Patents

Literature

136results about How to "Increase bearing pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

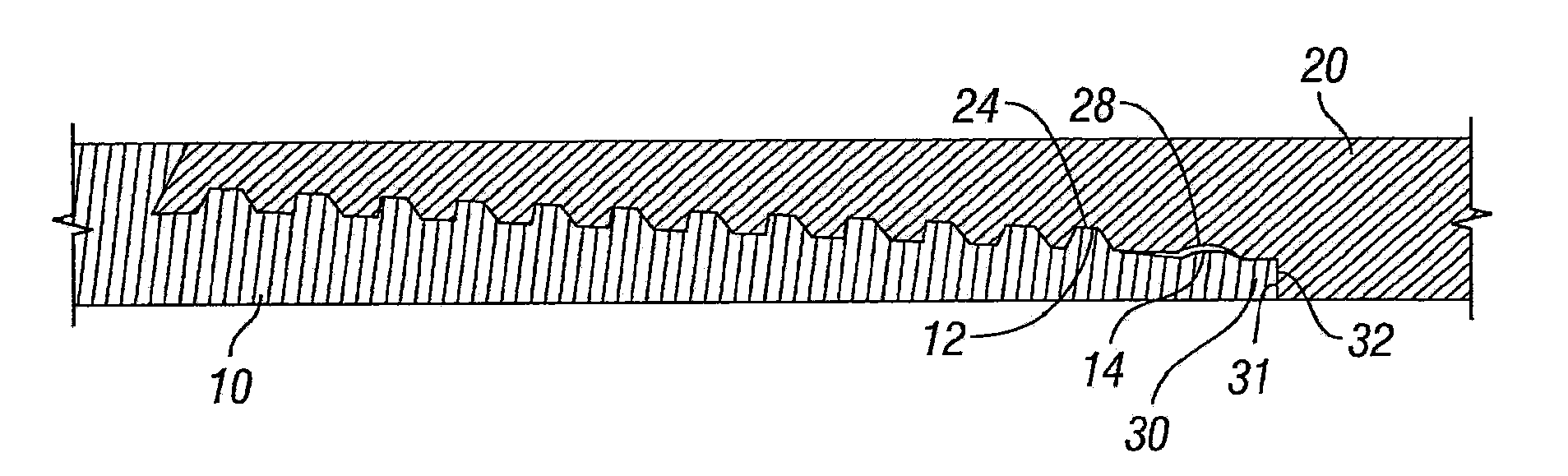

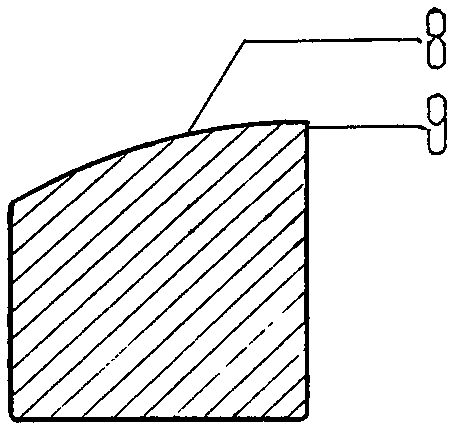

Reverse sliding seal for expandable tubular connections

InactiveUS20070035130A1High bearing pressure sealPrevent retractionDrilling rodsJoints with sealing surfacesInternal pressureEngineering

