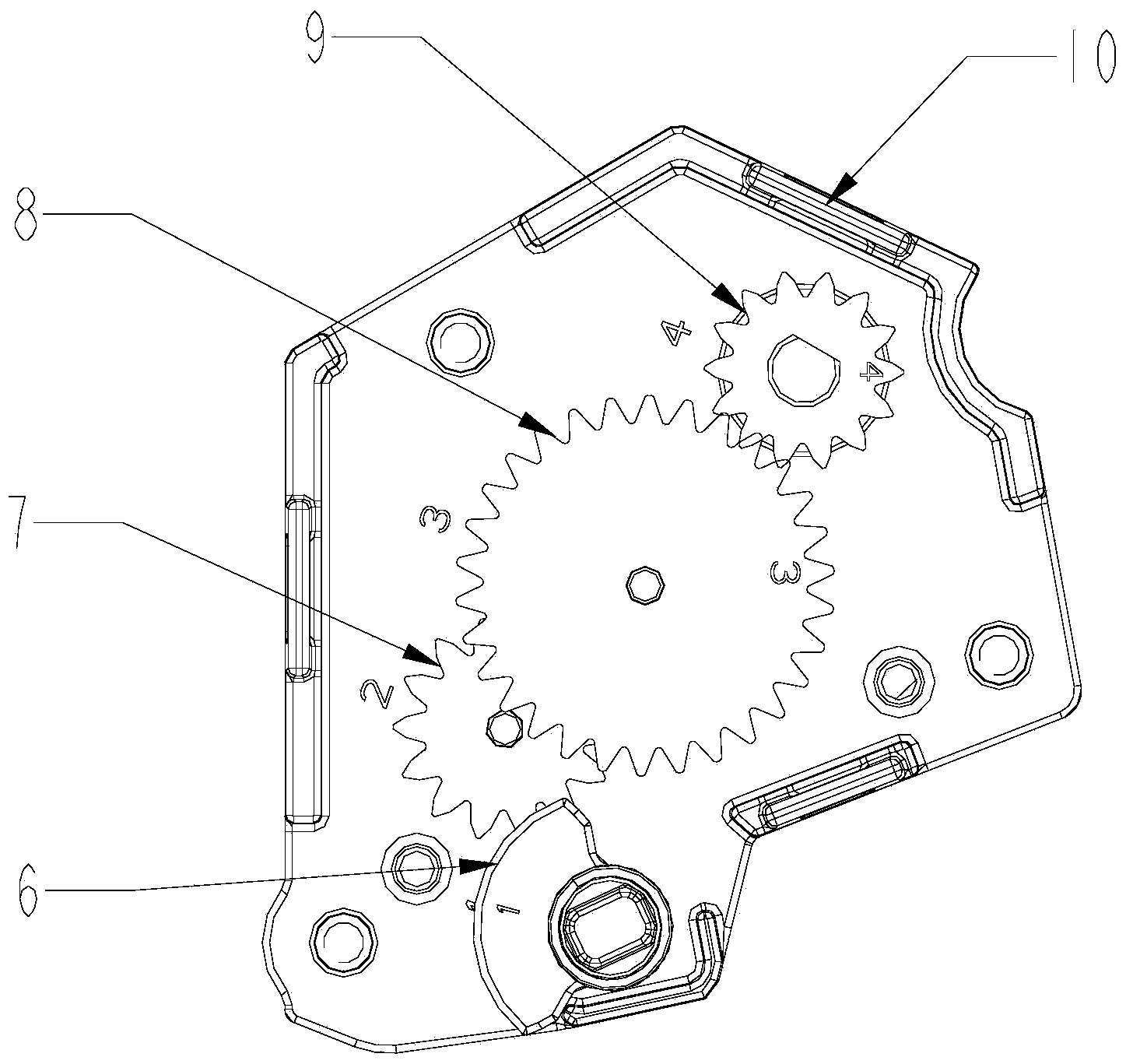

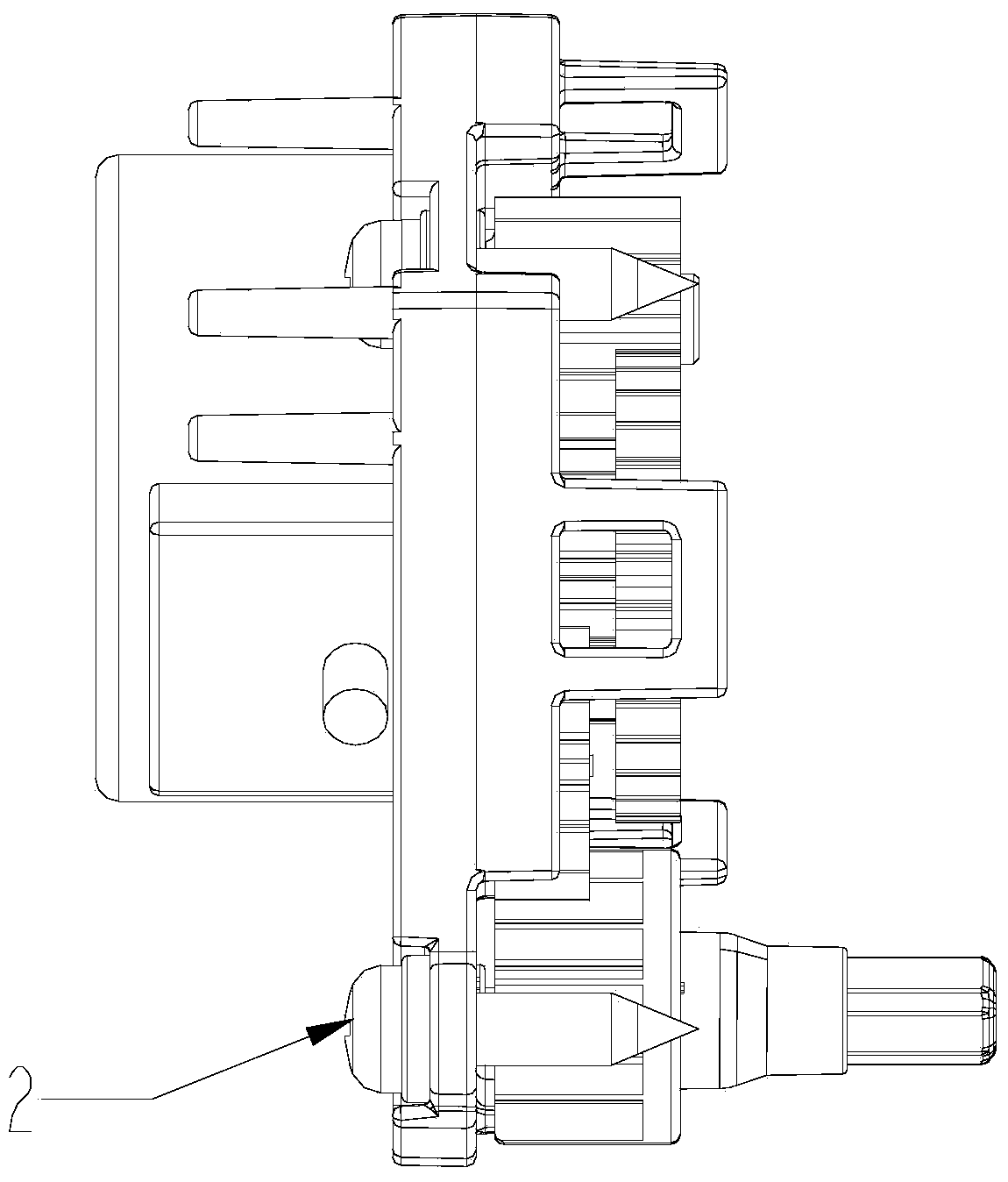

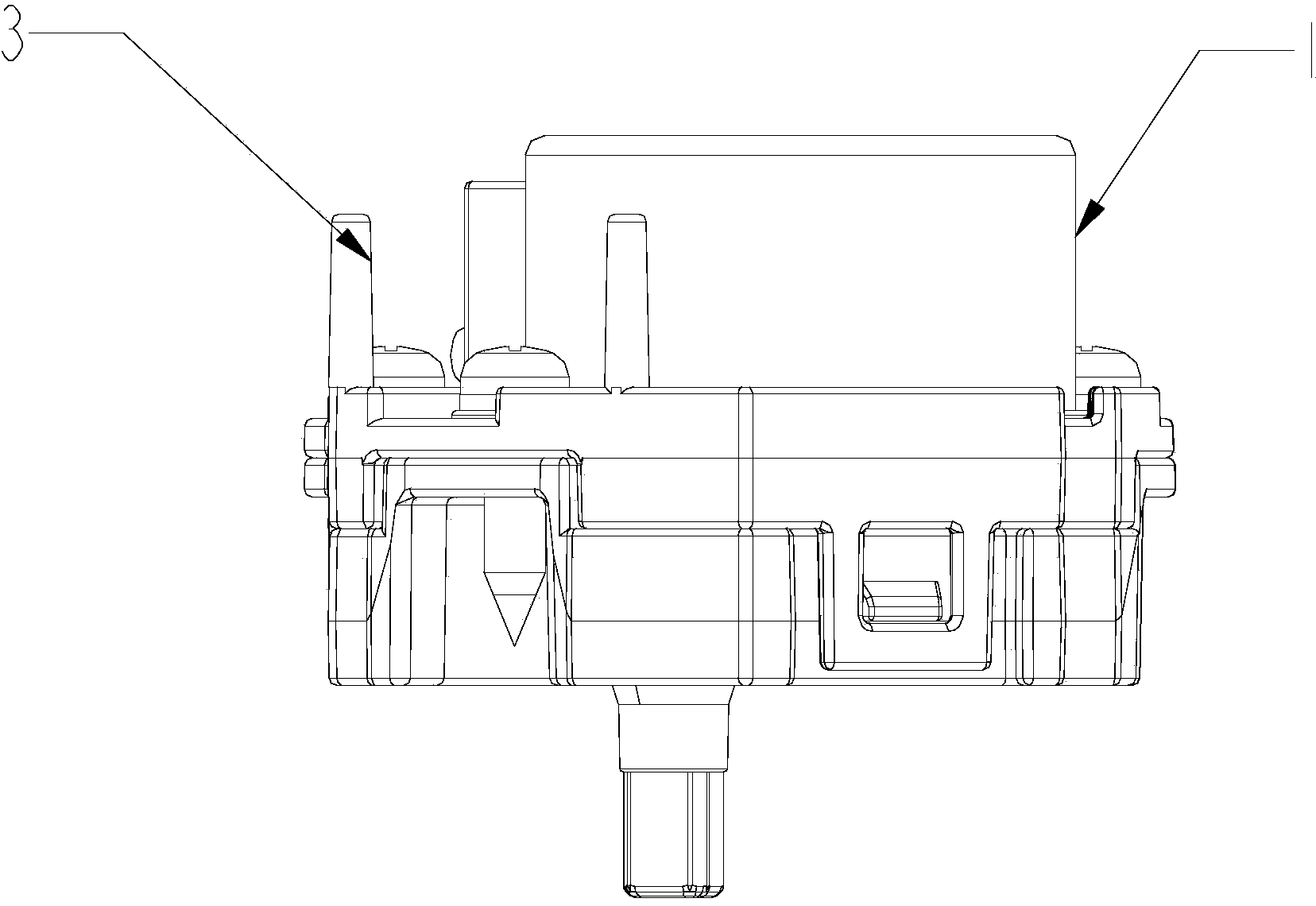

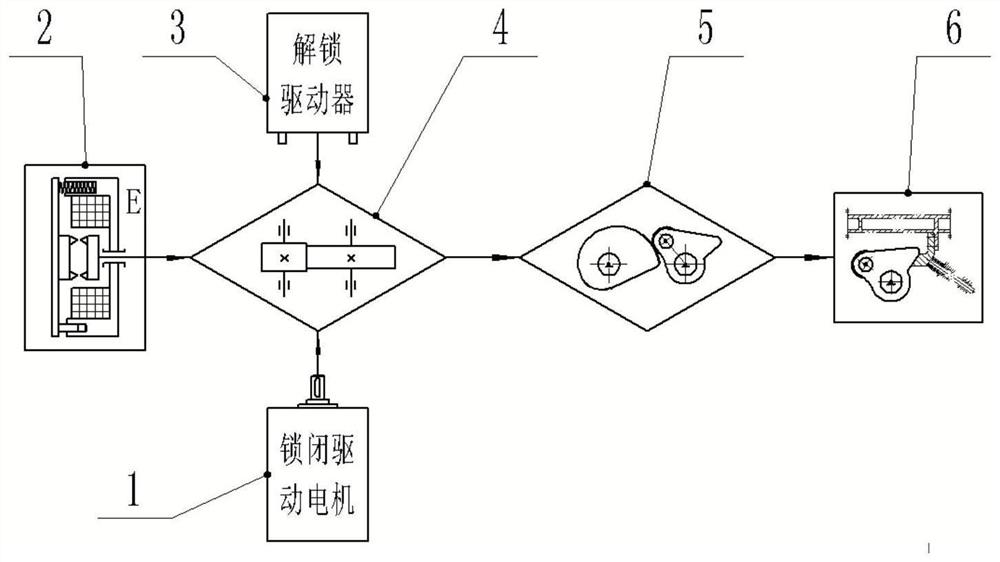

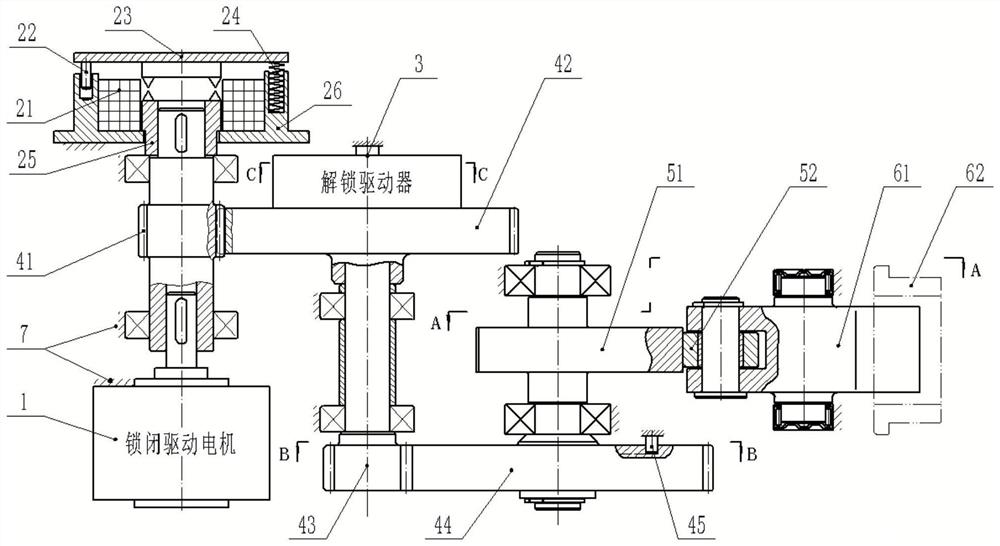

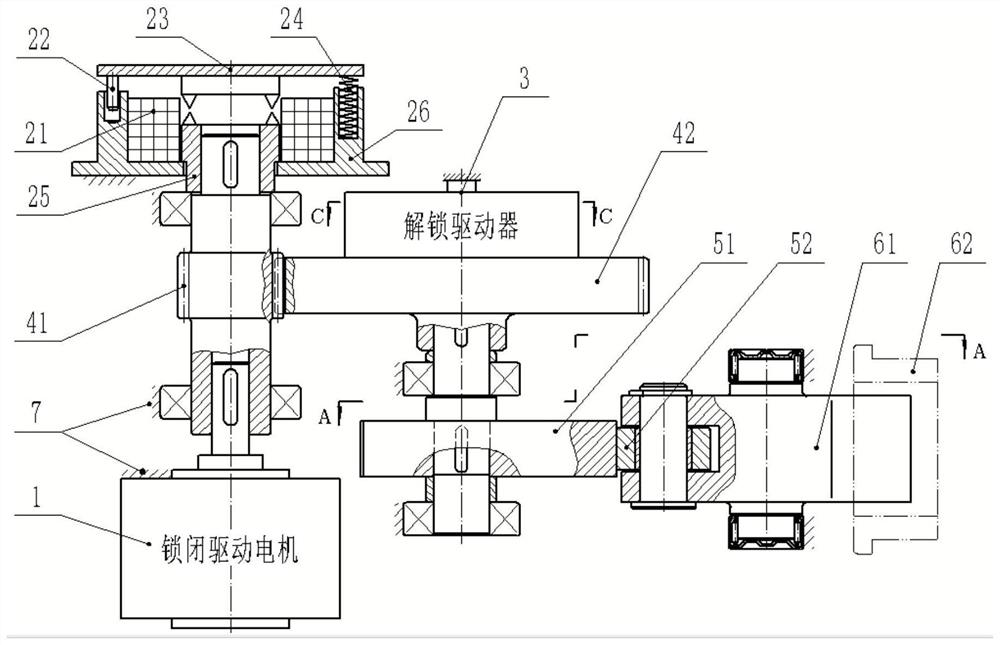

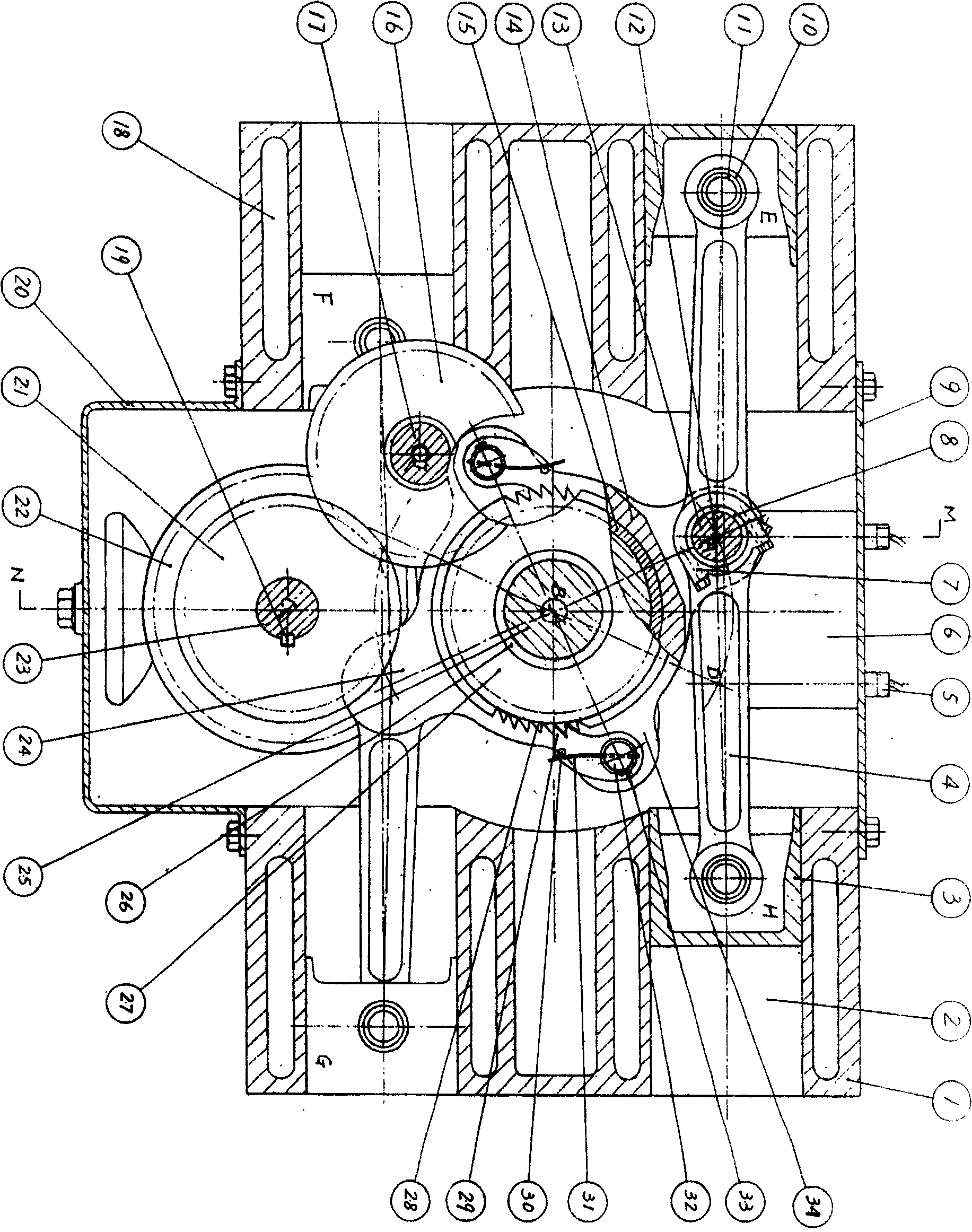

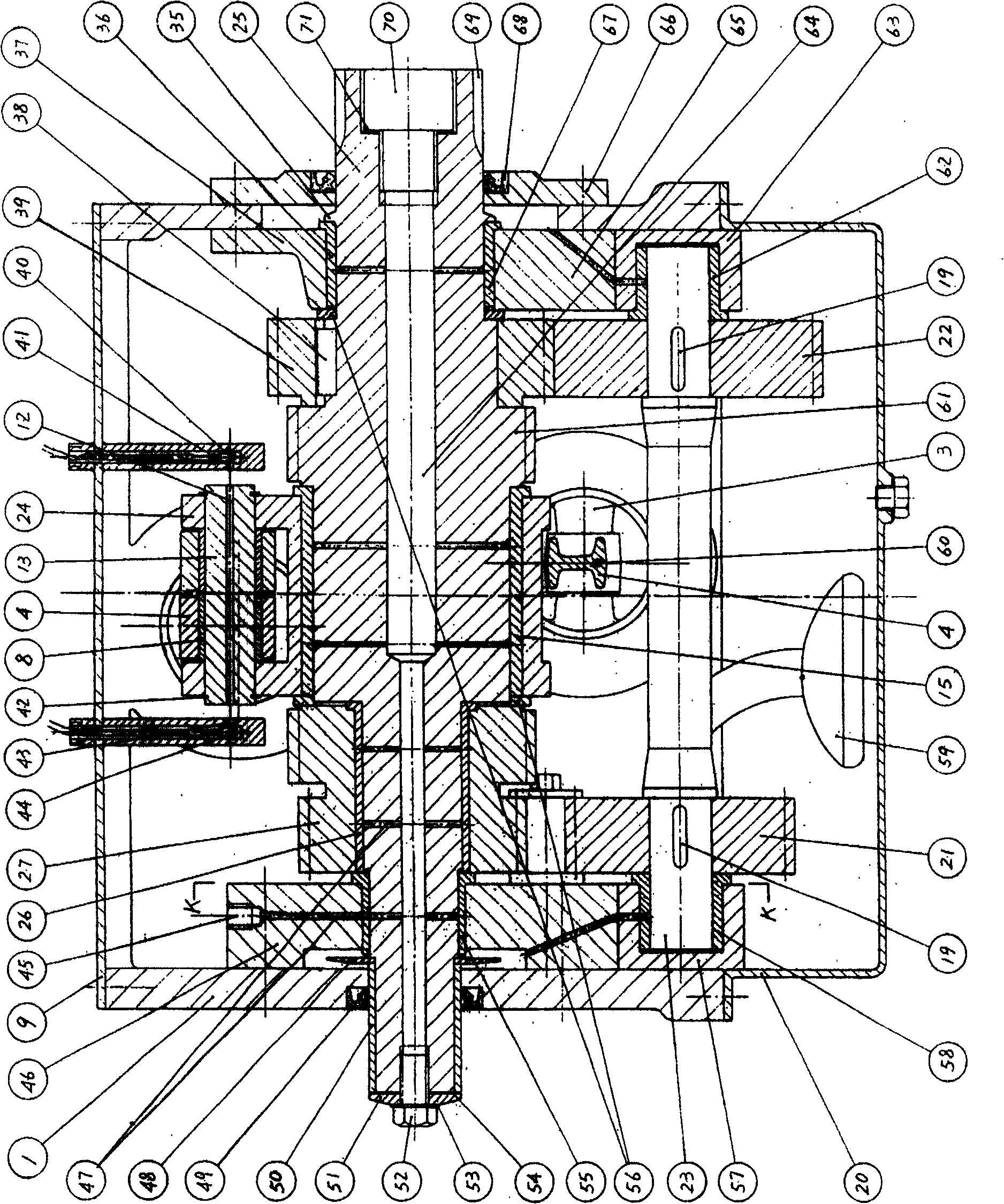

Novel electric safety locking device

ActiveCN113006614ALarge reduction ratioSmall reduction ratioPower transmission/actuator featuresElectrical locking actuatorsElectric machineryControl theory

The invention relates to a novel electric safety locking device. The locking device comprises a locking driving motor, a locking brake, an unlocking driver, a constant-speed-ratio transmission mechanism, a variable-speed-ratio executing mechanism and an executing component; the