Hollow series-connection mechanical arm

A robotic arm, hollow technology, applied in the field of robotics, can solve the problems of unfavorable construction of the moving range of the robotic arm, inability to achieve instantaneous braking, unfavorable component protection, etc., to achieve high transmission accuracy and carrying capacity, compact structure, and improved position accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

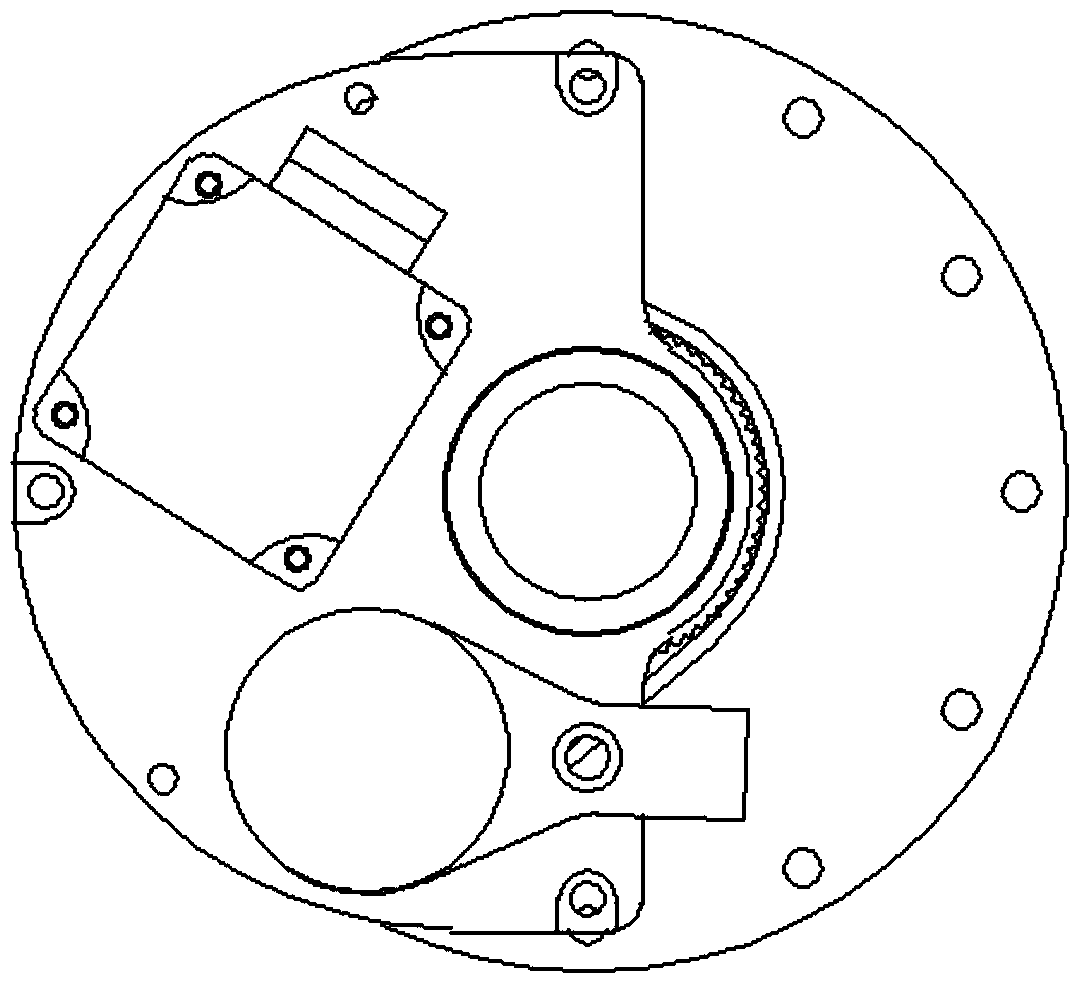

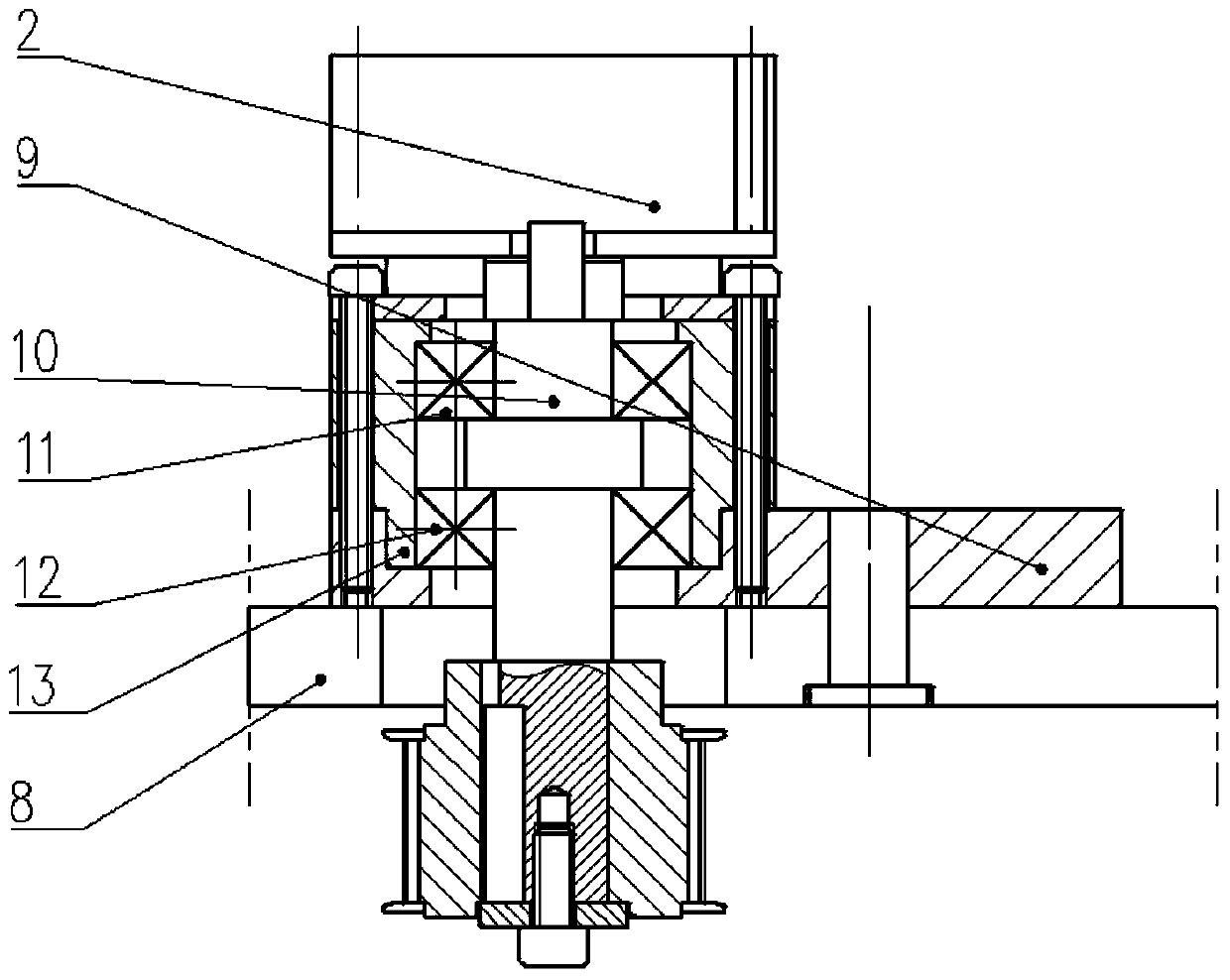

[0019] As an embodiment of the present invention, the pusher is a set screw installed in a through threaded hole on the housing 14, and the set screw can act on the pulley tension swing lever 9 through the threaded hole, Make the bearing seat rotate around the installation shaft, so that the pulley B4 rotates and the gear belt is tensioned.

[0020] The preferred bracket of the present invention is semicircular, which has the advantages of simple structure and space saving.

[0021] The preferred reducer of the present invention adopts a harmonic reducer, which has high transmission accuracy and load capacity, can realize small volume and large reduction ratio, stable movement, no impact, and low noise.

