Stepless automatic speed change device for bicycle

An automatic transmission device, bicycle technology, applied to vehicle gearboxes, wheel transmissions, vehicle components, etc., can solve problems such as inconvenient operation and inability to achieve automatic shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and preferred embodiments of the present invention.

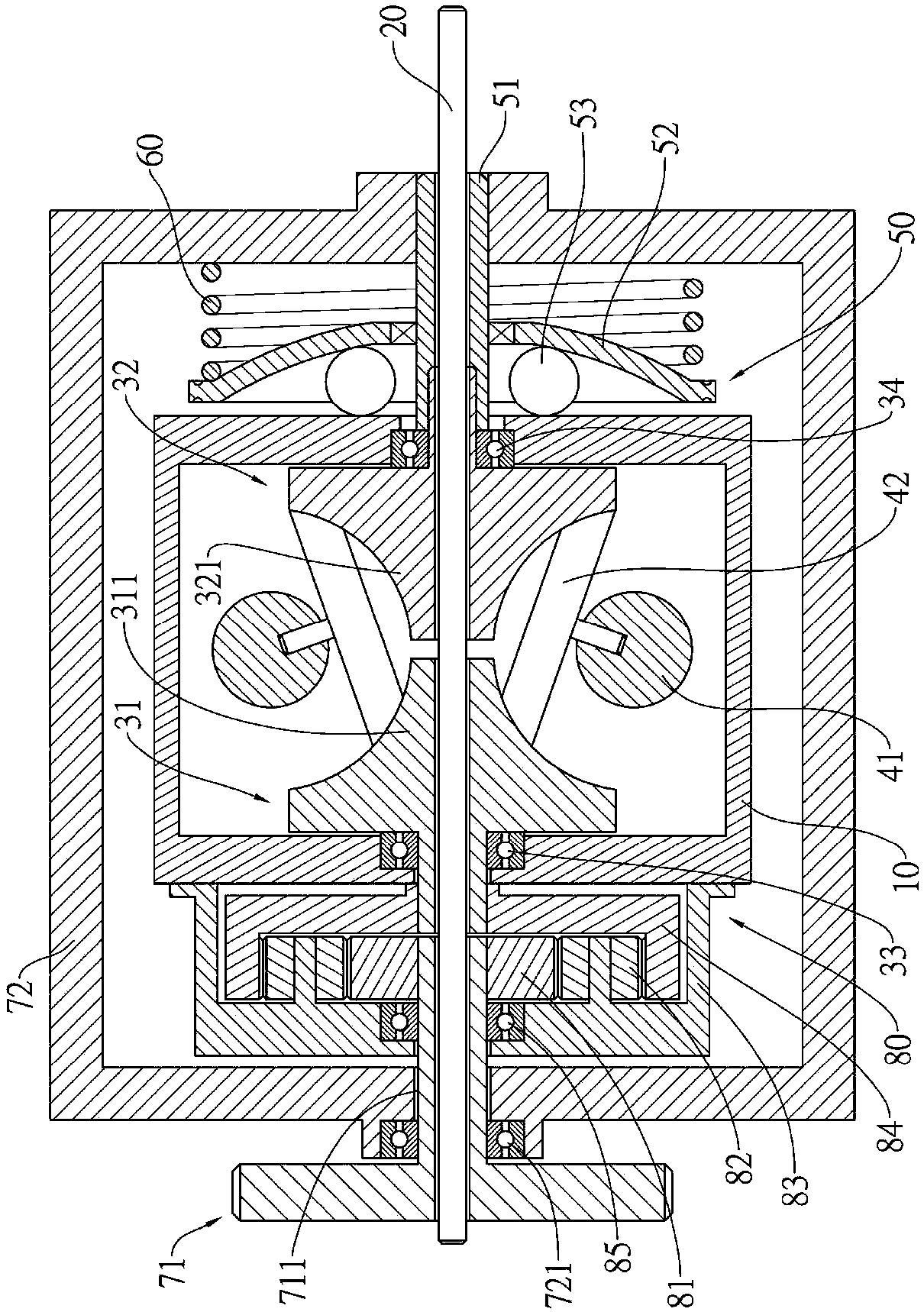