variable-speed-ratio executing mechanism comprises a variable-speed driving disc; the executing component comprises a spring bolt and an operation object lock catch of the spring bolt; an output shaft of the locking driving motor drives the variable-speed driving disc to rotate through the constant-speed-ratio transmission mechanism, and the variable-speed driving disc is used for driving the spring bolt to swing, so that the end of the spring bolt can press the lock catch; the locking brake can apply or release braking to the output shaft of the locking driving motor, the unlocking driver is compressed in the process that the spring bolt swings towards the lock catch direction to store energy for the unlocking action, and when the locking driving motor is powered off and the locking brake releases braking, the unlocking driver drives the variable-speed driving disc to move in the direction opposite to the locking action to realize unlocking. The locking device has the functions of locking driving, locking keeping and quick unlocking.

Owner:NANJING INST OF TECH

Toggle-type ratchet transmission of crank-shaft engine

InactiveCN100425878CSolution to short lifeNot prone to vibrationGearingReciprocating piston enginesGear wheelReciprocating motion

This invention relates to a kind of transmission mechanism comprised of a ratcheting and an elbow of connecting rod and sleeve arm. It can change the reciprocating motion into rotational movement. Its features are: four cylinders were layout in the steam cylinder body whose ax parallel to each other. Spindle and the sliding sleeve which coaxial line with the spindle placed between the four cylinders, vertically to cylinder axis but not intersect. On the sliding sleeve there were two large swing arms and two small ones. Piston connecting rode linked with the big arms through pin shaft. The reciprocating piston drove the big arms swing around. Small arms were equipped with the bidirectional pawls. When the big arms swung to the left, the reverse pawls played the ratcheting integrated spindle axis, drove the spindle axis counterclockwise rotation. When the big arms swung to the right, the positive pawls played the gear ratcheting components clockwise rotation, and through intermediate wheel, transmission gear wheel and spindle gear, drove spindle axis counterclockwise rotation. It can be used for the engine and other mechanical drive system.

