Patents

Literature

74results about How to "Reduce moment arm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

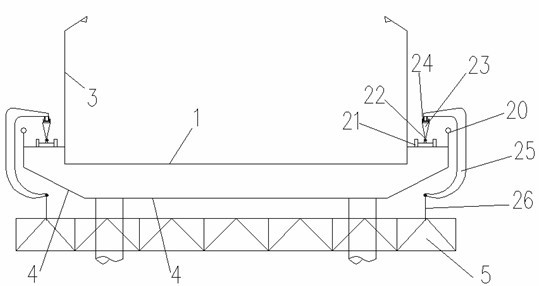

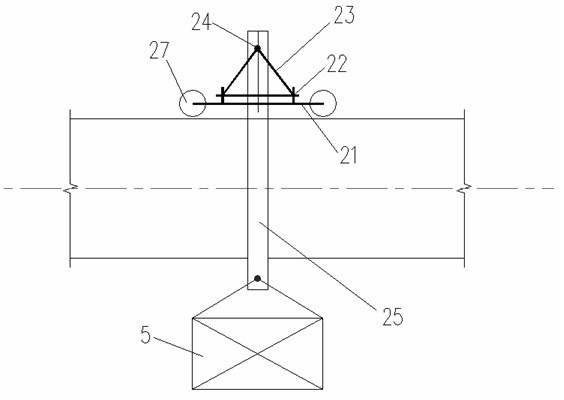

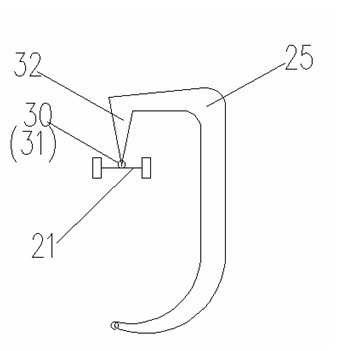

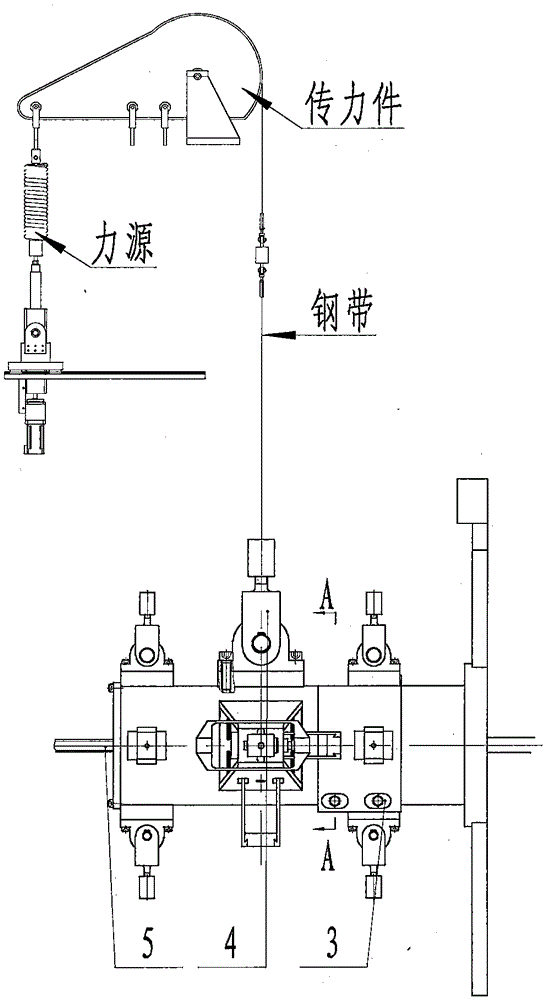

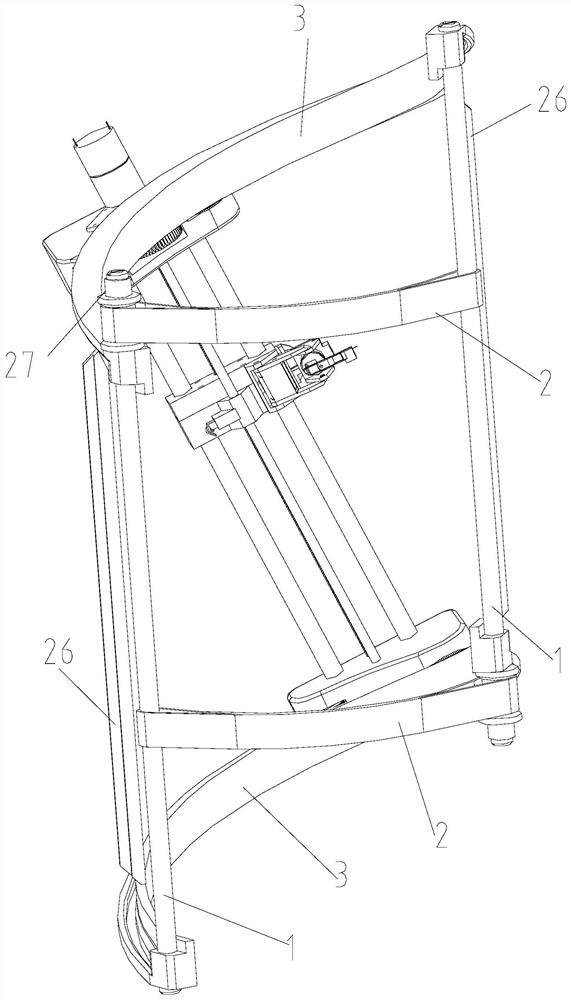

Hanger articulated bridge inspection vehicle

The invention discloses a hanger articulated bridge inspection vehicle, belonging to bridge maintenance and construction equipment. The hanger articulated bridge inspection vehicle comprises a frame chassis (21), a suspension arm is a C-type hanger (25), the frame chassis (21) is articulated with the lower end of a pillar (23) by a longitudinal axis hinge (22) and a longitudinal axis, the upper end of the pillar (23) is articulated with the protruded end of an upper cross beam of the C-type hanger (25) by a transverse axis hinge (24) and a transverse axis, or the frame chassis (21) is articulated with the protruded end of the upper cross beam of the C-type hanger (25) by the longitudinal axis hinge (22) and the longitudinal axis, and the protruded end of a lower cross beam of the C-type hanger (25) is at least provided with a fixed point of a lifting rope (26) or a lifting rope extending-retracting device. According to the invention, the pulling force of the lifting rope (26) on an inspection platform (5) can be directly transferred to a bridge floor (2), therefore, the vehicle disclosed by the invention is small in overturning moment, light in structure and convenient to assemble and use, and can be erected on sidewalks on both sides of a bridge, so that the vehicle is especially suitable to be applied to the bottom detection and maintenance engineering of heavy traffic bridges.

Owner:WUDA JUCHENG STRUCTURE CO LTD

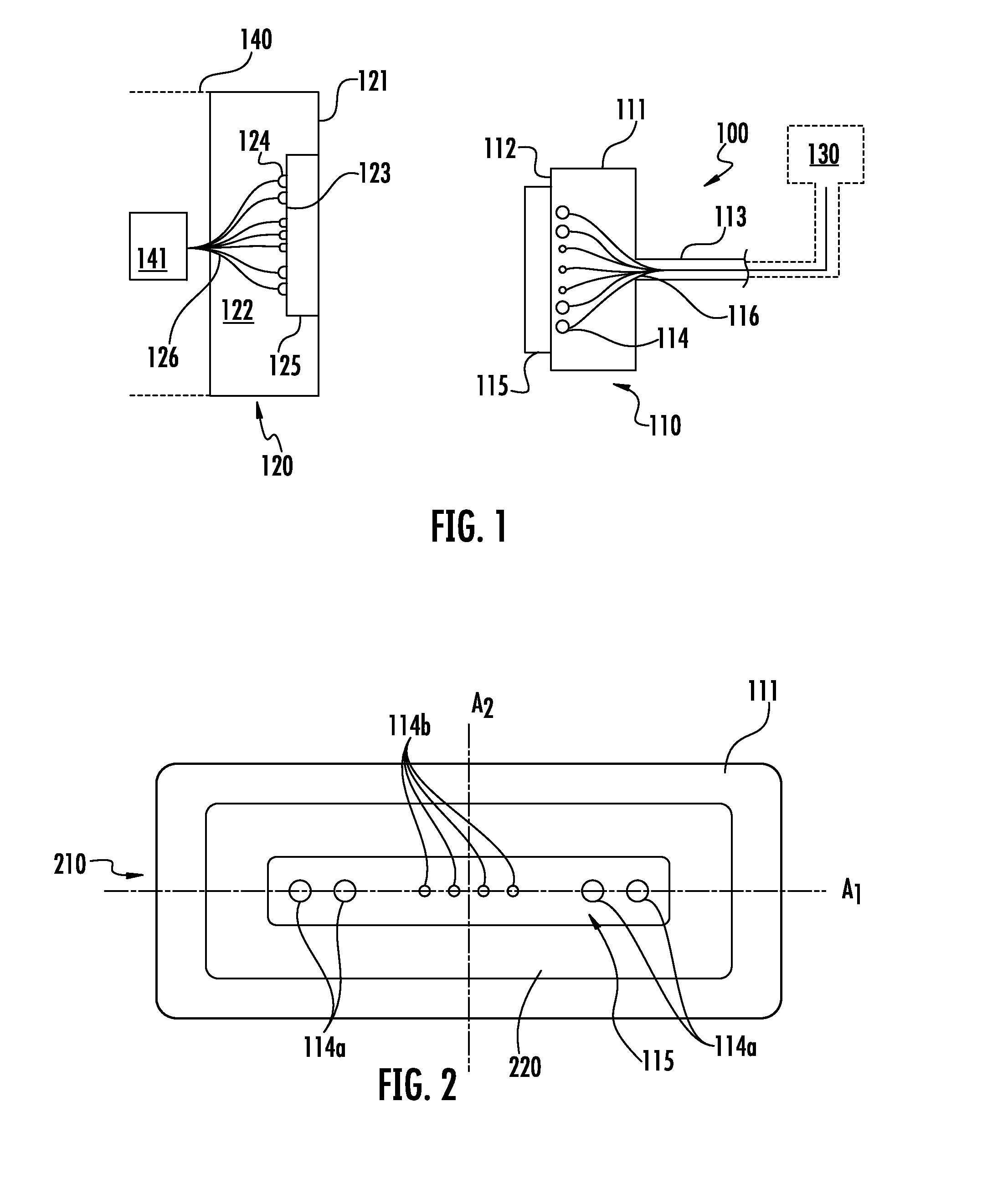

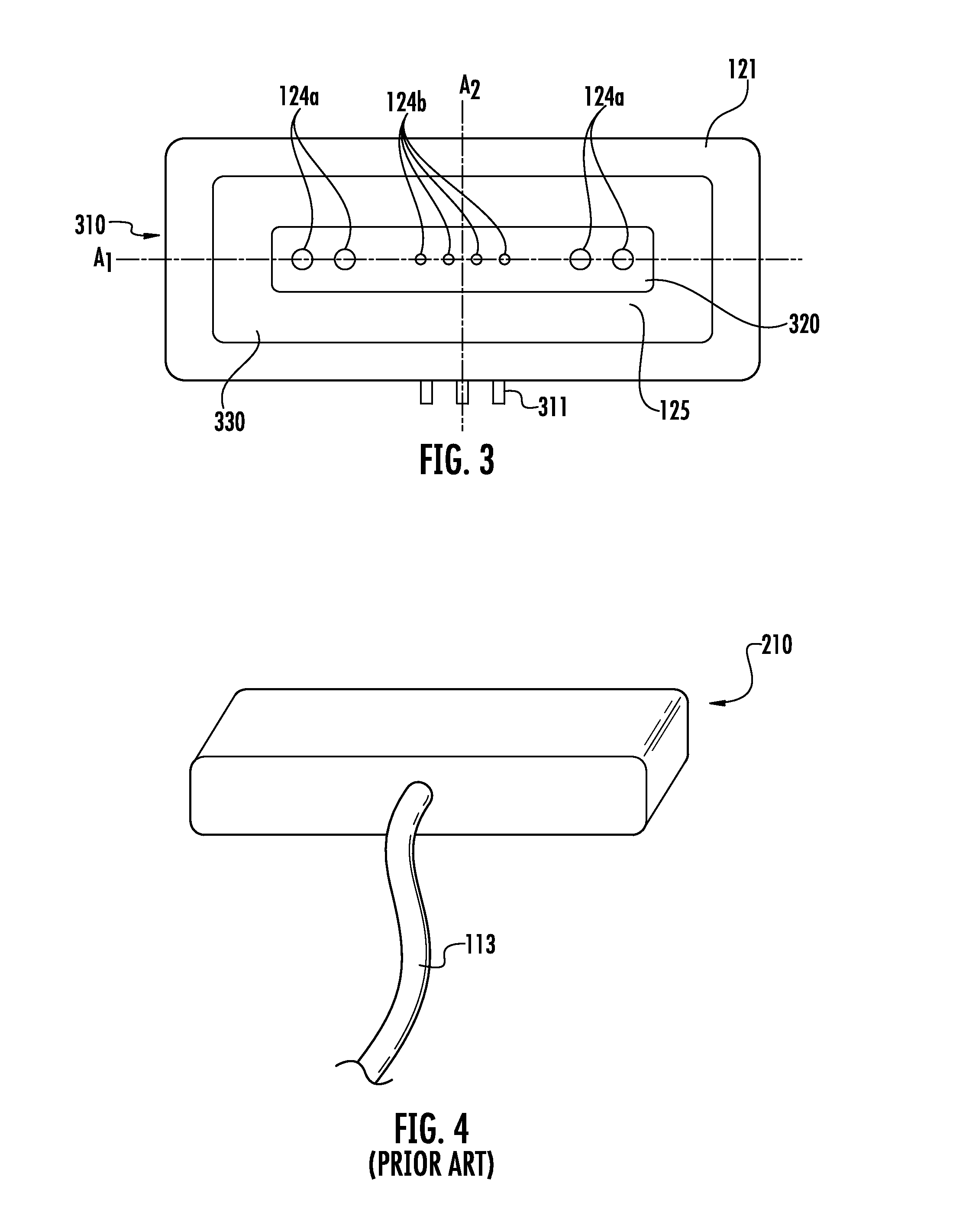

Magnetic coupling with low moment articulated plug

ActiveUS20150111398A1Reduce moment armEngagement/disengagement of coupling partsElectric connection structural associationsCouplingEngineering

Owner:CORNING OPTICAL COMM LLC

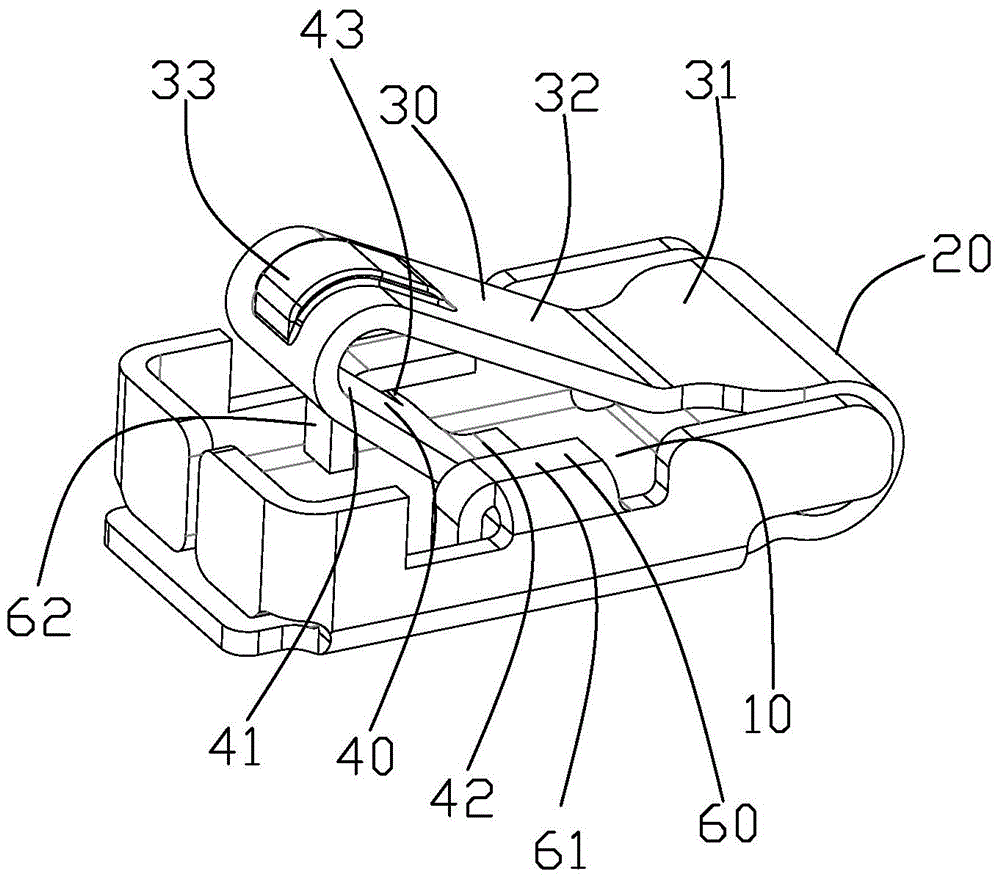

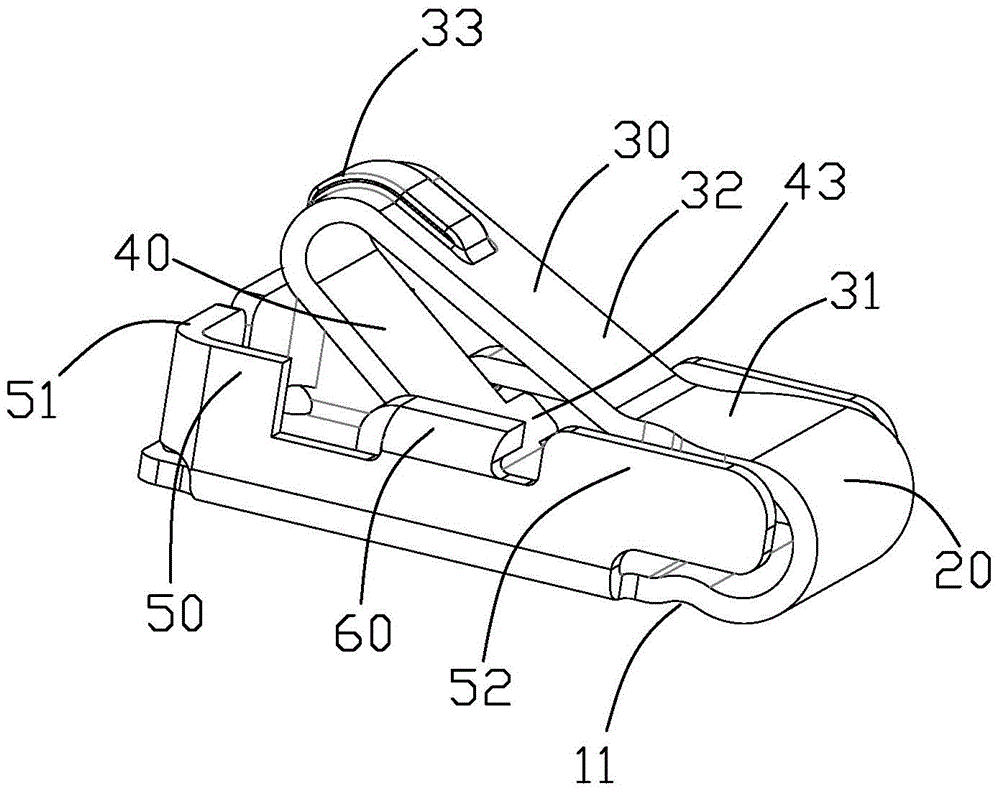

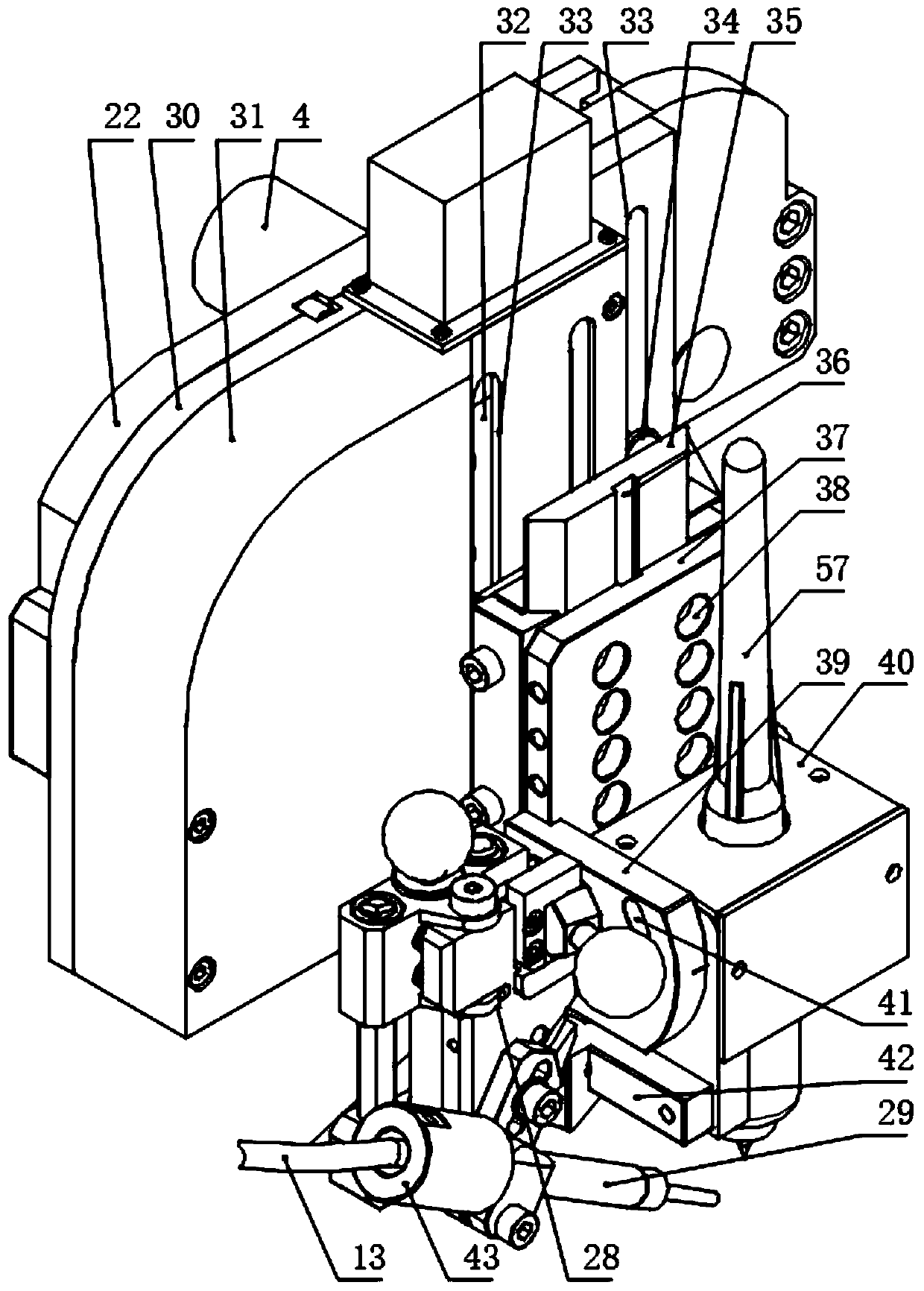

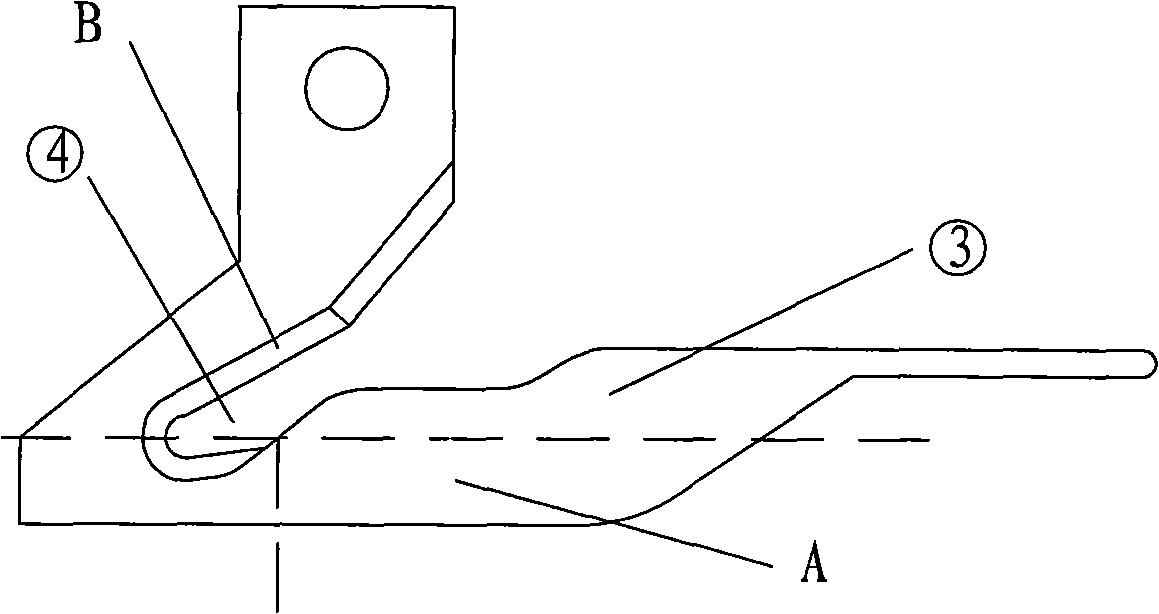

Antenna connection elastic sheet

InactiveCN104600462ANot easy to damageReduce moment armAntenna connectorsCoupling contact membersEngineeringMechanical engineering

An antenna connection elastic sheet comprises a plate base, a tensioning portion formed by reverse bending extension from the rear end of the plate base, an elastic arm formed by the inclined upward extending of the tail end of the tensioning portion and a supporting portion formed by reverse bending extending from the tail end of the elastic arm towards the plate base. Two sides of the lower end of the supporting portion extend towards the transverse direction to form retaining arms, the two cross sides of the plate base at the positions of the retaining arms are bent upwards to extend to form retaining sheets above the retaining arms, and the retaining arms comprise upper retaining sheets and front retaining sheets. The upper retaining sheets are formed by upward bending extending from the two sides of the plate base and bending extending towards the retaining arms, and the front retaining sheets are formed by downward bending extending from the front ends of the upper retaining sheets. The antenna connection elastic sheet is good in service life and not easy to damage.