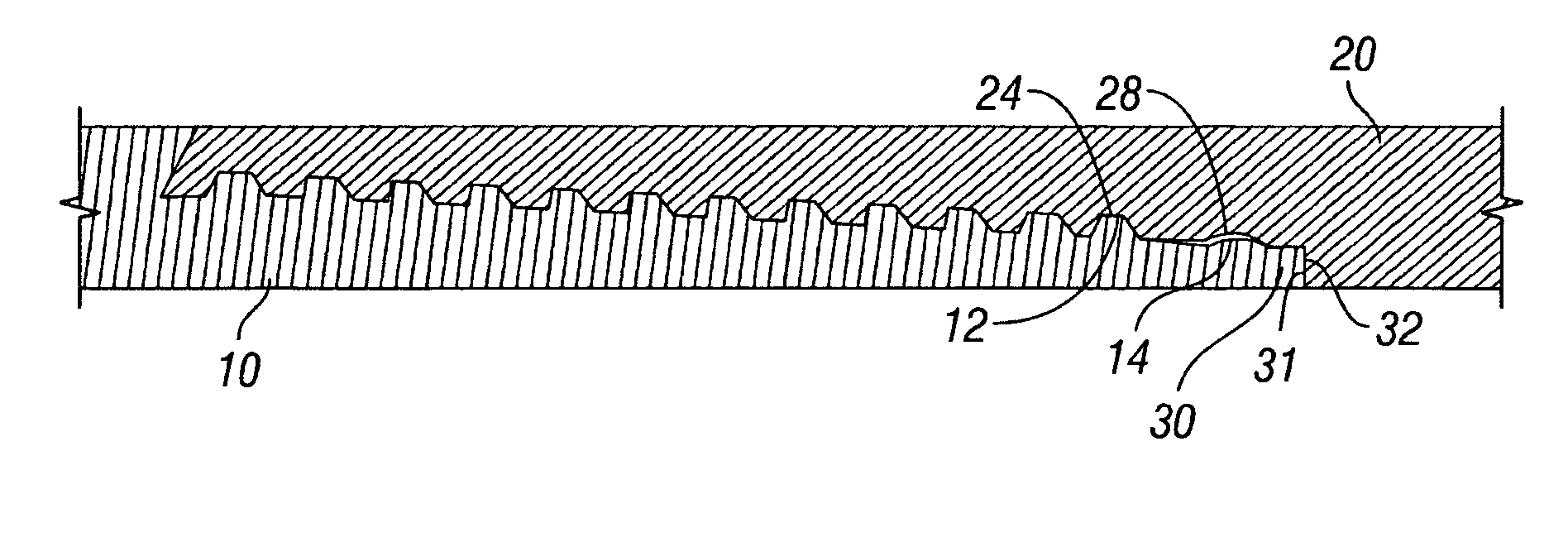

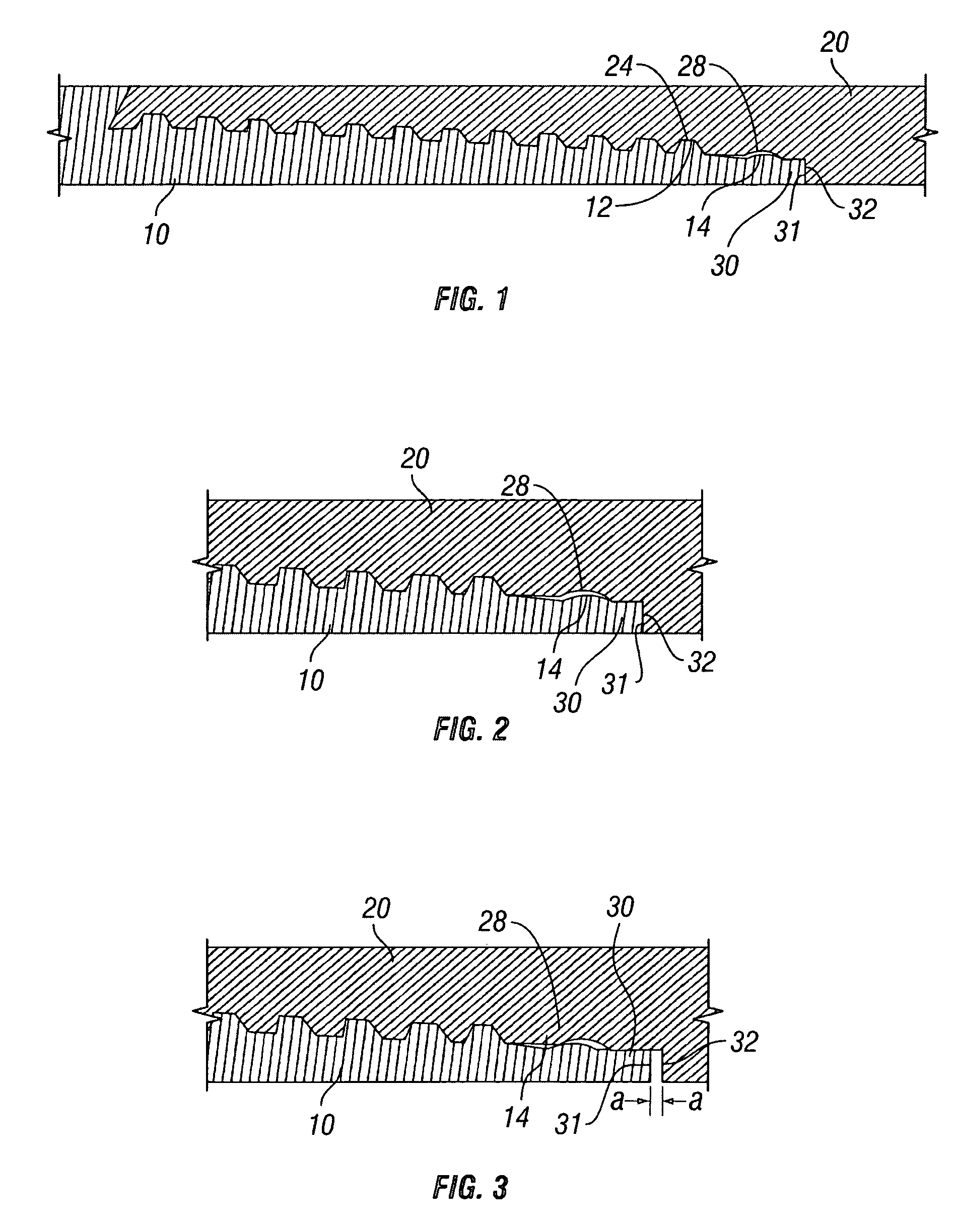

