Movable-arm-adjustable fast switching body paper frame for corrugated board production

A corrugated cardboard and fast switching technology, applied in the field of base paper racks, can solve the problems of reduced production efficiency, increased production investment, and need to replace, etc., to achieve the effects of reducing production investment, saving energy consumption, and reducing the force arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

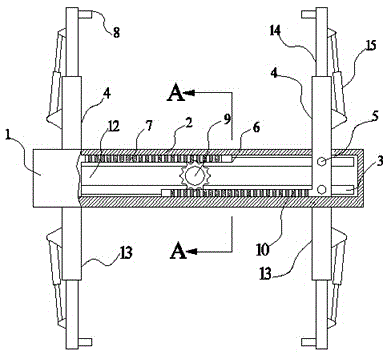

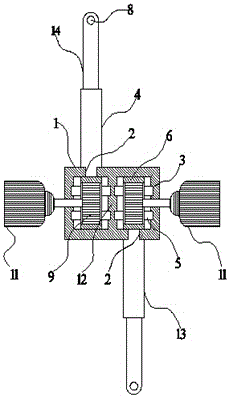

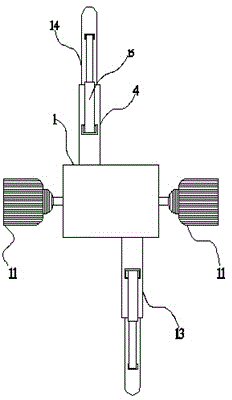

[0013] Embodiment of the present invention: the movable arm of the corrugated cardboard production can be adjusted to quickly switch the base paper holder, as attached Figure 1-4 As shown, it includes a square frame body 1, the square frame body 1 is a cavity structure, and a partition 12 is provided in the cavity, and the partition 12 divides the cavity into two chambers, one of which is provided with a Slot 2, the bottom of the other chamber is provided with chute 2, and two positioning grooves 3 are respectively provided on the cavity wall before and after the chamber; two groups of movable arms are connected on the square frame body 1, and the movable arms include two first Movable arm 4 and two second movable arms 13, movable arm one end is provided with telescopic arm 14, and the opposite sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com