Tester for testing multifunctional vane

A test device and multi-functional technology, applied in the field of wind power blade testing, can solve the problems of only being suitable for loading from the bottom, adapting to a single type of blade, and failing to complete fatigue tests, etc., to achieve good control and adjustment performance, accurate testing, and reduced loading effect of points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

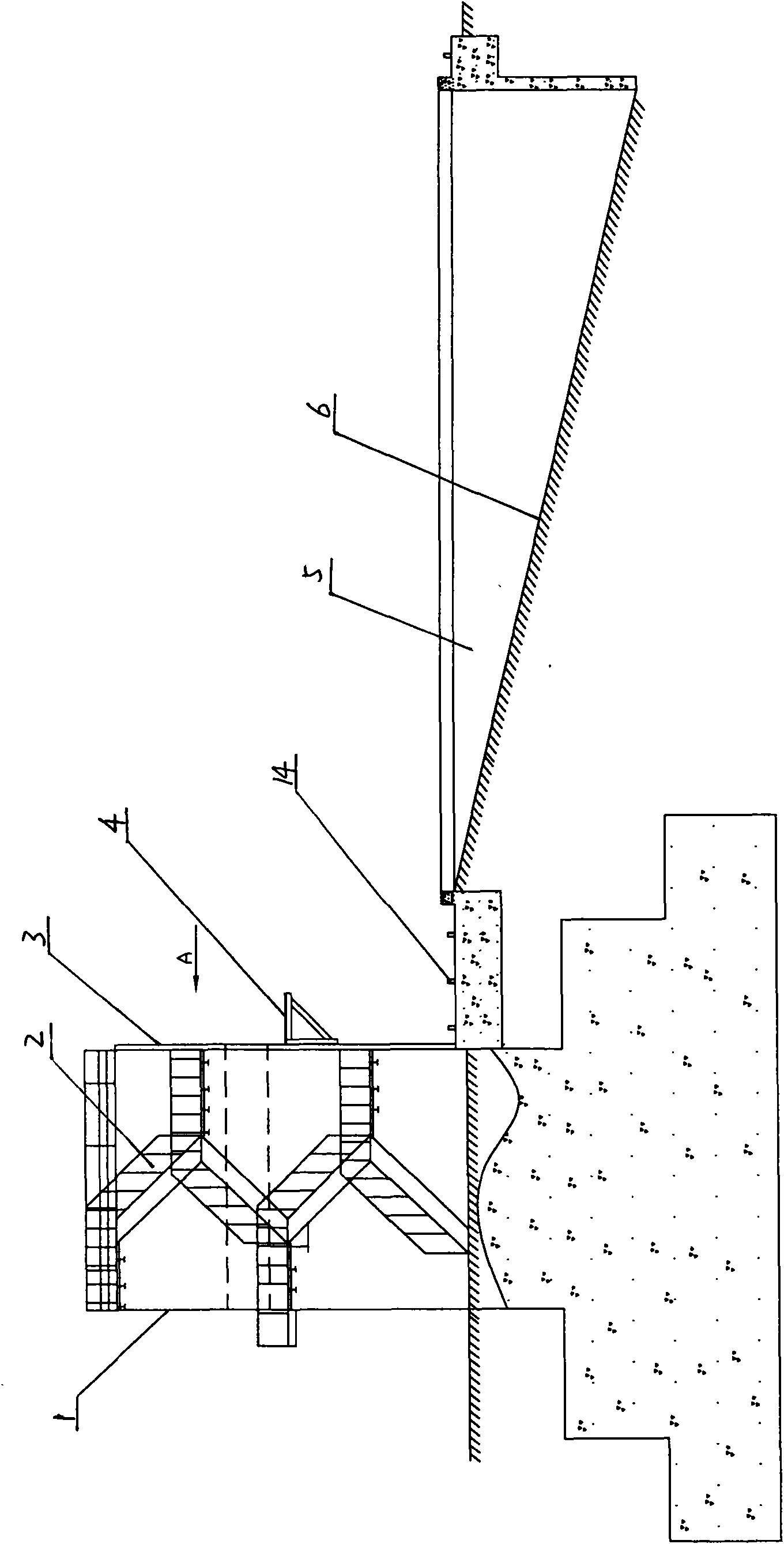

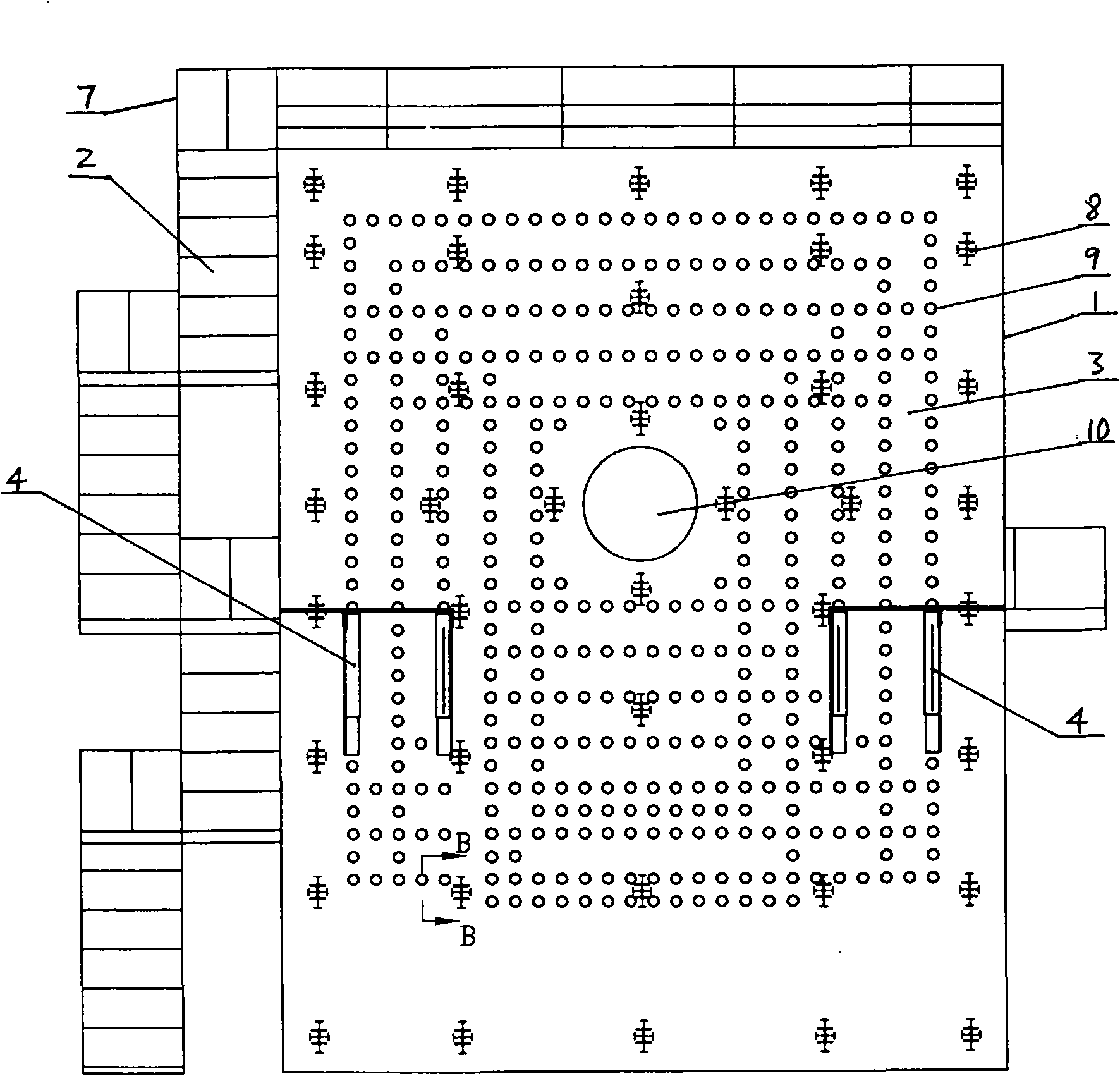

