Method for preparing carbon nanotube electromagnetic shielding film

A technology of carbon nanotubes and electromagnetic shielding, applied in the fields of magnetic/electric field shielding, conductive coatings, electrical components, etc., can solve the problems of difficulty in greatly improving performance, poor dispersion of carbon nanotubes, and low content of carbon nanotubes. Achieve the effects of modifying electromagnetic shielding performance, improving shielding performance and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

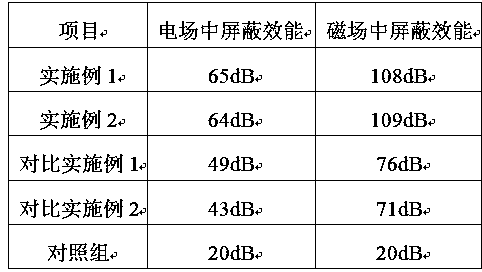

Examples

Embodiment 1

[0021] A method for preparing a carbon nanotube electromagnetic shielding film is characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0022] (1) Filling ferrocene-methanol solution to prepare carbon nanotube shielding film:

[0023] Dissolve 40 parts of ferrocene in methanol 1:5, and ultrasonically disperse for 10 minutes to obtain a filling solution. The reactor is heated to 1100°C, the carbon source rate is adjusted to deposit carbon nanotubes on the nozzle base, and the filling solution is introduced to prepare high-speed iron A large amount of carbon nanotube macroscopic body, the carbon source and fillers are quickly vaporized, and a high-shielding film is prepared by self-deposition technology;

[0024] Among them, the feed rate of the filling solution is 0.5ml / min;

[0025] (2) Preparation and coating of electromagnetic shielding paint:

[0026] Mix 10 parts of resin EPO, 4 parts of solvent xylene, 4 parts ...

Embodiment 2

[0030] A method for preparing a carbon nanotube electromagnetic shielding film is characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0031] (1) Filling ferrocene-methanol solution to prepare carbon nanotube shielding film:

[0032] Dissolve 50 parts of ferrocene in methanol 1:10, and ultrasonically disperse for 20 minutes to obtain a filling solution. The reaction furnace is heated to 1200°C, the carbon source rate is adjusted to deposit carbon nanotubes on the nozzle base, and the filling solution is introduced to prepare high-speed iron A large amount of carbon nanotube macroscopic body, the carbon source and filler are quickly vaporized, and a high-shielding film is prepared by self-deposition technology;

[0033] Among them, the feed rate of the filling solution is 1ml / min;

[0034] (2) Preparation and coating of electromagnetic shielding paint:

[0035] Mix 15 parts of resin EPO, 7 parts of solvent xylene, 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com