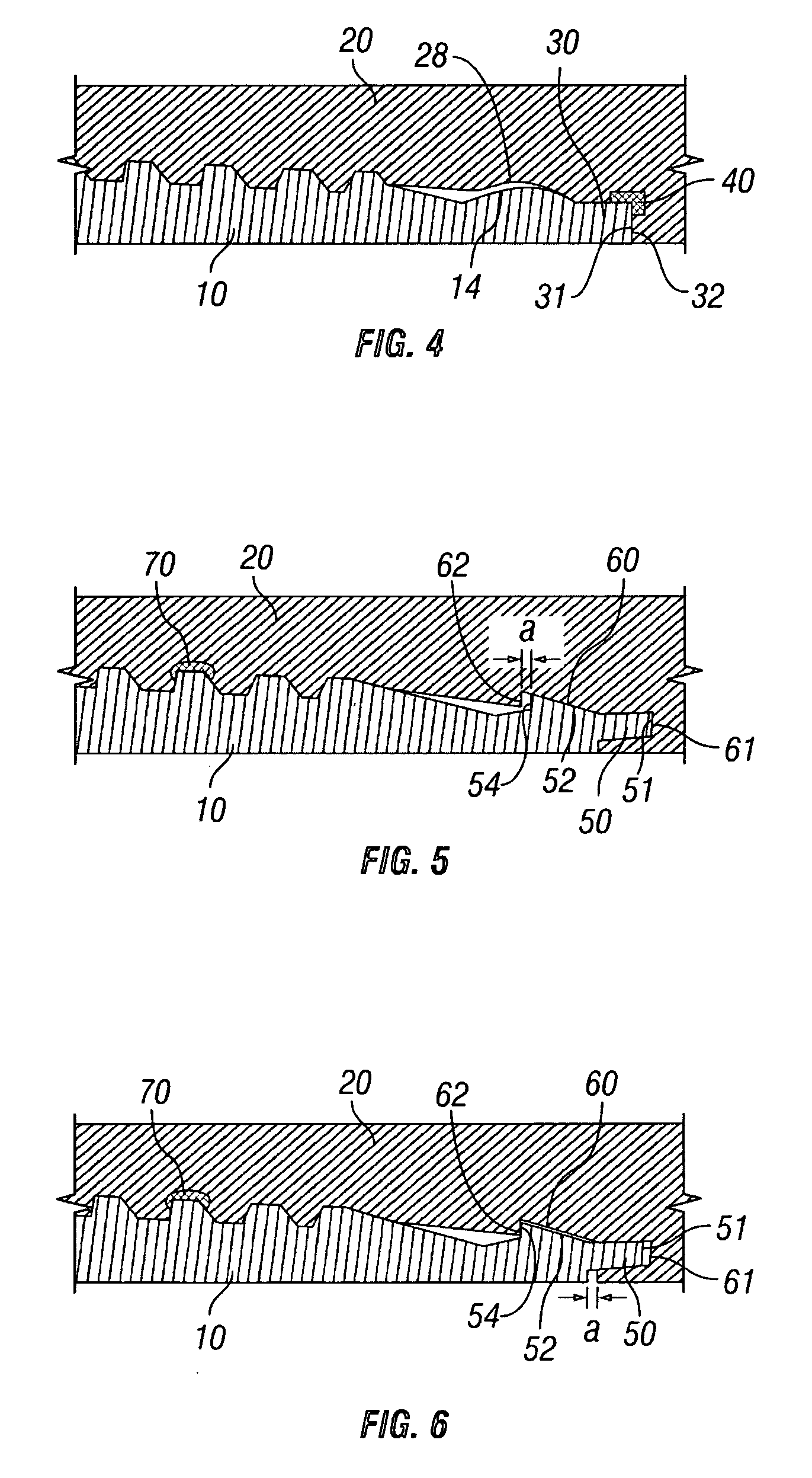