Owner:SHENZHEN EVERWIN PRECISION TECH

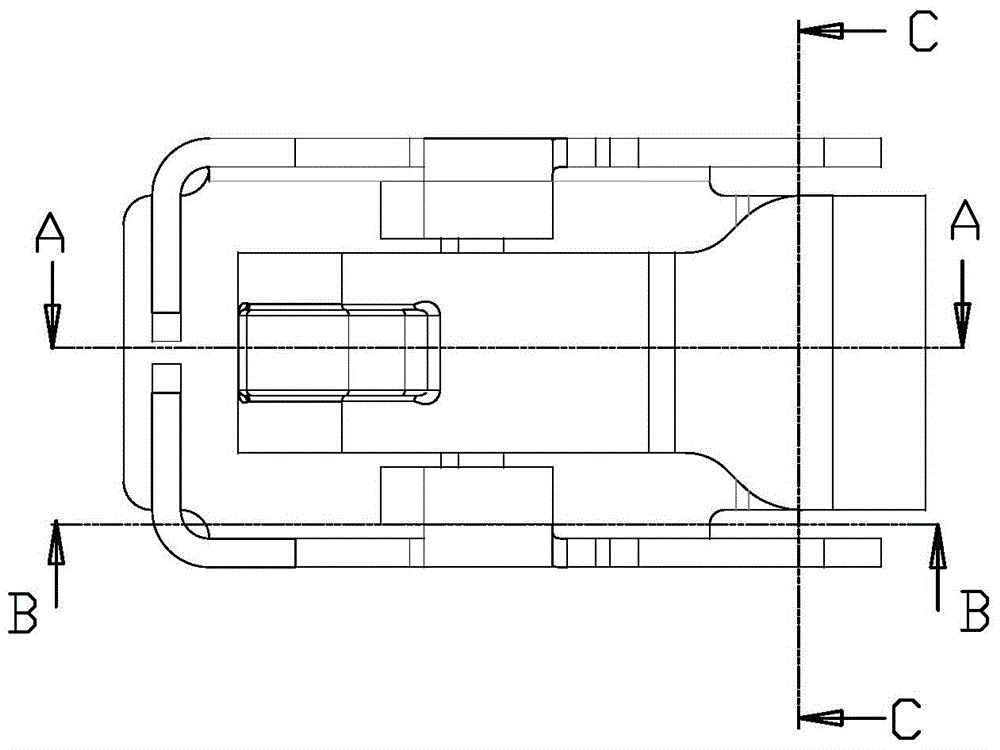

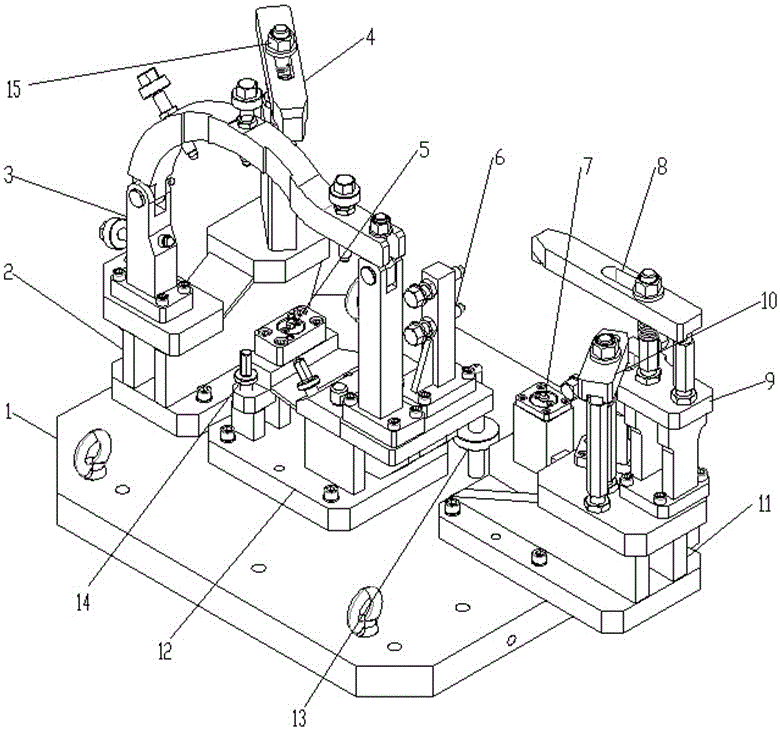

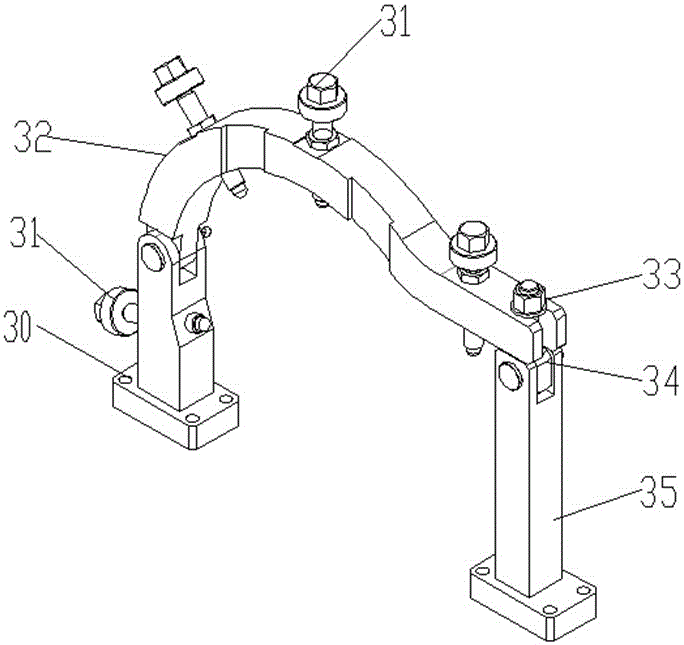

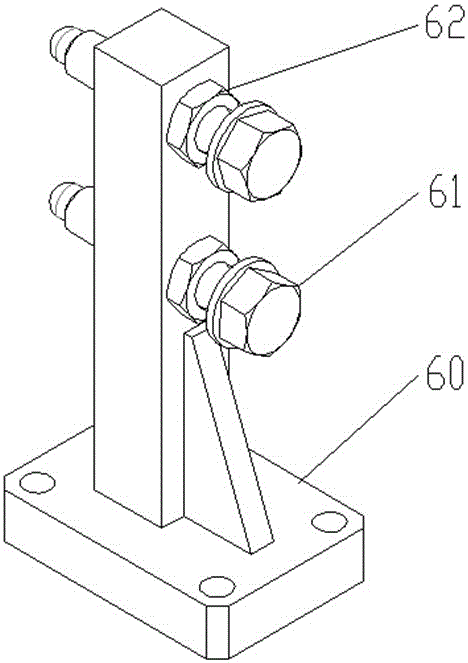

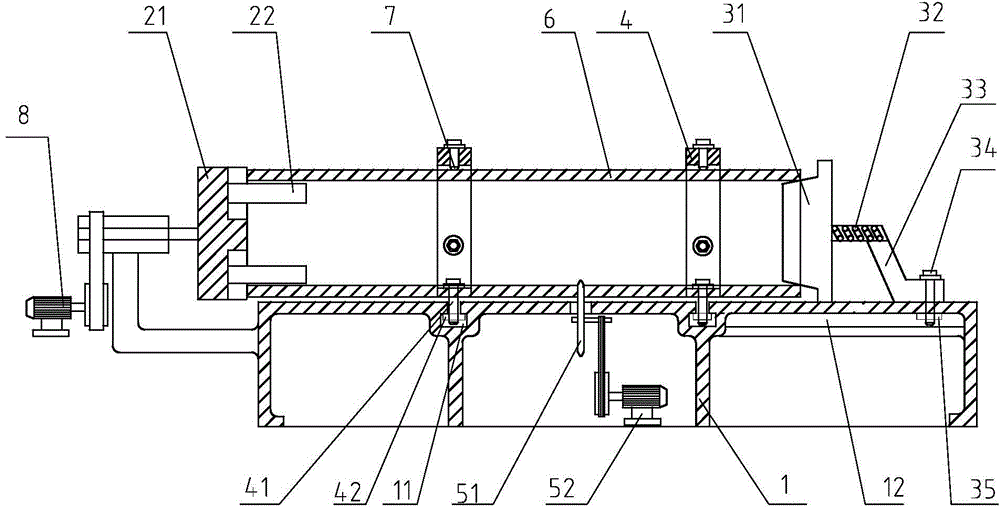

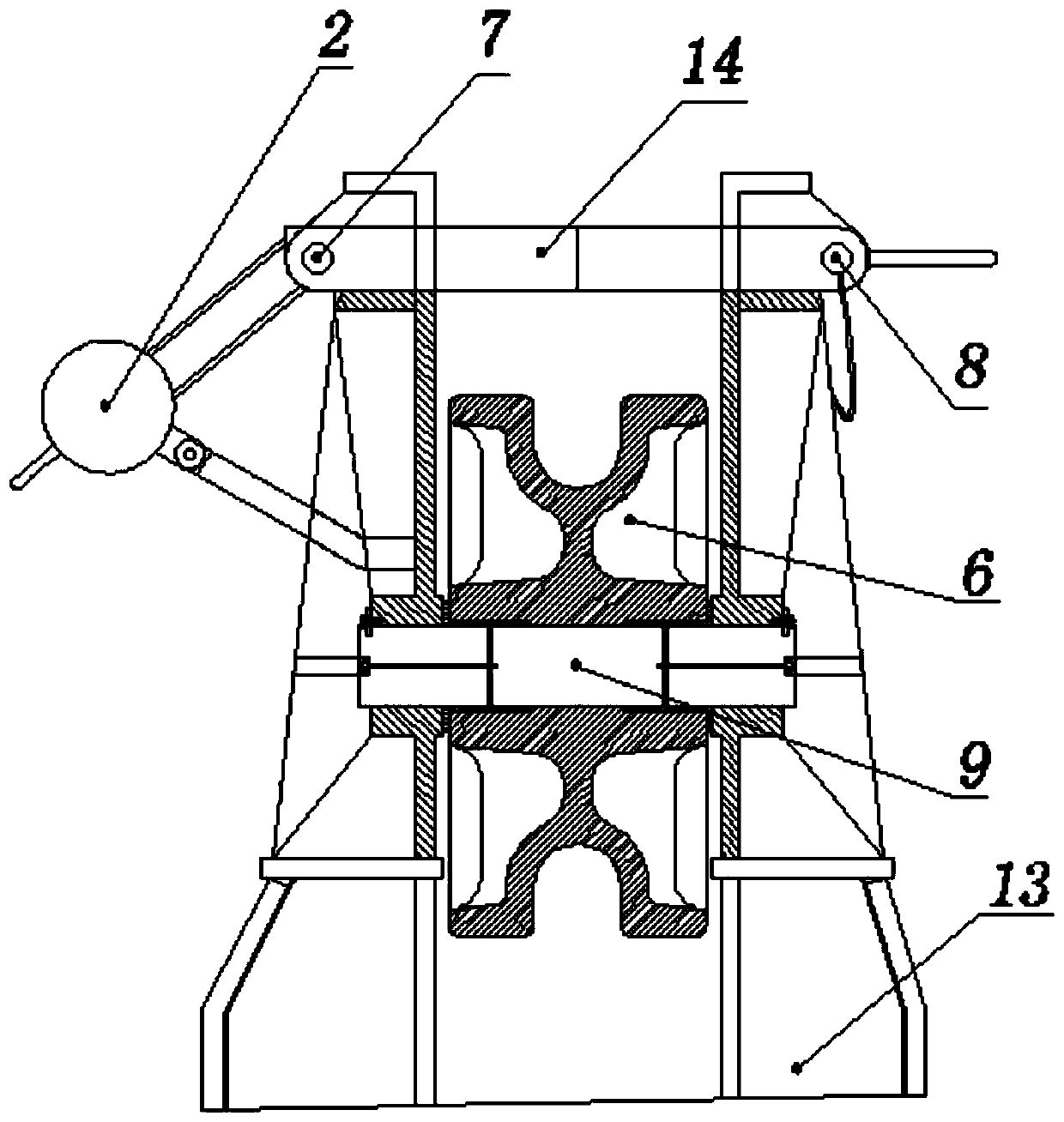

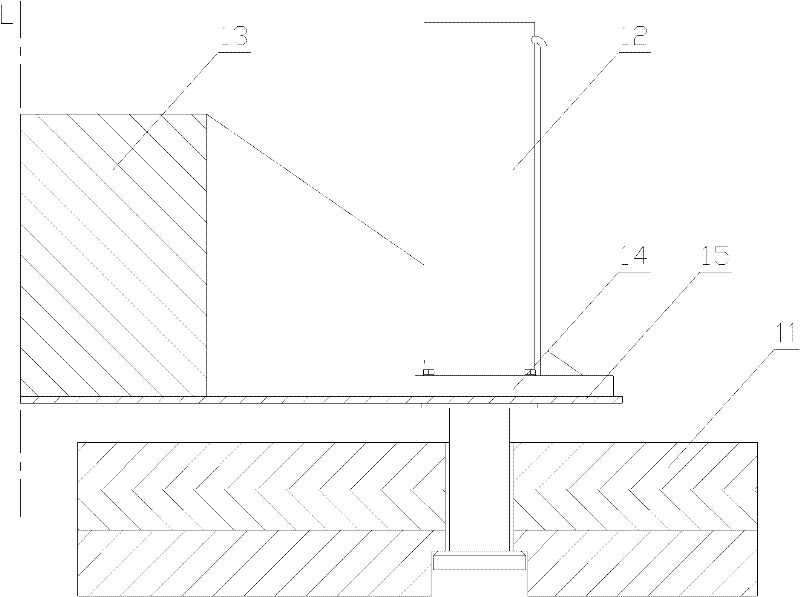

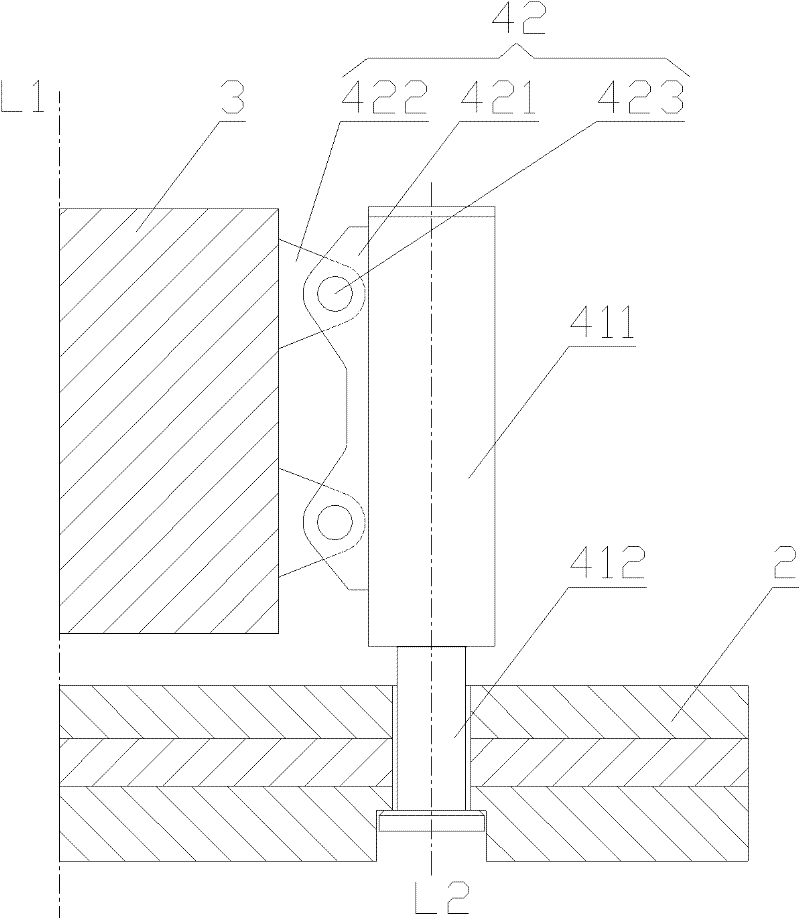

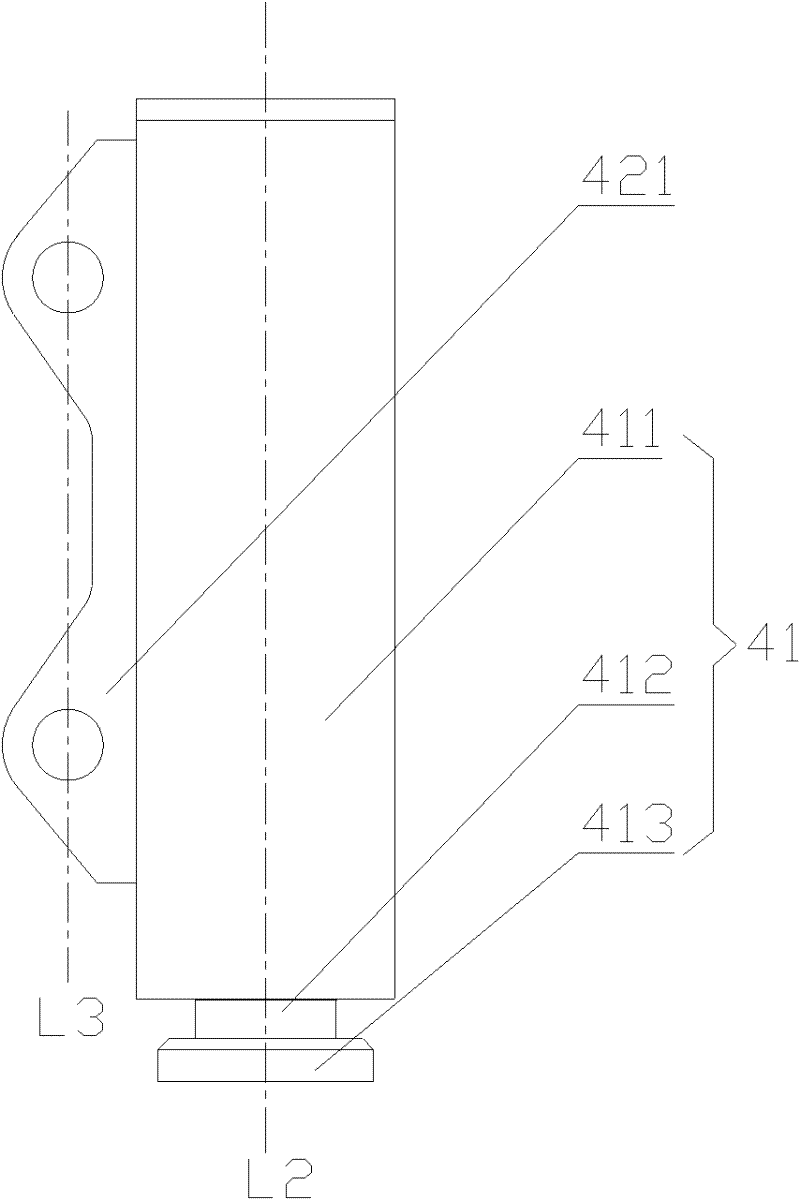

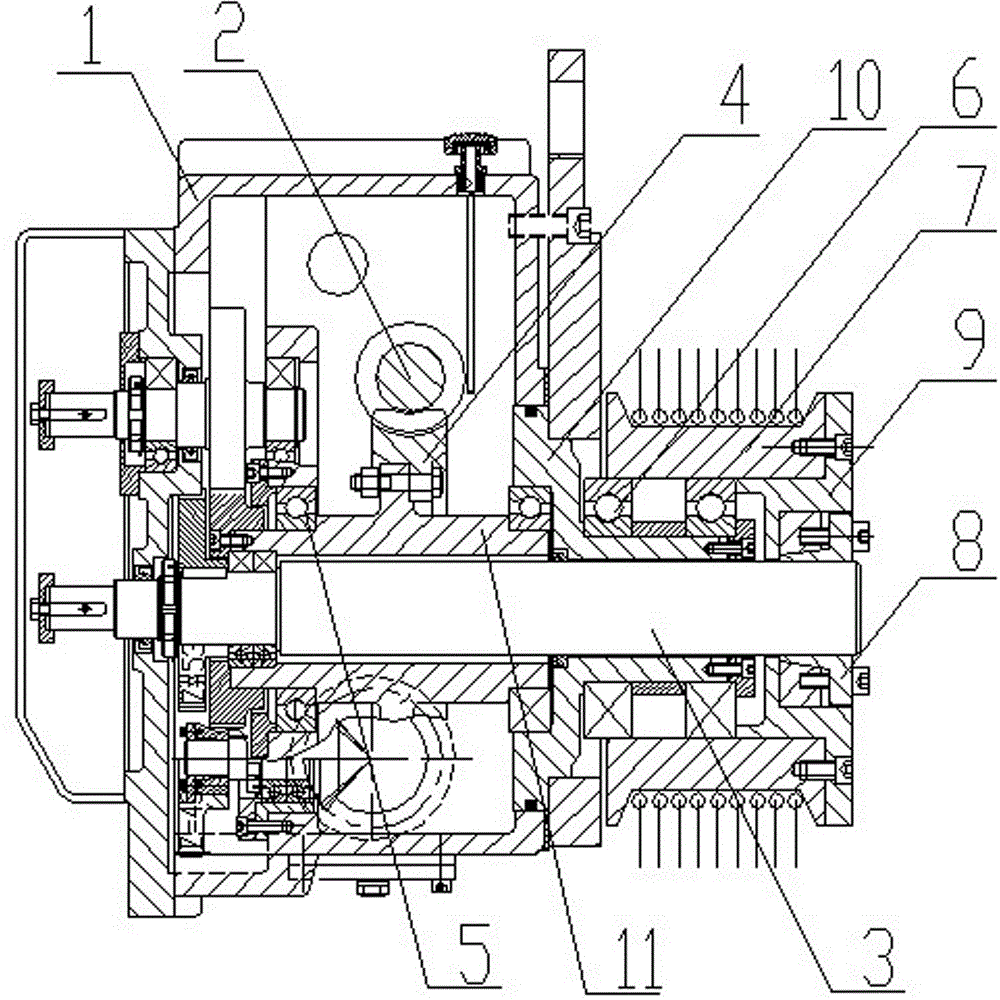

Clamp for processing gearbox body of forklift

ActiveCN105149985ASolve the processing vibration problemReliable compressionPositioning apparatusMetal-working holdersEngineeringMulti point

The invention relates to a clamp for processing a gearbox body of a forklift. The specific structure of the clamp is that a left pressing plate mechanism, an intermediate mechanism and a right pressing plate mechanism are correspondingly arranged on a bottom plate, wherein a first locating pin and a second locating pin are correspondingly arranged on the bottom plate parts at two sides of the intermediate mechanism; the left pressing plate mechanism comprises an arc-shaped pressing plate and a left pressing plate; the right pressing plate mechanism comprises a locating pressing plate and a right pressing plate; one side of the gearbox body to be processed, of the forklift, is a differential housing and the other side of the gearbox body to be processed, of the forklift, is a motor mounting housing; when the clamp is put into use, the gearbox body to be processed, of the forklift, is positioned on the first locating pin and the second locating pin, the arc-shaped pressing plate and the left pressing plate are pressed to the top part of the differential housing, the right pressing plate is pressed to the top part of the motor mounting housing, and the locating pressing plate is pressed onto a lug on the motor mounting housing, so that the gearbox body to be processed, of the forklift, can be positioned and clamped. The clamp is reliable to locate and compress; the problem of vibrating in processing can be solved; the one-point compressing in the prior art is adjusted to be multi-point compressing, thereby removing the influence of human factors on the workpiece clamping effect.

Owner:ANHUI HELI CO LTD

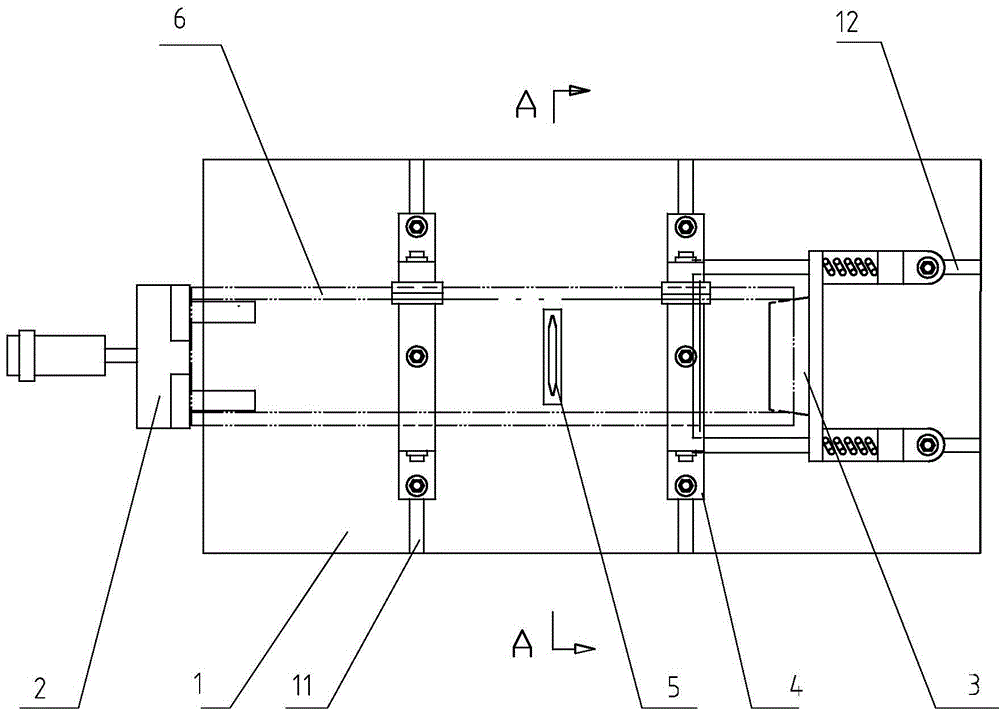

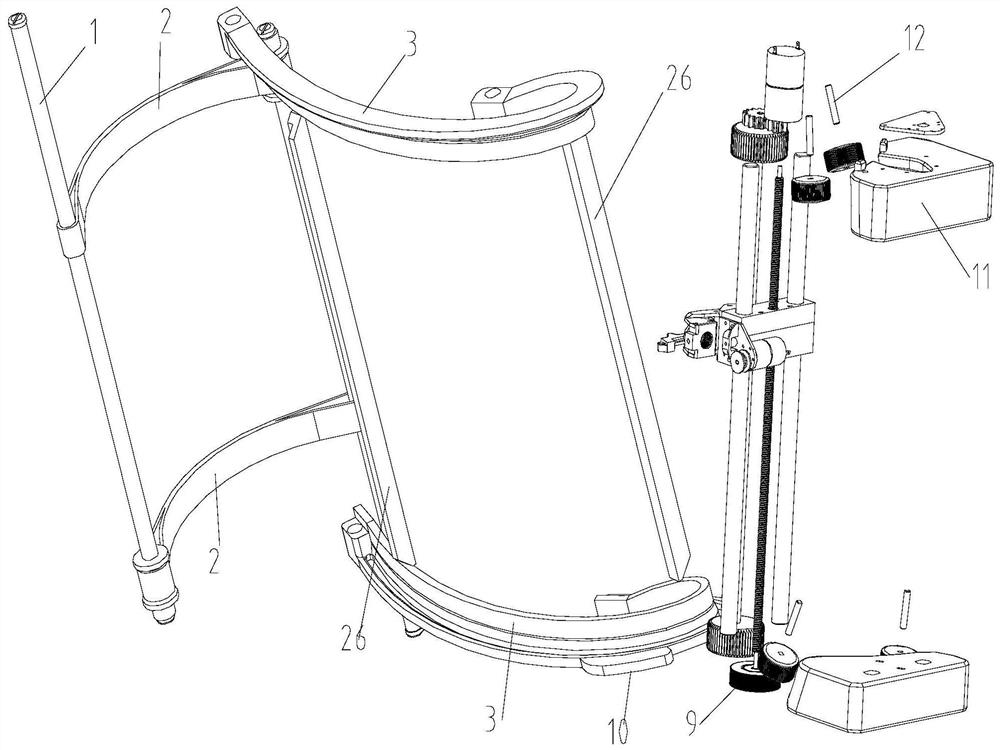

Pipe cutting device

ActiveCN104552621AReduce torqueReduce spacingWorking accessoriesStone-like material working toolsEngineeringPipe support

The invention discloses a pipe cutting device, belongs to the field of casting, and solves the technical problem that in the prior art, the ceramic cast pipe is easy to break. The pipe cutting device provided by the invention includes a pedestal, a cutting tool and a fixture assembly, wherein the fixture assembly includes a left chuck, a right chuck and a chuck driving unit; a pipe is clamped between the left and right chucks; the chuck driving unit drives the left or right chuck to further drive the pipe to rotate around the axis of the pipe; the cutting tool cuts along the rotating direction of the pipe; the pipe cutting device also includes a pipe support fixedly connected onto the pedestal, wherein the pipe support is arranged on the outer wall of the pipe in an embracing manner, and a positioning piece for clamping the pipe in the radial direction is arranged on the pipe support. The pipe cutting device is applied to cutting the pipes, particularly cutting the ceramic pipes.