Owner:左学禹

Coaxial two-gear planet row electric drive axle for automobile

PendingCN111439119AMeet driving needsSmall reduction ratioControl devicesGear wheelElectric machinery

The embodiment of the invention discloses a coaxial two-gear planet row electric drive axle for an automobile. The electric drive axle comprises a sun gear, a plurality of planet gears, a planet carrier, a gear ring, a synchronizer, a differential mechanism, a synchronizer gear shifting motor and a drive motor which are all installed in a shell. The sun gear, the planet carrier, the gear ring, thedifferential mechanism and the synchronizer are coaxial, the axis of each planet gear is parallel to the axis of the sun gear, a power output shaft of the driving motor is connected with the sun gear, the sun gear is externally meshed with the plurality of planet gears, the planet gears are installed on the planet carrier, the planet gears are internally meshed with the gear ring, the synchronizer gear shifting motor is connected with the synchronizer, the synchronizer is fixedly connected with the gear ring, and the planet carrier is connected with the differential mechanism. By applying thescheme provided by the embodiment of the invention, when the torque and the rotating speed input by the driving motor are not changed, the high torque and the low rotating speed can be output, and the low torque and the high rotating speed can also be output, so that the driving requirements of different road conditions can be met.

Owner:常州易控汽车电子股份有限公司

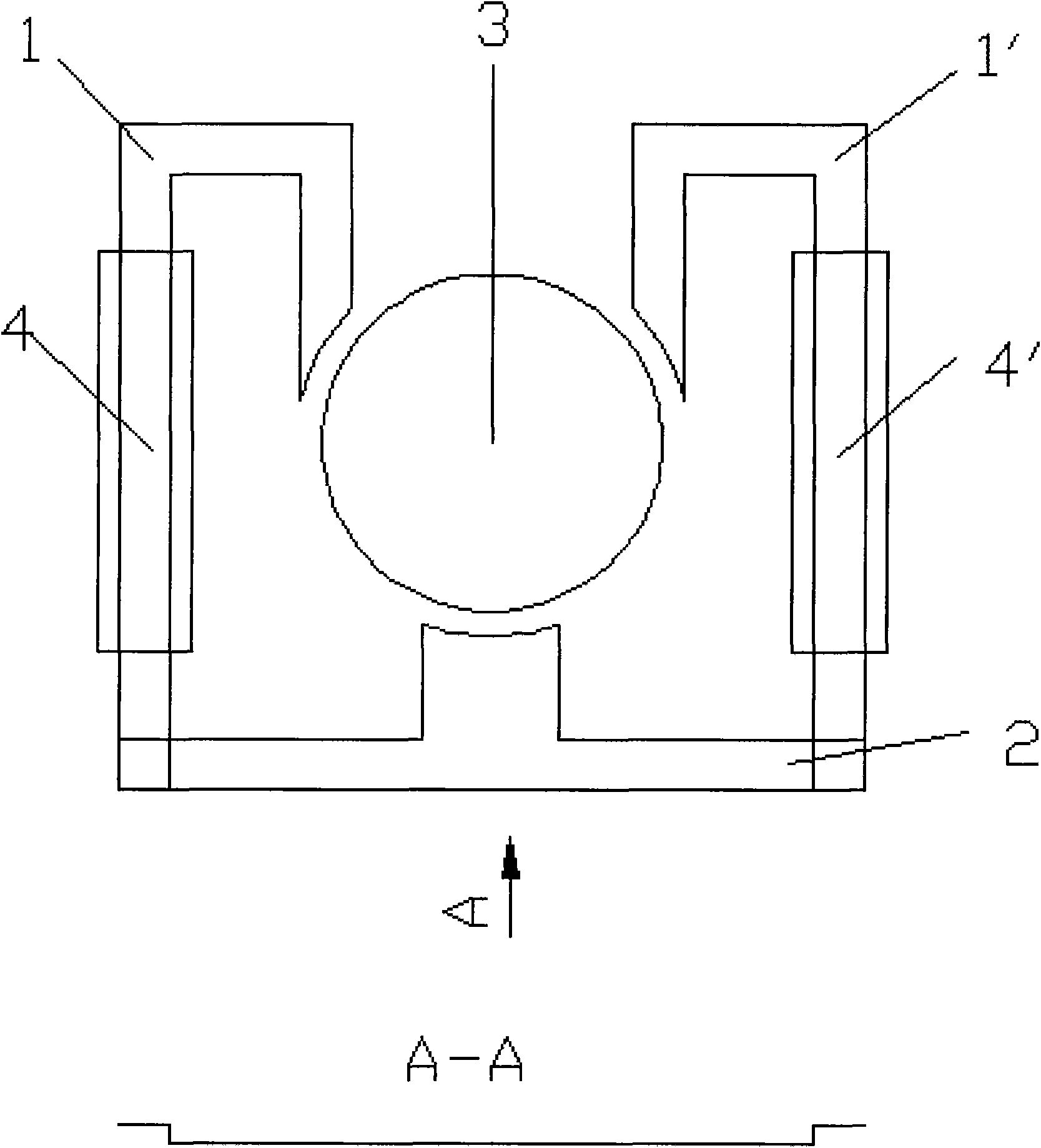

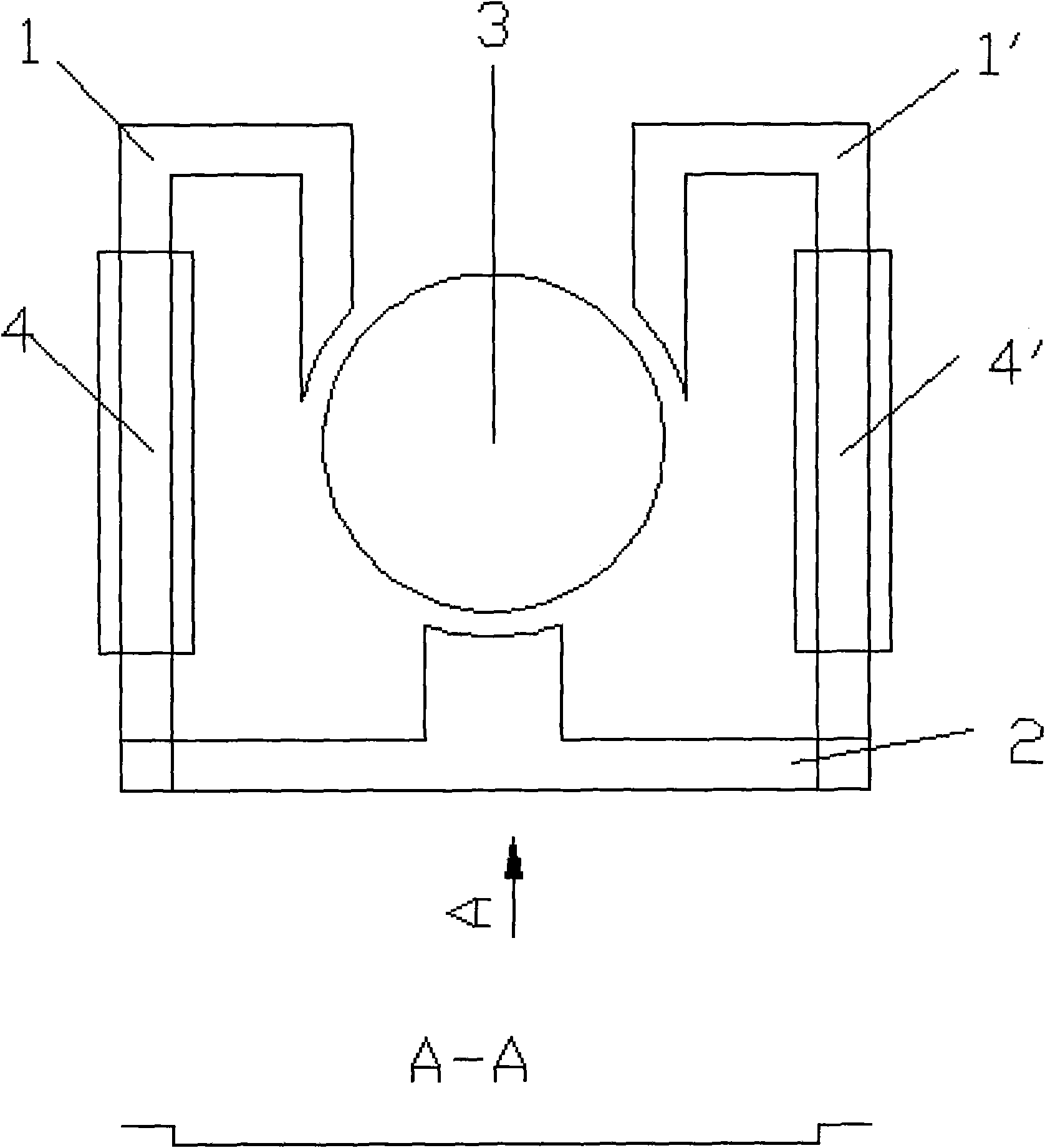