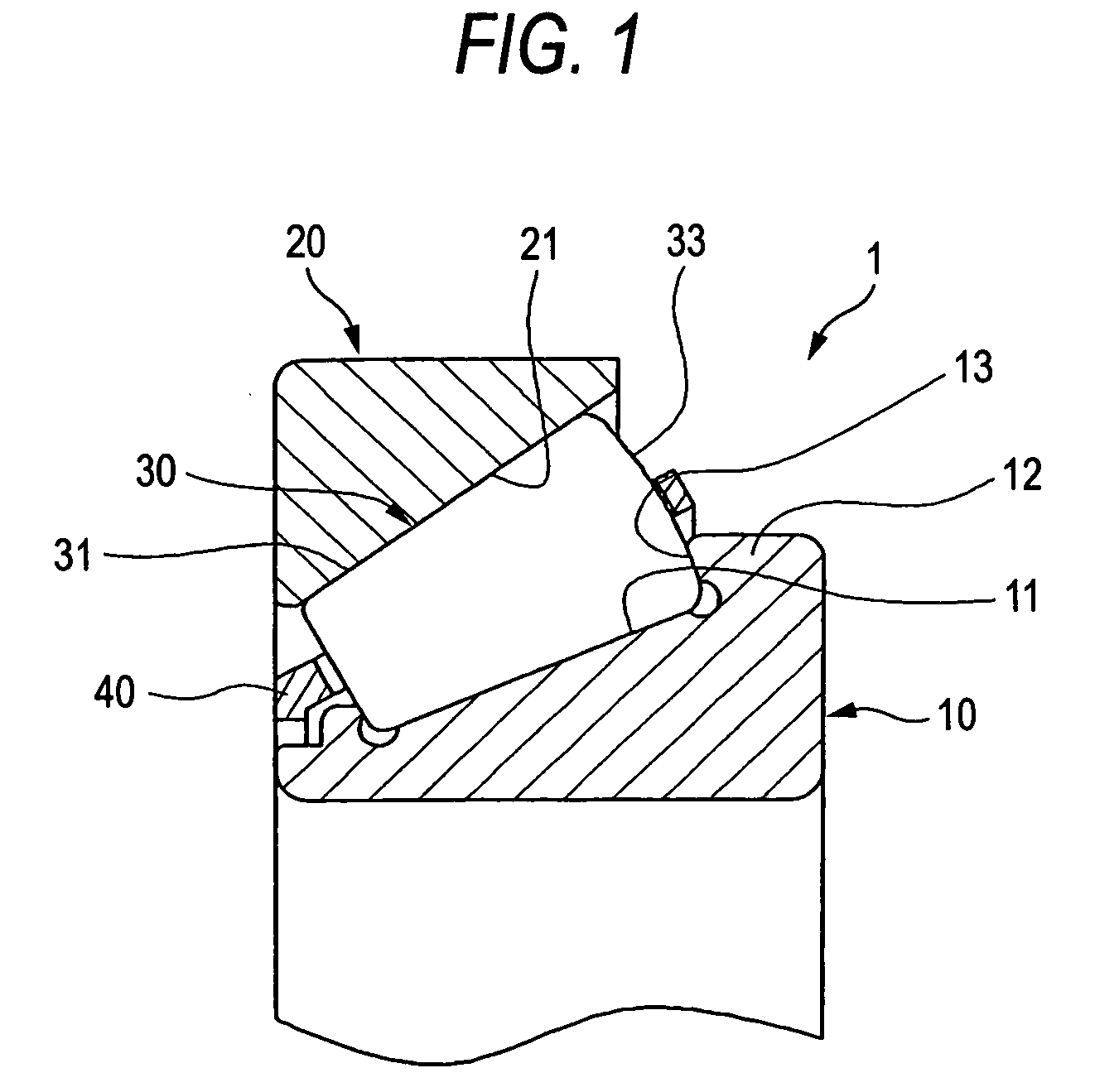

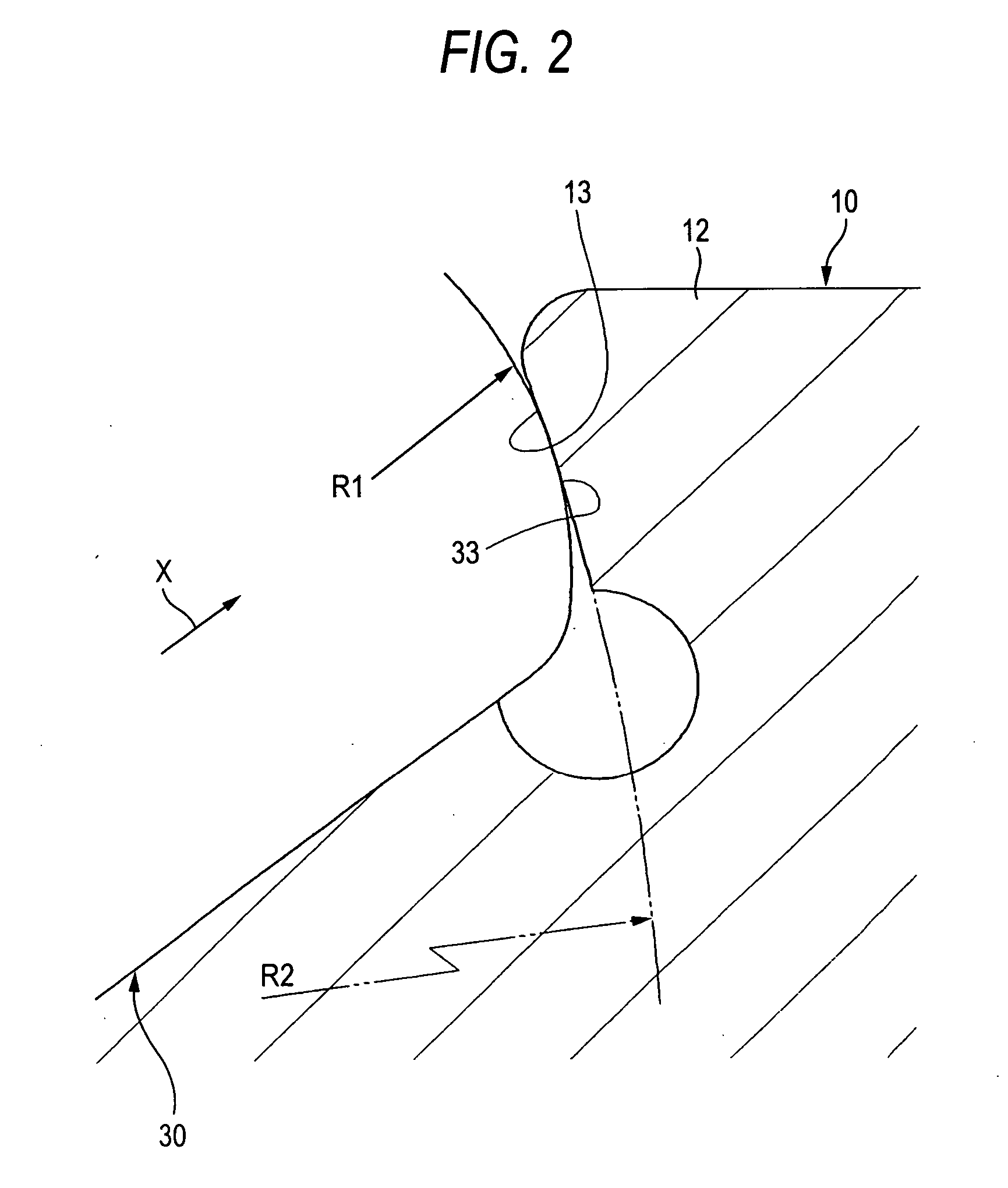