Owner:浙江杭机铸造有限公司

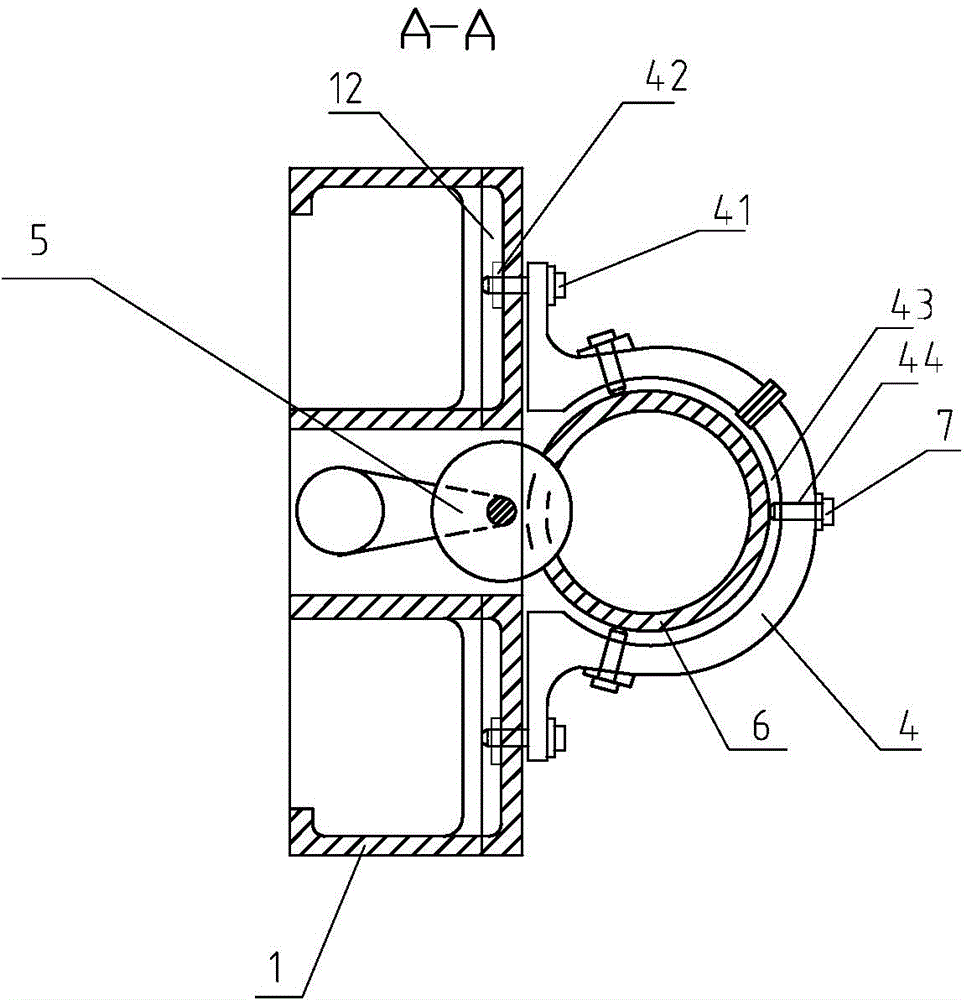

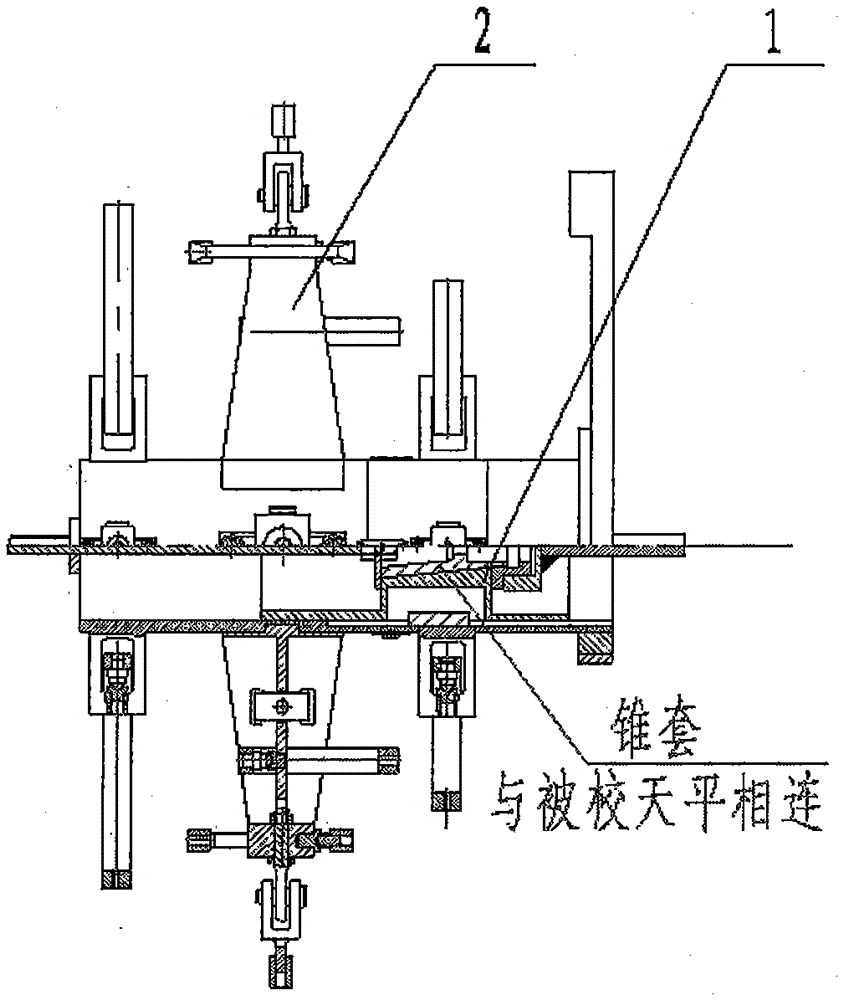

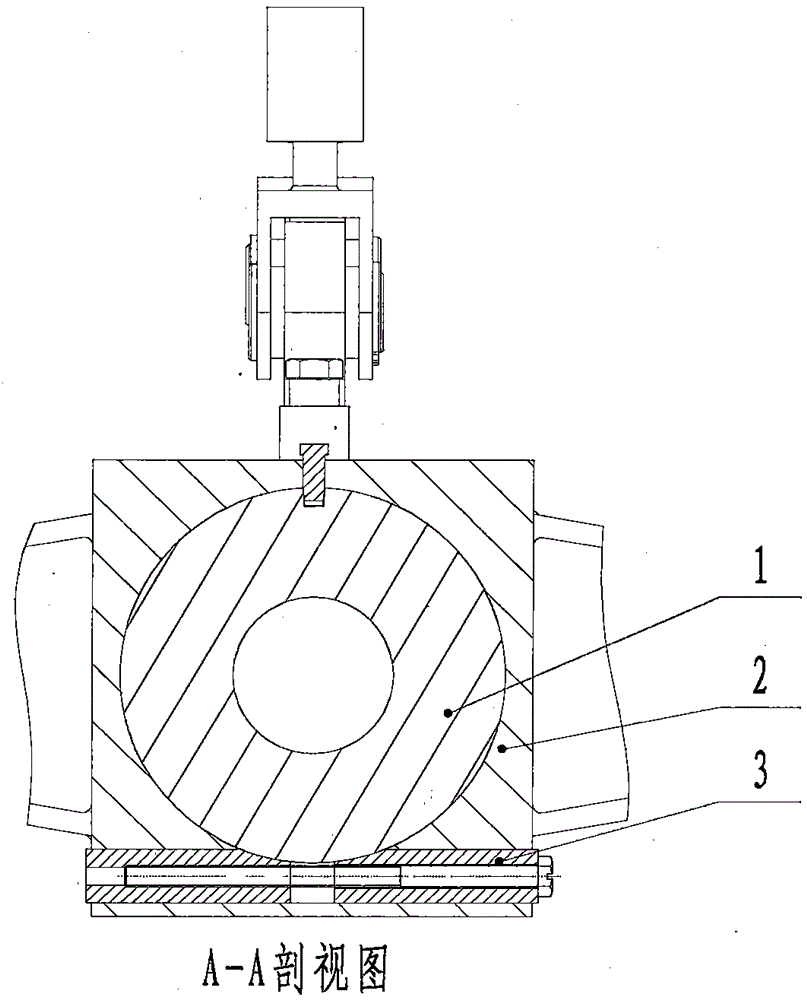

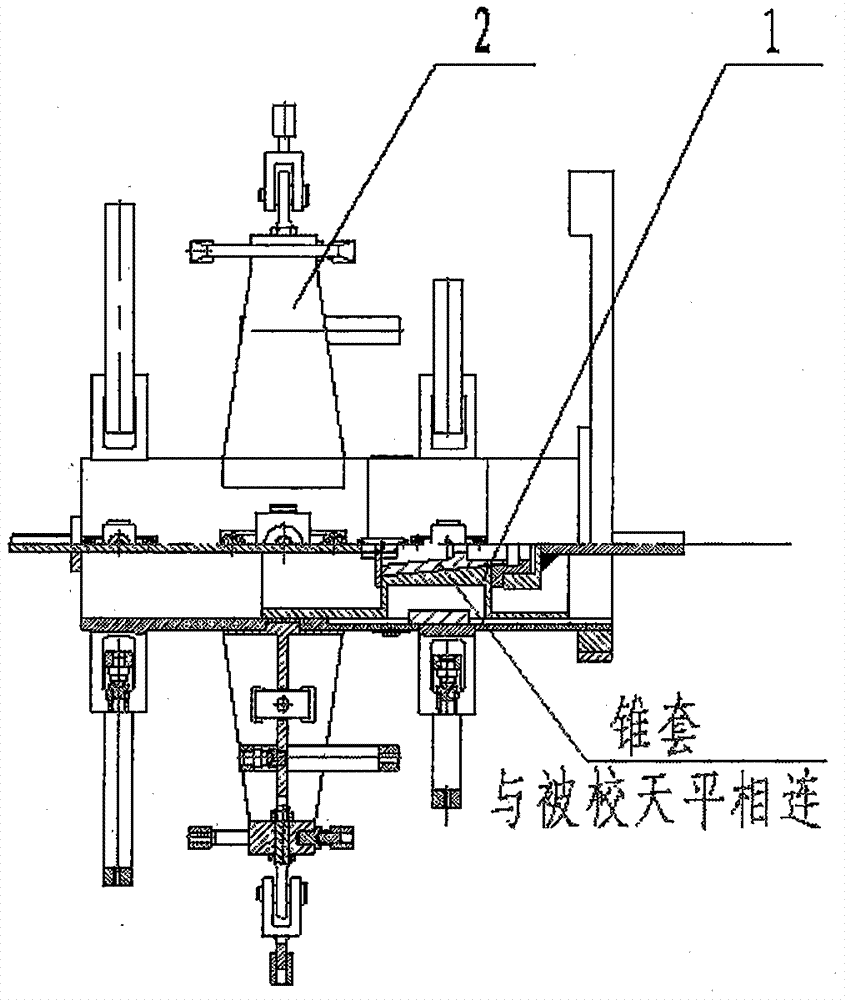

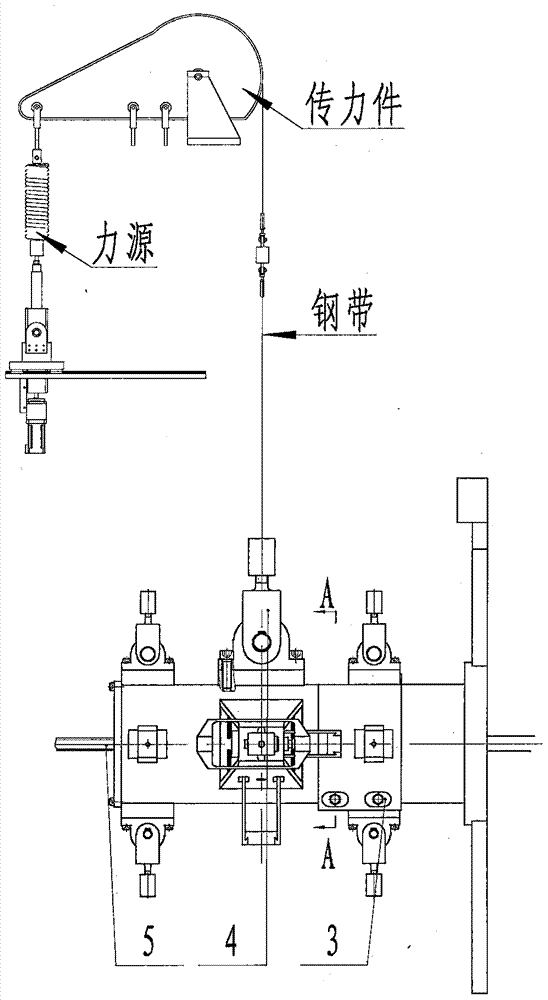

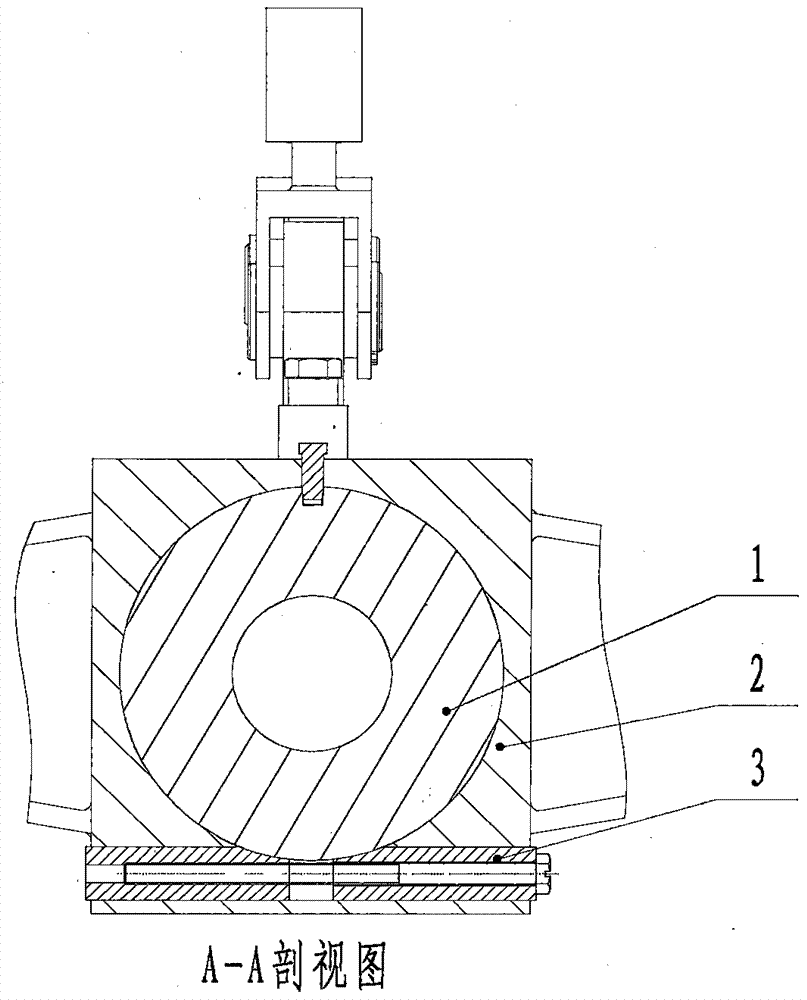

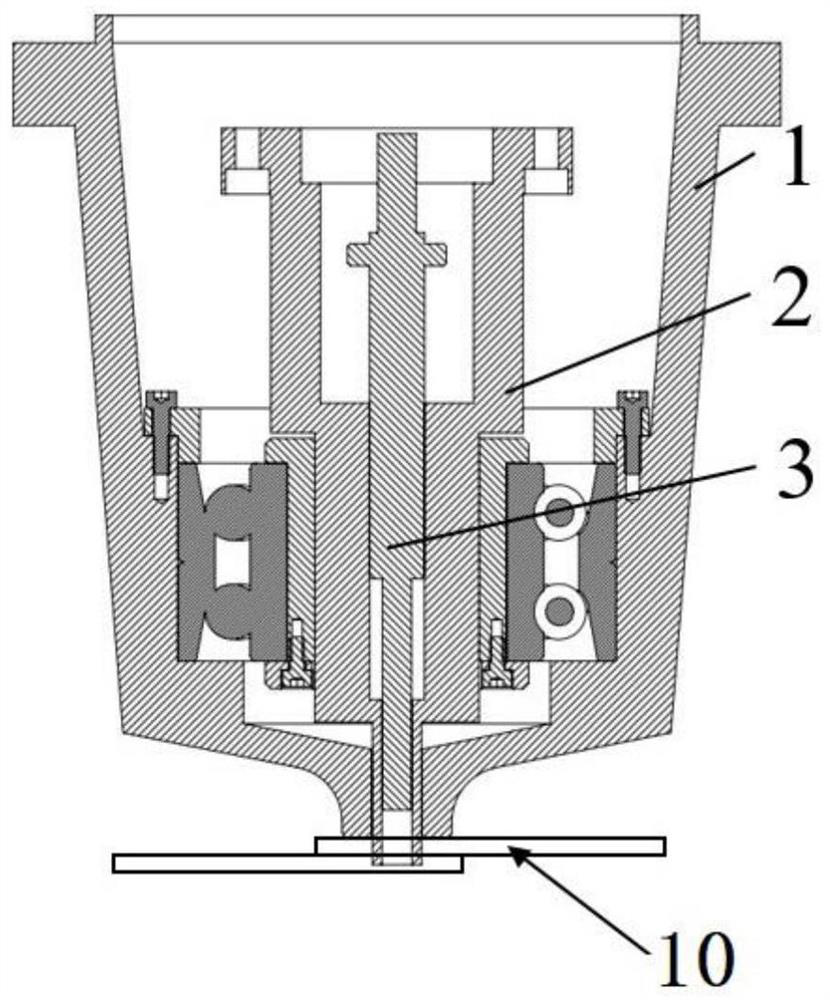

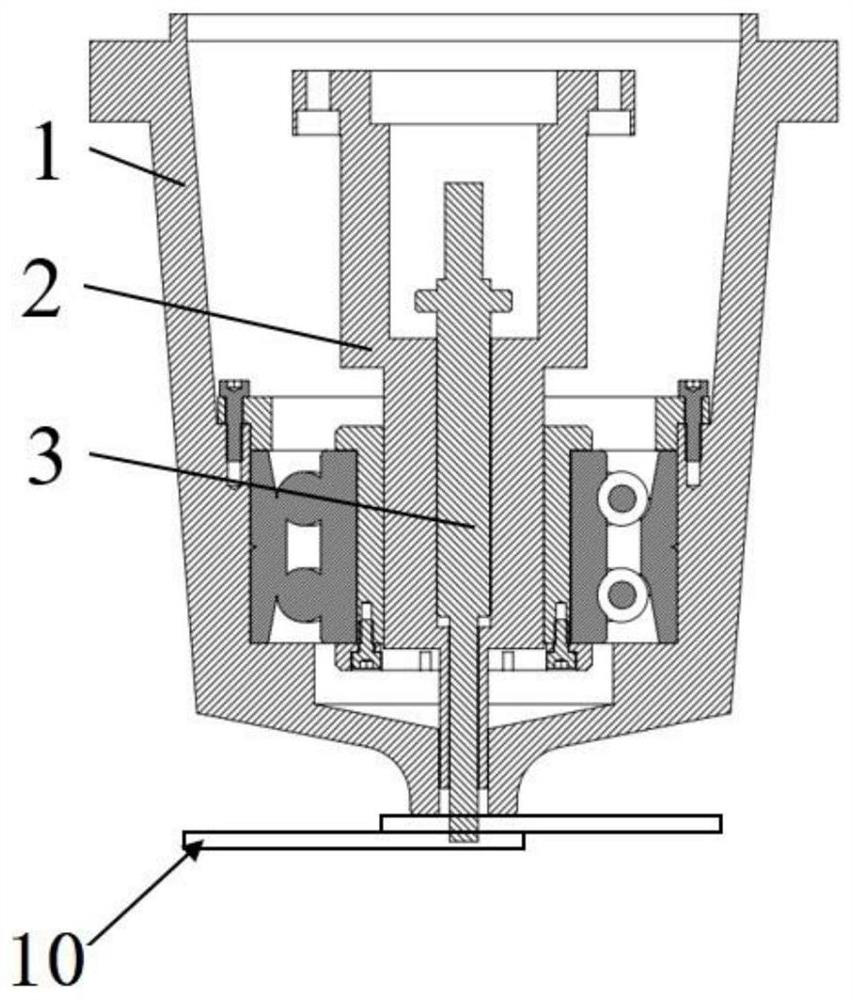

Wide-range high-rigidity loading head used for balance calibration system

The invention provides a wide-range high-rigidity loading head used for a balance calibration system. The wide-range high-rigidity loading head comprises an inner sleeve, an outer sleeve, an inner sleeve positioning device, a high-precision joint bearing and a cranked lever. The inner sleeve is connected with a model end of a calibrated balance through a corresponding taper sleeve. The outer sleeve is arranged outside the inner sleeve. The inner sleeve positioning device is installed on the outer sleeve, fixes the inner sleeve through a screw tightening force and limiting the free degree of the inner sleeve in each direction. The other end of the high-precision joint bearing is connected with a calibration system force transmitting member. The cranked lever is connected with the inner sleeve. The loading head is high in bearing capability, high in rigidity and capable of rapidly and accurately positioning the inner sleeve.

Owner:AVIC SHENYANG AERODYNAMICS RES INST

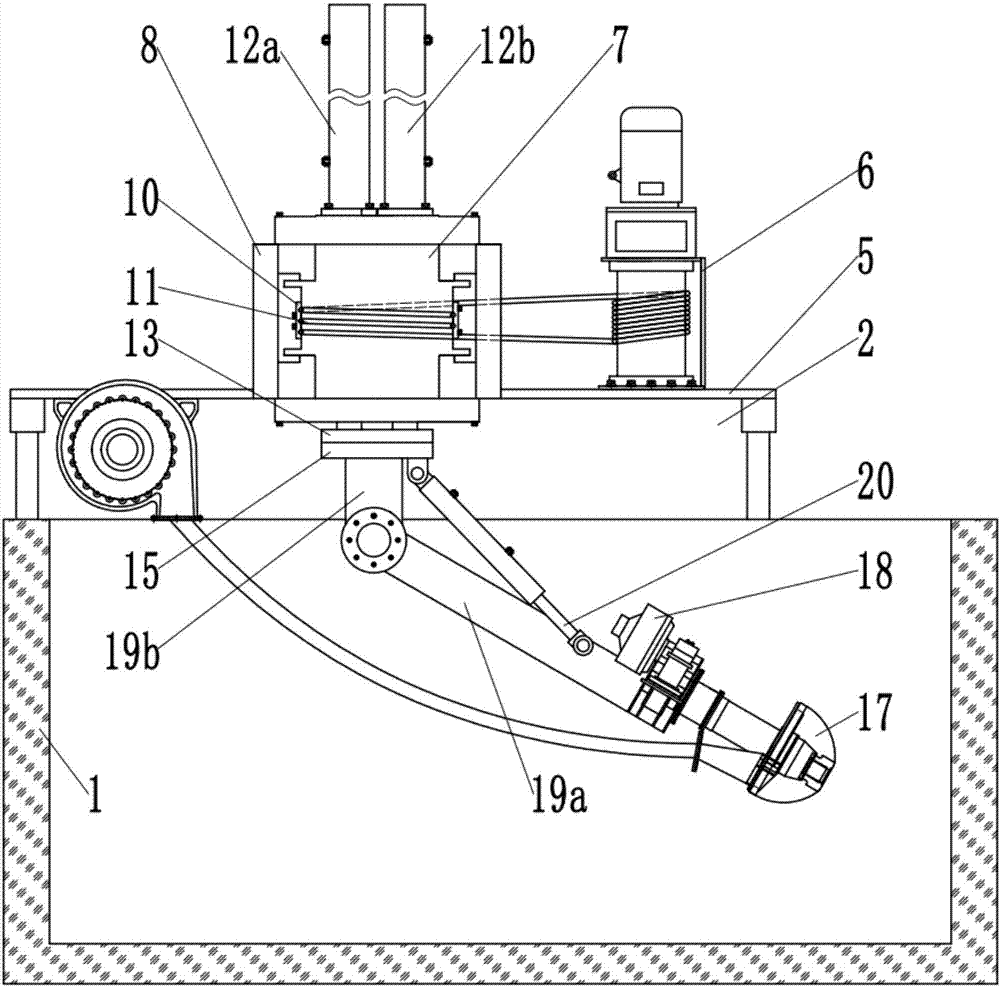

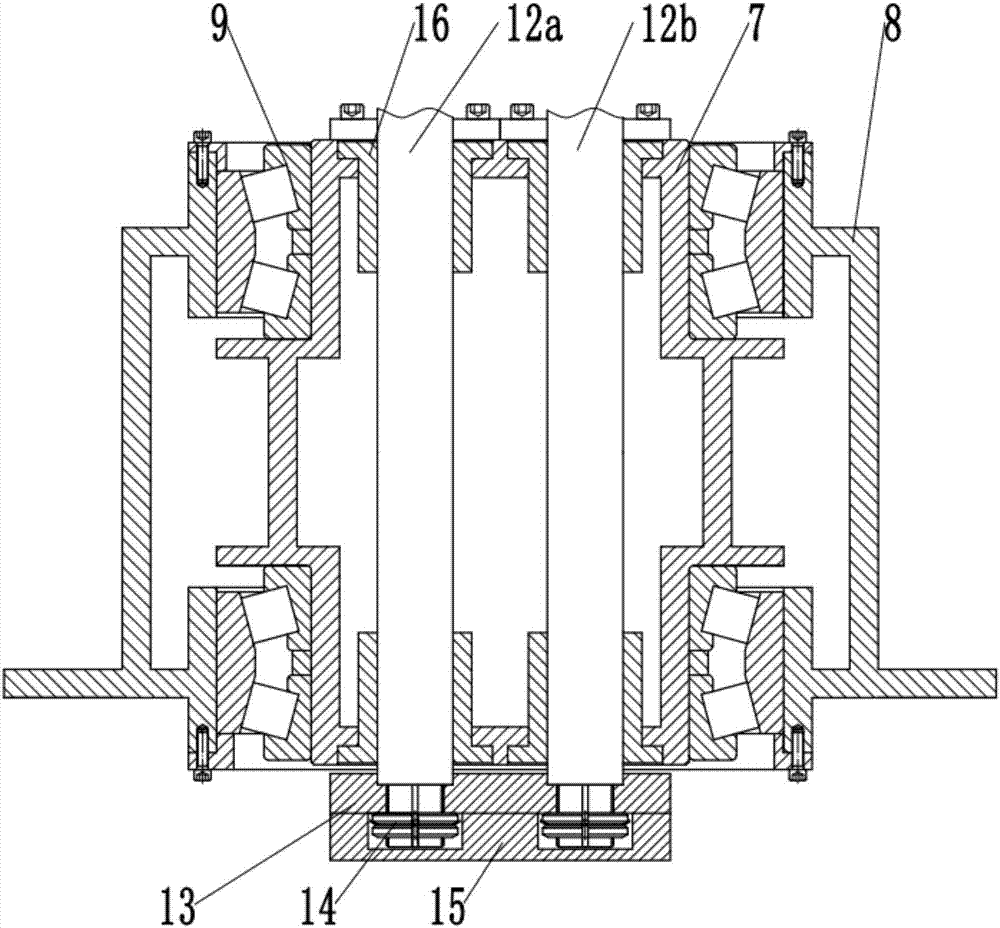

Cutter-suction dredger operation simulator

InactiveCN106875818AFlexible adjustment of feed amountReduce design difficultyEducational modelsOptical axisEngineering

The invention discloses a cutter-suction dredger operation simulator. The bottom of a vertical planetary hoist is installed on a bench stepping mechanism through a flange. A groove is arranged in the circumference of a cylindrical drum. The steel rope of the vertical planetary hoist is wound inside the groove. In a bridge height adjustment mechanism, a front flange hydraulic lever I and a front flange hydraulic lever II are installed in the cylindrical drum through front flanges. A connecting block I is provided with two shaft holes which match the optical shaft of the front flange hydraulic lever I and the optical shaft of the front flange hydraulic lever II respectively and are axially positioned through shaft shoulders and round nuts. In a reamer power output mechanism, one end of a reamer bridge II is welded to a connecting block II, a rotating shaft is arranged between the other end of the reamer bridge II and one end of a reamer bridge I, and the rotating shaft is arranged on the reamer bridge I through a rolling bearing. The device can be adjusted based on different soil quality, and improve the output of dredgers. The device has a longer service life.

