Shallow foundation pit stacking truck

A technology for stacking trucks and shallow foundation pits, which is applied in the direction of object stacking, object destacking, auxiliary forming equipment, etc., and can solve the problems of large space for the pushing mechanism, reduced foundation pit depth, and accidents, etc. Achieve the effect of reducing production cost and maintenance cost, lowering the position of the bottom surface, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

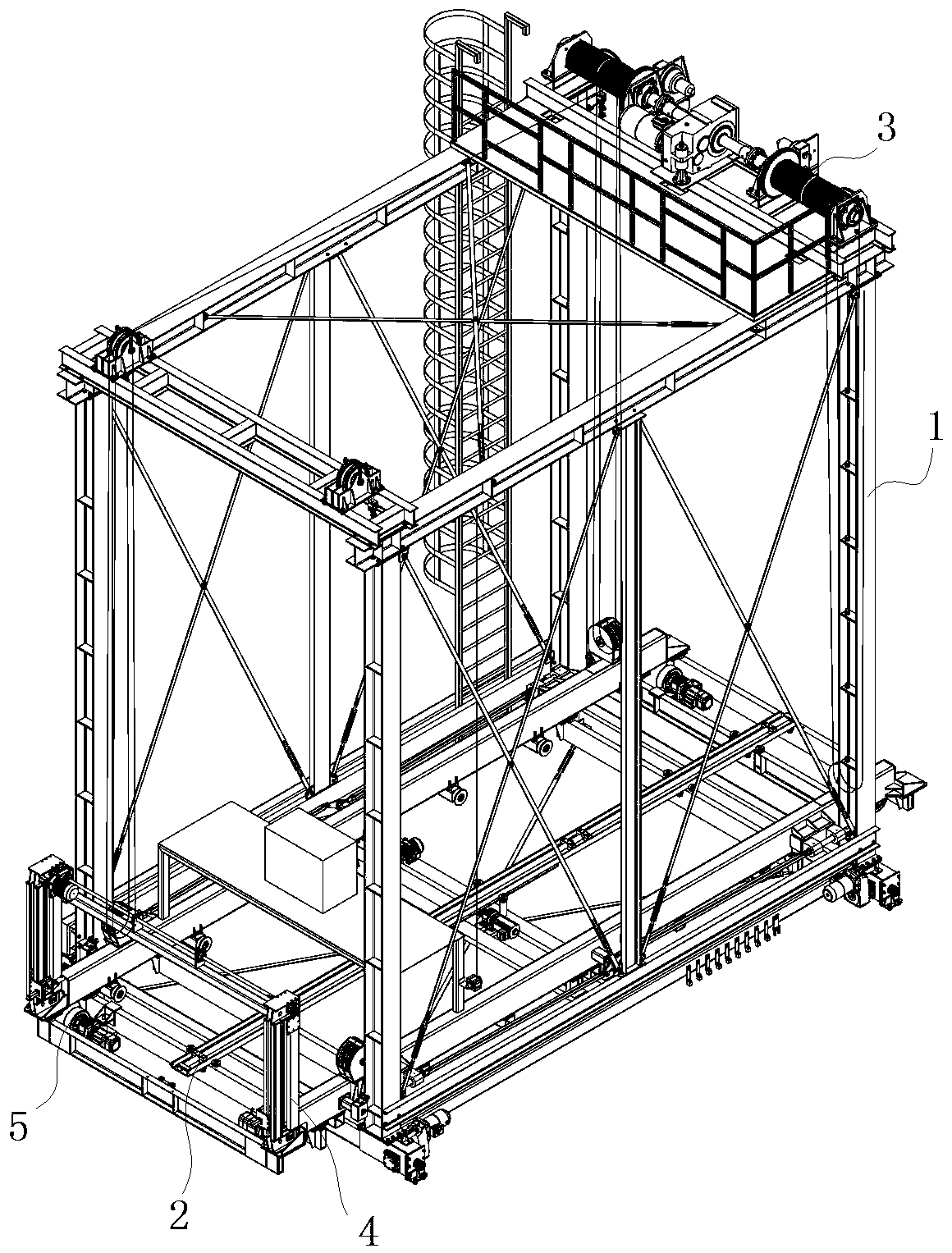

[0026] as attached Figure 1-7 As shown, the present invention includes a frame 1, a bracket 4, a lifting device 3, a pushing device 2 and a mold platform support device 5; the bracket 4 is installed on the frame 1, and the lifting device 3 is installed on the frame 1 and drives the bracket 4 up and down, the pushing device 2 and the mold table supporting device 5 are installed at the bottom of the bracket 4, the pushing device 2 pushes and pulls the mold table onto the mold table supporting device 5, and the mold table supporting device 5 drives the mold platform to run; the traveling wheels 6 at the bottom of the frame 1 are arranged on the guide rails on the ground and run on the guide rails.