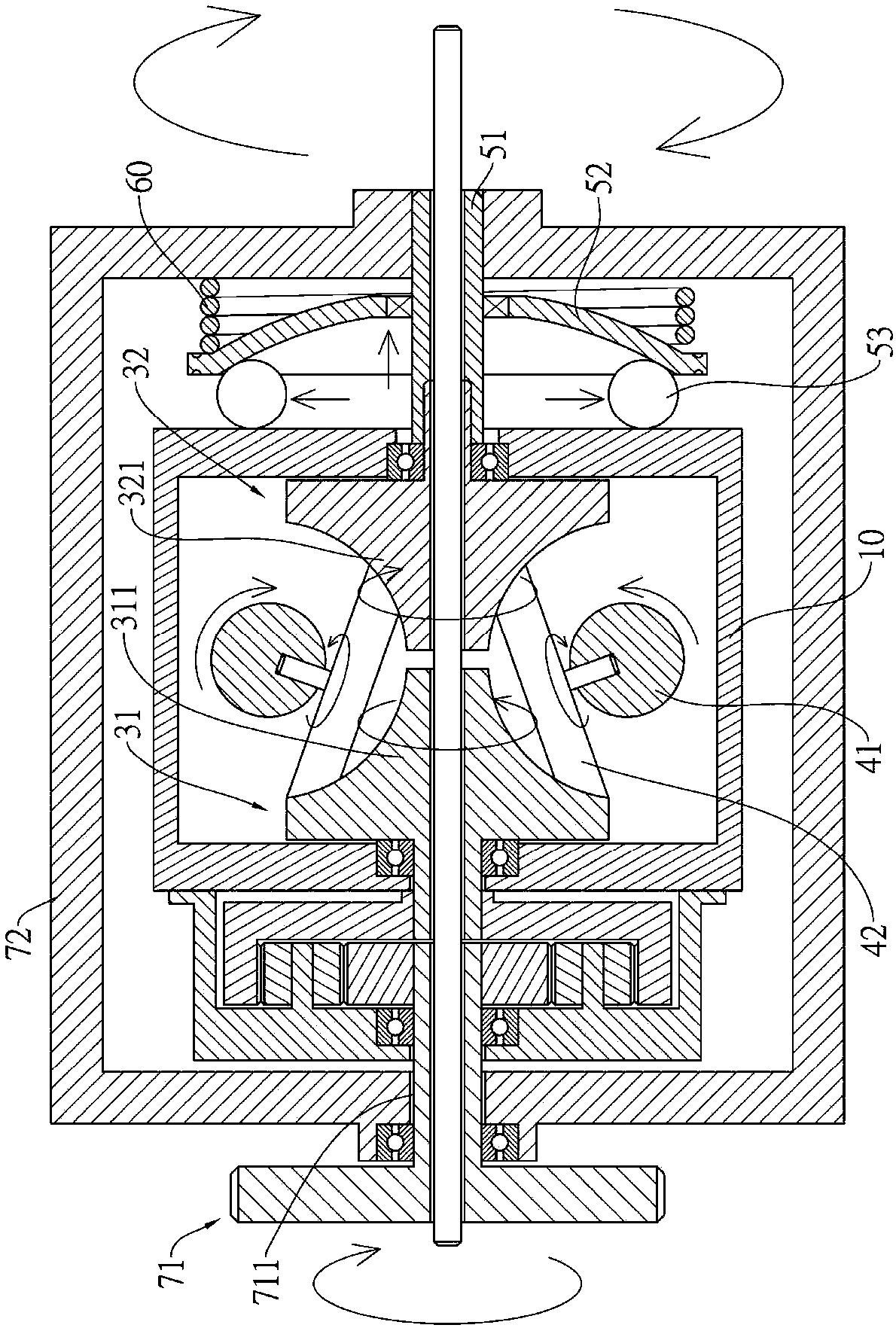

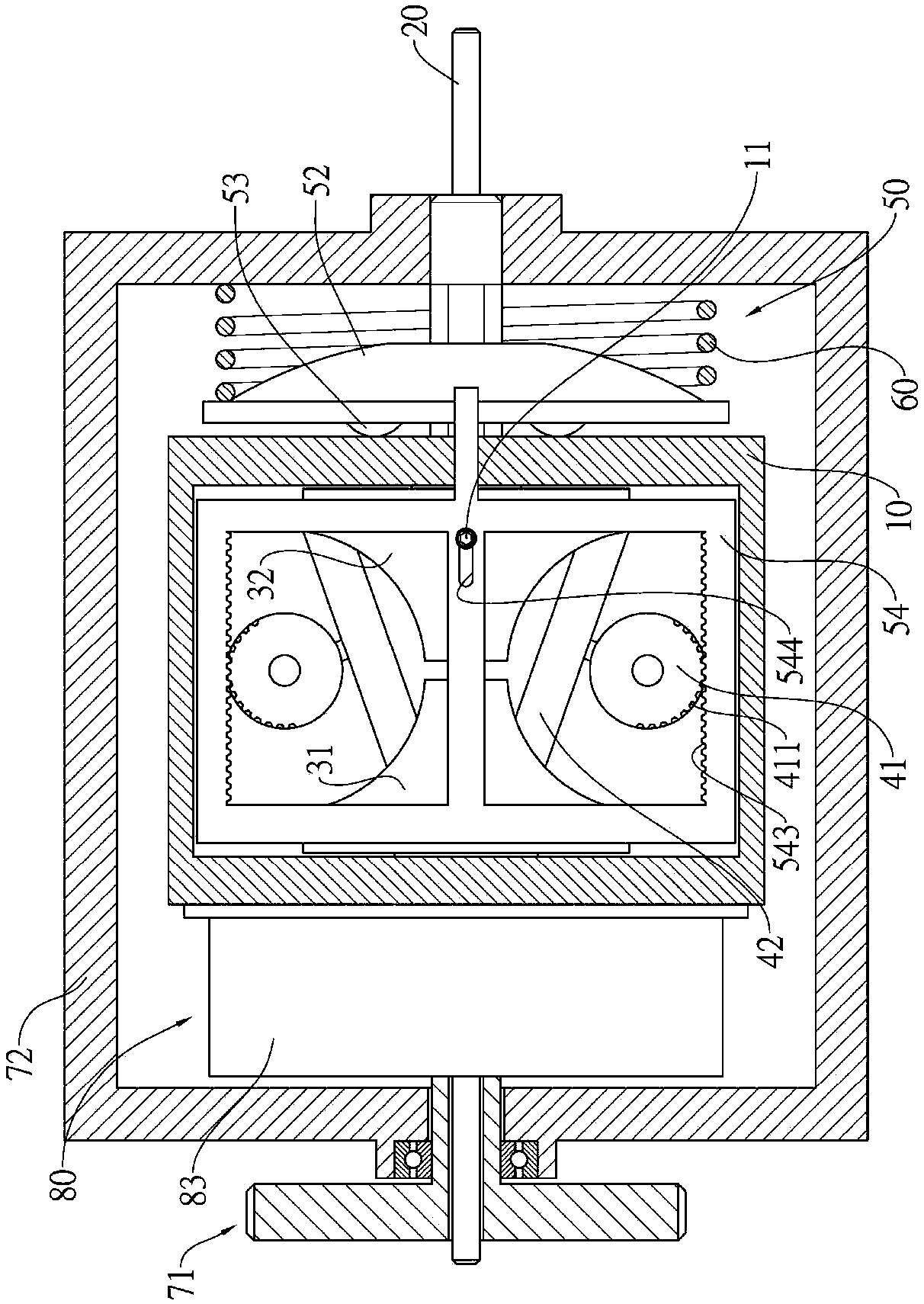

[0035] see figure 1 and image 3 As shown, the bicycle stepless automatic transmission of the present invention includes a housing 10, a central shaft 20, a power input disc 31, a power output disc 32, two rotors 41, two transmission discs 42, a centrifugal assembly 50, a The elastic element 60 , an input toothed plate 71 , a hub 72 and a reverse assembly 80 .

[0036] The aforementioned casing 10 is rectangular in this embodiment, but its shape is not limited thereto; the casing 10 is a fixed component relative to the whole bicycle and does not rotate with other components.

[0037] The aforementioned central shaft 20 runs through the housing 10, and the central shaft 20 is the axle of the rear wheel of the bicycle. Therefore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com