Owner:WUHAN UNIV OF TECH

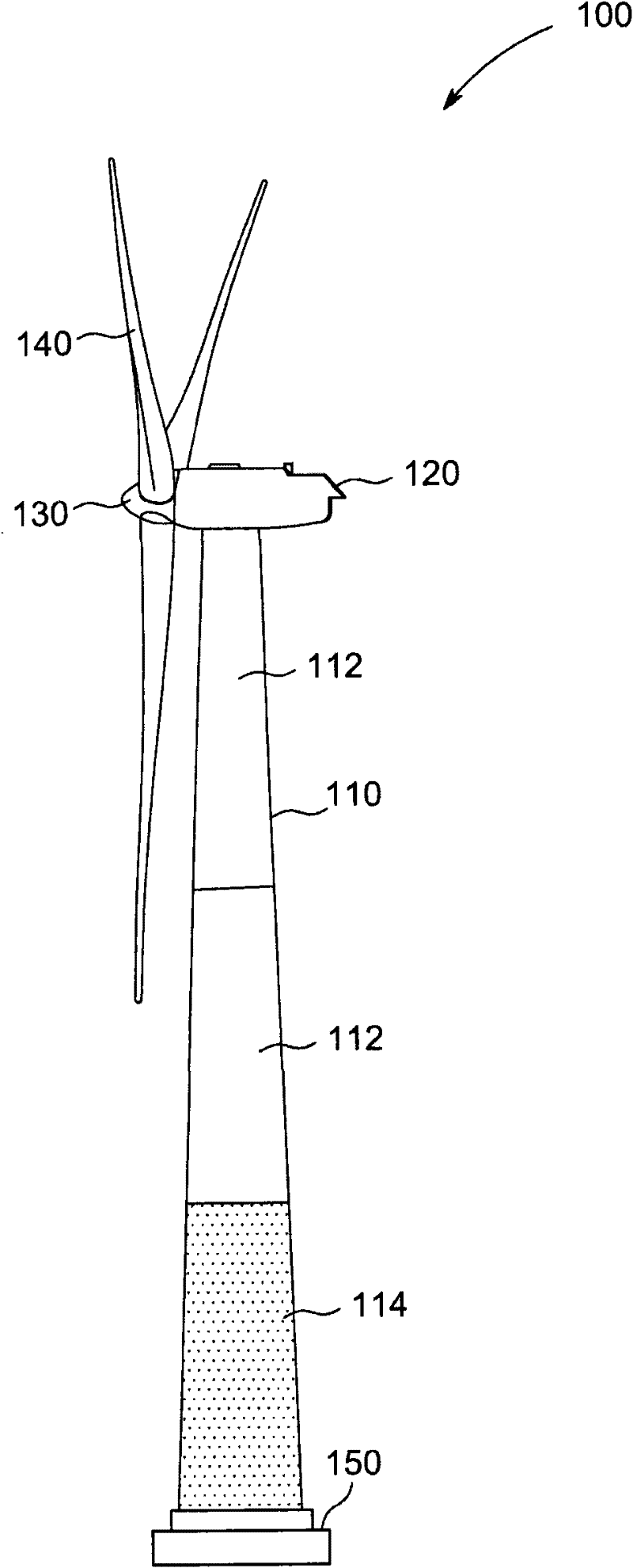

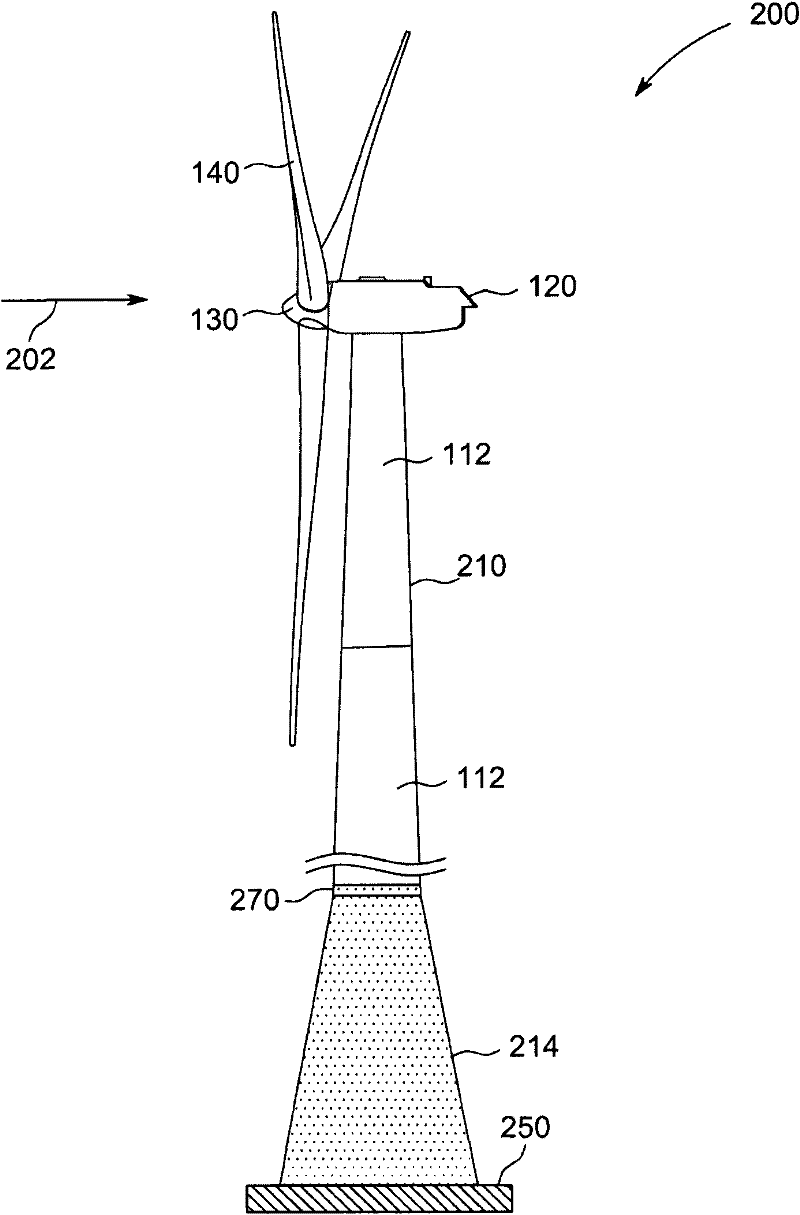

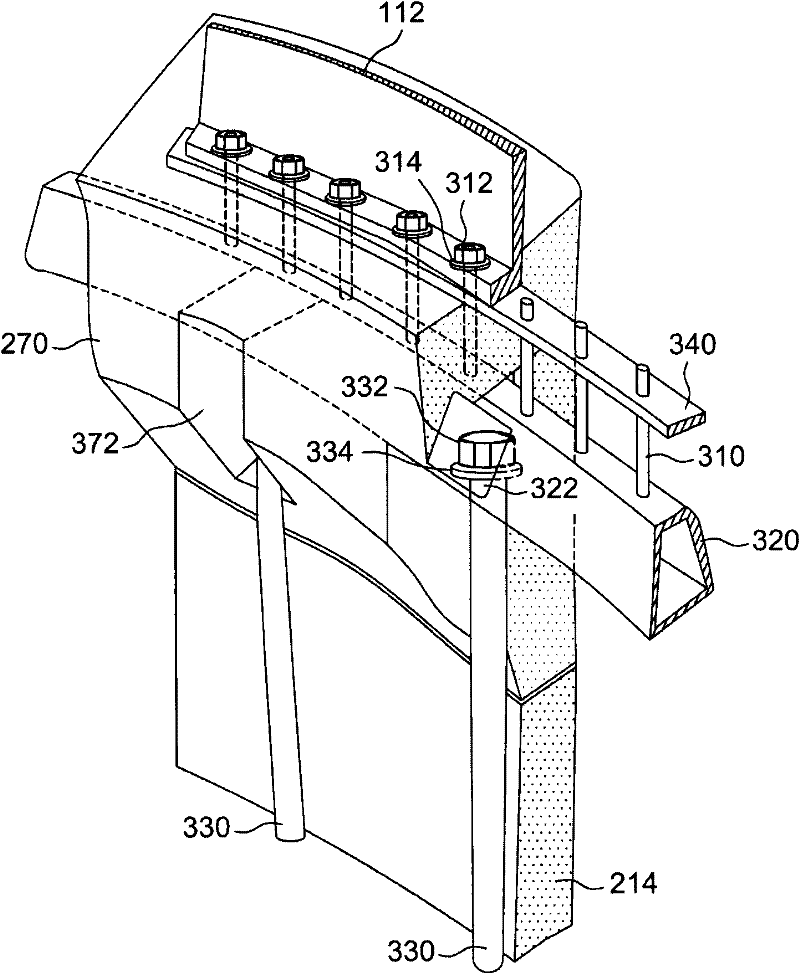

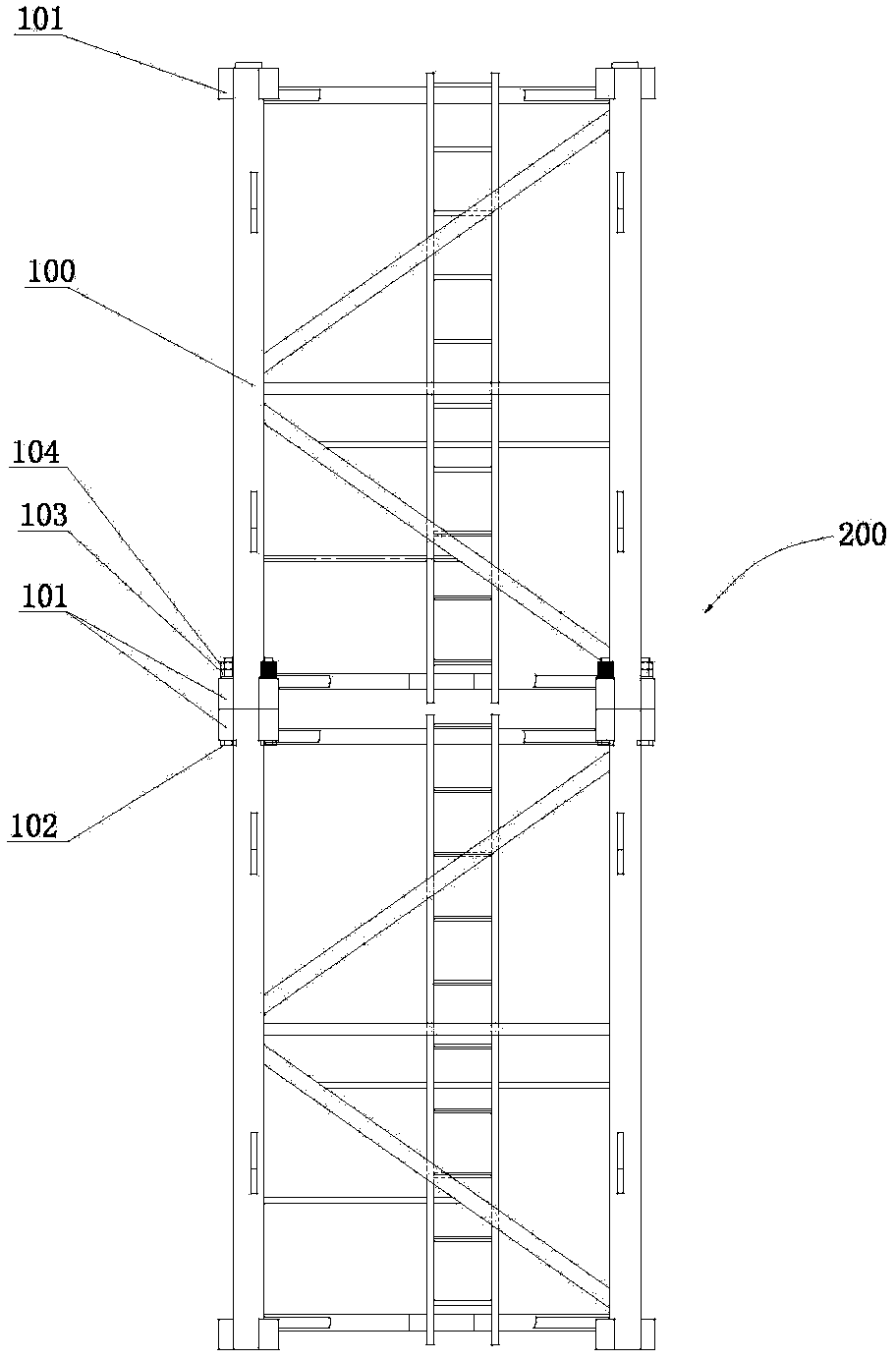

Tower with adapter section

The invention relates to a tower with an adapter section, and specifically provides the tower (210) which has a foundation (250), at least one concrete tower section (214) located above the foundation (250) and one or more upper tower sections (112). An adapter section (270) is located between the concrete tower section (214) and one of the upper tower sections (112). The adapter section (270) is connected to one of the upper tower sections (112) by a fastening system and to the foundation (250) by a plurality of tensioning cables (330), which are configured to induce a compressive force on the concrete tower section (214). The fastening system and the plurality of tensioning cables (330) are substantially vertically aligned so that tower loads are transmitted from the upper tower sections (112) to the plurality of tensioning cables (330).

Owner:GENERAL ELECTRIC RENOVABLES ESPANA SL

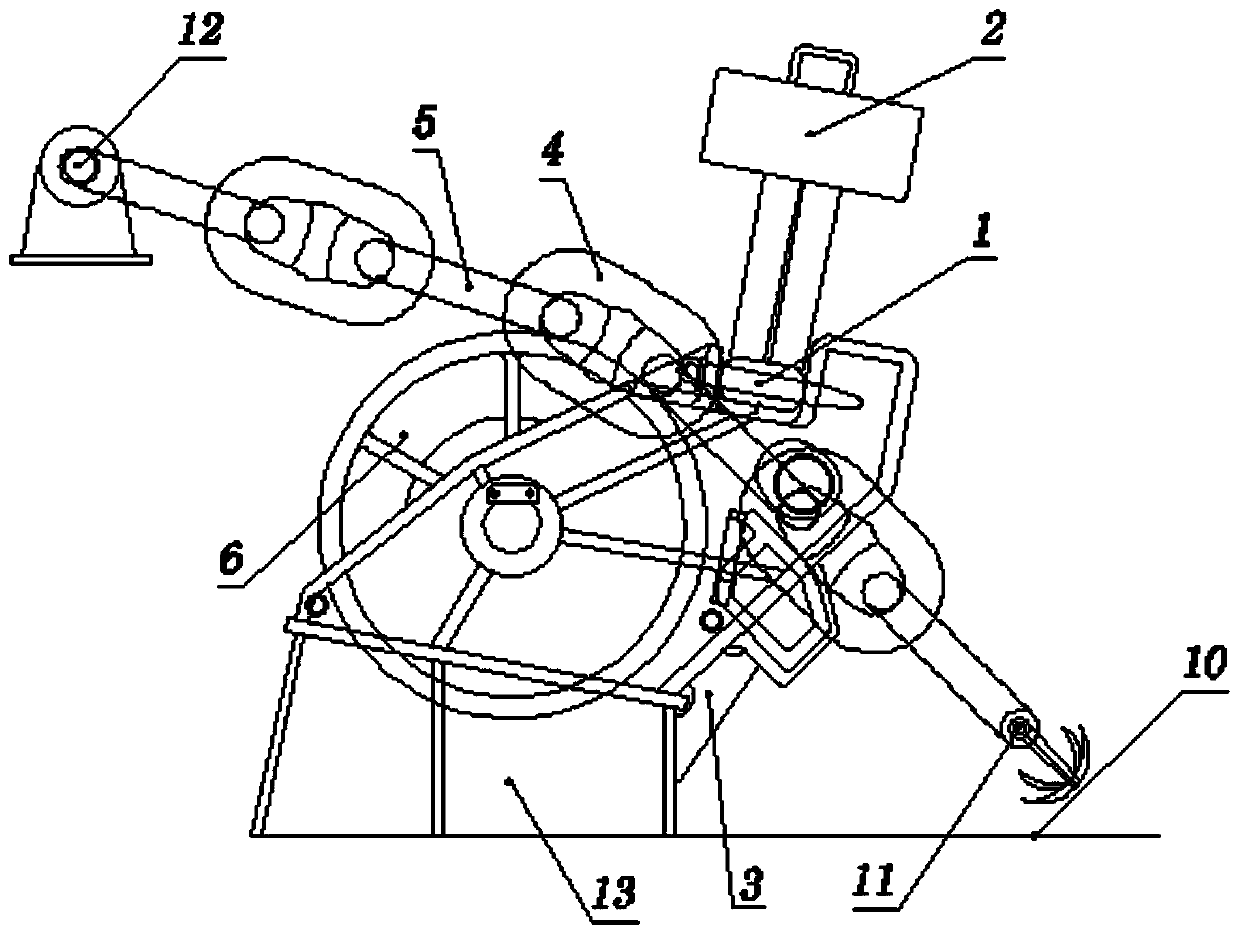

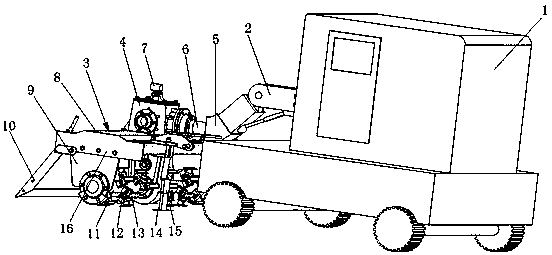

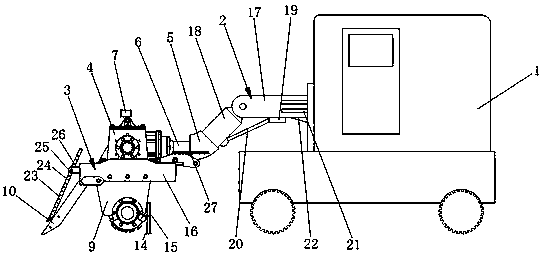

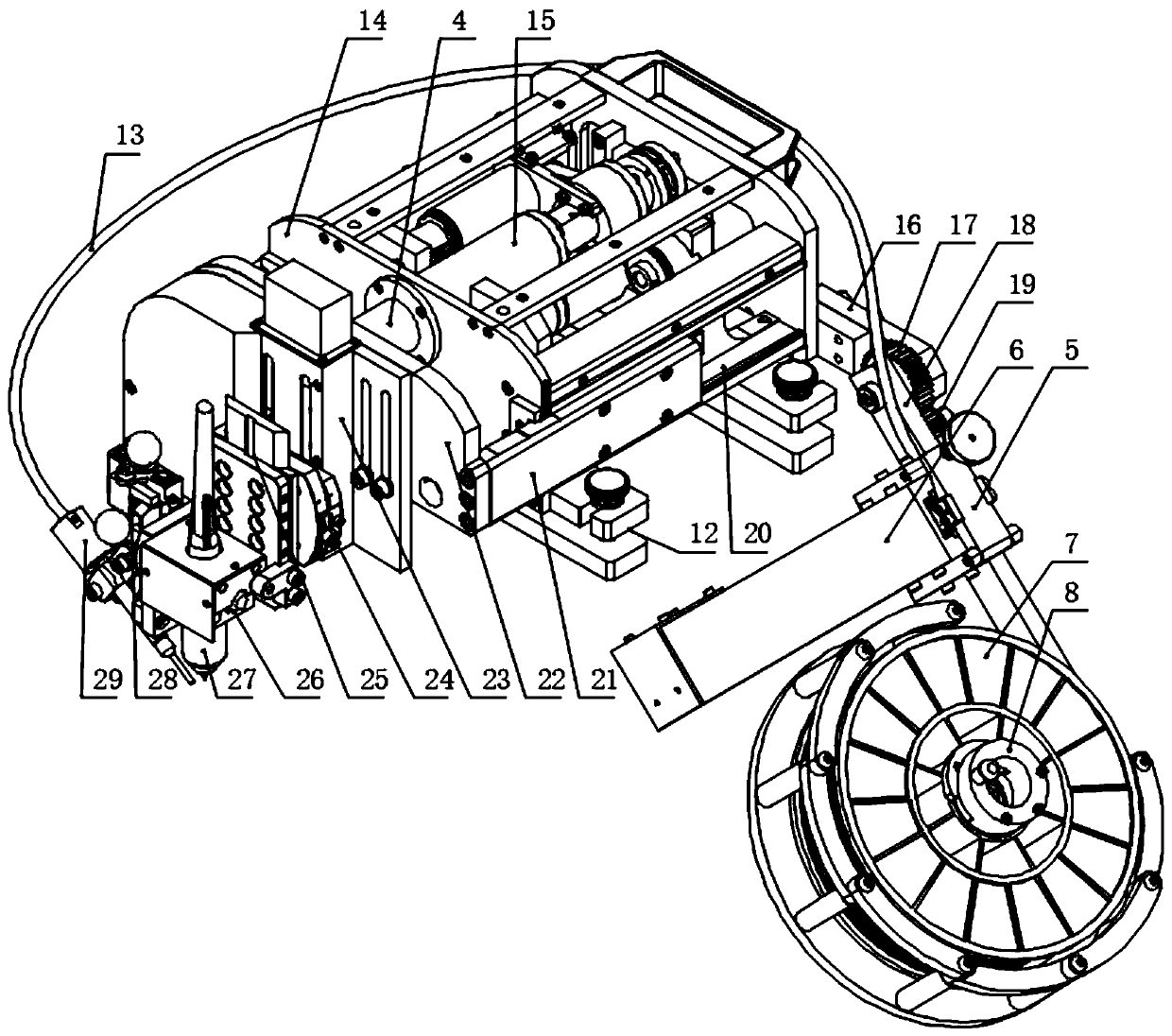

Rubber tapping machine and rubber tapping method

PendingCN111972250ARealize unmanned automatic tappingSolve labor intensityForestryElectric machineryEngineering

The invention discloses a rubber tapping machine and a rubber tapping method. The rubber tapping machine comprises two supporting steel pipes, wherein one sides of the two supporting steel pipes are connected through binding belts, the other sides of the two supporting steel pipes are connected through an upper spiral guide rail and a lower spiral guide rail, and the positions of the spiral guiderails are opposite to the positions of the binding belts on the opposite sides of the spiral guide rails; the rubber tapping machine further comprises a knife rest assembly with a motor and a limit switch; the upper end and the lower end of a power steel shaft of the knife rest assembly are provided with power wheels capable of rolling along the spiral guide rails respectively; in addition, the knife rest assembly is further provided with a lead screw and more than one fixing rod in the vertical direction; the upper end and the lower end of the knife rest assembly penetrate through the lead screw and the fixing rod to be provided with main machine shells respectively; the main machine shells are clamped in grooves of the spiral guide rails; guide roller shafts are arranged in the main machine shells; guide rollers are arranged on the corresponding guide roller shafts; and the rubber tapping machine further comprises a rubber tapping knife assembly. According to the rubber tapping machine, manual work is replaced with automatic machinery, unmanned automatic rubber tapping of a rubber tree is achieved, and the problems that the labor intensity of manual rubber tapping is large and manual rubber tapping is not refined enough are solved to the maximum extent.

Owner:NINGBO CIHEVEA TECH CO LTD

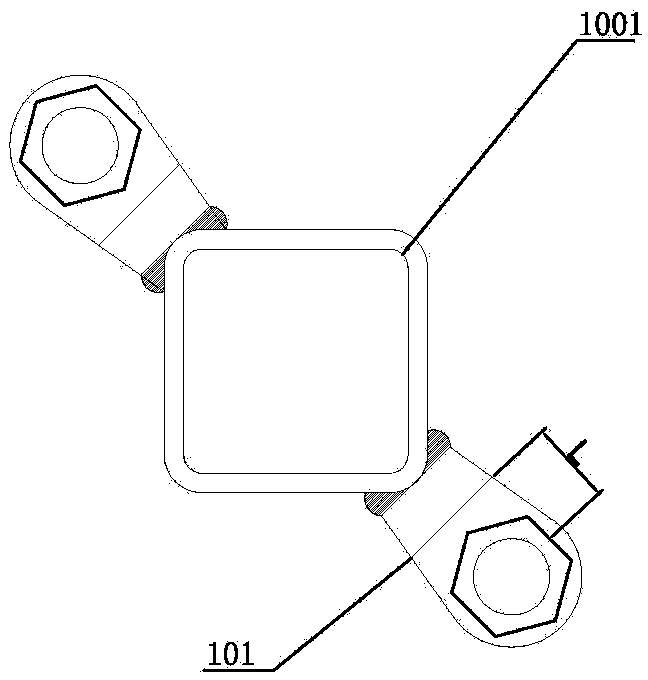

General operation method for reaching given pre-tightening torque of high-strength bolt for tower crane

ActiveCN104192734AAdapt quicklyImprove construction efficiencySpannersWrenchesEngineeringTower crane

The invention discloses a general operation method for reaching the given pre-tightening torque of a high-strength bolt for a tower crane. The general operation method comprises the following steps: firstly, using a climbing frame to lift a tower crane rotating assembly and a part above the tower crane rotating assembly; secondly, placing additional standard sections at the top of a crane body; thirdly, penetrating each high-strength bolt; screwing a lower nut on the corresponding high-strength bolt, screwing each lower nut to be in the place with hands and preliminarily applying pre-tightening force by using a general wrench; fourthly, clamping a first open sleeve on the corresponding lower nut, rocking a torque wrench back and forth by using special tools until the pre-tightening torque is reached; fifthly, repeating the fourth step, wherein the special tools comprise the first open sleeve, a torque amplifier and the torque wrench; the first open sleeve comprises a first lower sleeve and a first panel; an opening which can be clamped on the lower nuts is formed in the first lower sleeve. By using the operation method disclosed by the invention, the determined pre-tightening force can be given for each high-strength bolt, the operation is convenient, both labor are saved in operation, the application range is wide, mounting persons can quickly adapt the high construction efficiency is high and the safety performance is high.

