Metal-sealed double-plate hydraulic-operated adjusting butterfly valve

A metal sealing and hydraulic technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of enlarged radial size of butterfly valve, small operating pressure and working temperature range, increased disc thickness, etc., to improve the bearing capacity Pressure, reduce the overall thickness, meet the effect of flow requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

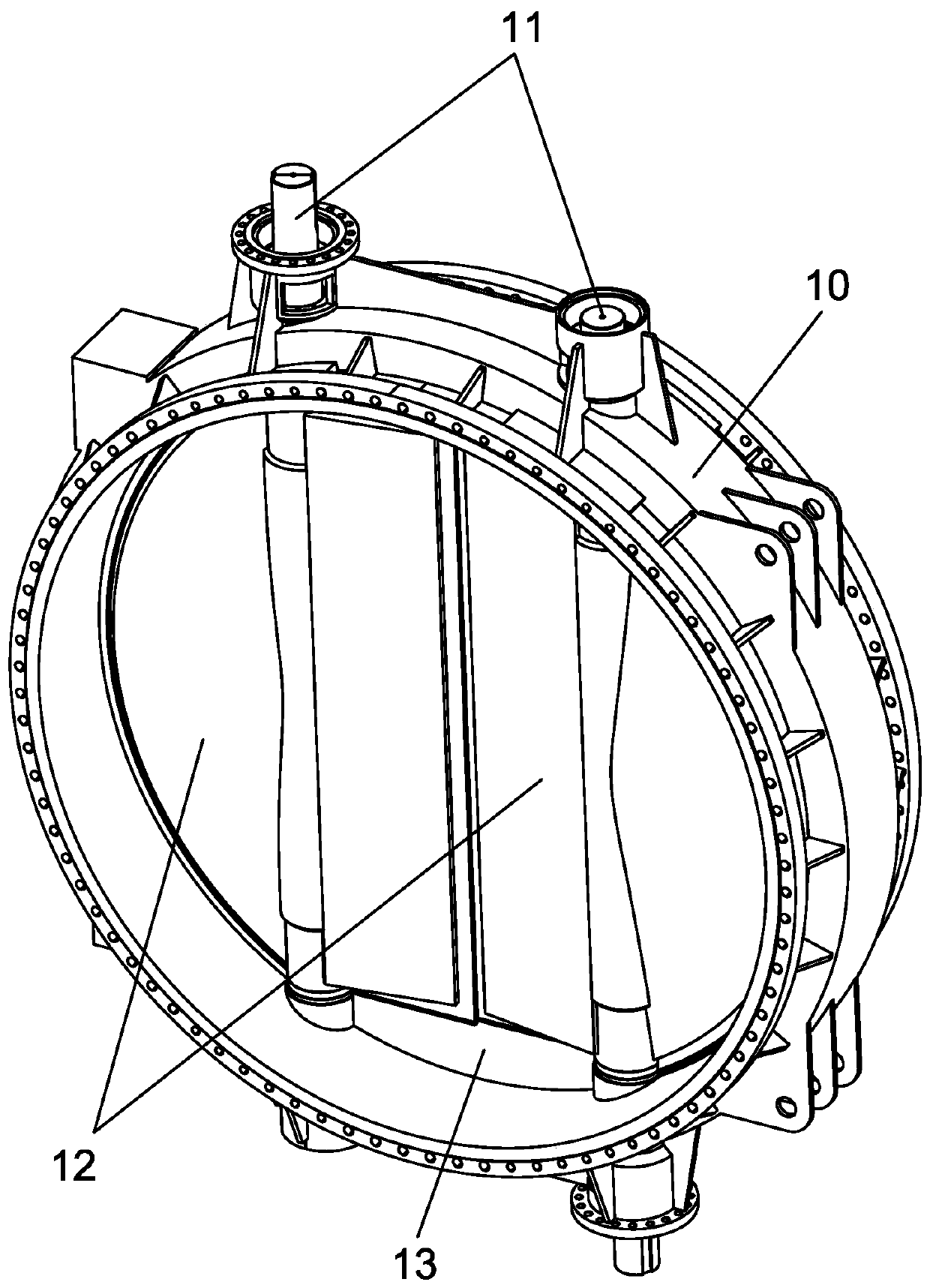

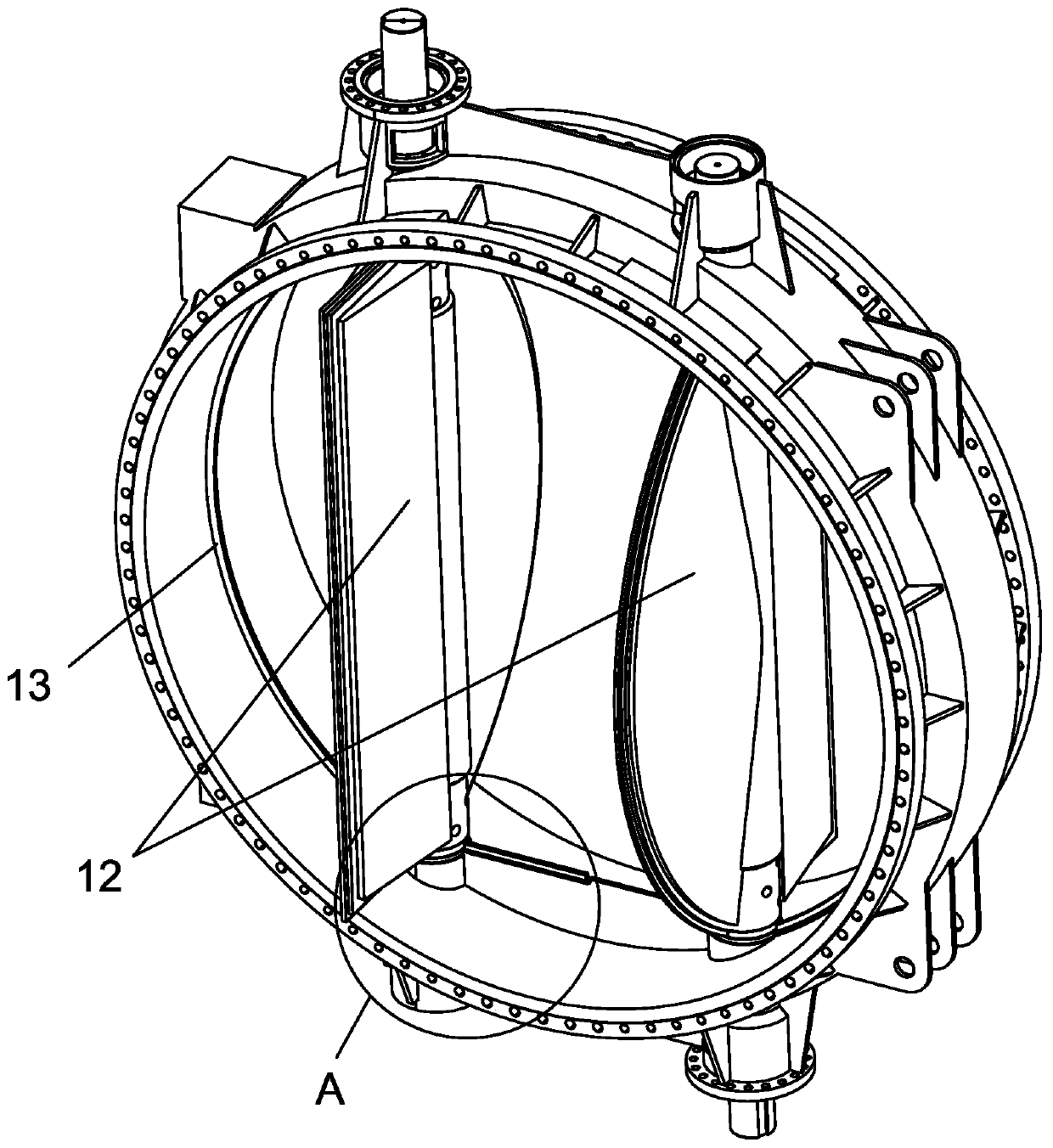

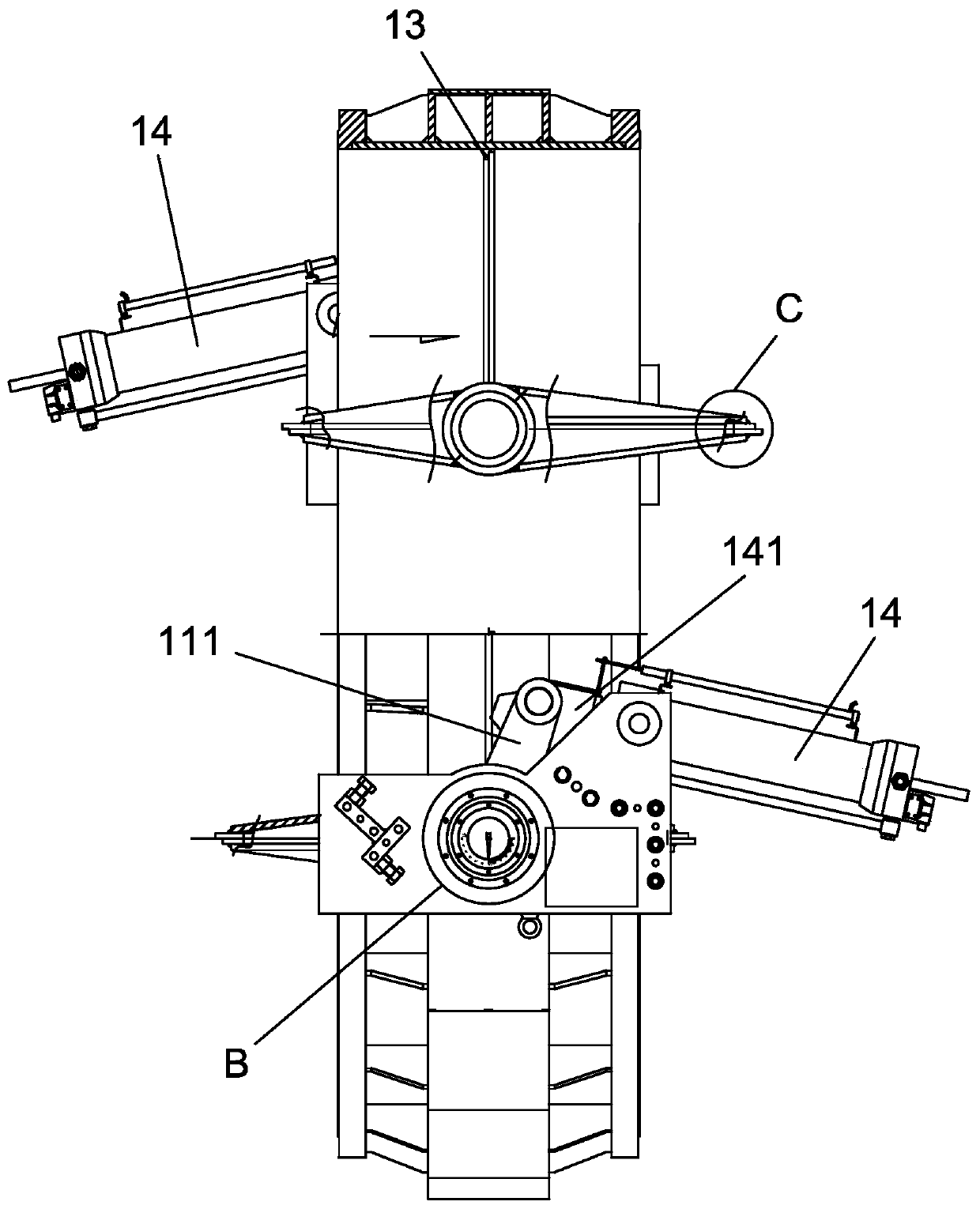

[0038] refer to Figure 1 to Figure 7 ,Such as Figure 1 to Figure 7 The shown metal-sealed double-plate hydraulic regulating butterfly valve includes a valve body 10, the valve body 10 is ring-shaped, and two symmetrically arranged valves are arranged on the cross-sectional surface of the valve body 10 and on both sides of its midline. Rod 11, the valve stem 11 is provided with a disc 12, the disc 12 is in the shape of "D", the valve body 10 is provided with a valve seat 13 on the inner cylindrical wall, and the two discs 12 rotate on the valve stem 11 When the control disc 12 is in contact with the valve seat 13, the sides of the two discs 12 facing the centerline of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com