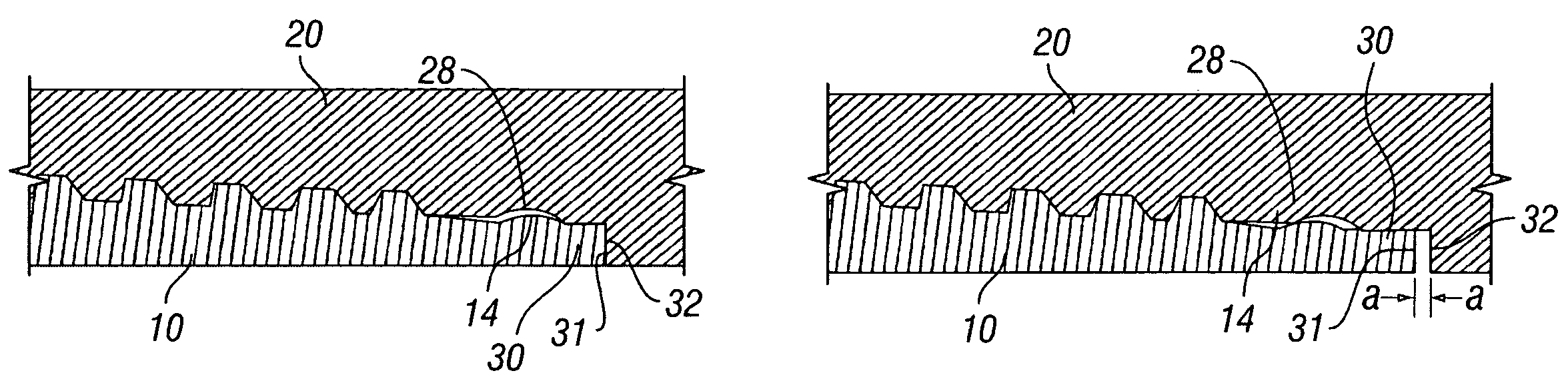

