Knitting needle method of yarn change machine and yarn feeding mouth structure used thereof

A thread-adjusting machine and knitting needle technology, used in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of time-consuming maintenance or replacement, reduce the working efficiency of the knitting machine, and reduce the property loss of users. The effort of manpower or time, the effect of reducing needle wear and tear, and reducing injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

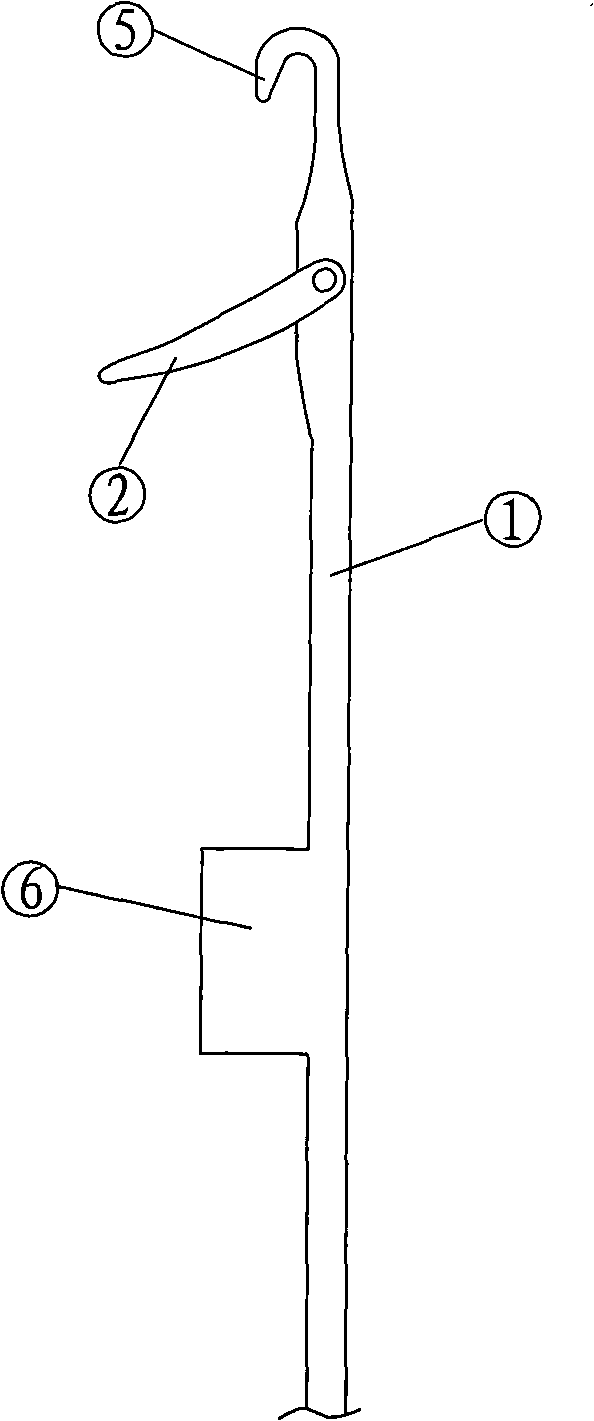

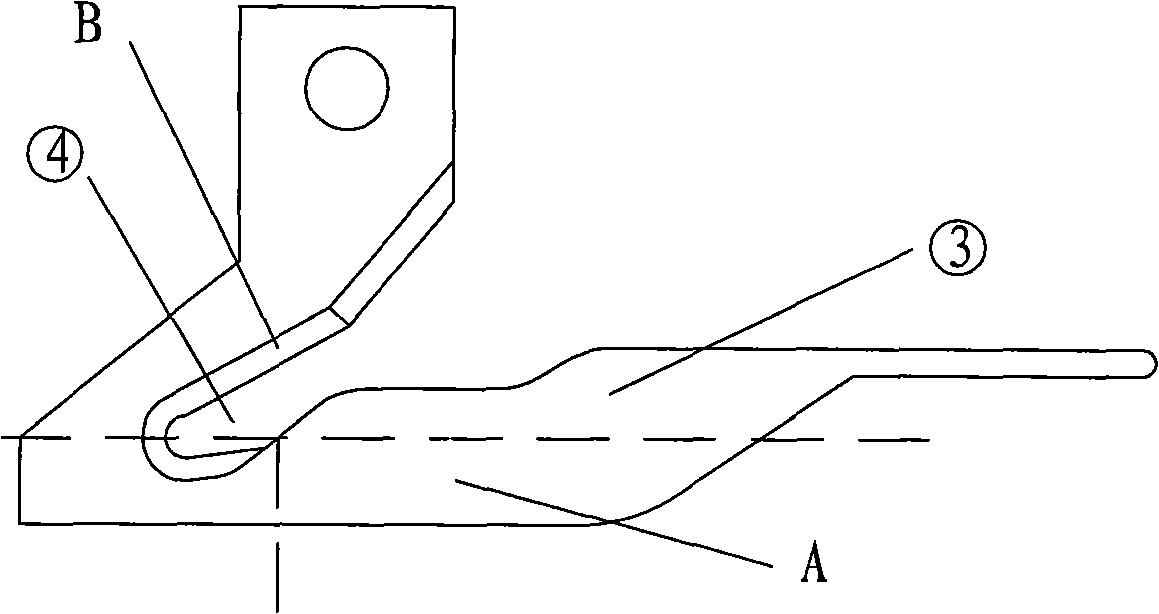

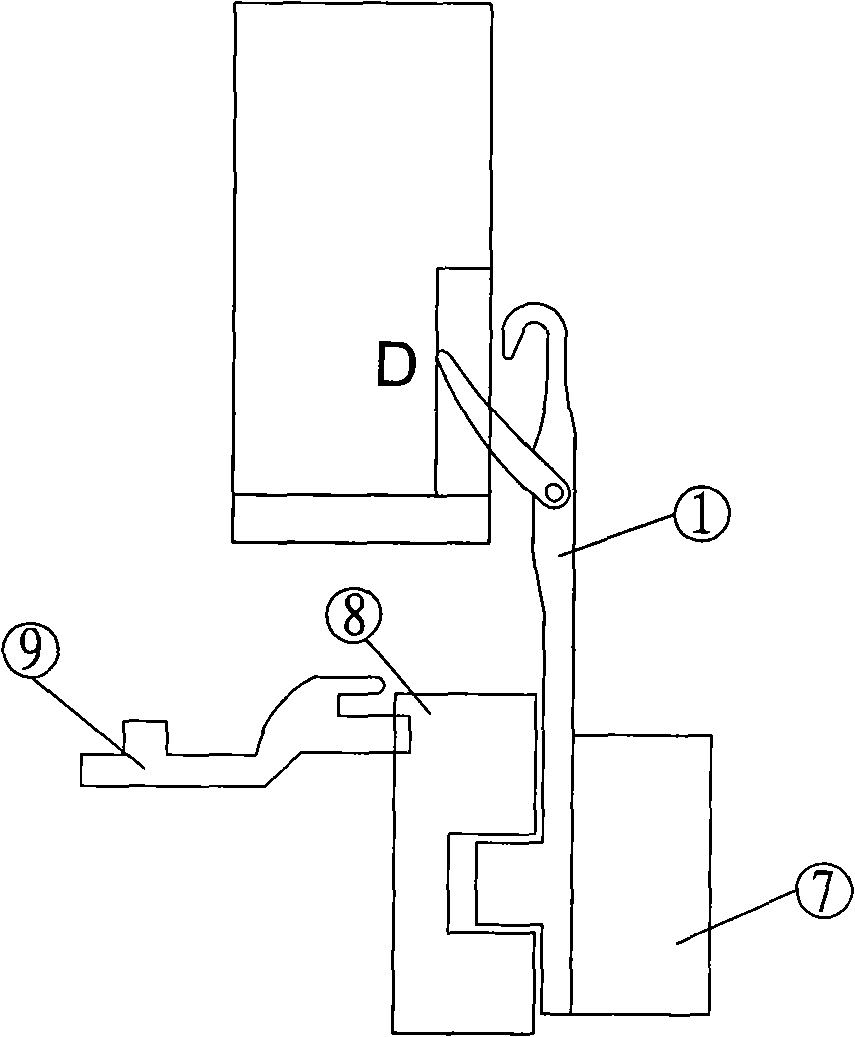

[0030] Example: a structure such as Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a needle-moving method of a thread-adjusting machine, the knitting needle 1 makes a circular motion around the center line of the machine under the action of the needle cylinder, and at the same time the stitches of the knitting needle 1 move up and down in the track of the mountain corner, when the knitting needle 1. When there is yarn in the needle hook: the latch opens and closes under the action of the yarn, and the yarn forms coils interlaced with each other under the action of the movement of the knitting needle and the take-up device; when the needle of the knitting needle When there is no yarn on the hook: After the needle latch 101 is closed by the old coil, it cannot be opened because there is no new coil in the needle hook. Due to the high-speed movement and the inertia of the needle latch, the needle latch will open at a certain angle, along the back of the yarn feeder. S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com