[0028] Figure 1, figure 2 , image 3 ,Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Picture 9 , Picture 10 , Picture 11 , Picture 12 with Figure 13 As shown, this embodiment includes a test bench, a side pull loading device, and a vibration exciter.

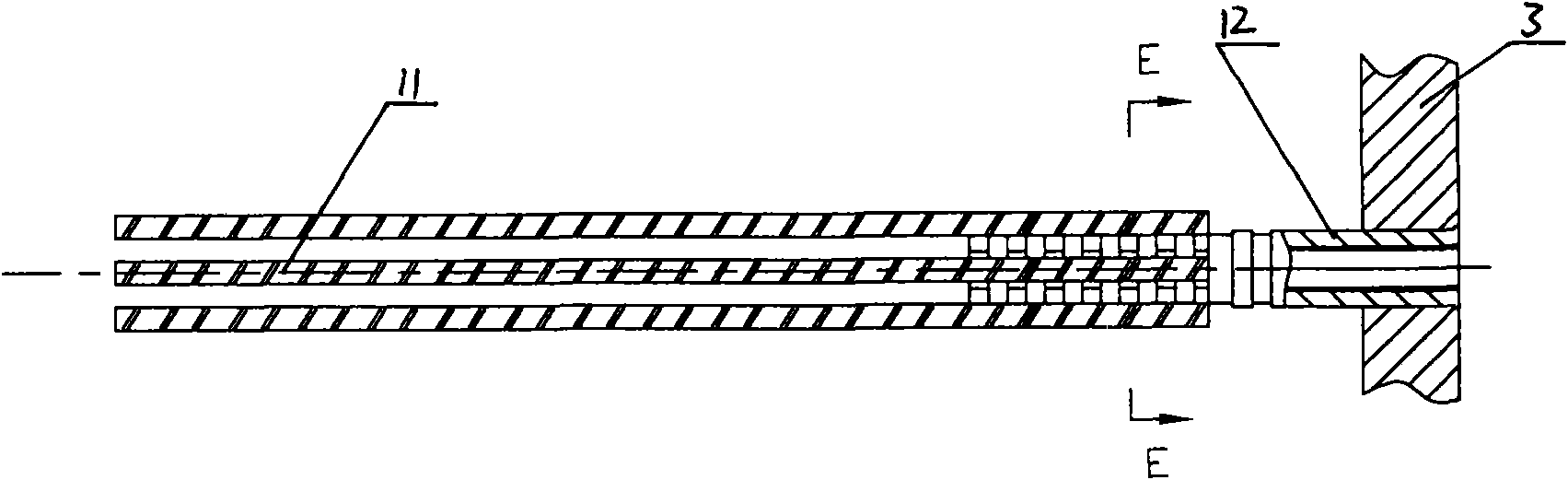

[0029] The test bench includes a table body 1, a test pit 6, and a guide rail of the side tension loading device. The platform 1 is made of reinforced concrete. The part below the ground has a stepped shape, and the front end of the part above the ground has 40 fixing parts: the blade connecting plate 3 fixed by the I-beam anchor 8. A number of blind holes 9 arranged in rows and columns are opened in the blade connecting disc 3 and the corresponding table body 1. The blind holes 9 and the I-steel anchors 8 are arranged at intervals, and the blind holes 9 are provided with blade connecting discs. 3 The bolt sleeve 12 is inlaid together, and the bolt sleeve 12 is also welded with the elongated steel bar 11 fixed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com