Toggle-type ratchet transmission of crank-shaft engine

A technology of ratchet transmission and engine, which is applied in the direction of variable displacement engine, machine/engine, reciprocating piston engine, etc. It can solve the problems of machining accuracy limitation, gap between rack and gear, etc., and achieve high mechanical efficiency and not easy to vibrate , the effect of large pressure area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

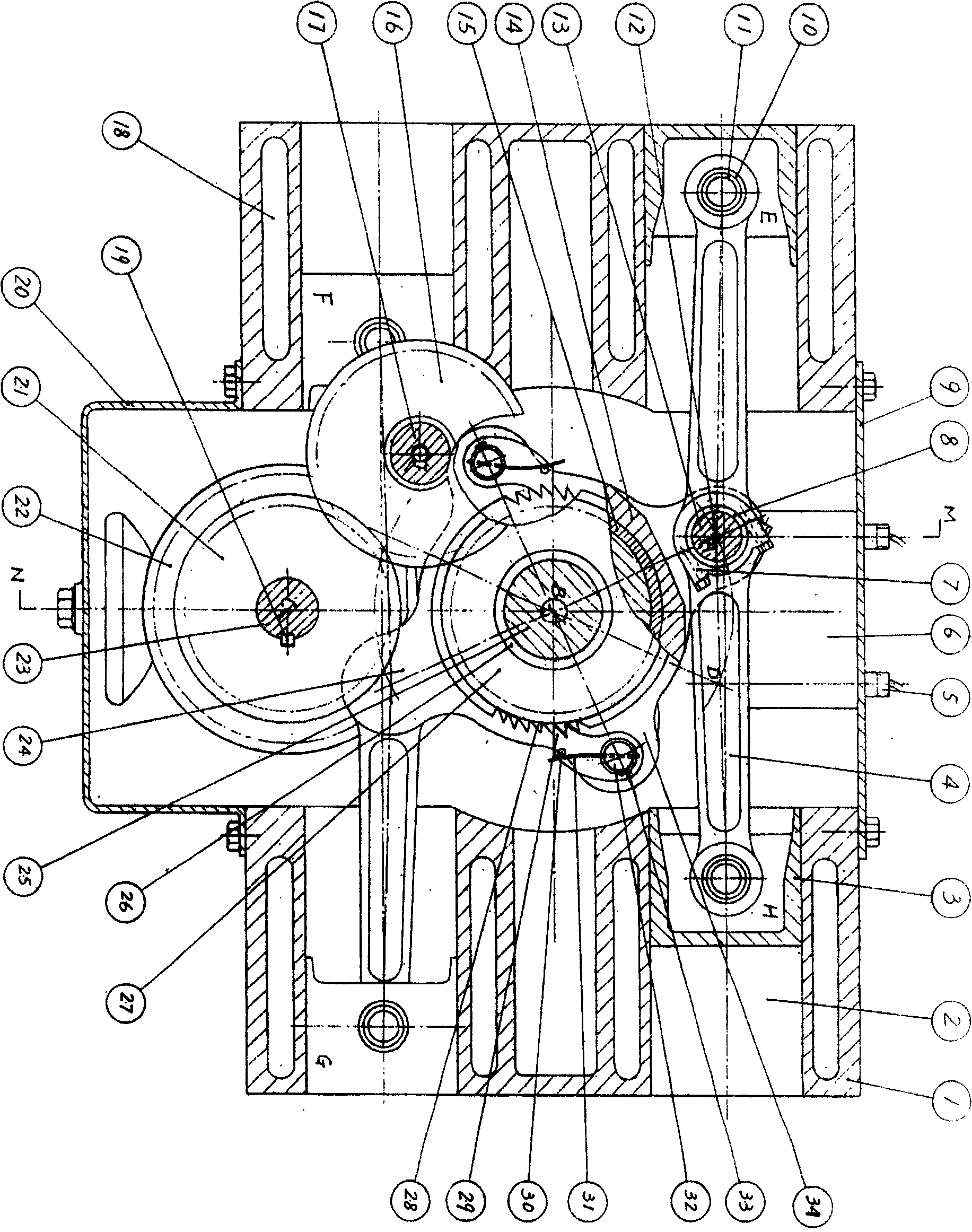

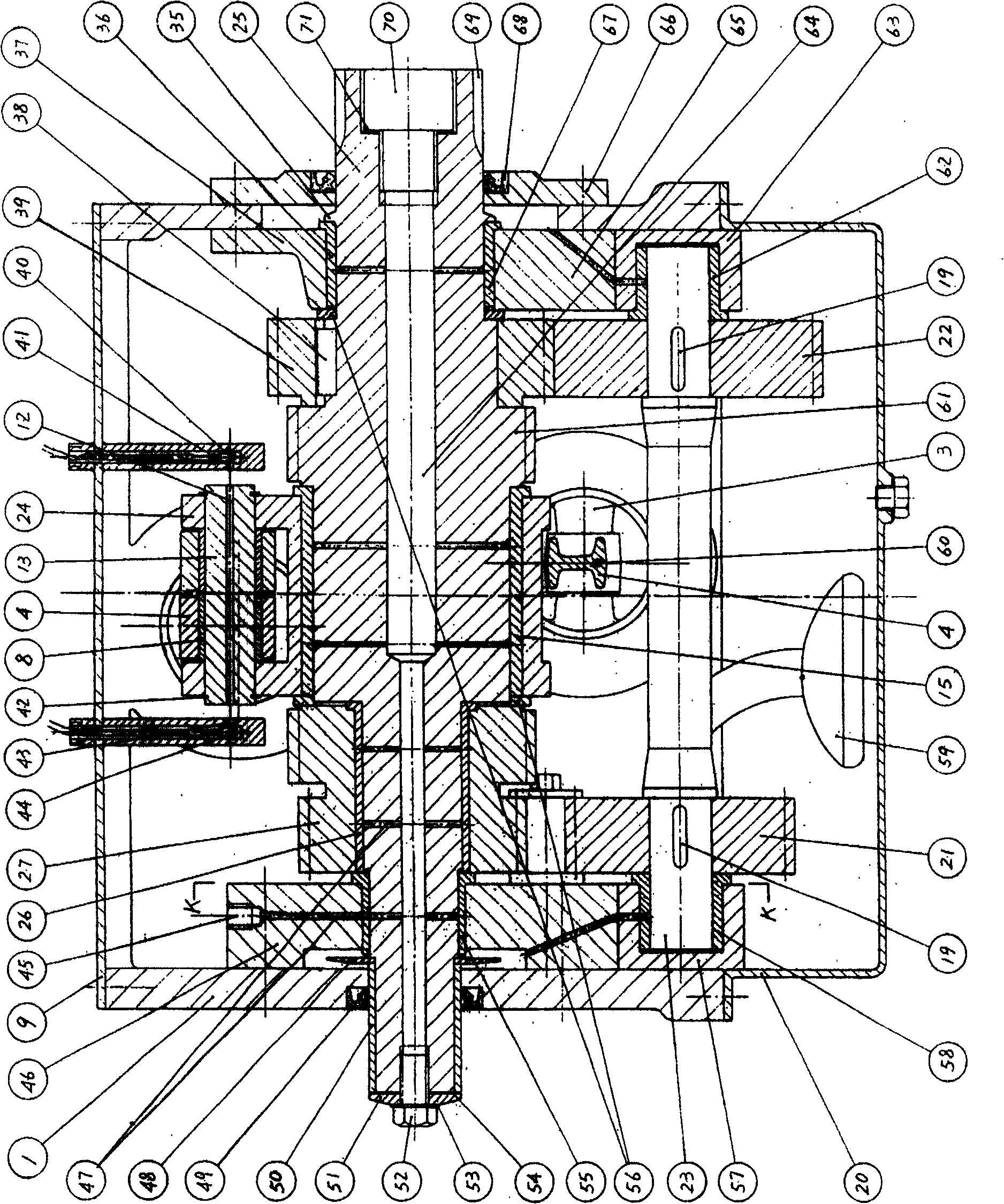