Instrument step motor with large rotor and low speed ratio

InactiveCN101964583ANot easy to twistEasy to manufactureDynamo-electric machinesLow speedStator coil

The invention relates to an instrument step motor with a large rotor and low speed ratio. A core of an instrument comprises a stator, stator coils and a magnet rotor. The stator is made of a soft magnetic material and is divided into three pieces, one end face of each piece is used as a magnetic pole face, and the three pieces are distributed on the circumference at equal intervals by 120 DEG, wherein the other end of the first stator piece and the other end of the second stator piece respectively pass through the two stator coils to be overlapped with the third stator piece, i.e. the other end of the third stator piece is overlapped on the parts of the first stator piece and the second stator piece, stretching out of the stator coils, by being separated in 180 DEG. In order to solve the problem that three magnetic poles are not on the same plane because of overlapping, a folding mark of the third stator piece is processed in the overlapping position, and thus, the magnetic poles of the three stator pieces can be ensured to be on the same plane. The magnet rotor with 5-8 mm in diameter is assembled in the circumference and provided with four pairs of magnetic poles along the radial direction.

Owner:宁波九菱电机有限公司

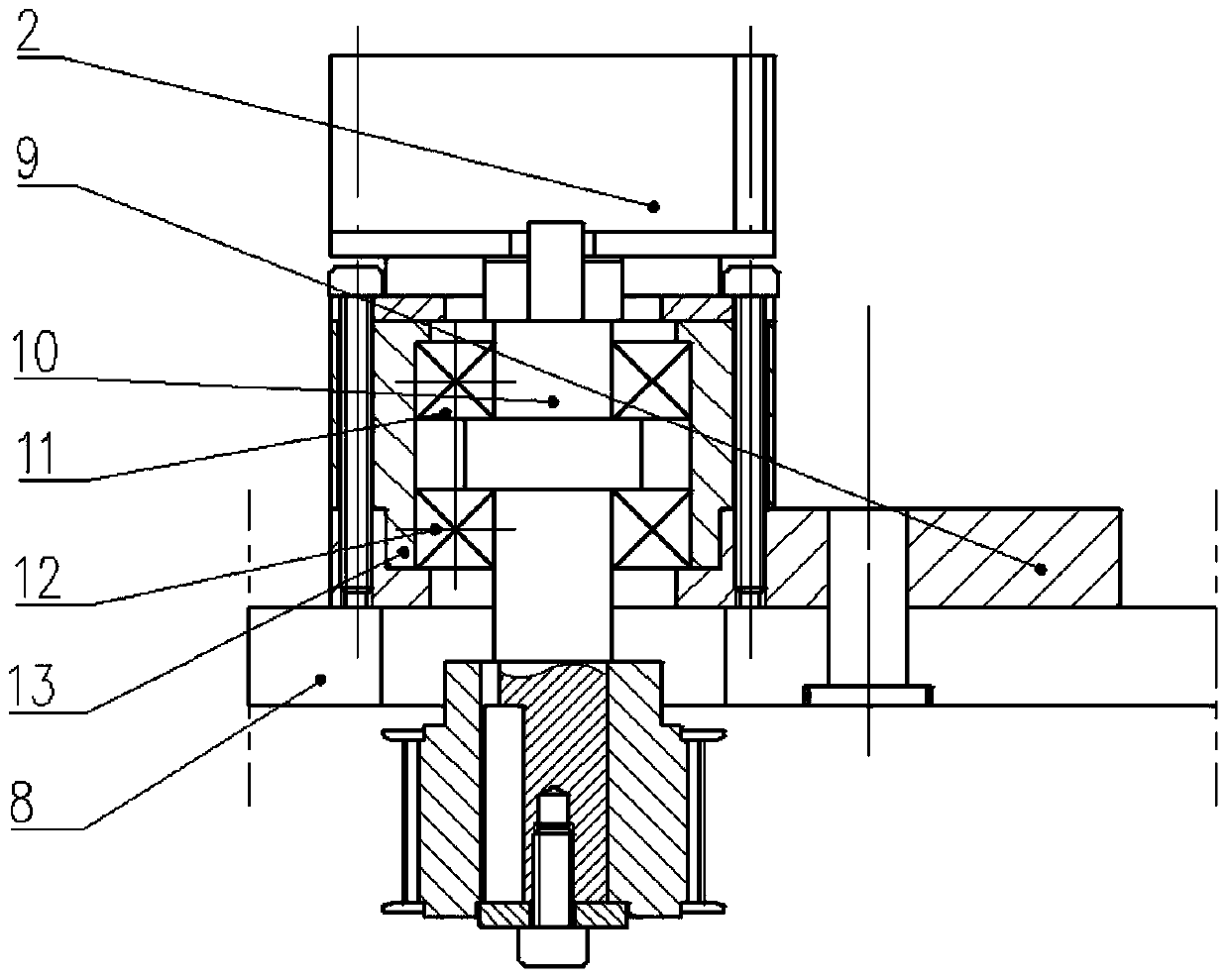

Vehicle Parking Brake Transmission

ActiveCN104343860BReduce in quantityImprove transmission performanceBrake actuating mechanismsActuatorsEngineeringParking brake