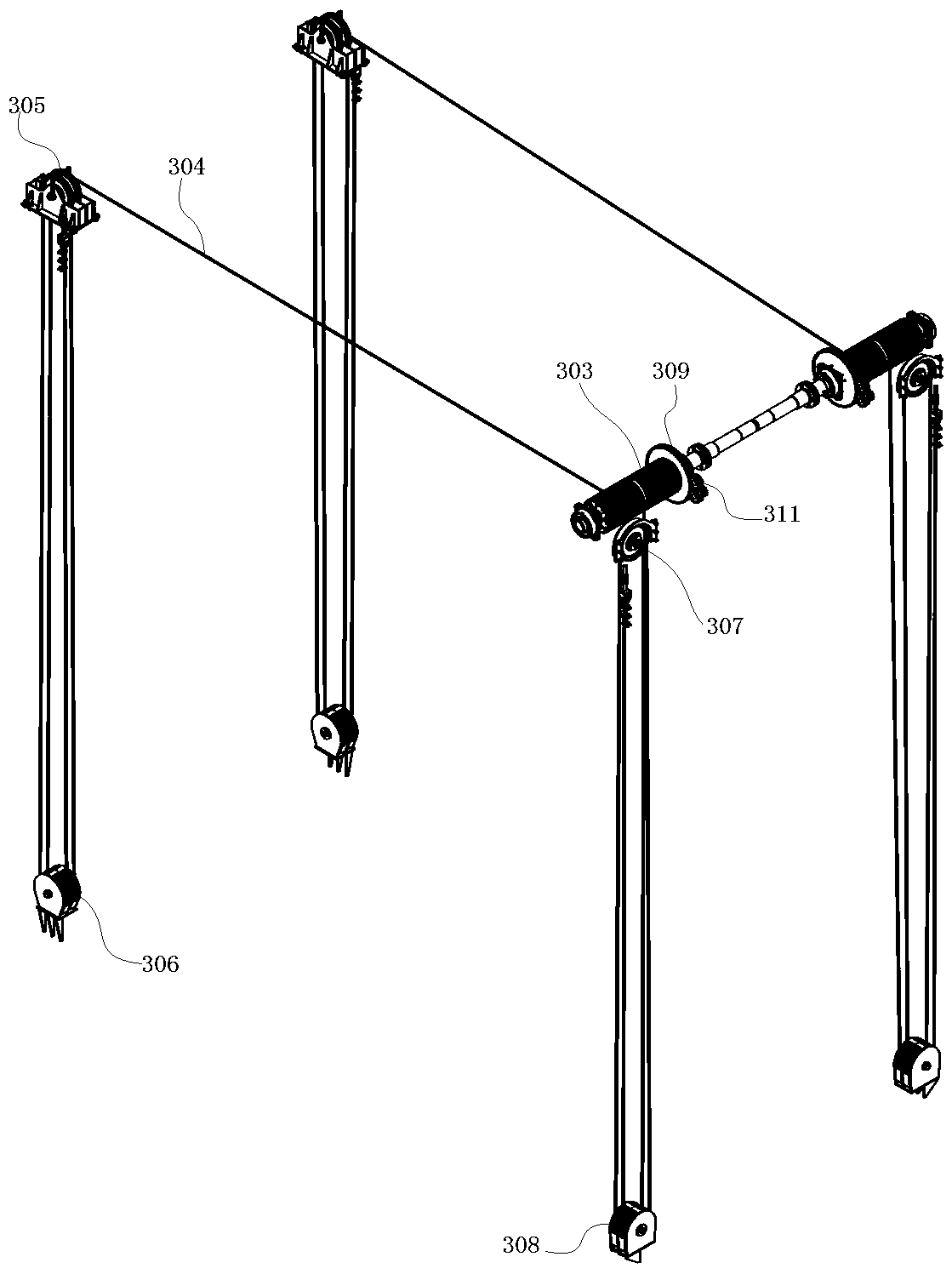

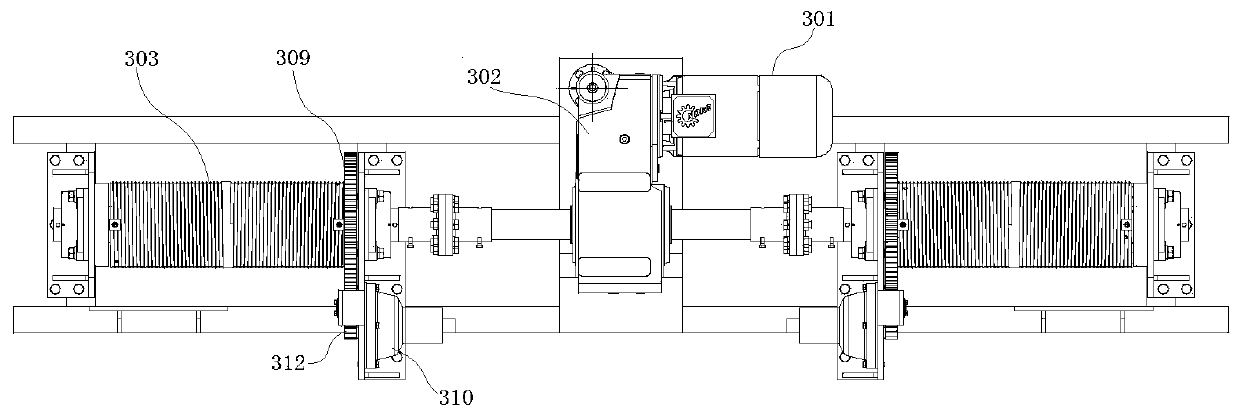

[0027] The lifting device 3 of the present invention includes a drive motor 301 installed on one end of the top of the frame, a reducer 302 installed on the drive shaft of the drive motor 301, and a front lifter mounted on both ends of the drive shaft of the reducer 302 to lift synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com