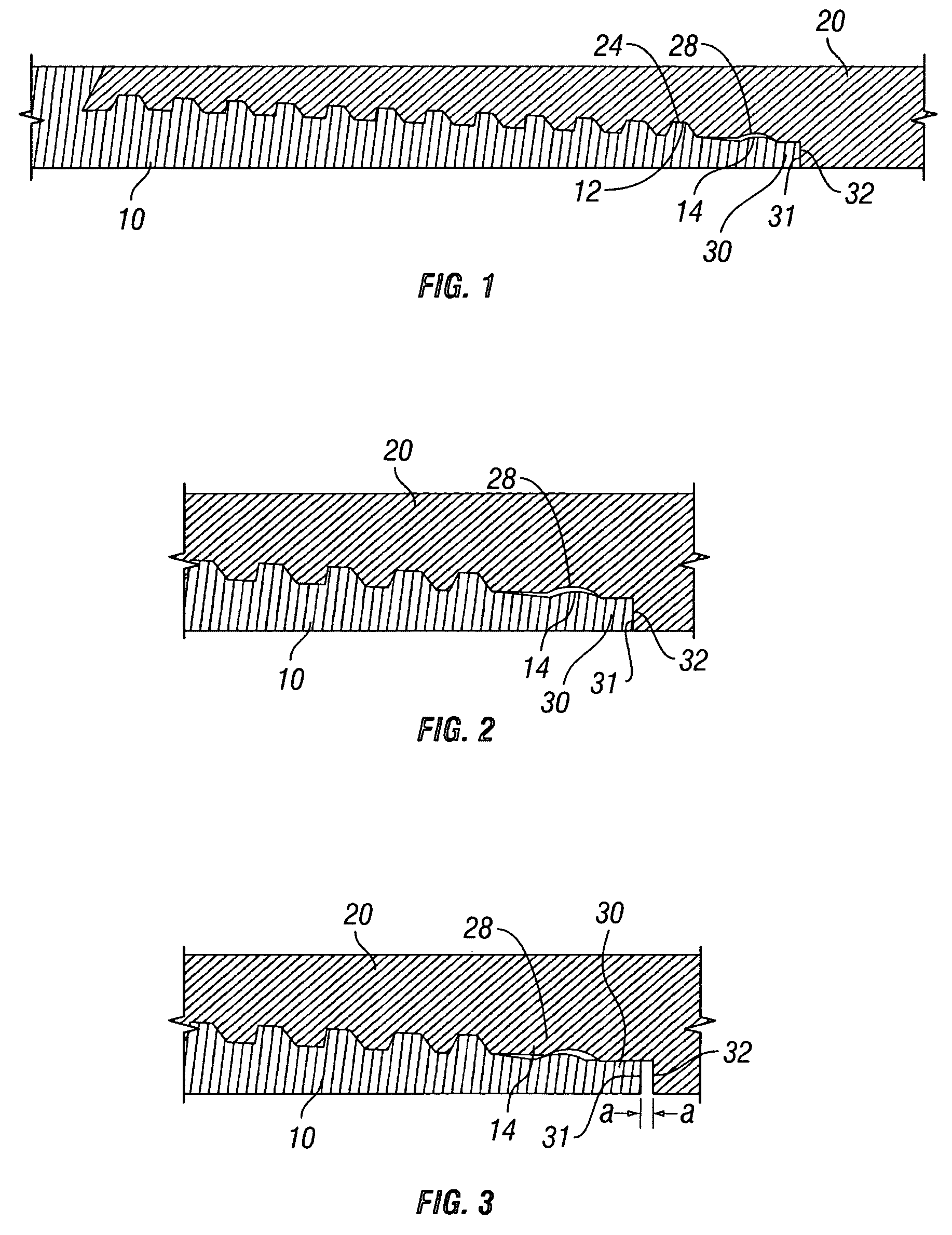

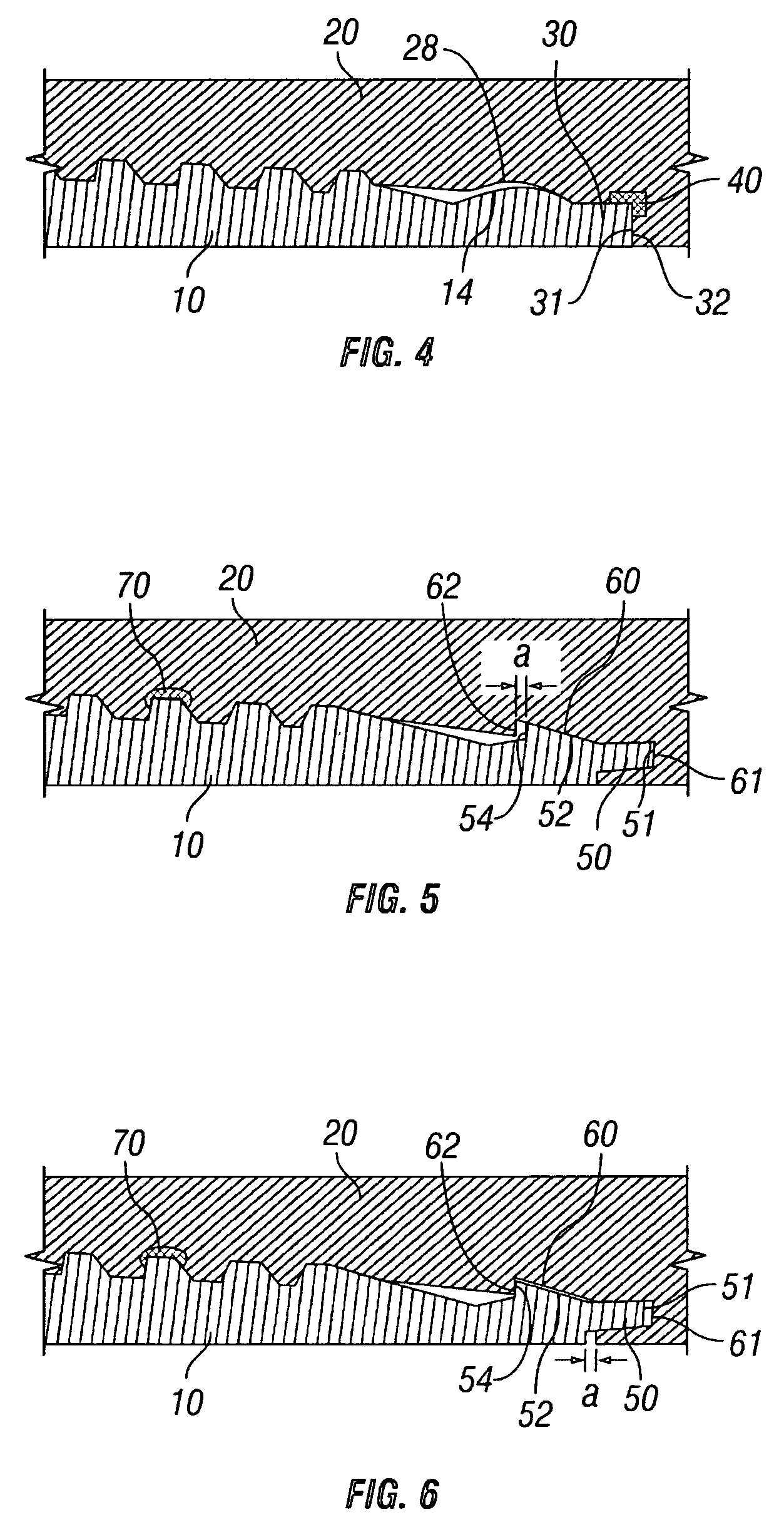