Owner:DONGGUAN YIXIN QINGJIANG MACHINERY MFG

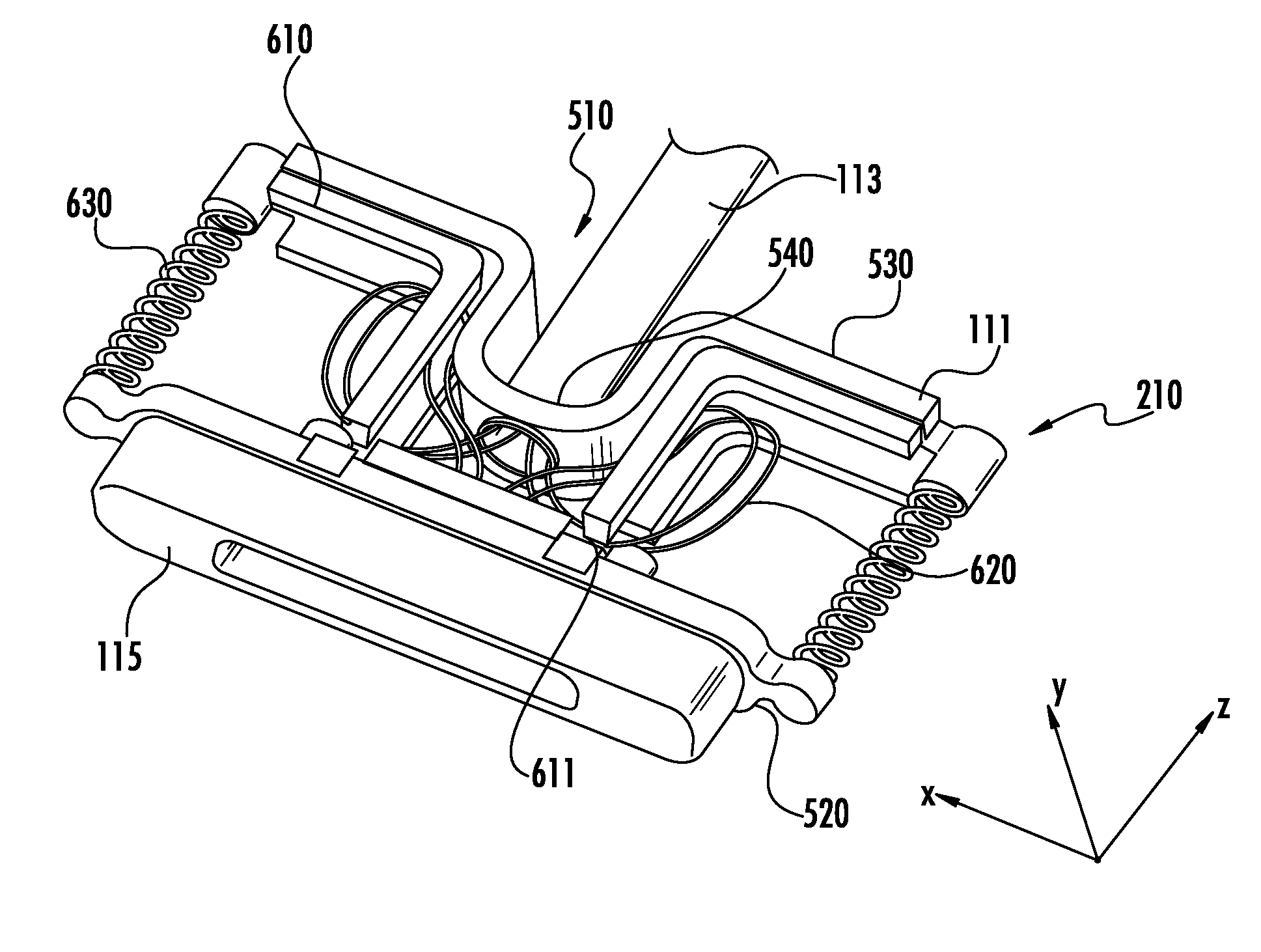

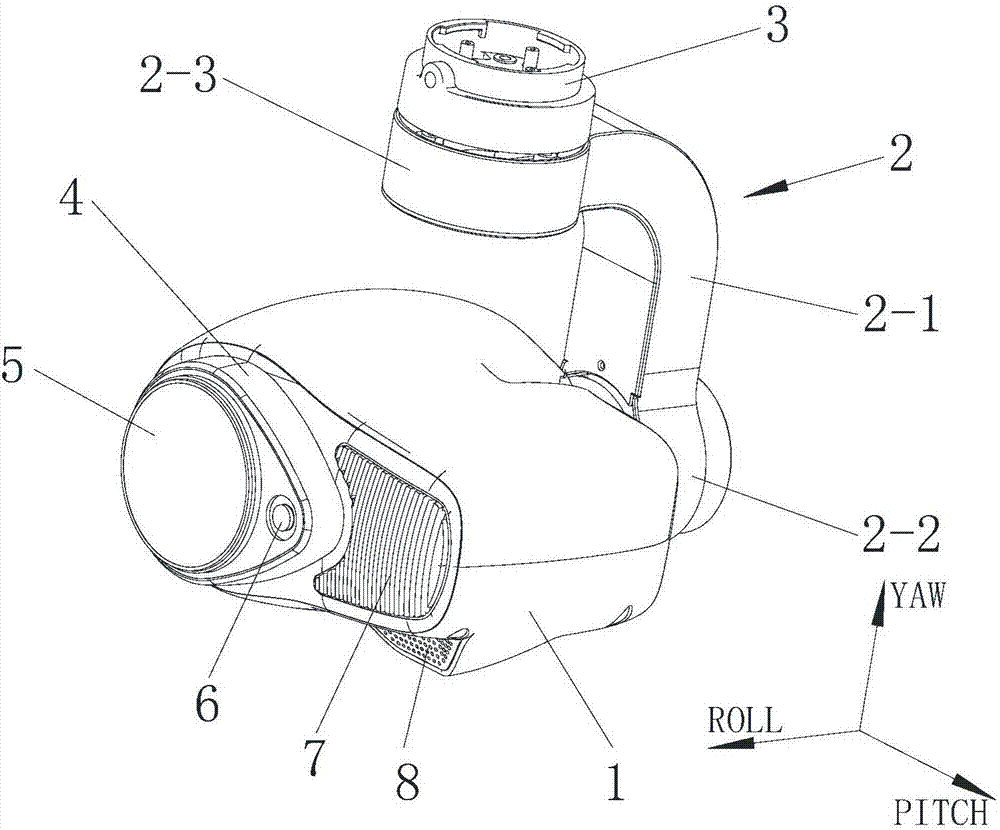

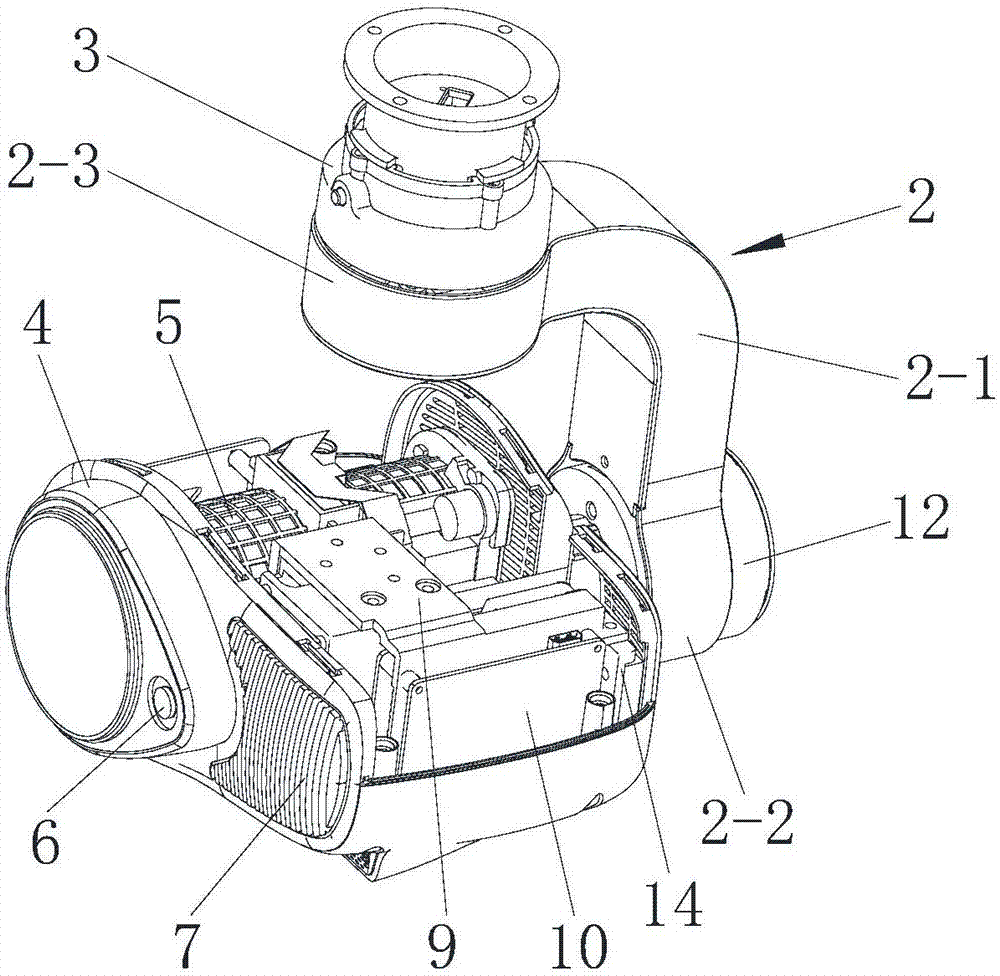

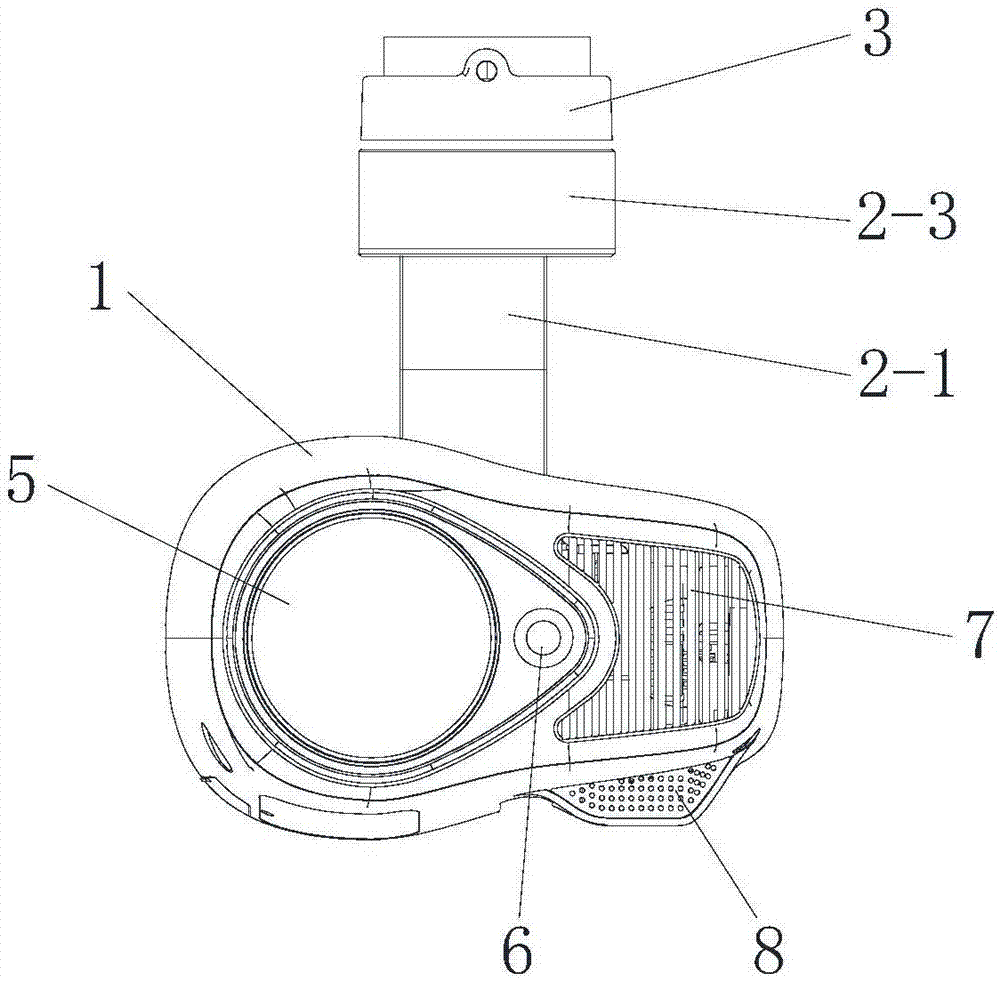

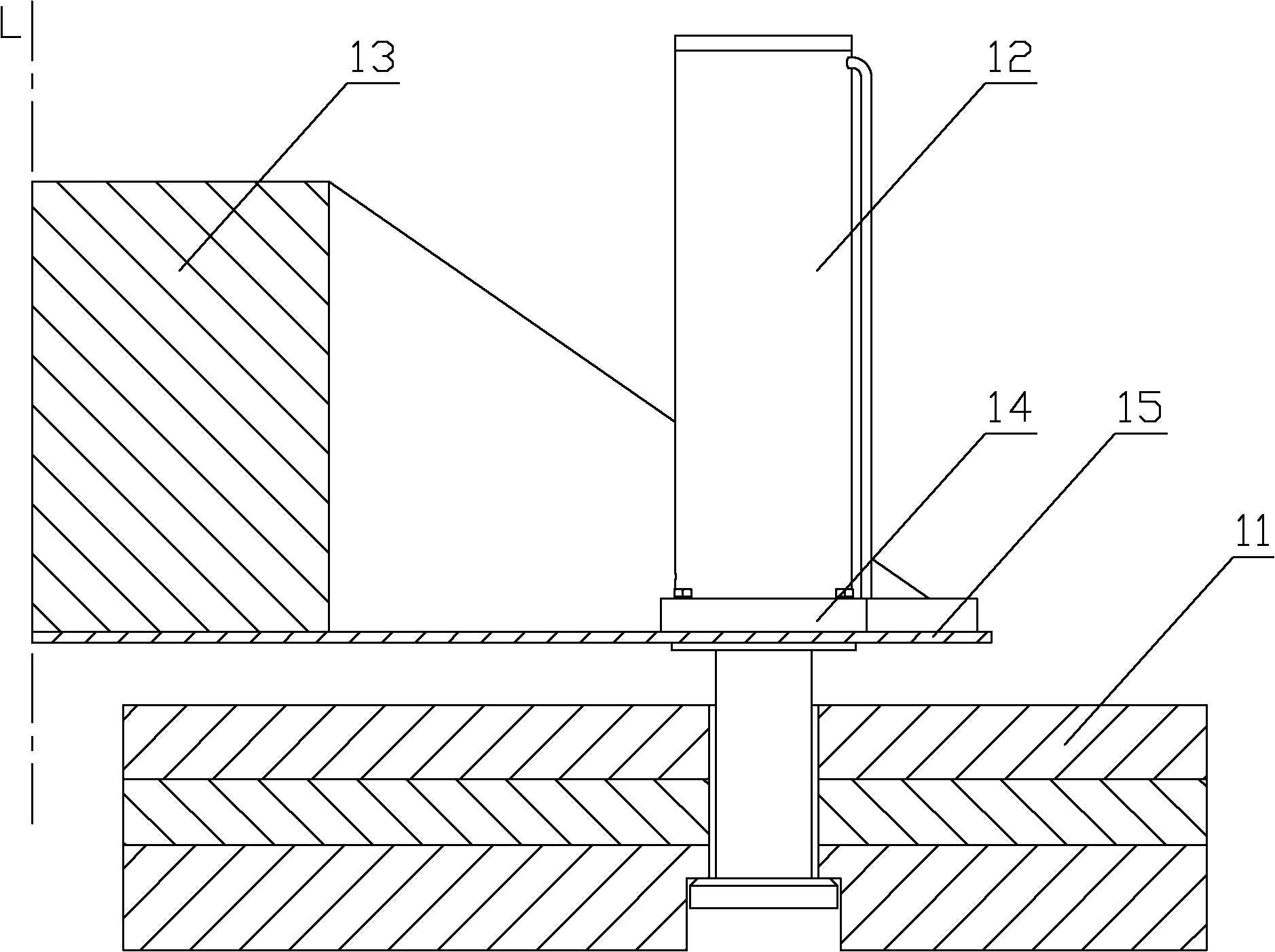

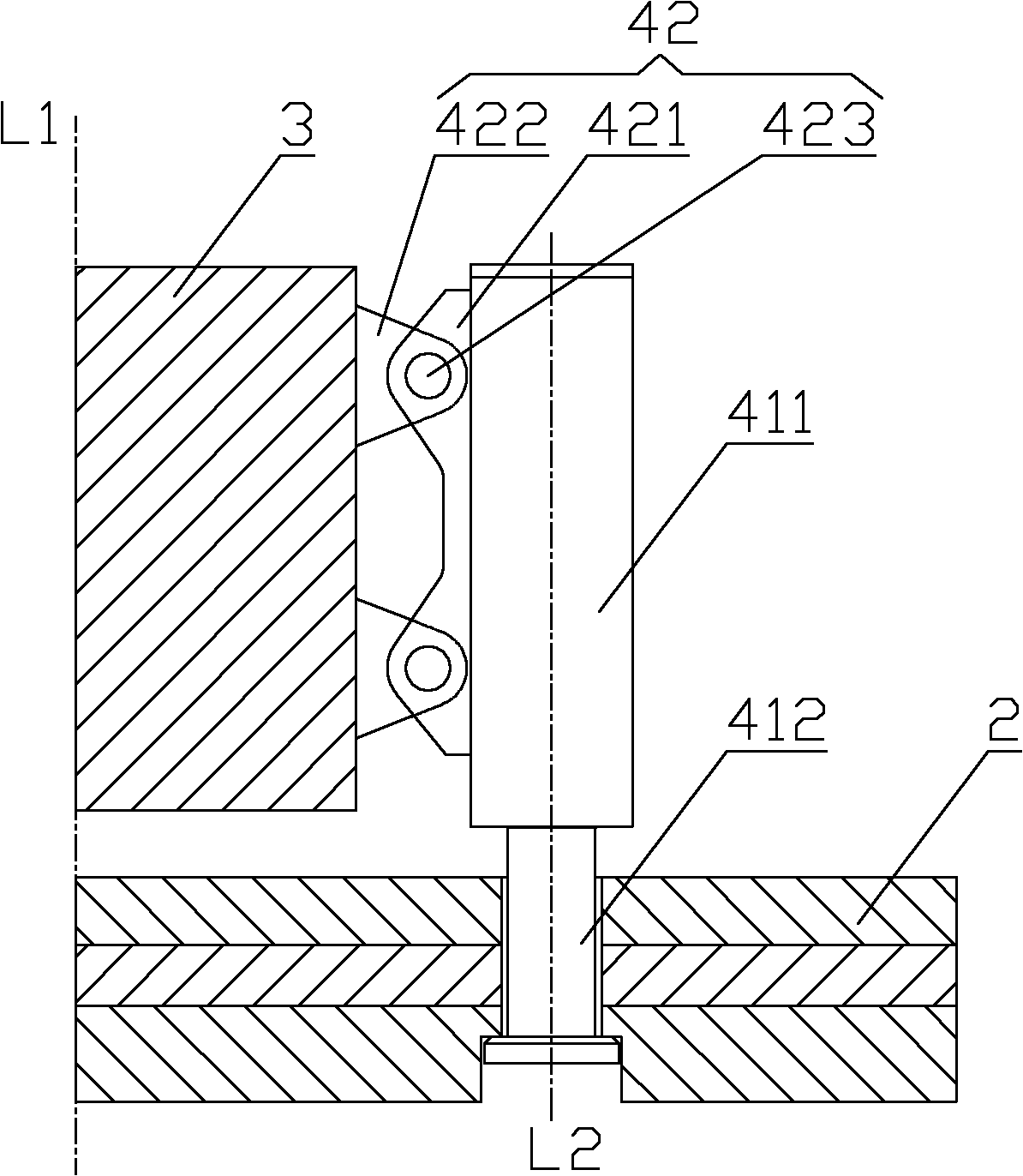

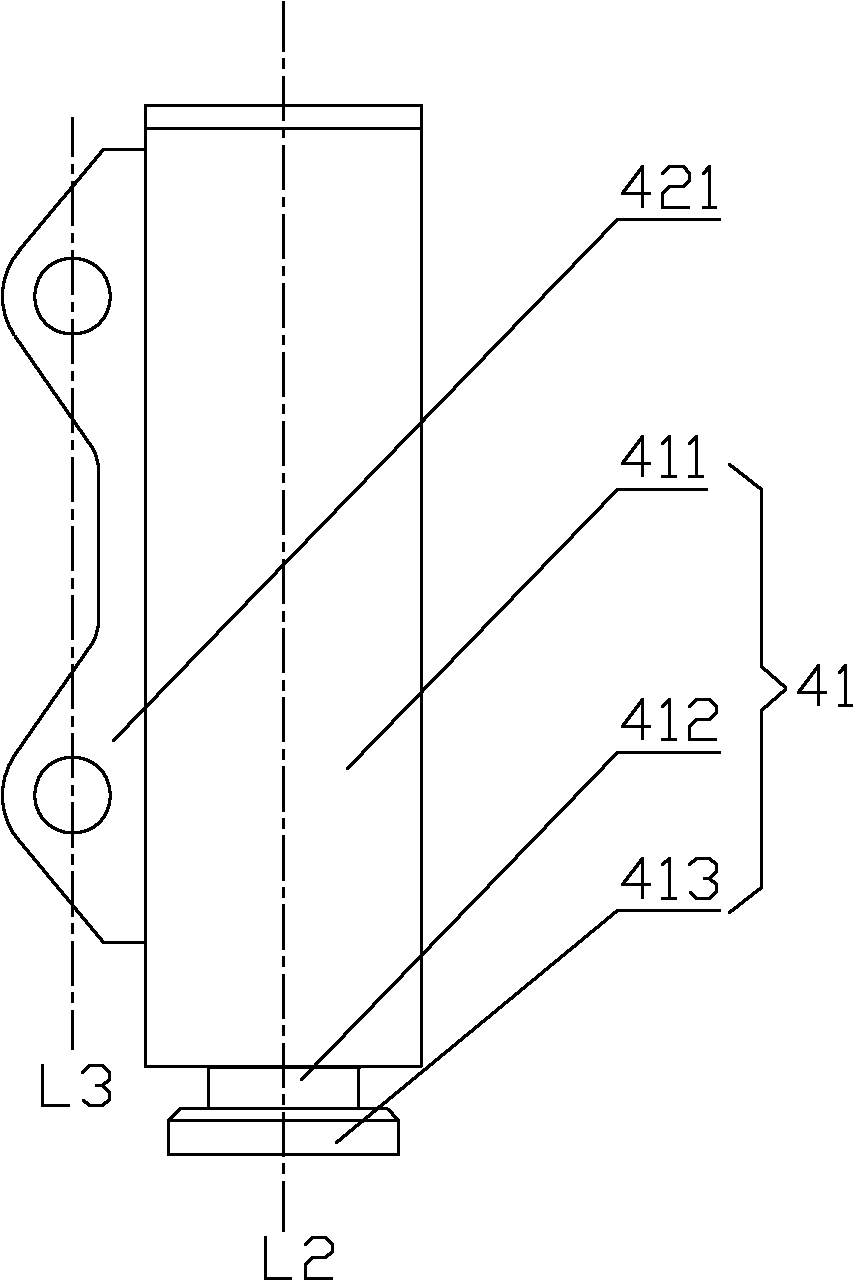

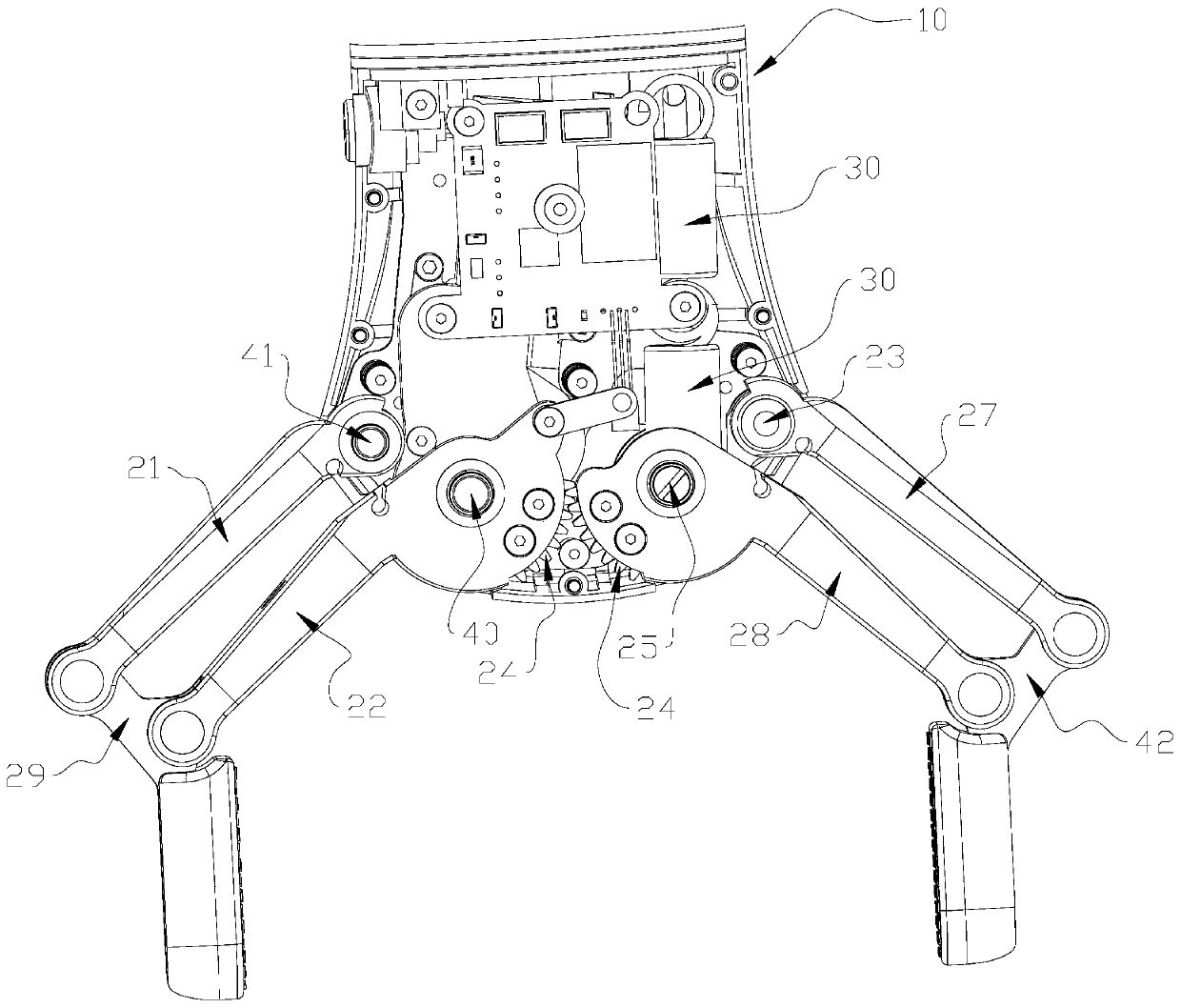

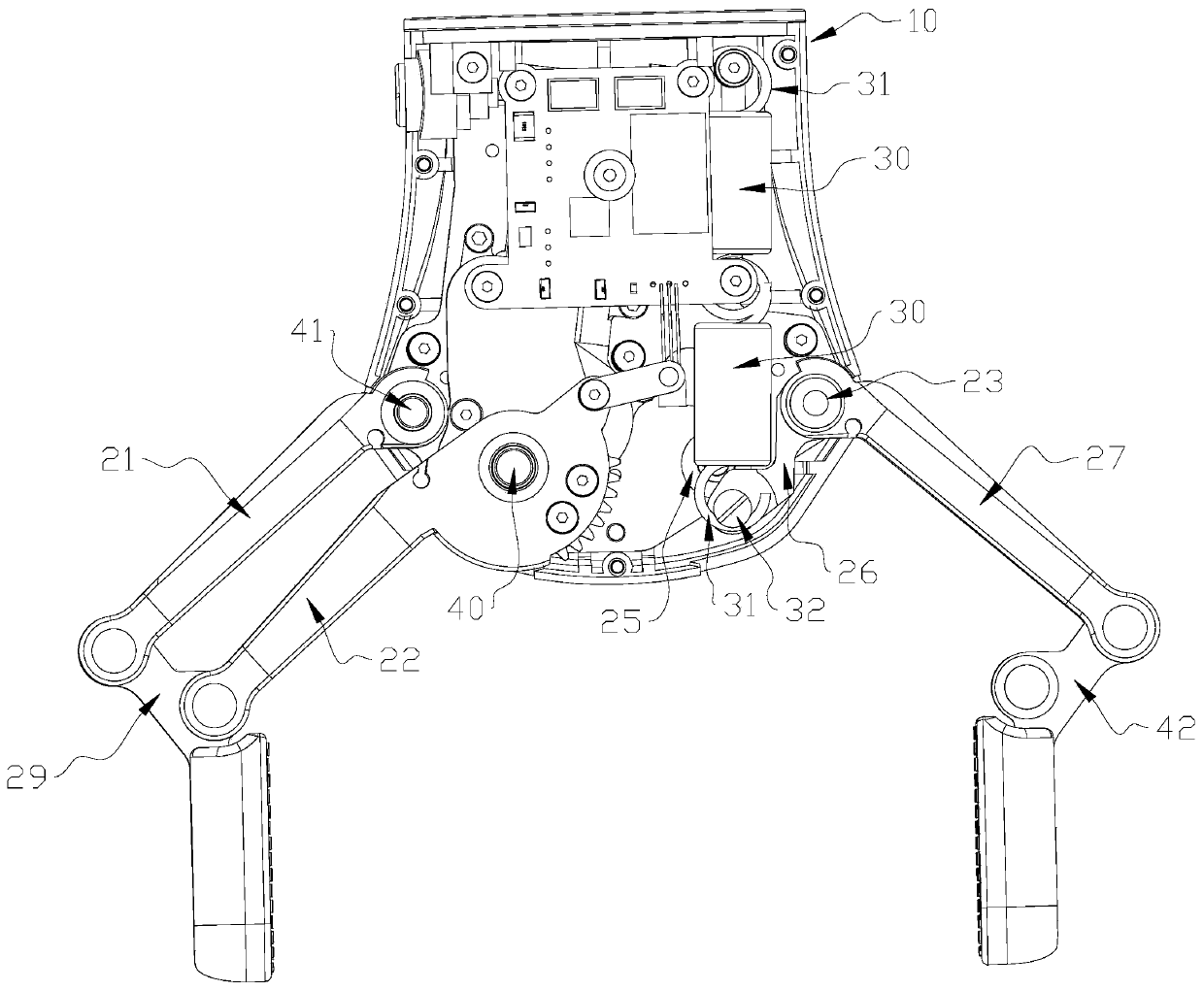

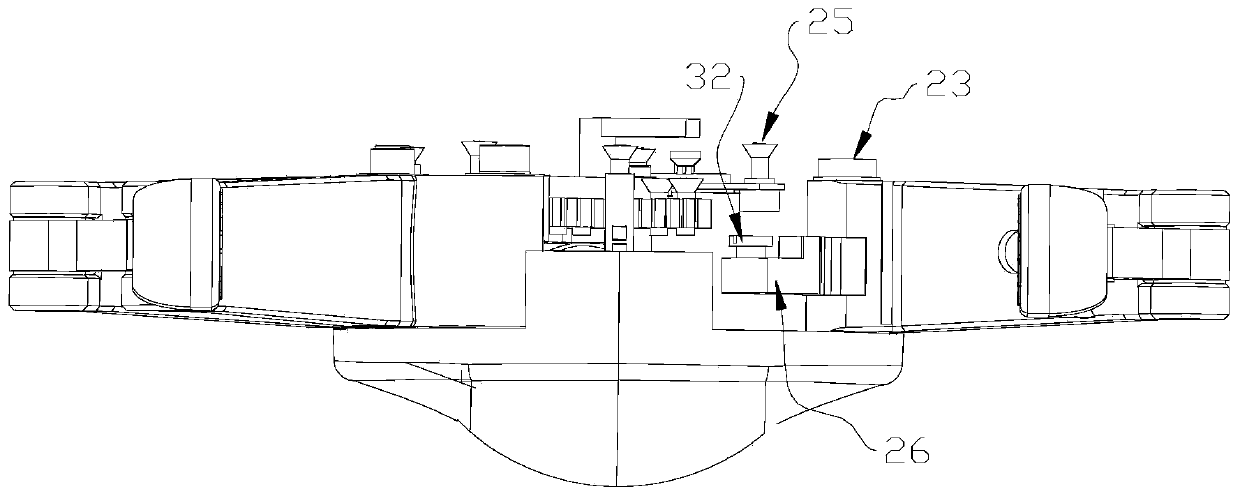

Three-axis holder, shooting device, shooting system and unmanned shooting system

ActiveCN107124534ACompact structureGood lookingTelevision system detailsColor television detailsEngineeringTripod head

The invention discloses a three-axis holder, a shooting device, a shooting system and an unmanned shooting system. The three-axis holder comprises a main force arm, a secondary force arm, a chassis, a first motor, a second motor and a third motor, wherein the third motor is arranged in the chassis, one end of the main force arm is connected to a stator of the first motor, and the other end of the main force arm is connected to a stator of the second motor; one end of the secondary force arm is connected to a rotor of the second motor and the other end of the secondary force arm is connected to a stator of the third motor. The three-axis holder is provided with the chassis for components of the shooting device and has the advantages of compact structure, concise appearance, small wind resistance and more stable shooting images, and the shooting effect is improved.

Owner:GOERTEK INC

Movable crane and balance weight connecting device thereof

The invention discloses a balance weight connecting device of a movable crane, which comprises a bearing cylinder and a connecting assembly, wherein the bearing cylinder and the connecting assembly are connected with a balance weight and a rotary table of the movable crane, the axes of the bearing cylinder is parallel to the center line of the rotary table, the connecting assembly is fixedly connected with the axial outer wall of the bearing cylinder and the rotary table, i.e. the rotary table is horizontally connected with the bearing cylinder, thus the movable crane can be designed more compactly so as to greatly reduce an arm of force that the balance weight can be transferred through the bearing cylinder and ensure that the reliability and the safety of the movable crane are remarkably improved. In addition, the bearing cylinder is connected with the side surface of the rotary table, thus an installing support can be not arranged on the side surface of the rotary table, the structure of connecting the balance weight with the rotary table can be simplified, the structure of the movable crane is simpler, and the large development space of the movable crane is enlarged. The invention also provides a movable crane comprising the balance weight connecting device.