The invention discloses a driving device for parking brake of a vehicle. The driving device comprises a casing unit, a motor assembly and a speed reducing unit, wherein the casing unit comprises a ring gear around a first axis; the motor assembly comprises a motor and a worm extending along a second axis perpendicular to the first axis; the speed reducing unit is arranged in the casing unit and comprises a worm gear driving part, a planet carrier and a plurality of planet gears; the worm gear driving part is provided with a worm gear meshed with the worm, and a sun wheel which is arranged on the bottom side of the worm gear, extends along the first axis and is meshed with the planet gears; the planet carrier is provided with an input shaft which is connected to a clamping device and extends along the first axis; the motor can drive the worm to rotate so as to drive the worm gear driving part and the planet gears to rotate, and further the input shaft of the planet carrier is driven to rotate, and the clamping device is actuated to perform the parking brake action.

Owner:AUTOMOTIVE RES & TESTING CENT

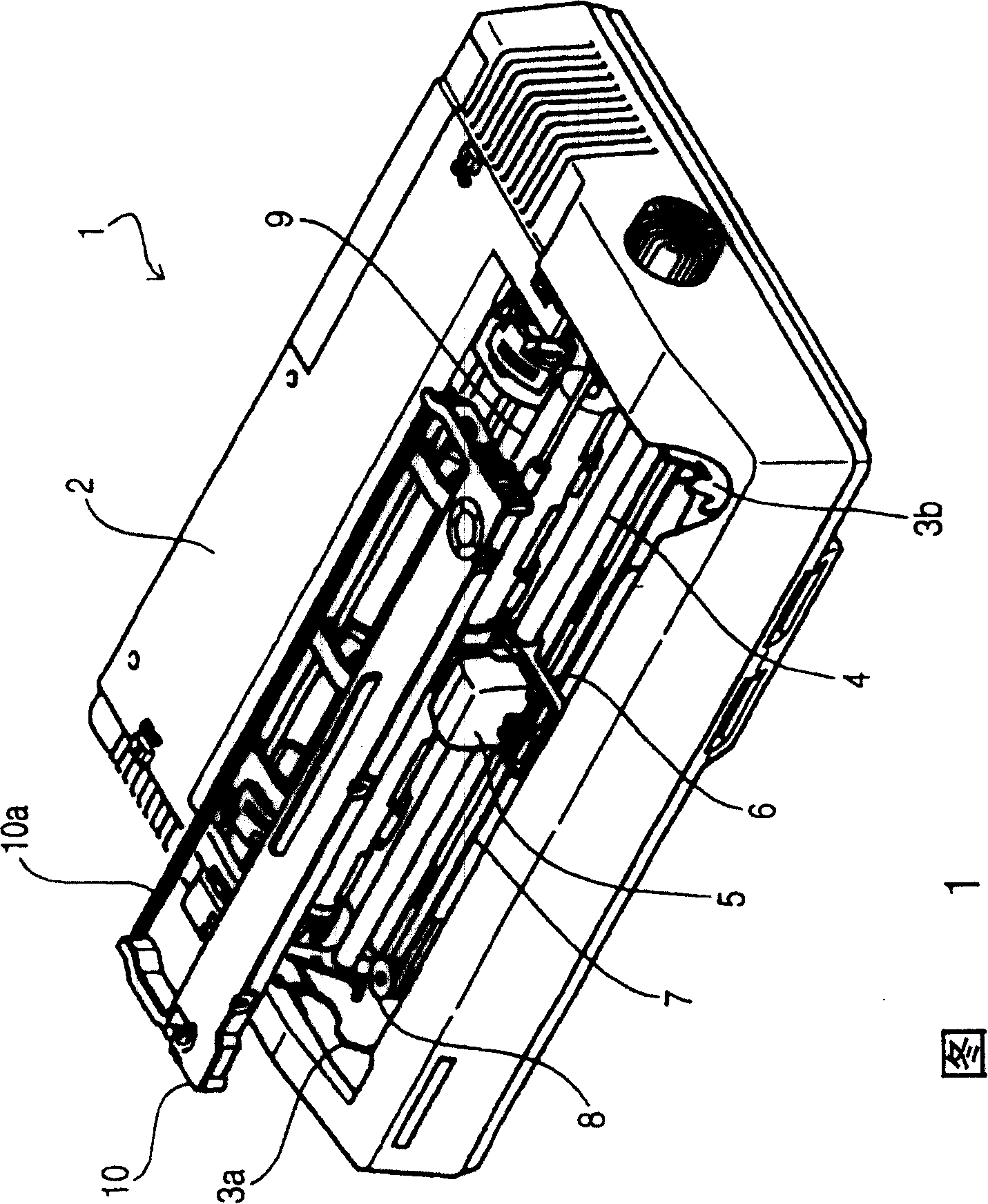