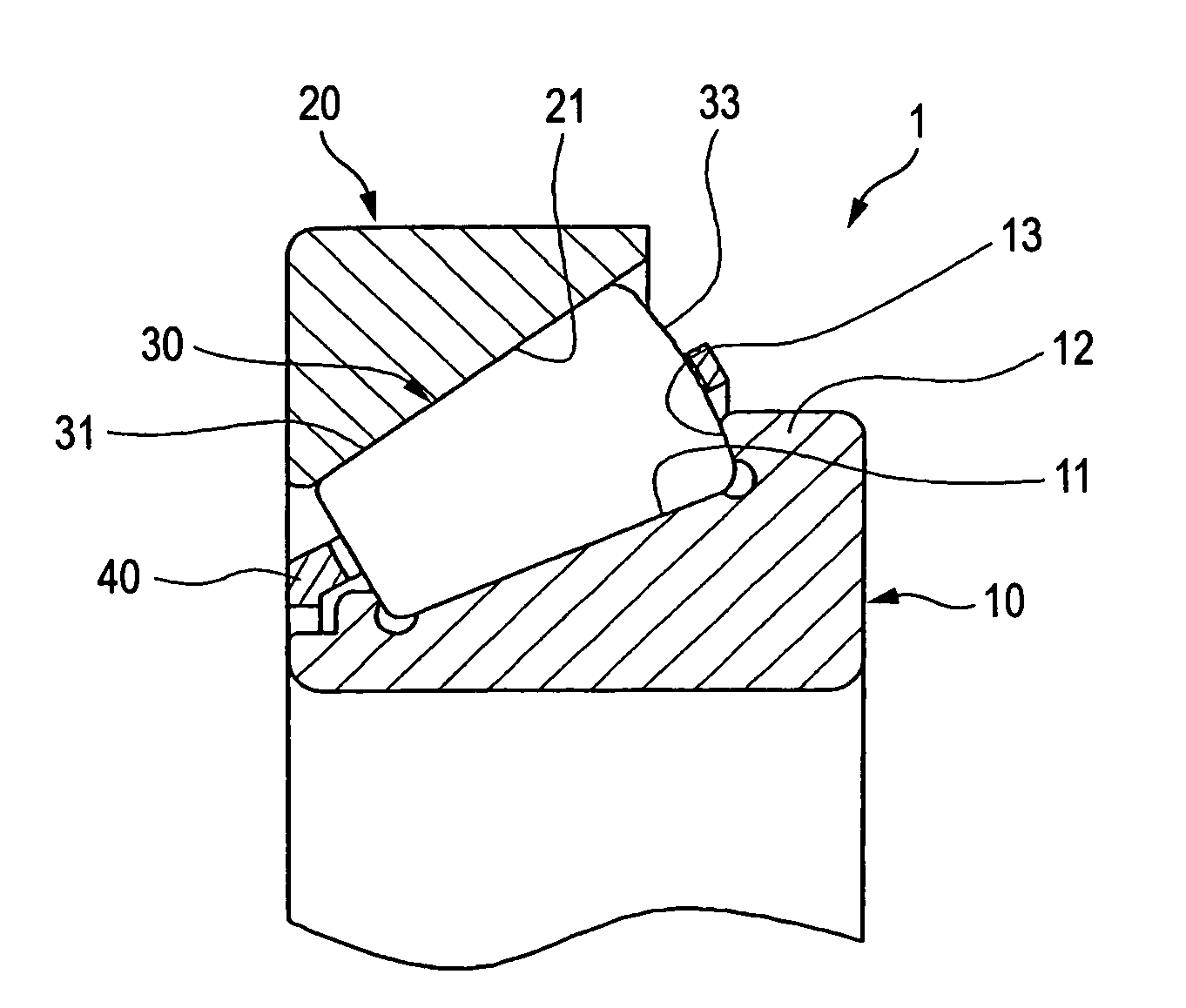