Owner:XUZHOU HEAVY MASCH CO LTD

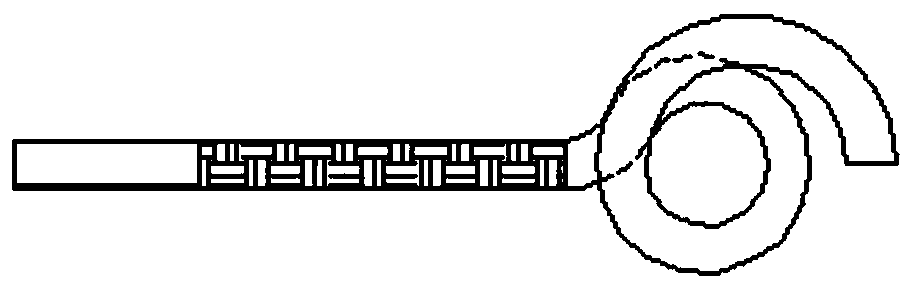

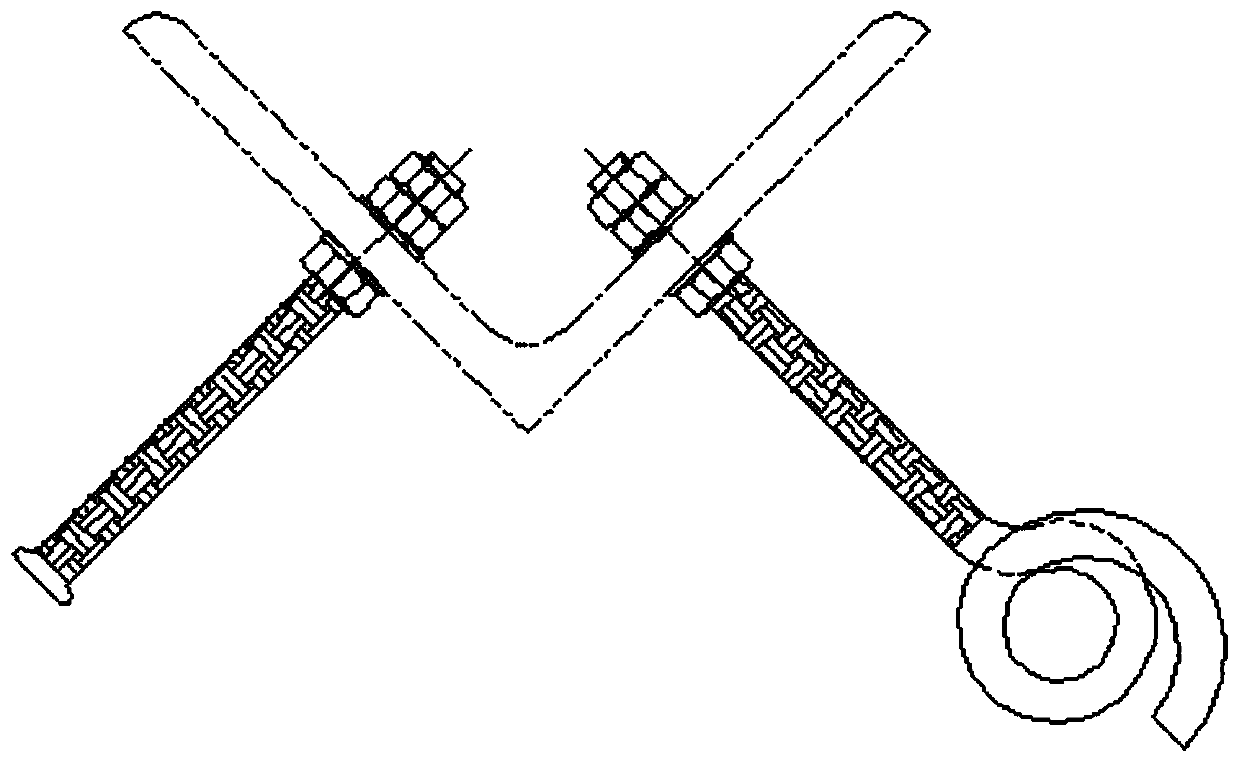

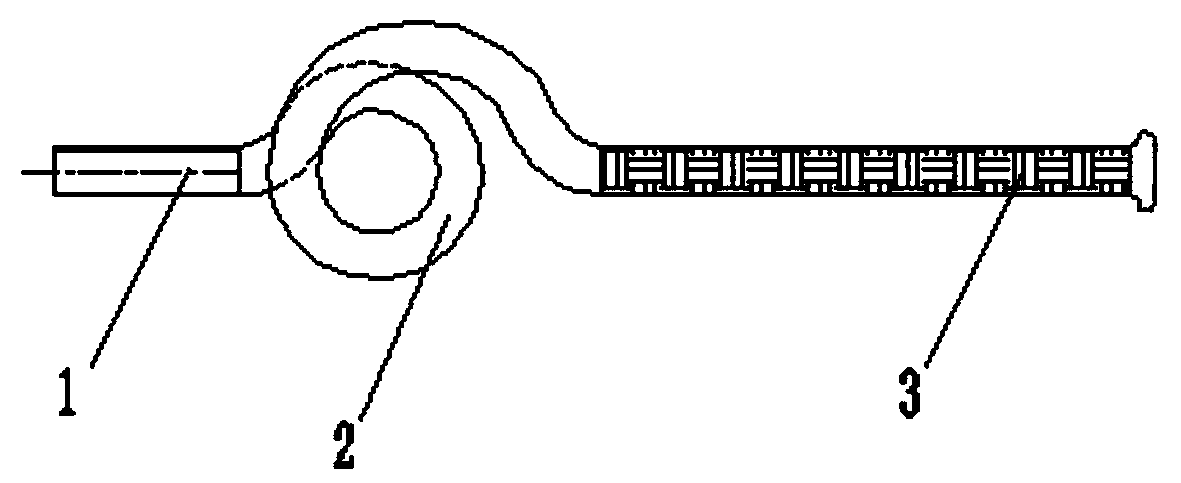

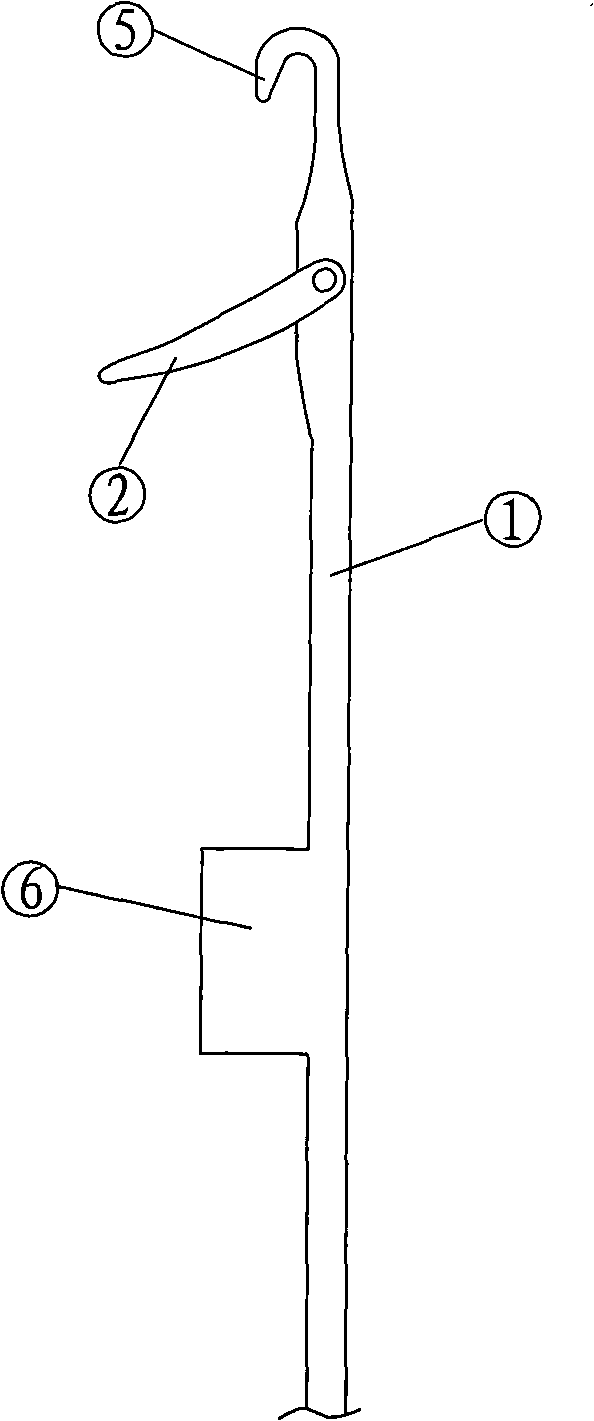

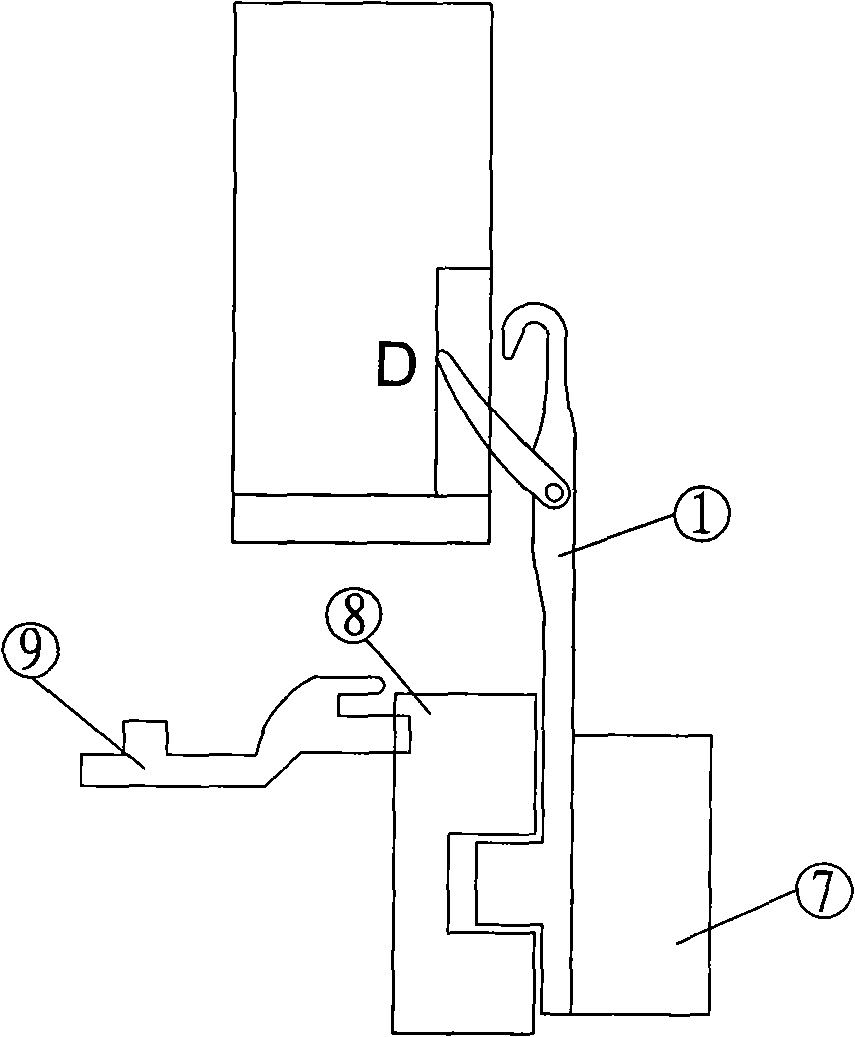

Anti-falling foot nail capable of preventing rope interference

The invention relates to an anti-falling foot nail capable of preventing rope interference. The anti-falling foot nail capable of preventing rope interference is composed of a common foot nail and ananti-falling foot nail body and characterized in that the anti-falling foot nail body comprises an installing fixing rod (1), one end of the installing fixing rod (1) is detachably installed on a power transmission iron tower through a fastening part, the other end of the installing fixing rod (1) is connected with a pedal rod (3) into a whole through a spiral rod (2), and the middle section of the spiral rod (2) is in a spiral shape and is provided with a clearance used for allowing a rope to pass in the vertical direction. According to the anti-falling foot nail capable of preventing rope interference, the structural design of an existing anti-falling foot nail is improved, therefore, the problem that in the tower climbing operation process, the rope rubs with the anti-falling foot nailor is separated from the anti-falling foot nail is solved, and meanwhile the problem that the moment of the force bearing point of the anti-falling foot nail is too large is solved.

Owner:国网宁夏电力有限公司超高压公司 +1

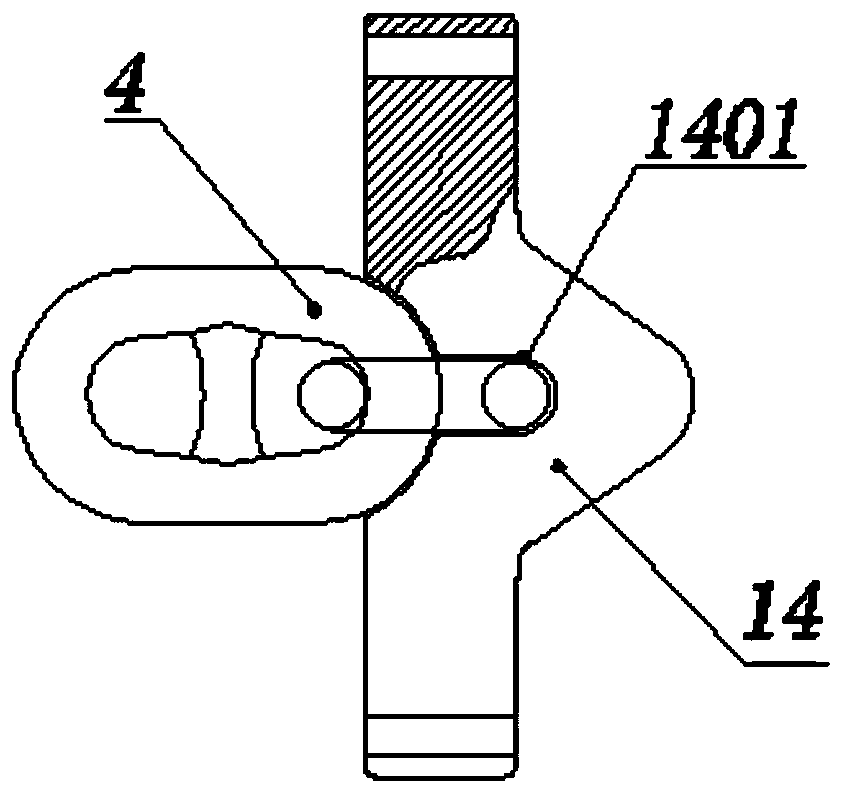

Non-standard wear-resistant stop block feeding and stopping device

PendingCN111017112AReduce wearIncrease contact areaWaterborne vesselsStructural engineeringStops device

The invention discloses a non-standard wear-resisting stop block chain feeding and pulling device, which comprises a chain stopper, wherein a roller shaft is connected to the upper portion of the chain stopper through a supporting piece; a roller is assembled on the roller shaft; a balance block is connected to one side of the roller shaft through the supporting piece; the balance block is connected with a novel stop block through a rotary pin shaft; and a positioning pin shaft is installed at the other end of the novel stop block. The end face of one side of the novel stop block of the deviceadopts a U-shaped ring surface design and is obviously increased in contact area, therefore, the abrasion of the stop block is reduced. In addition, a chain guide groove is additionally formed in therear part of the U-shaped ring surface; the limiting function is achieved, a motion space is provided for the vertical chain ring, the novel stop block does not need to be opened during anchor weighing, and only the positioning pin shaft needs to be moved away. Thus, operation is convenient, and in the anchor weighing process, if the anchor windlass is overloaded, a chain disengaging phenomenon occurs. Therefore, the novel stop block is not opened at the moment, an anchor chain can be effectively clamped, and therefore the anchor windlass is protected.

Owner:NANTONG HONGBO MACHINERY

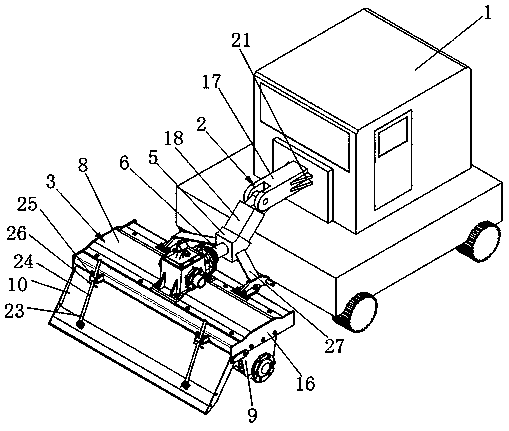

Hydraulic driven lawn mower

The invention discloses a hydraulic driven lawn mower, which comprises a vehicle body. A connecting rod mechanism is arranged at the front of the vehicle body, the connecting rod mechanism is connected with a bearing seat, a connecting shaft is arranged at the front of the bearing seat, and a lawn mowing mechanism is arranged at the front of the connecting shaft. The lawn mowing mechanism comprises a cover plate, a power chassis is arranged on the cover plate, the power chassis is connected with the connecting shaft, and a hydraulic transmission mechanism is arranged inside the power chassis.Frame side plates are arranged on the two sides of the cover plate respectively, the bottom of each frame side plate is connected with a cutter shaft side plate, a rotating shaft is arranged on the two cutter shaft side plates, a plurality of cutter groove seats are arranged on the rotating shaft, and a cutter is arranged on each cutter groove seat. The power chassis penetrates the middle of the rotating shaft, a shaft bevel gear is arranged in the middle of the rotating shaft, and the shaft bevel gear matches the hydraulic transmission mechanism. A frame baffle is arranged at the front of theframe side plates. The hydraulic driven lawn mower has a large cutting surface and high cutting efficiency, and the force arms of the cutters are small. The hydraulic driven lawn mower has the advantage that the cutters are not easy to damage and are simple to replace.

Owner:WENZHOU UNIV OUJIANG COLLEGE

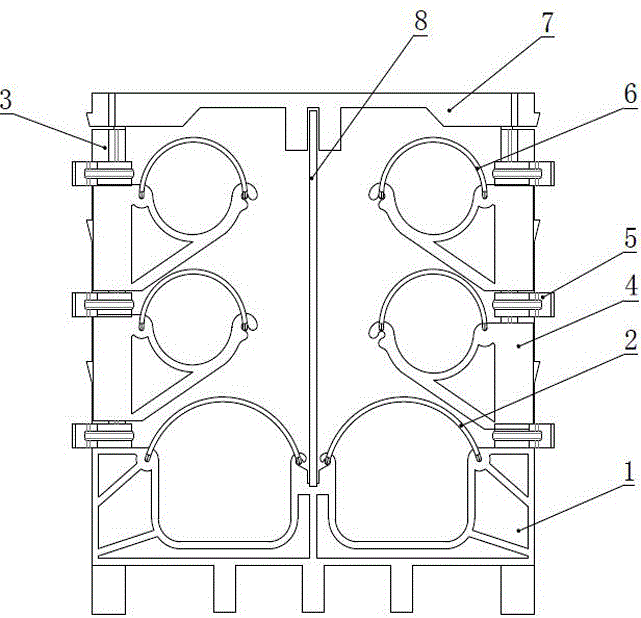

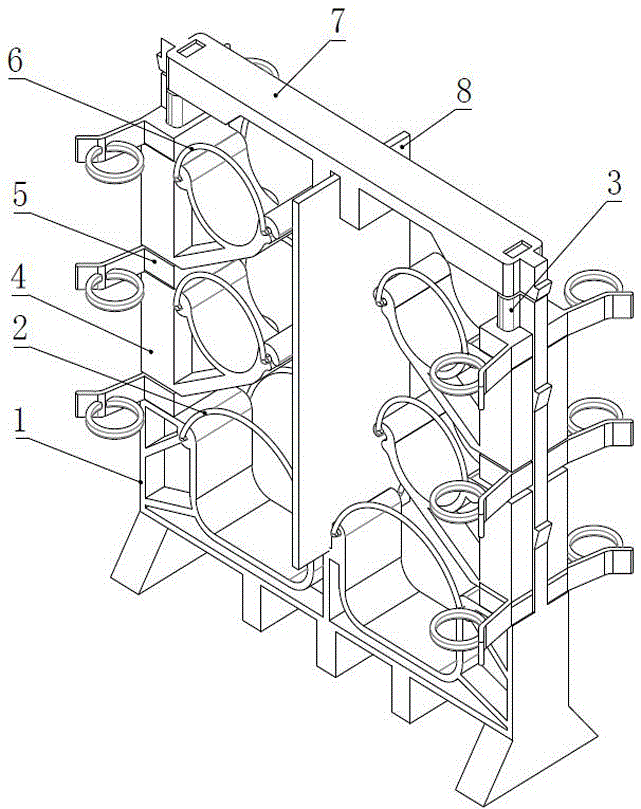

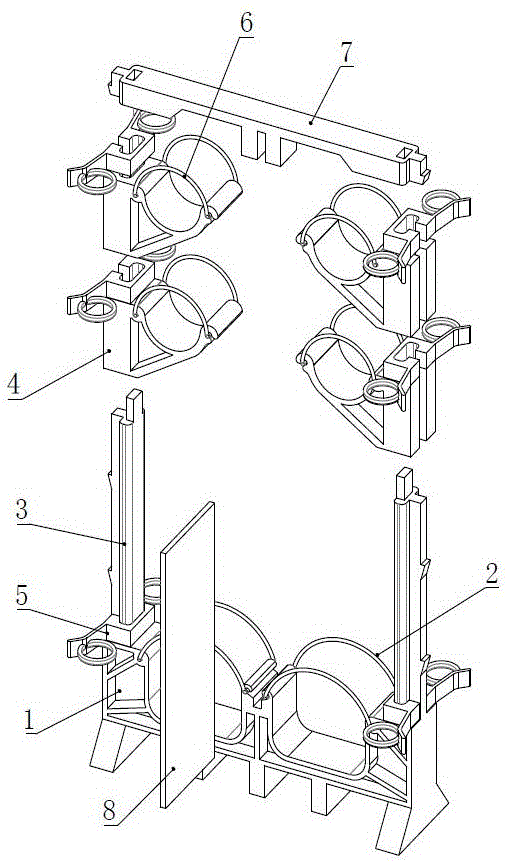

Combined trench cable support

The invention relates to a combined trench cable support. The combined trench cable support is characterized by comprising a support body and a top clamping block, wherein a pair of hook guiding rails perpendicular in direction are arranged at the top of the support body; the two ends of the top clamping block are connected with the top ends of the two hook guiding rails; the outer side faces at the two ends of the top clamping block and the outer side faces of the hook guiding rails are each provided an anti-pulling inverted clamp; a plurality of cable hook modules are arranged on the hook guiding rails in a sleeving mode; anti-tilting clamping blocks are arranged on the upper portion and the lower portion of each cable hook module; a fireproof partition plate is arranged between the top clamping block and the support body. The combined trench cable support has the advantages that the cable support is of a frame structure, stressing is stable and reliable, joints are not prone to fracture, and therefore the service life is long, and the maintenance amount is small; in addition, by the adoption of the anti-pulling inverted clamps, the top clamping block and the support body are prevented from being pulled out easily, the antitheft performance is good, the application range is wide, the combined trench cable support can be applied to various tunnels, coal mines, roadways and drainage ditches, and erecting requirements of ground cables are met.

Owner:NANTONG YUANRUI ELECTRONICS

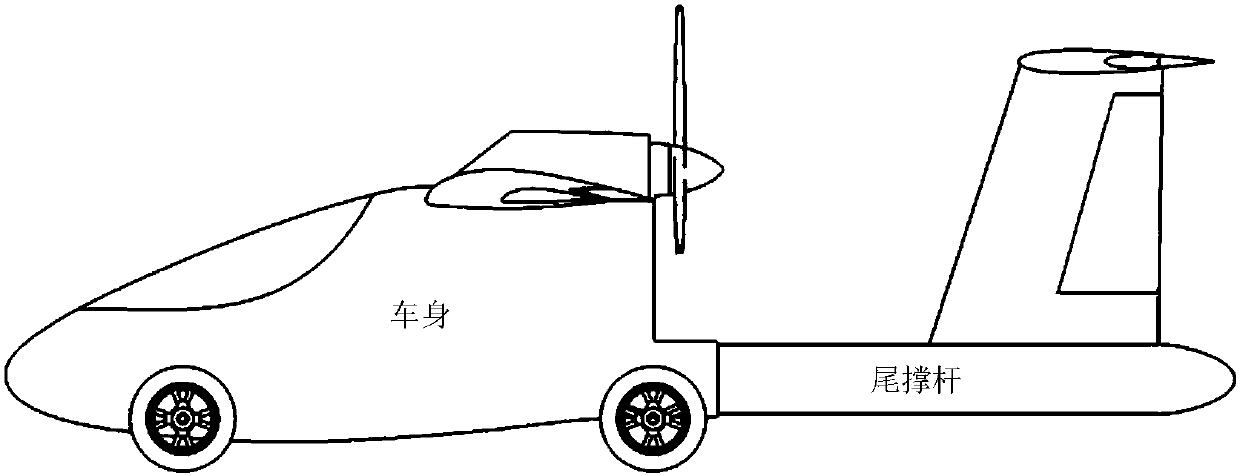

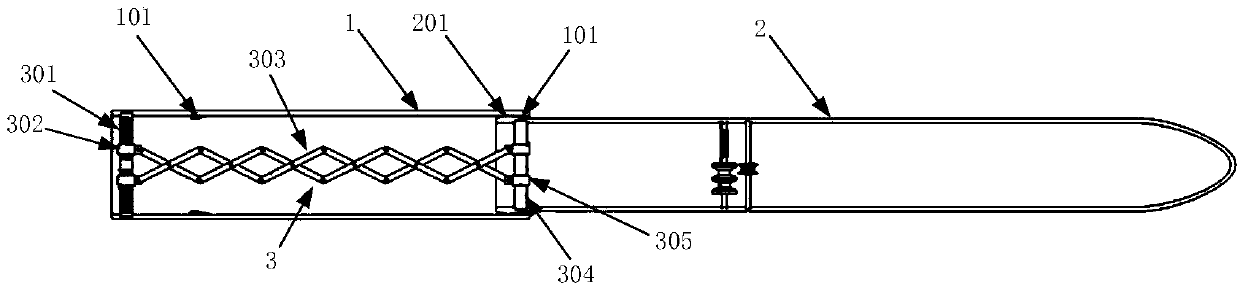

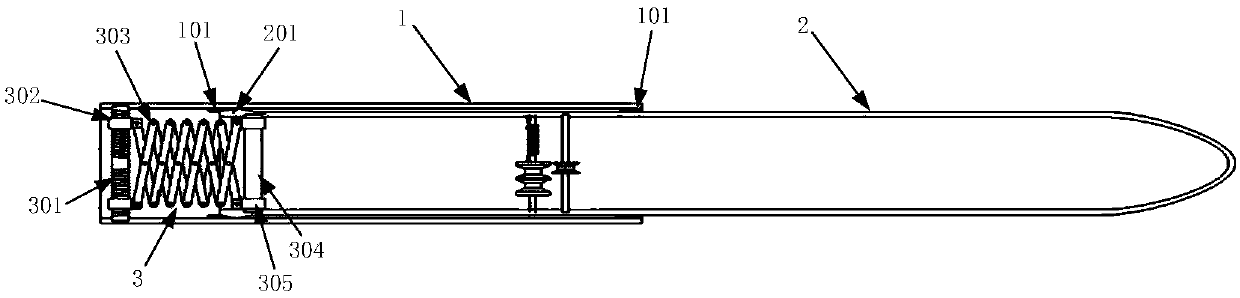

Telescopic tail brace rod for aerocar

ActiveCN107791763AReduce vertical footprintSimple structureAircraft stabilisationAircraft convertible vehiclesEngineeringCable line

The invention discloses a telescopic tail brace rod for an aerocar, is applied to the aerocars, and can effectively reduce the longitudinal space usage of the aerocars during the ground travelling andparking. The tail brace rod is divided into a front tail brace rod and a rear tail brace rod, wherein the expanding and contracting of the tail brace rod is realized by a scissors mechanism; and a cable line storing device is arranged in the rear tail brace rod, so that the situation of line winding is avoided. The telescopic tail brace rod for the aerocar is smooth in expanding-contracting motion, and an expanding and contracting mechanism and a control law are simple.

Owner:BEIHANG UNIV

A Loading Head with Large Range and High Rigidity for Balance Calibration System

ActiveCN105222982BImprove carrying capacityIncrease stiffnessAerodynamic testingHigh stiffnessCarrying capacity

The invention provides a large-range and high-rigidity loading head for a balance calibration system, which includes an inner sleeve, an outer sleeve, an inner sleeve positioning device, a high-precision joint bearing and a curved rod; the inner sleeve is connected with the corresponding taper sleeve The model ends of the balance to be calibrated are connected, the outer sleeve is installed on the outside of the inner sleeve, the inner sleeve positioning device is installed on the outer sleeve, and the inner sleeve is fixed by the tightening force of the screw to limit its freedom in all directions The other end of the high-precision joint bearing is connected to the force transmission part of the calibration system, and the curved rod is connected to the inner sleeve. The loading head has the advantages of high bearing capacity, high rigidity, and fast and accurate positioning of the inner sleeve.