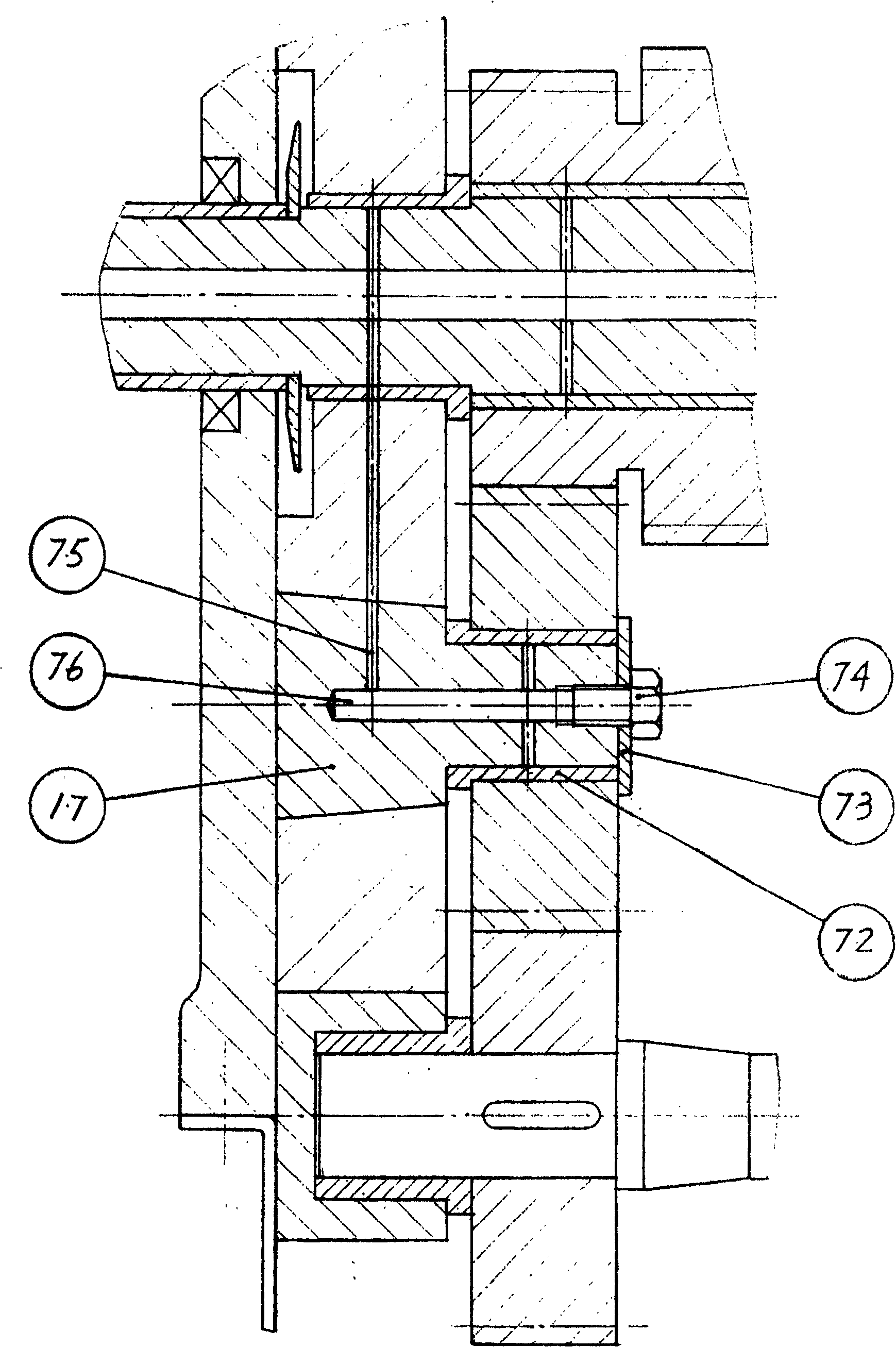

[0011] Combine below Figure 1 to Figure 4 The details and working conditions of the specific structures proposed in the present invention are described in detail, which are not intended to limit the present invention.

[0012] The present invention at least consists of a cylinder block 1, a cylinder 2, a piston 3, a connecting rod 4, a main shaft 25, a sliding sleeve 14, a ratchet 61 integrally connected with the main shaft, a gear ratchet assembly 27 that is rotatably matched with the main shaft, and a large pendulum fixed on the sliding sleeve. The pin shaft 13 on the arm 24, the pin shaft 32 fixed on the small swing arm 34 of the sliding sleeve, the ratchet 29 installed on the small swing arm, the cantilever shaft 17 fixed on the bearing seat 46 on the cylinder block, and its rotation fit The intermediate wheel 16, the pinion 21 and the bull gear 22 that are fixed on the power transmission shaft 23, the bull gear 39 that is fixed on the main shaft, and the photoelectric se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com