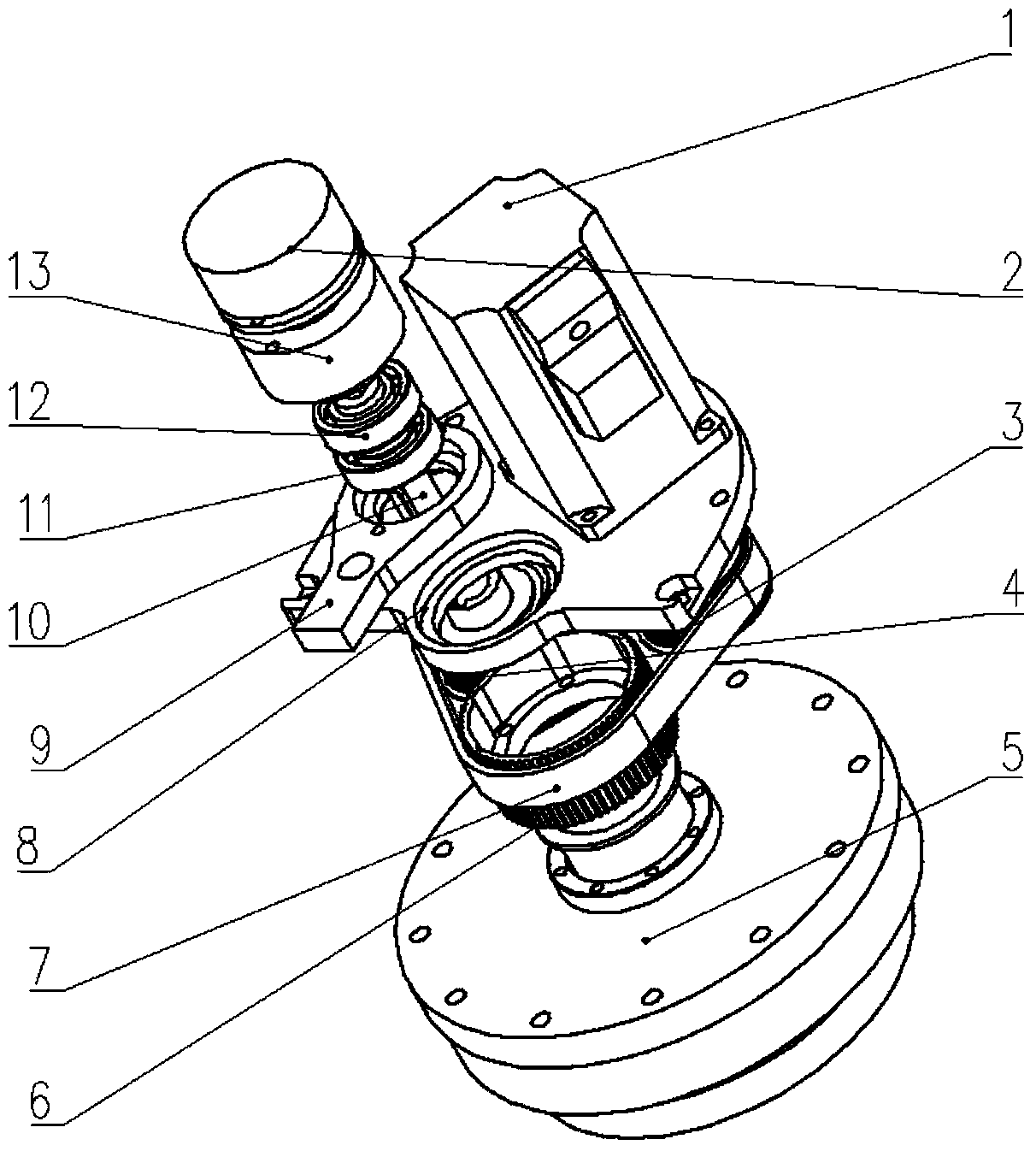

[0022] As the first embodiment of the present invention, the hollow series mechanical arm includes a plurality of modular joints, and also includes a base 16, the rotating end of the first modular joint 17 is connected to the base for vertical rotation, and the fixed end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com