Owner:AVIC SHENYANG AERODYNAMICS RES INST

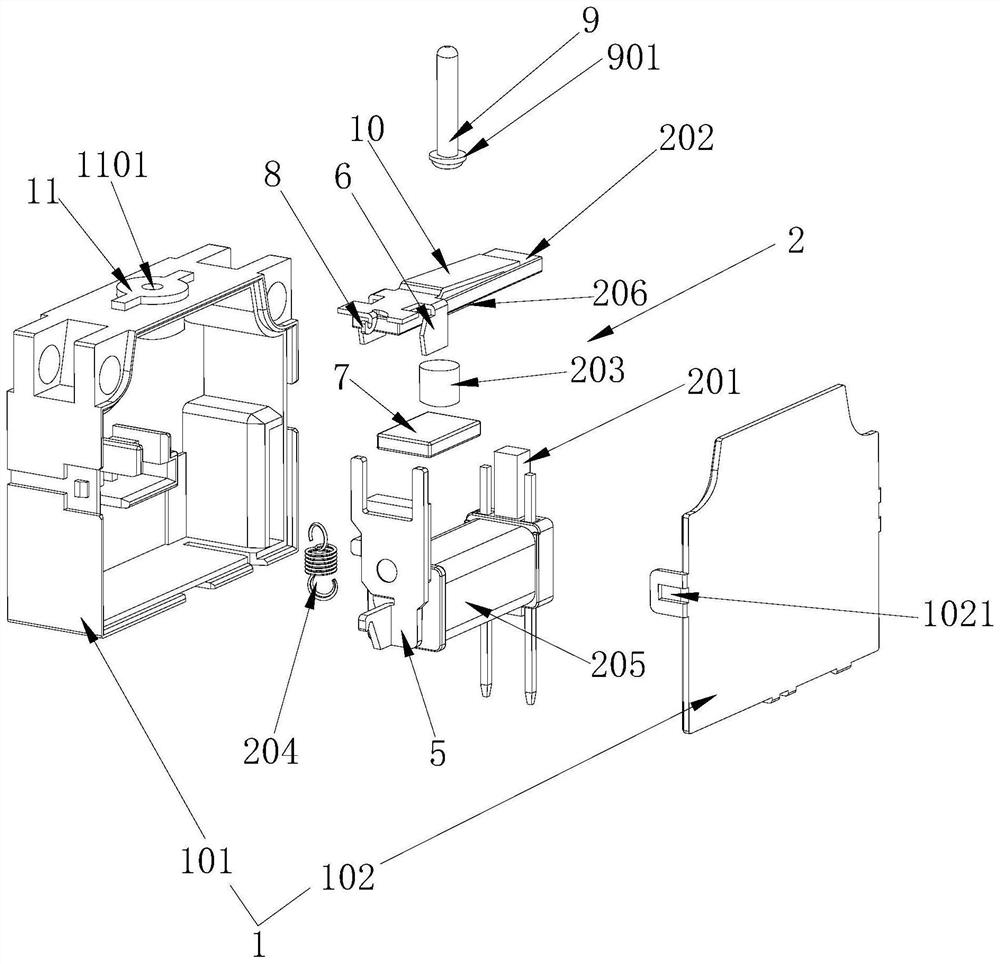

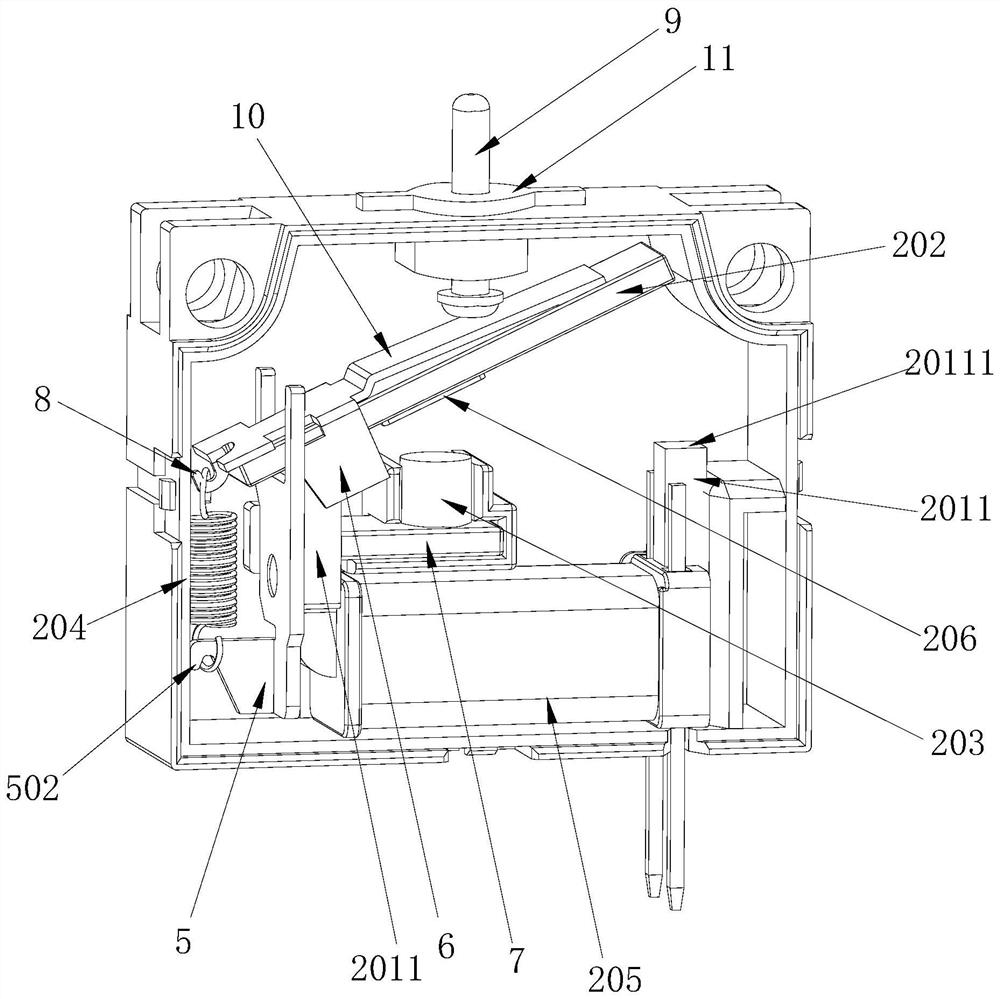

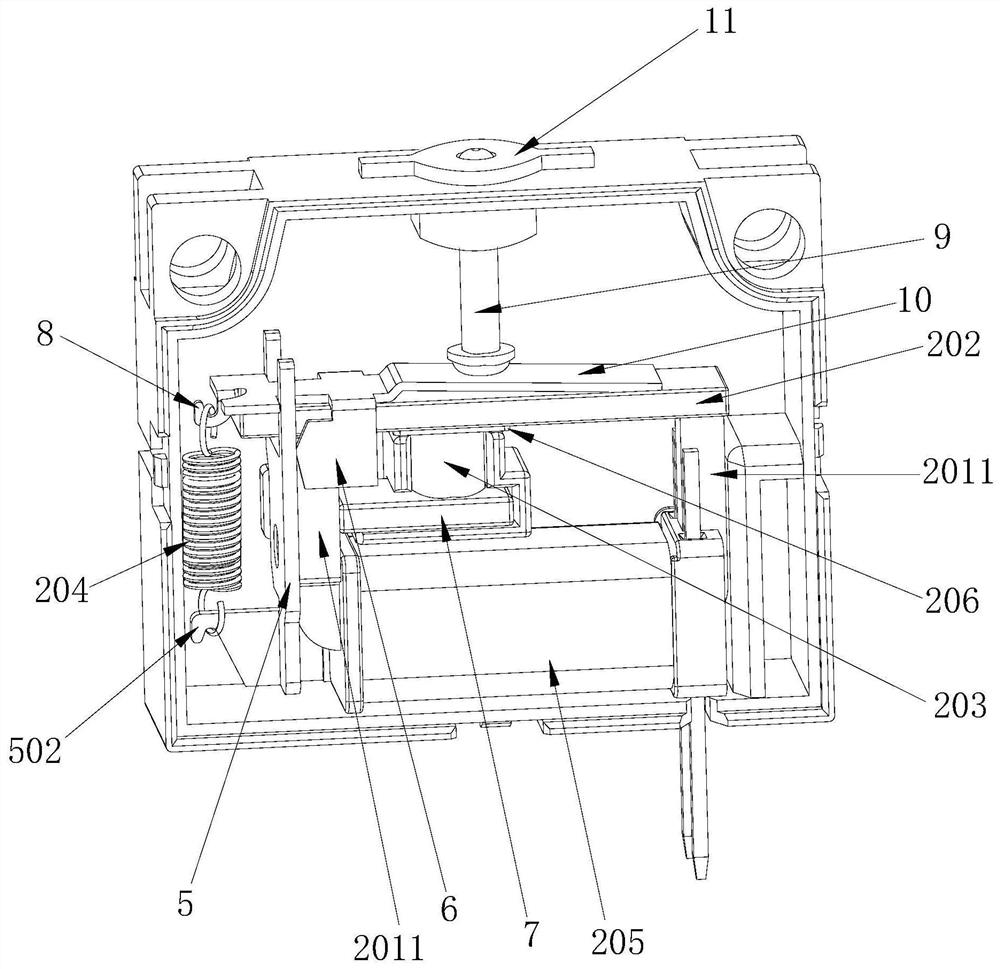

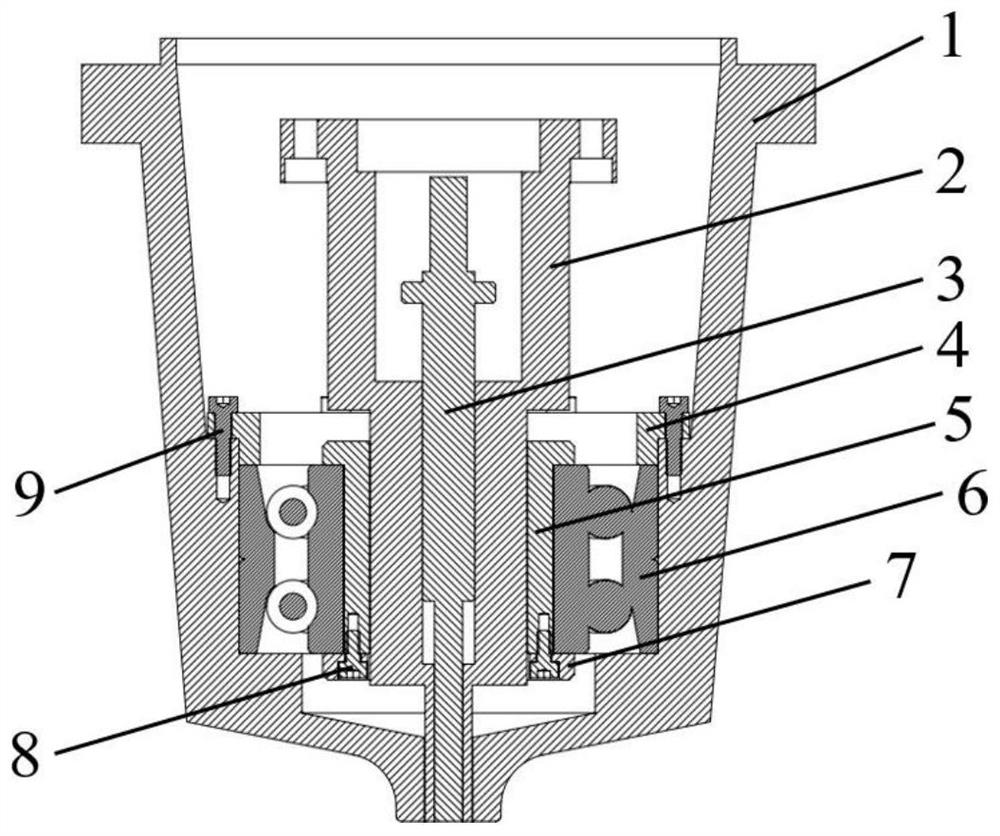

Electromagnetic release and electrical protection equipment comprising same

PendingCN113223904AWork reliablyAccurate design of balance torqueProtective switch terminals/connectionsProtective switch operating/release mechanismsSuction forceElectrical polarity

The invention discloses an electromagnetic release and electrical protection equipment comprising the same, and relates to the technical field of electromagnetic tripping devices. The electromagnetic release provided by the invention comprises a U-shaped magnet yoke, an armature, a permanent magnet and a reset spring, and further comprises an air gap maintaining device which is used for enabling an air gap between the permanent magnet and the armature to be a constant preset value when the armature is attached to the two polar surfaces of the magnet yoke end, when the armature is attached to the polar surfaces of the two branches of the magnet yoke through the air gap maintaining device, the air gap between the permanent magnet and the armature is constantly kept at a preset air gap value, so that the attraction force of the magnet to the armature is constant, the work of the electromagnetic release is reliable and stable, the balance moment of the reset spring and the magnet is conveniently and accurately designed, the moment balance of the reset elastic piece and the permanent magnet can be destroyed by adopting a small current, the scheme of the low-power electromagnetic release becomes possible, and the low-power electromagnetic release is suitable for low-power-consumption and low-current use working conditions.

Owner:SANYOU CORP LTD

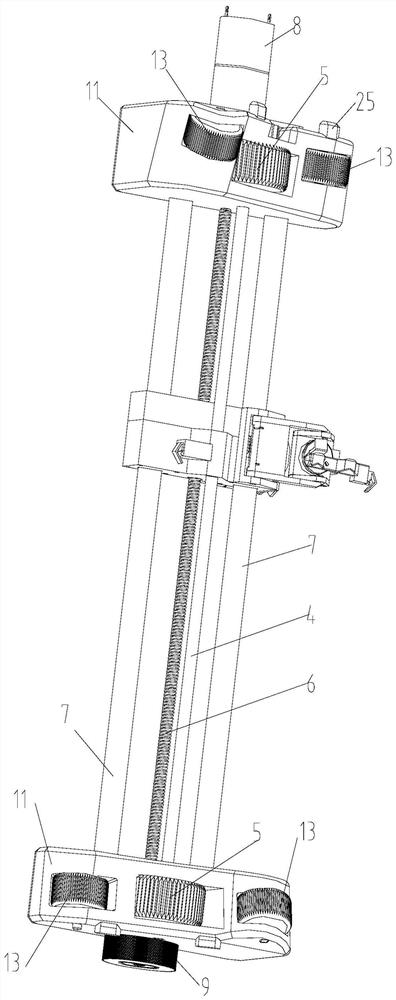

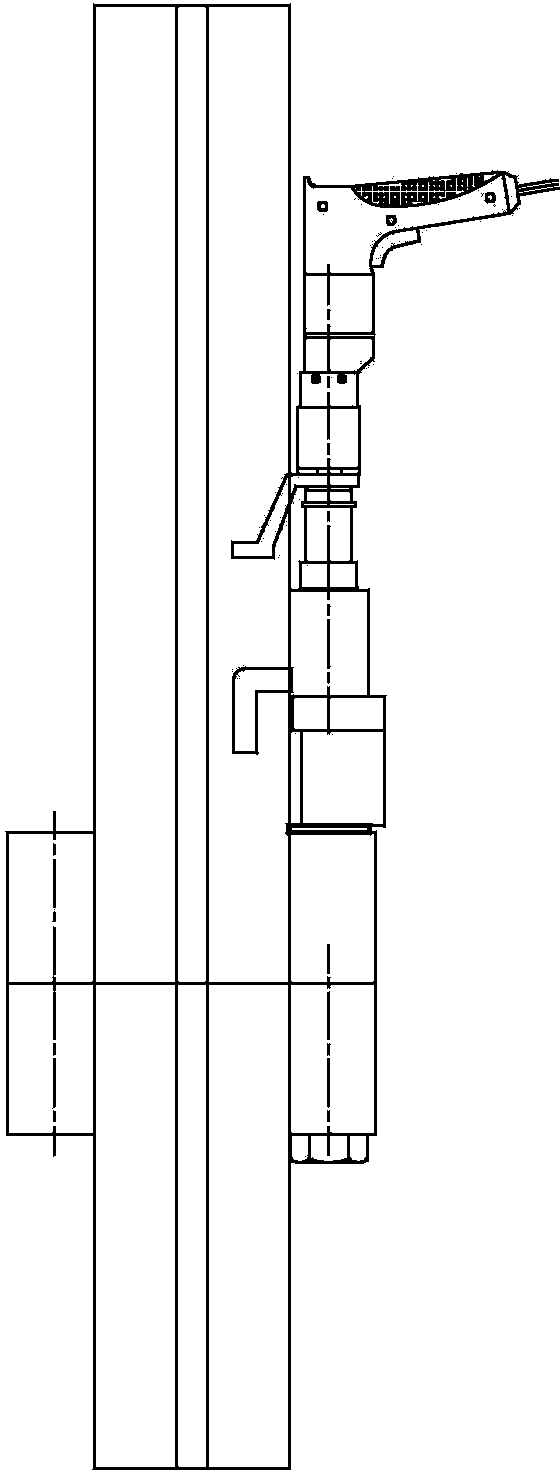

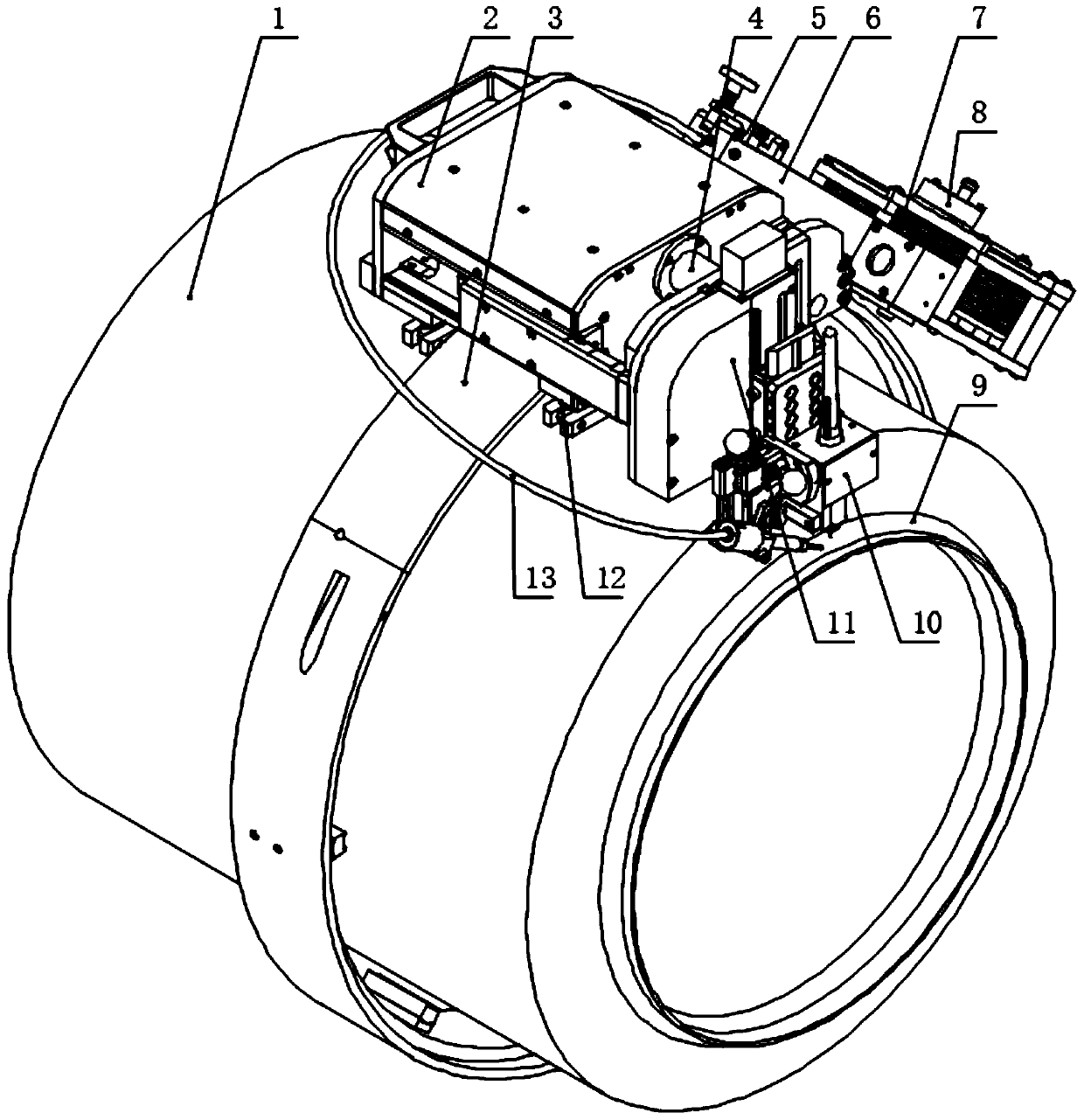

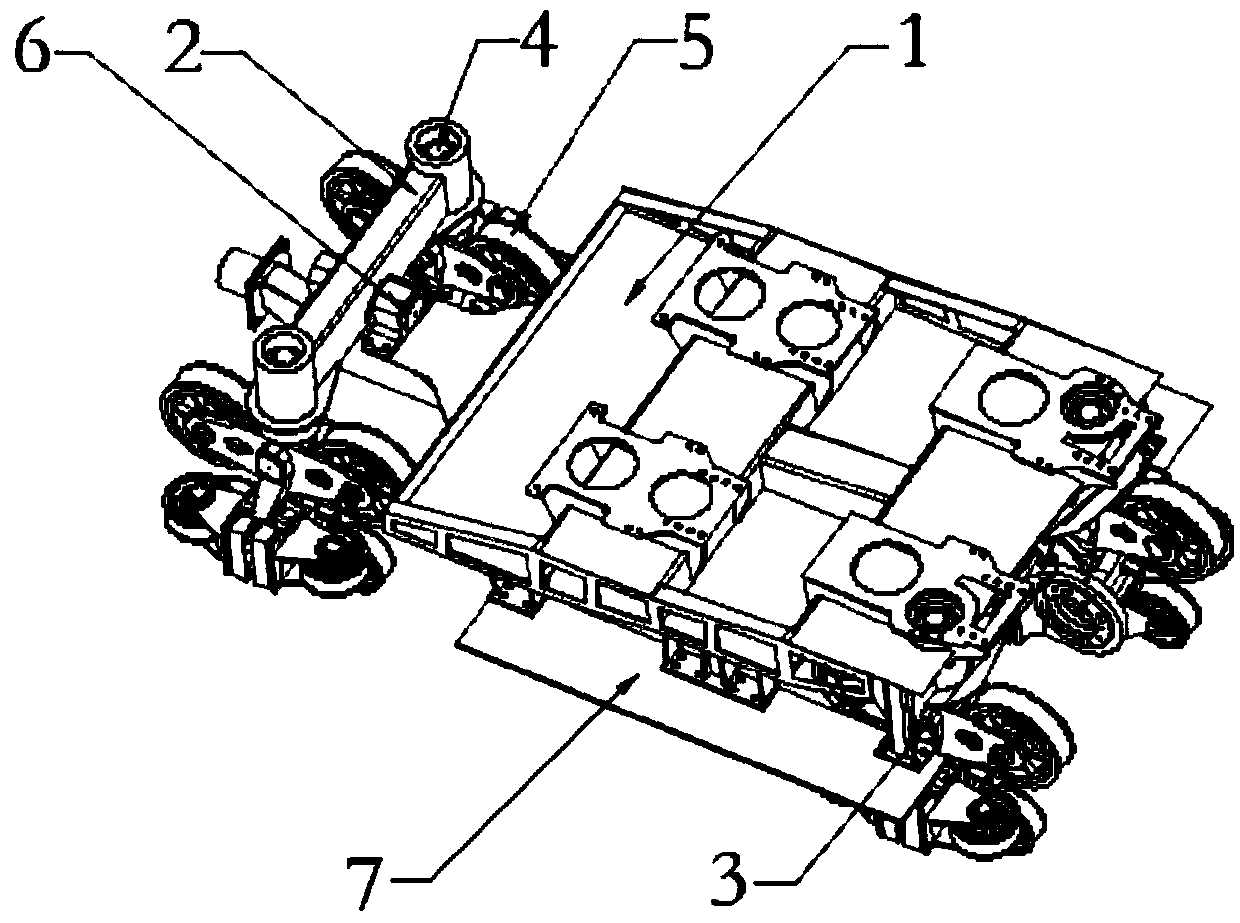

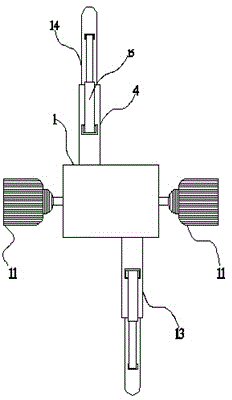

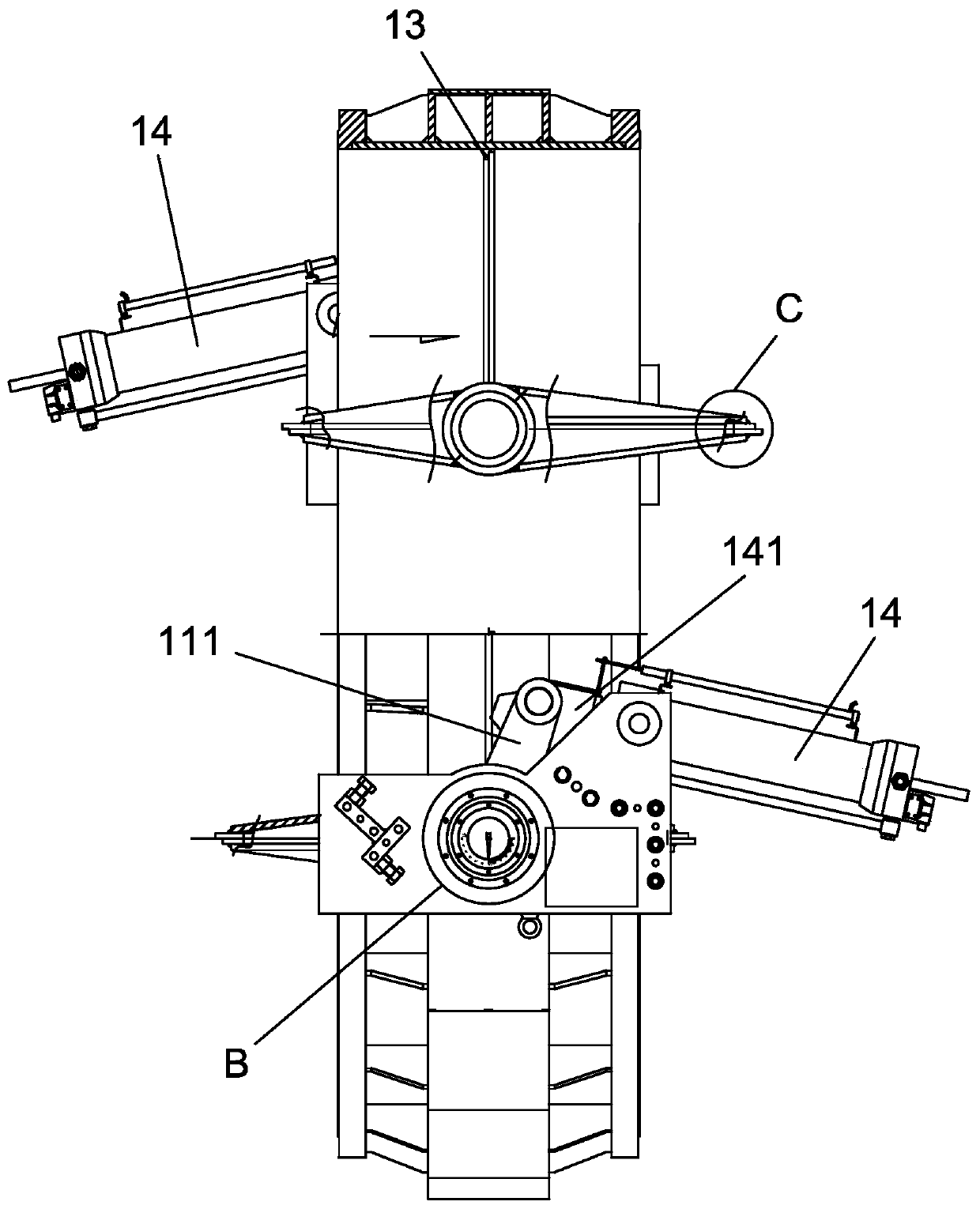

Pipeline welding robot integrating functions of TIG welding and MIG welding

PendingCN111360379AReduce the overall heightReduce volumeShielding gas supply/evacuation devicesElectrode holder supportersEngineeringPipe welding

The invention relates to a pipeline welding robot integrating functions of TIG welding and MIG welding. A welding unit comprises a pedestal, a nozzle and a welding stick, wherein the pedestal is arranged at the front end of a position adjusting unit, the nozzle is arranged on the pedestal, and an air outlet of the nozzle faces a weld joint of the pipeline and sprays inert gas. TIG welding and MIGwelding can be transformed conveniently and flexibly, so that the fitness of the whole robot is improved, the labor intensity of a welder is reduced and the welding work efficiency is improved. In addition, the whole robot can be suitable for welding pipelines of different wall thicknesses by means of multi-stage adjustment in all the direction. The optimum relative positions can be kept between atungsten electrode or the welding stick and the weld joint. Furthermore, the height and volume of the whole robot are reduced by means of flatted improvement and adjustment of adhesion of a wire reelunit, so that the robot is suitable for finishing welding work in a scene where the separation distance between pipelines is relatively small.

Owner:TIANJIN HUAYOU PETRO CHEM ENG CO LTD

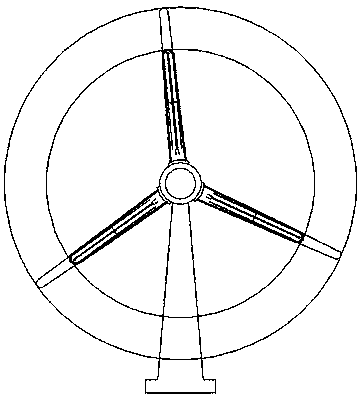

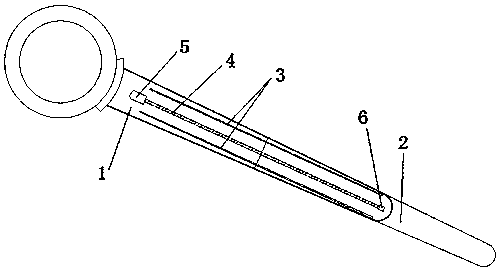

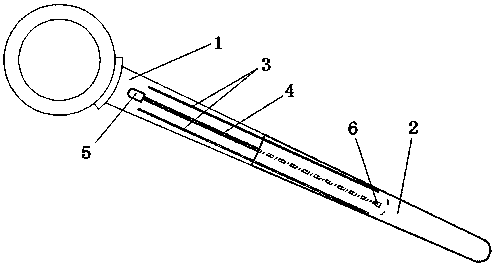

Vertical adjustable variable wind face blade for wind driven generator

PendingCN108150345AImprove the range of adaptationReduce moment armWind motor controlMachines/enginesWind sensorWind driven

The invention discloses a vertical adjustable variable wind face blade for a wind driven generator. The vertical adjustable variable wind face blade comprises a blade fixing device, a main blade, an auxiliary blade, guide rail grooves, a screw rod, a screw rod terminal fixing device and a wind sensor. Lugs are arranged at the bottom of the auxiliary blade. The screw rod is arranged on the main blade. A controller and a screw rod total segment fixator are arranged on the two sides of the left side of the screw rod correspondingly. The upper side and the lower side of the screw rod are both provided with the guide rail grooves. The main blade is connected with the auxiliary blade, and the auxiliary blade is arranged at the top of the main blade. The guide rail grooves in the main blade are connected with the lugs on the auxiliary blade. The auxiliary blade is provided with the wind sensor. In this way, the wind area of the vertical adjustable variable wind face blade can be changed according to the magnitude of wind power, the adaptive range of the wind driven generator to wind speed is widened, the arm of force is reduced while the wind face is reduced, and the load of the blade joint is lowered.