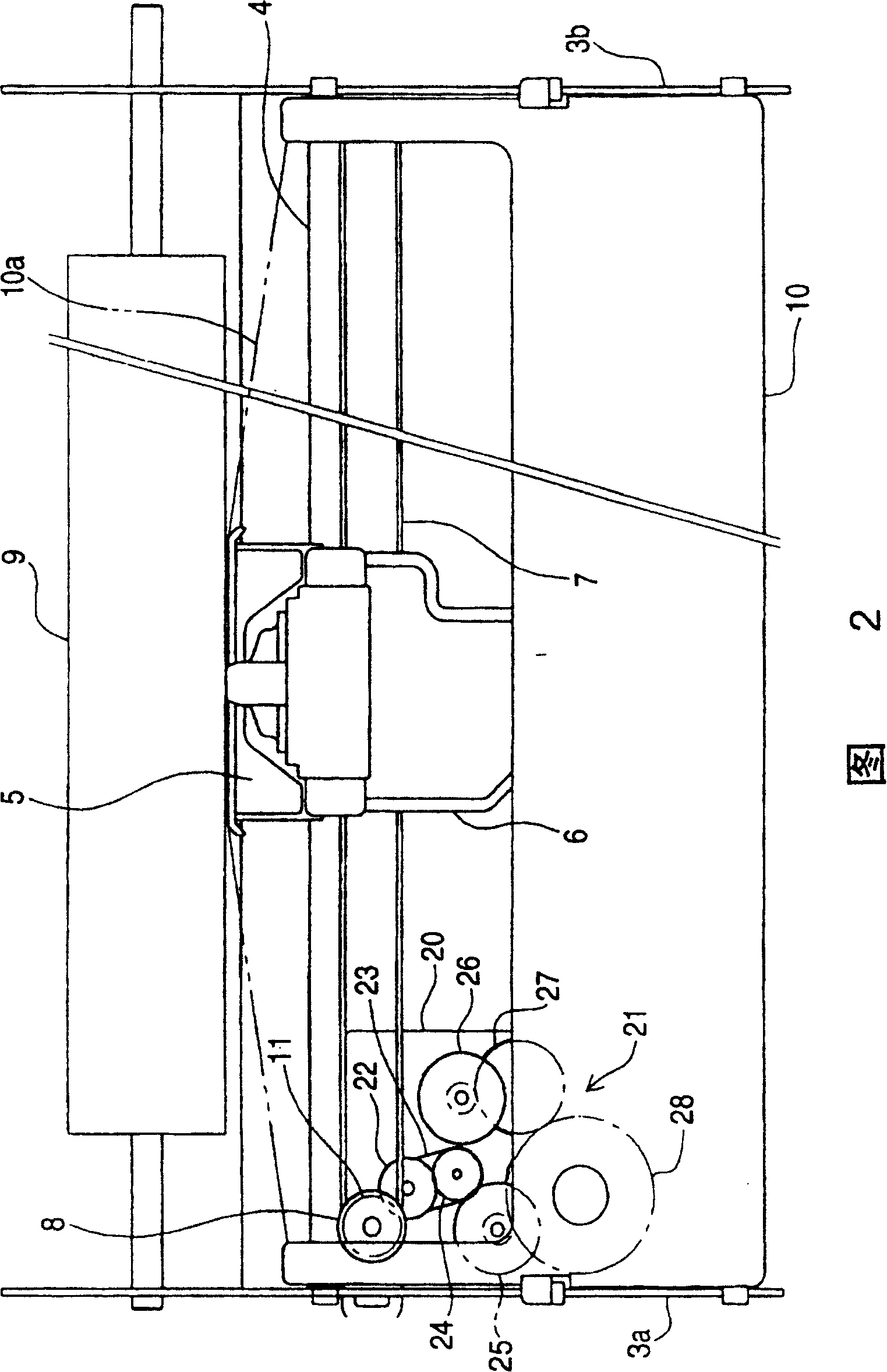

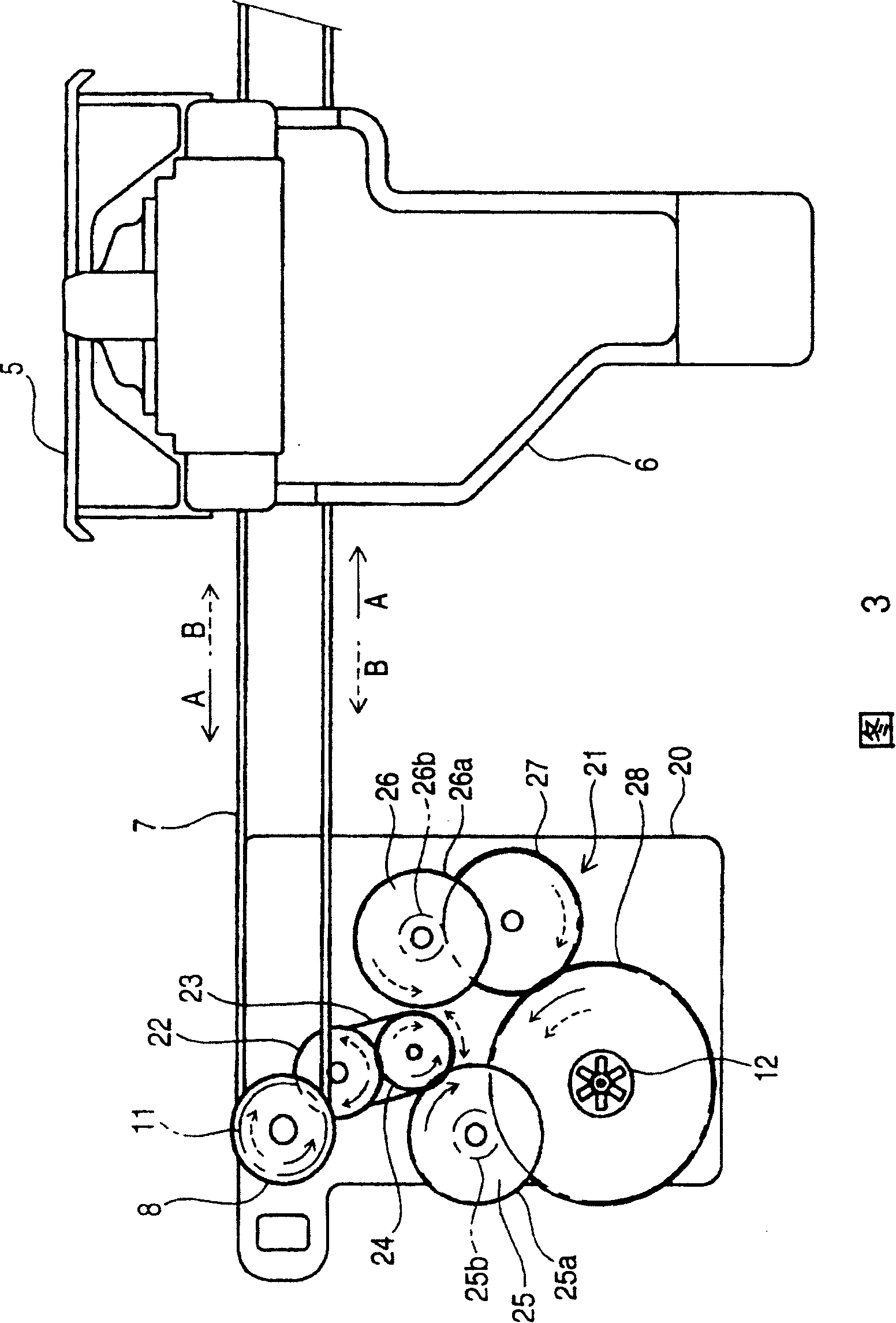

Control method of printer and printer thereof

InactiveCN100400304CSmall reduction ratioShorten the no-wrap areaInk ribbonsSpacing mechanismsEngineeringElectrical and Electronics engineering

The invention provides a method for controlling a printer and, a printer wherein a movement amount of a carriage is shortened as much as possible for shortening a printing time, and at the same time, an ink ribbon is surely taken up even when a printing region of one line is short. From a carriage movement start position to an ink ribbon take-up start position where speed reducing gears 21 drive thereby actually taking up the ink ribbon 10a is set as an ink ribbon non take-up region. Before the carriage 6 starts moving, it is judged whether or not the movement amount of the carriage 6 required for printing one line exceeds the ink ribbon non take-up region. When the movement amount does not exceed the region, a slow down region of the carriage 6 is increased until the movement amount exceeds the ink ribbon non take-up region.

Owner:STAR MICRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com