Ink supply mechanism and stepping motor driver therefor

A stepper motor, motor technology, applied in the general parts of printing machinery, printing presses, printing and other directions, can solve the problems of deterioration acceleration, wear time, damage, etc., and achieve the effect of reducing noise, reducing wear or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

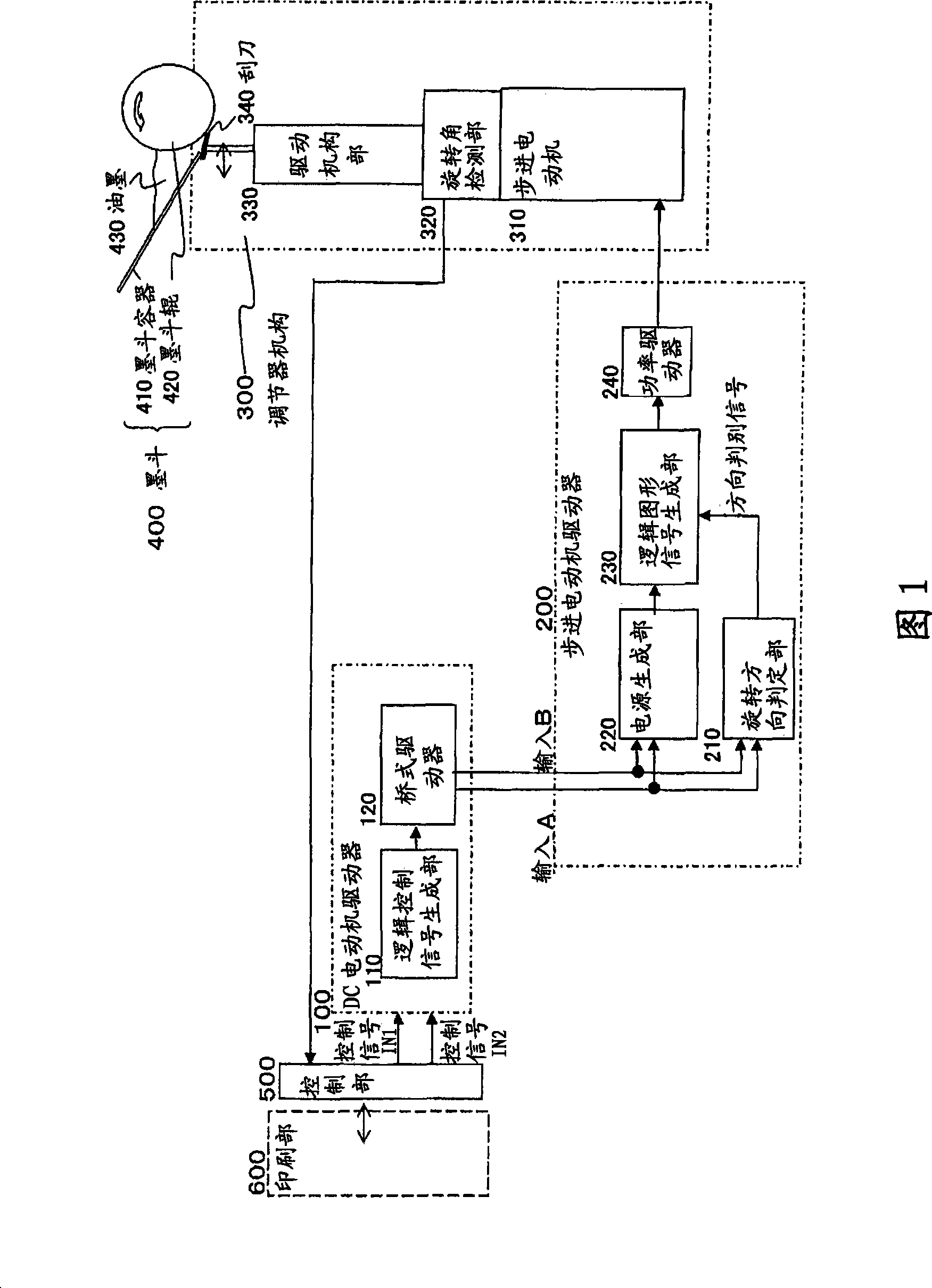

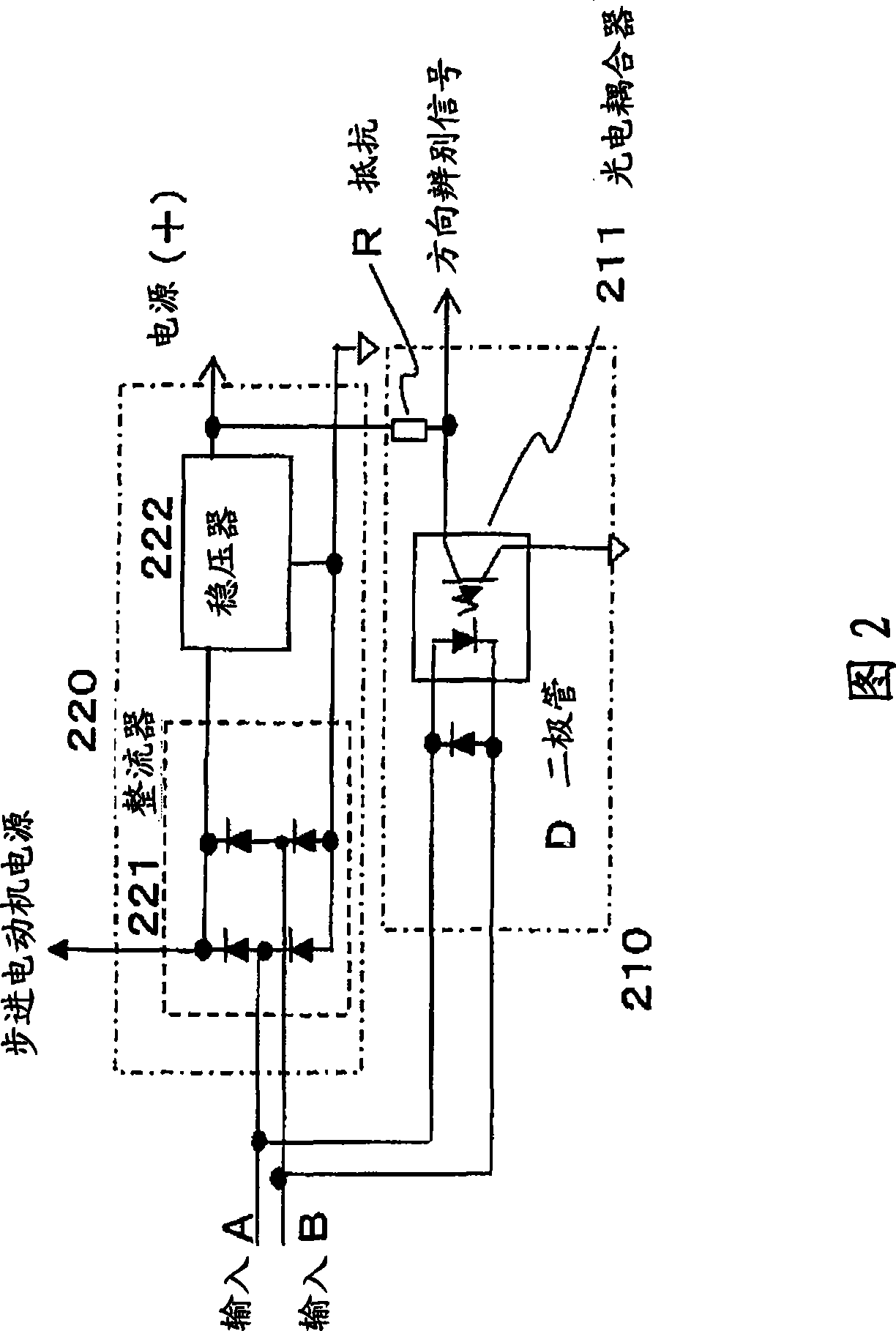

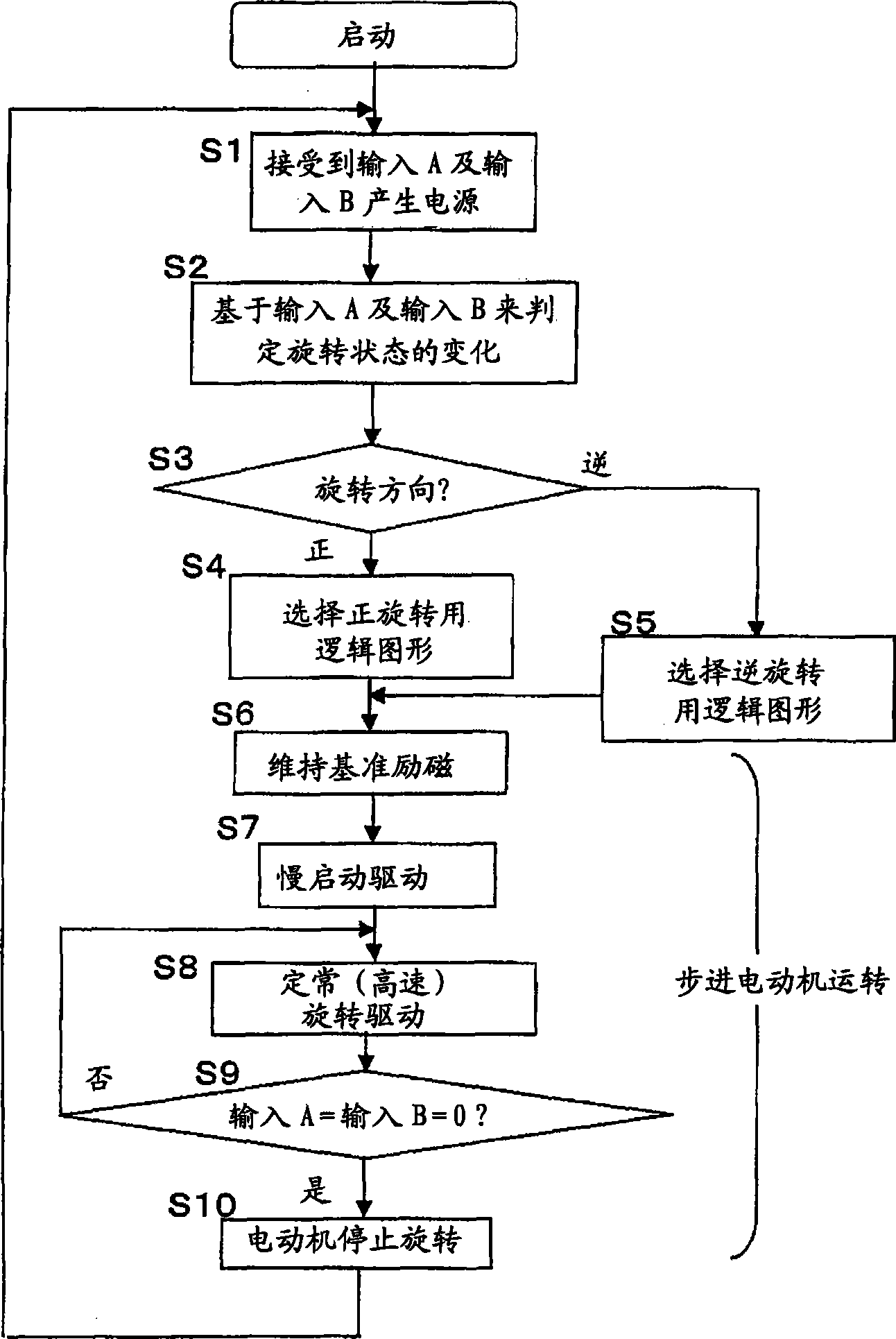

[0050] Embodiments of the present invention will be described using the drawings. Fig. 1 is a diagram showing a functional structure of an embodiment of the present invention. FIG. 2 is a diagram illustrating details of a power generation unit and a rotation direction determination unit in FIG. 1 . image 3 It is a diagram showing the operation flow of the stepping motor driver in FIG. 1 . FIG. 4 is an illustration of logic pattern signals used to drive a stepping motor. Figure 5 It is a graph showing the change of the signal value of the logic pattern in FIG. 4 . Figure 6 It is a graph showing the input and output values of the DC motor driver.

[0051] In FIG. 1 , the background art part and the present invention part are separated, as described in (A) and (B) below. That is, (A) the control part 500, the printing part 600, the DC motor driver 100, the actuator mechanism 300 and the ink fountain 400 except the stepping motor 310 are the background technology, (B) inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com