Owner:SUZHOU UNIV OF SCI & TECH

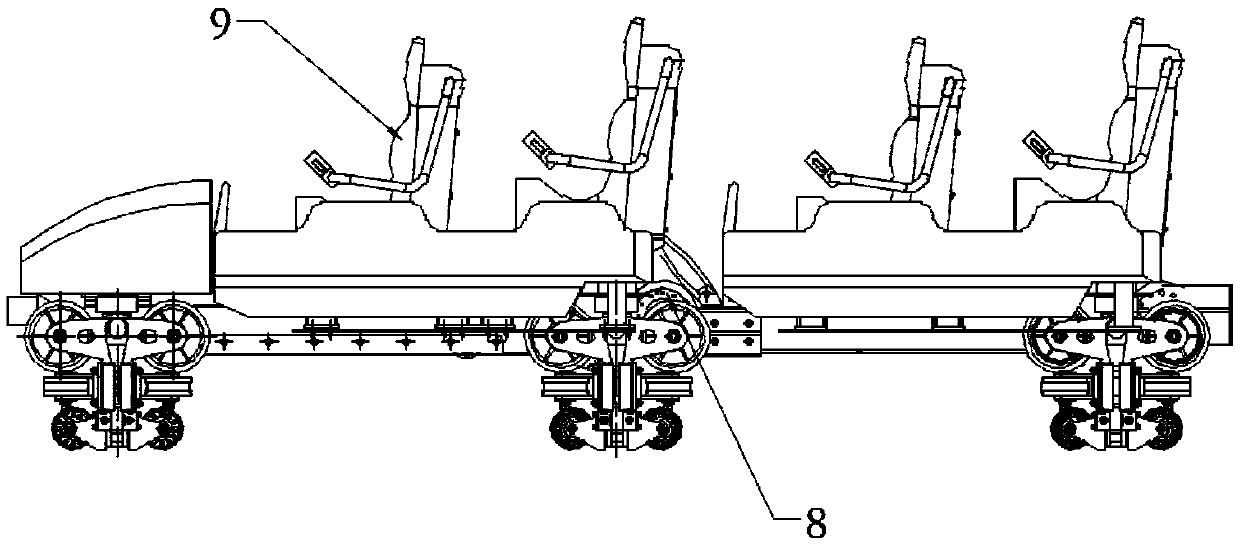

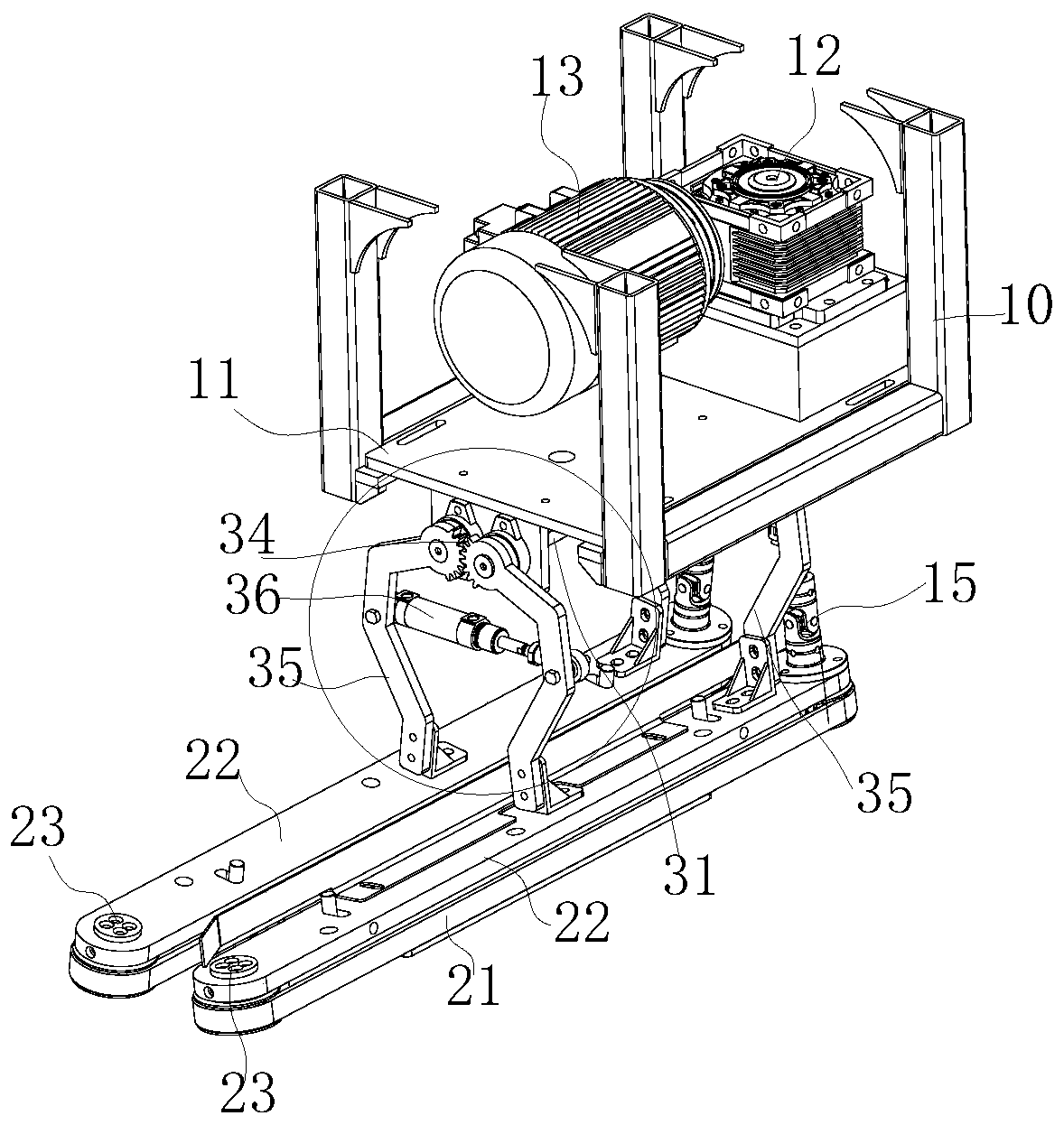

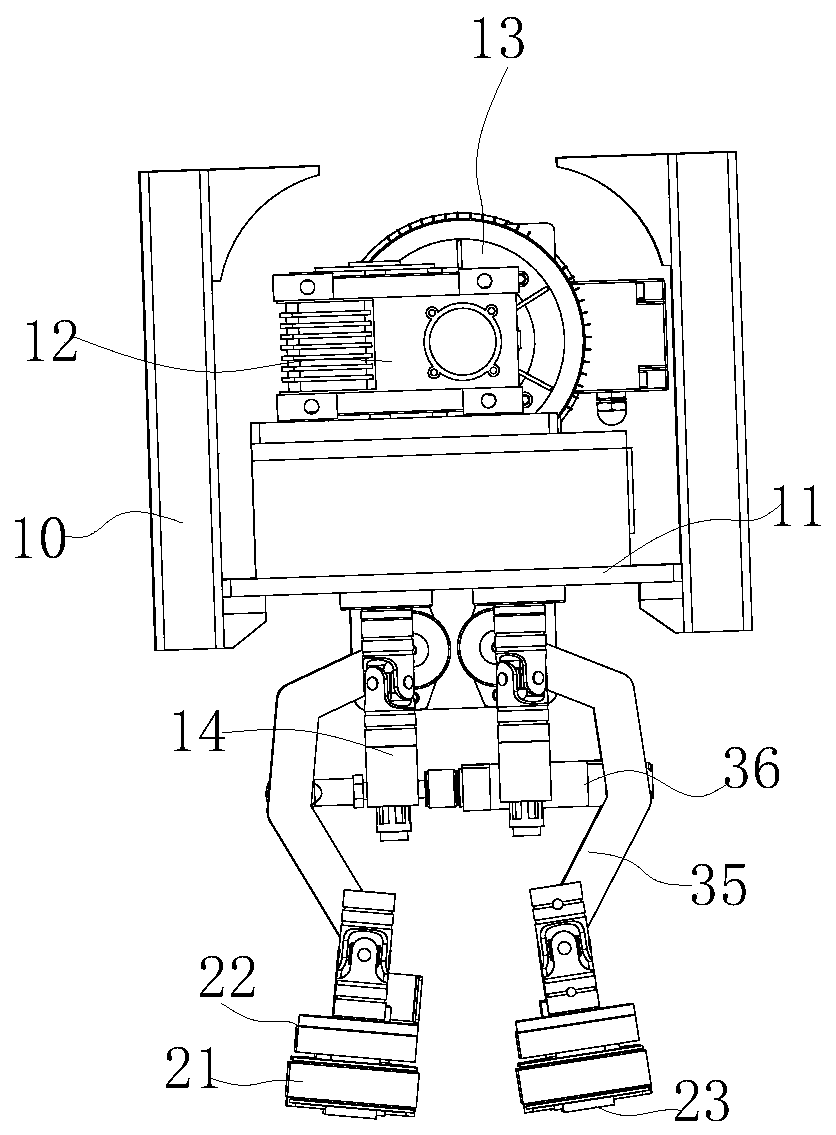

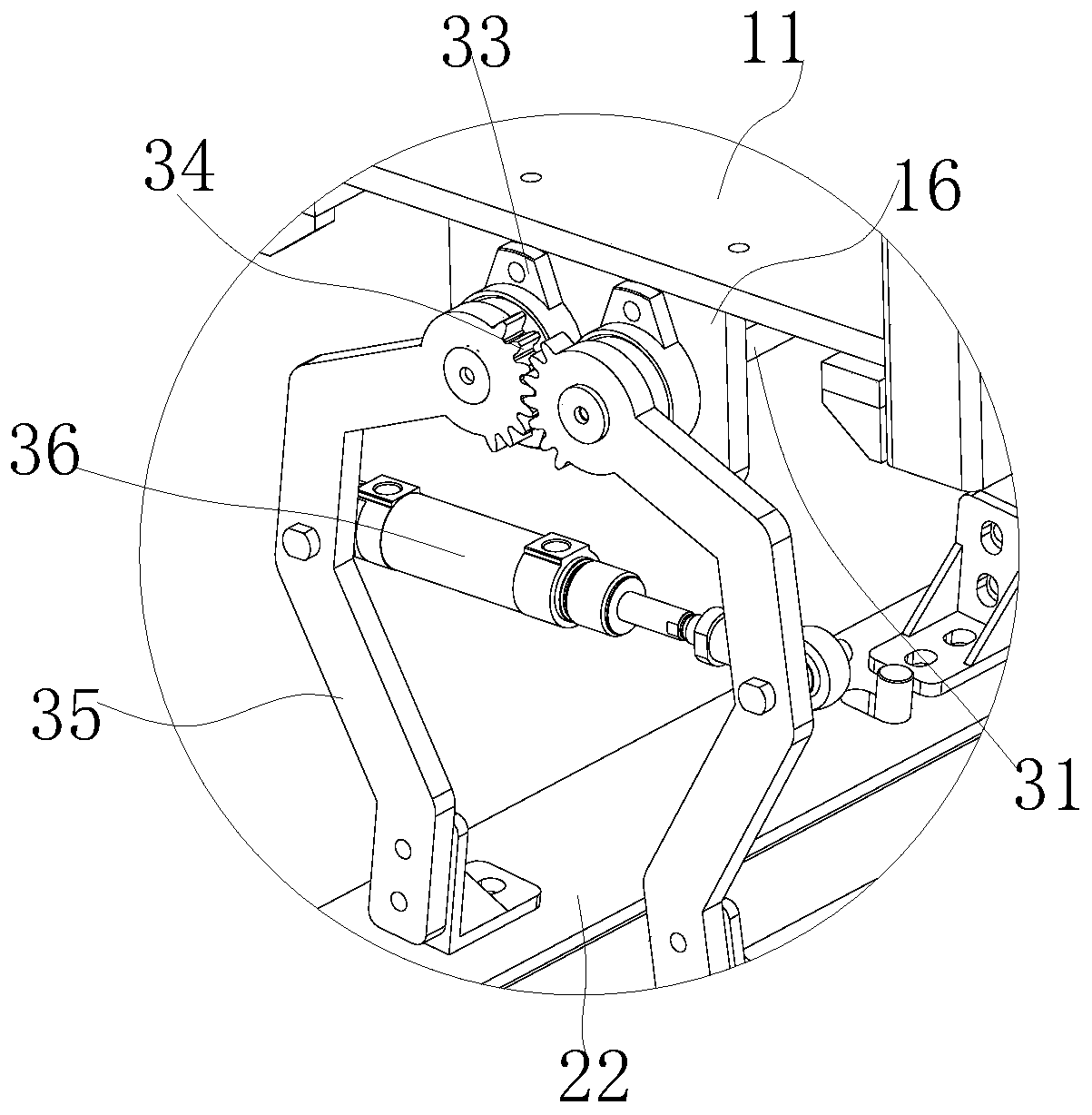

Roller coaster device

The invention provides a roller coaster device, which comprises a plurality of train units which are sequentially connected, wherein the train units comprise a frame, wherein the frame is horizontallyarranged; a bridge frame, the bridge frame is arranged at the front end of the frame and is connected with the frame, the bridge frame comprises concave'-shaped connectors, two ends of each connectorare respectively provided with a vertical shaft, and the vertical shaft is used for being connected and fixed with a gear train; a tail seat, the tail seat is arranged at the central position of thetail part of the frame, a gear train which is consistent with the vertical shaft is fixed on the tail seat, the tail seat is used for mounting a spherical hinge connector, and the tail seat is connected with a plurality of train units through the spherical hinge connector. The roller coaster device has the advantages of simple structure, easy realization, capability of improving the integral stress intensity of the roller coaster, capability of respectively keeping independent rotation angles of the gear train in the direction changing or track changing process, ensuring uniform stress distribution of the gear trains, enabling the roller coaster to run on the tracks with sufficient degrees of freedom, so that the driving safety and the service life of the roller coaster device are furtherimproved.

Owner:北京中冶设备研究设计总院有限公司

Clamping and conveying mechanism for packaging bag

The invention aims to provide a clamping and conveying mechanism for a packaging bag. The clamping and conveying mechanism is characterized in that a packaging bag discharging direction is determinedto be consistent and the clamping and conveying mechanism has a simple structure. The rack is provided with two groups of clamping and conveying belts at an equal height, oscillating arms connected with the clamping and conveying belts form rotatable cooperation with the rack; rotary shafts are driven by power to rotate to drive two groups of clamping and conveying belts to synchronously oscillateto clamping and conveying positions which are mutually near or bag feeding positions which are mutually far; on the clamping and conveying positions, the belt surfaces of the two groups of clamping and conveying belts are mutually in parallel and are all positioned in a plumb surface; and in a belt-shaped constraint area formed by the adjacent belt surfaces on the position, the length direction of the belt-shaped constraint area is consistent with the belt feeding direction of the packaging bag. The two groups of clamping and conveying belts oscillate in the plumb surface around the rotary shafts through the oscillating arms. Compared with oscillation around the end part of one end of a clamping plate in a horizontal plane, an arm of force is small, and movement is stable. In addition, the two groups of clamping and conveying belts synchronously oscillate to guarantee that the center lines of the two groups of clamping and conveying belts are constant all the time, and therefore, thebag mouth of the packaging bag discharged from the tail end of each clamping and conveying belt can accurately enter a subsequent mechanism.

Owner:ANHUI XINYUAN PACKING TECH

Movable crane and balance weight connecting device thereof

Owner:XUZHOU HEAVY MASCH CO LTD

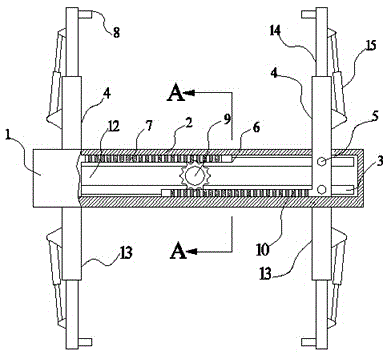

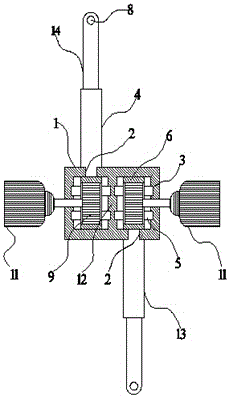

Multi-mode stirring friction welding set, system and method

The invention relates to the technical field of stirring friction welding, in particular to a multi-mode stirring friction welding set, system and method. The multi-mode stirring friction welding setcomprises a jacket, a sleeve, a stirring needle and a bearing part, wherein both the sleeve and the stirring needle can rotate under the driving action of external force, and can move along the axialdirection under the driving action of the external force in order to extend out of or retract into a through hole; and the sleeve and the stirring needle can move relatively along the axial direction.The sleeve and the stirring needle are adjusted according to different welding ways in order to adapt to a plurality of different stirring friction welding modes. A bearing part structure is integrated inside the welding set, the coaxiality of the multi-mode welding set is increased, and the moment arms of the sleeve and the stirring needle in the stitch welding process are reduced, so that the bending moments on the sleeve and the stirring needle in the stitch welding process are relatively small, the small deformation and large rigidity of the stirring needle and the sleeve are ensured, thesleeve and the stirring needle can move along the axial direction in the rotating process in order to finish stitch welding, and the durability of the multi-mode stirring friction welding set is realized.

Owner:昆山万洲特种焊接有限公司

Movable-arm-adjustable fast switching body paper frame for corrugated board production

The invention discloses a movable-arm-adjustable fast switching body paper frame for corrugated board production. The movable-arm-adjustable fast switching body paper frame comprises square frame body with a cavity structure. First movable arms and second movable arms are connected to the square frame body. Telescopic arms with chucks are arranged at one ends of the movable arms. The telescopic arms and the movable arms are provided with telescopic oil cylinders. One end of each first movable arm and one end of each second movable arm extend into the cavities. The parts, in the cavities, of the first movable arms and the second movable arms are provided with positioning pins. One end of each positioning pin extends into a positioning groove. The parts, in the cavities, of the first movable arms and the second movable arms are provided with toothed plates, the two toothed plates in the same cavity are arranged in a staggered mode, a gear is arranged between the two toothed plates in the same cavity, and the gears are connected with a motor arranged on one side of the square frame body. The movable-arm-adjustable fast switching body paper frame for corrugated board production has the advantages that the widths between the movable arms and the lengths of the movable arms can be adjusted, the requirements for production of body paper with different widths and radii can be met, the production investment can be reduced, and the body paper can be fast replaced.

Owner:WENGAN CHUANGXIN PACKAGING

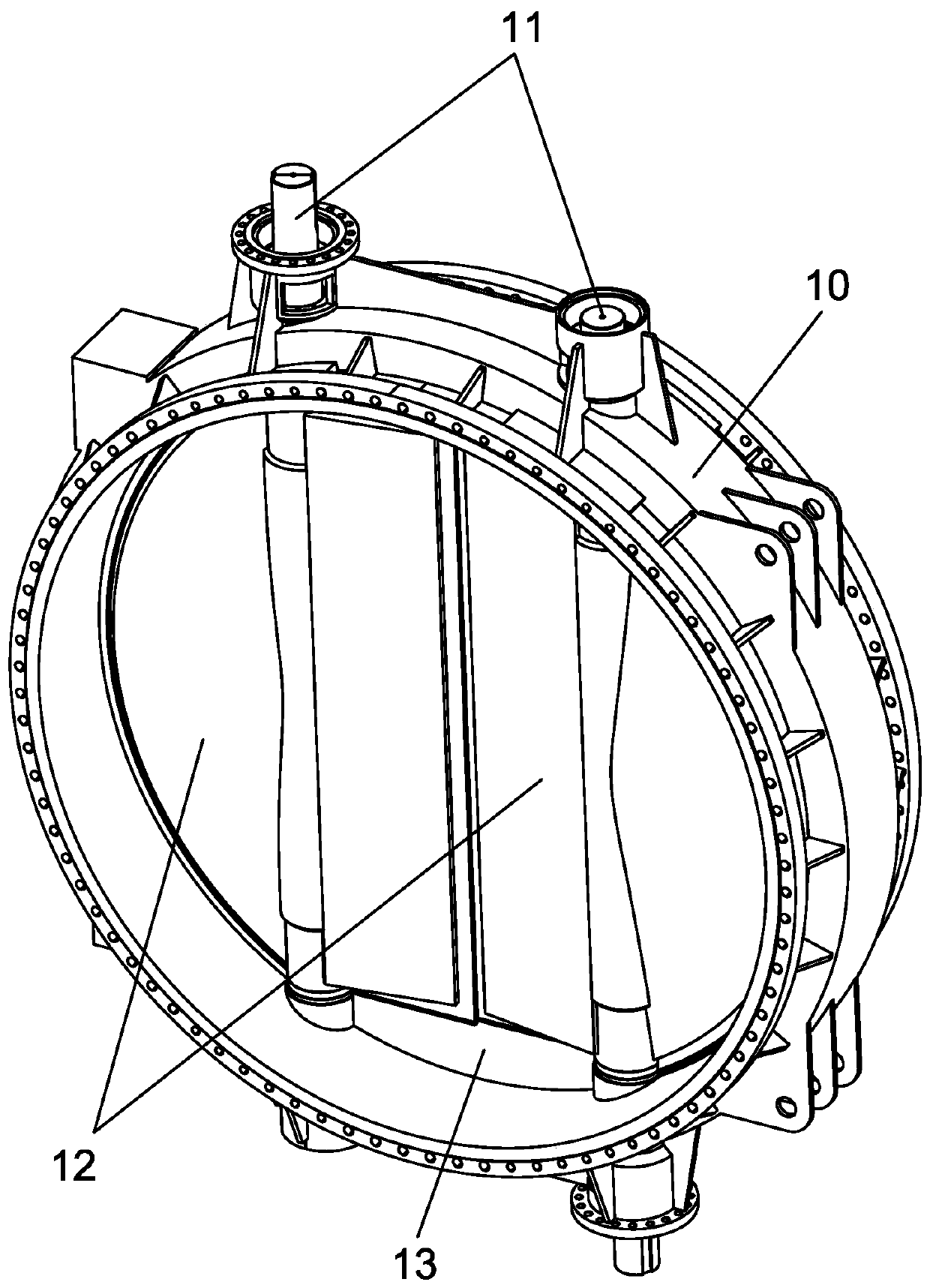

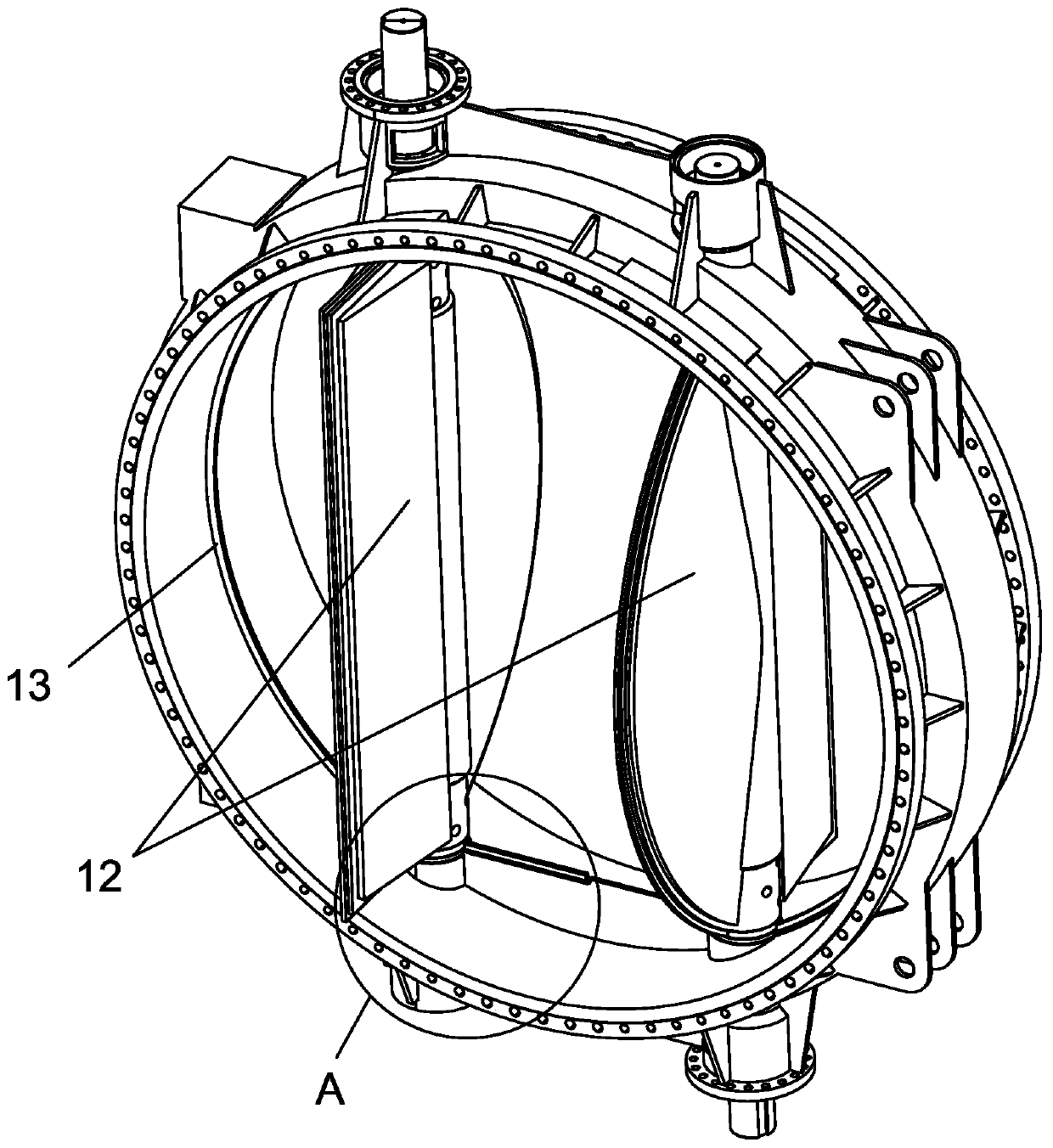

Metal-sealed double-plate hydraulic-operated adjusting butterfly valve

InactiveCN110762232AReduce thicknessEasy to controlOperating means/releasing devices for valvesLift valveButterfly valveControl valves

The invention discloses a metal-sealed double-plate hydraulic-operated adjusting butterfly valve. The metal-sealed double-plate hydraulic-operated adjusting butterfly valve comprises a valve body, thevalve body is in an annular shape, two valve stems symmetrically arranged are arranged at the position, on the two sides of the middle line of the valve body, of the cross section surface of the valve body, a butterfly board is arranged on each valve stem and in a D shape, a valve seat is arranged on the inner cylindrical wall of the valve body, the sides, facing the middle line of the cross section surface of the valve body, of the two butterfly boards are in contact sealing with each other when the valve stems rotate to control contact sealing of the butterfly boards and the valve seat, a hydraulic-operated actuator is arranged on the valve body, the valve stems are hinged to the valve body, a swing rod is arranged on the end, penetrating through the valve body, of each valve stem, andthe pushing rod of the hydraulic-operated actuator is hinged to the swing rods and used for pushing the swing rods to swing so as to control the valve stems to rotate. The metal-sealed double-plate hydraulic-operated adjusting butterfly valve has the advantages that the sealing performance is high, the pressure bearing capacity is high, effort-saving and quick switching is achieved, the opening flow can be adjusted conveniently, and the erosion is reduced.

Owner:WUZHOU VALVE

Mechanical clamping claw capable of stably grasping workpiece

Owner:GUANGZHOU FUGANG WANJIA INTELLIGENT TECH CO LTD

Knitting needle method of yarn change machine and yarn feeding mouth structure used thereof

InactiveCN101492856AReduce moment armReduce torqueCircular knitting machinesYarnBiomedical engineering

The invention discloses a method for needling a knitting needle of a yarn regulating machine and a feed nozzle structure thereof, belonging to the technical field of yarn regulating machine manufacture. The feed nozzle structure body of the yarn regulating machine is provided with a depressed area, wherein the lower edge of the depressed area is contacted with the middle position of a needle latch, while the other side surface of the depressed area is an inclined plane. The invention also provides the method for needling the knitting needle of the yarn regulating machine, comprising the following steps: the needle latch slightly opens at a certain angle, slides along the side surface of the feed nozzle; after the knitting needle slides a chute, the middle part of the needle latch is constantly contacted with the lower edge of the depressed area of the feed nozzle, so that clearance is reserved between the tip of the needle latch and the bottom surface of the depressed area of the feed nozzle; and the needle latch slides the inclined plane on the tail end of the depressed area to enter the next process. The method and the structure have the characteristic of safe needling, moreover, cooperation of the feed nozzle structure and the needling method can reduce consumption of the knitting needles, thereby reducing the defective rate of cloth.

Owner:HUIAN KING TANSO PRECISION MACHINERY

Winding worm-gear speed reducer

The invention relates to a winding worm-gear speed reducer. A worm and gear mechanism is arranged in a shell body. A worm gear is fixedly connected to an output shaft in series. An extending end of the output shaft is connected with a winding wheel. A shaft sleeve is connected to the extending end of the output shaft in a sleeved mode. The shaft sleeve is fixedly connected with the shell body. A large bearing is connected to the outer surface of the shaft sleeve in a sleeved mode. The winding wheel is connected to the outer surface of the bearing in a sleeved mode. The winding wheel and the extending end of the output shaft are fixedly connected through a connecting device. The worm gear is connected to the output shaft in a sleeved mode. The left end and the right end of the worm gear are provided with circular cylinders connected to the output shaft in a sleeved mode. The circular cylinders are connected with bearings in a sleeved mode and are supported on the shell body through the bearings. The specifications of the bearings are improved, and the intensity of the bearings is improved. At least one bearing group is arranged between the winding wheel and the output shaft. The number of supporting points of the output shaft is increased, the force arm of the output shaft is lowered, force borne by the bearings is lowered, and the risks of bearing damage are reduced.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com