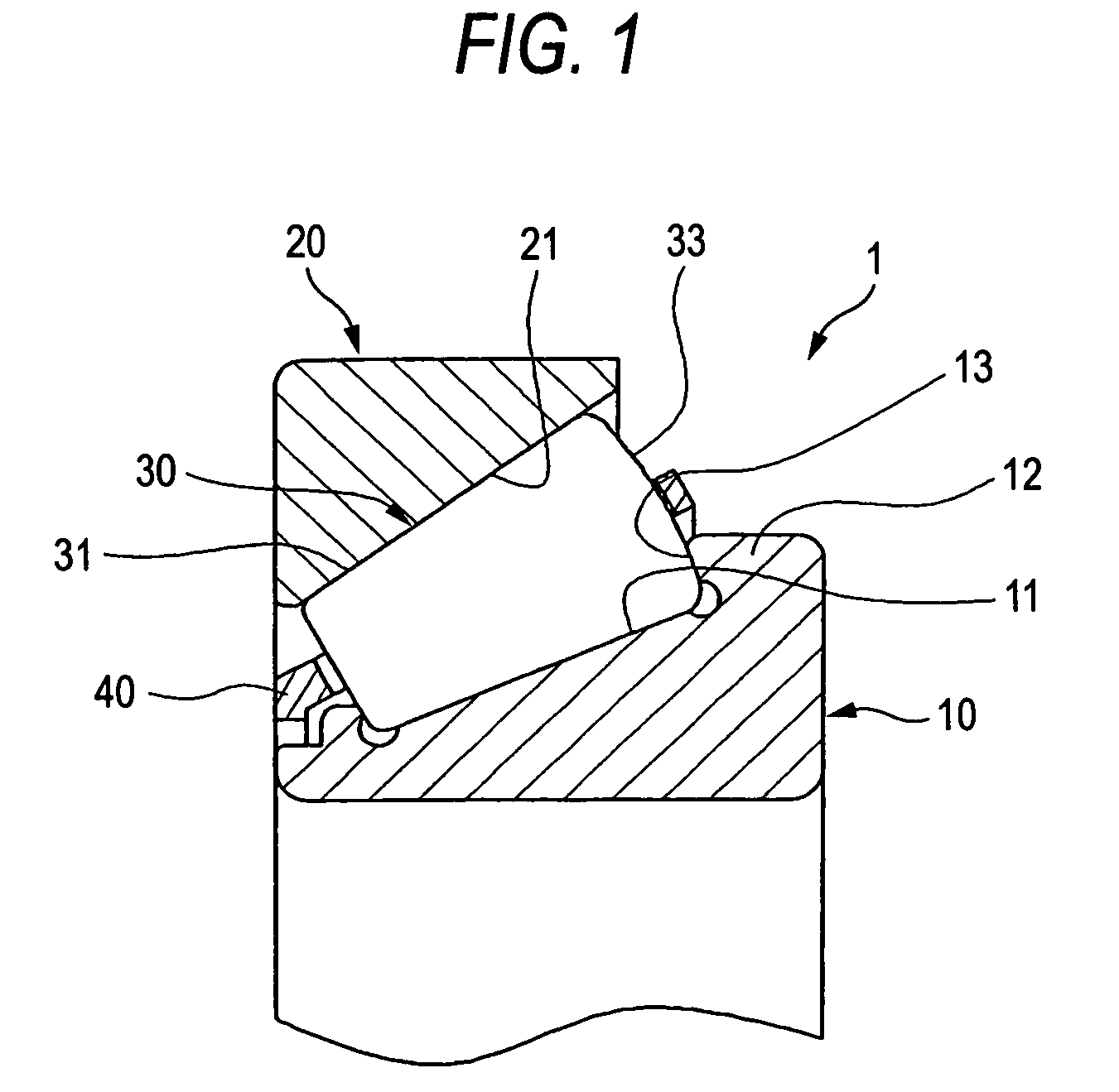

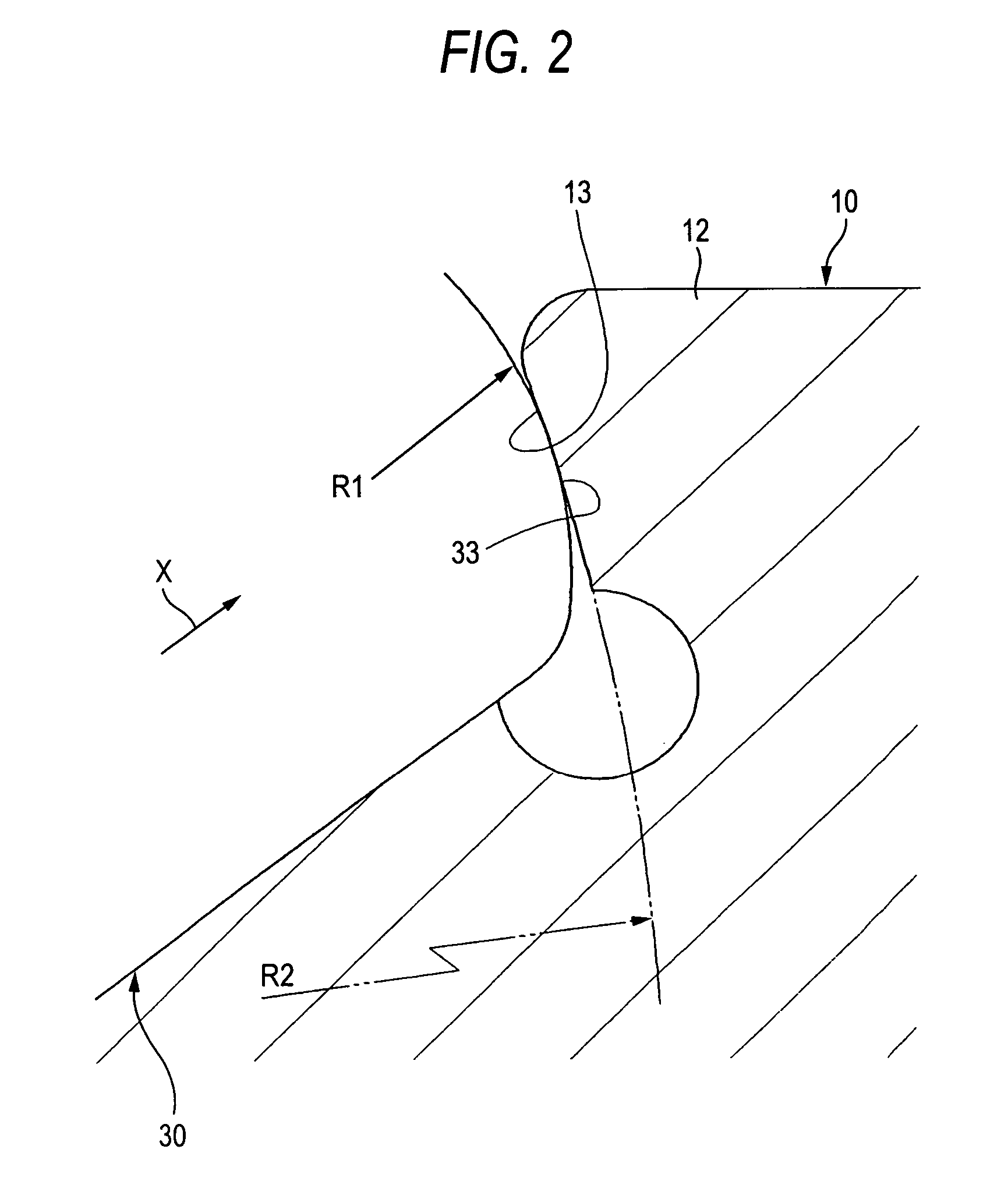

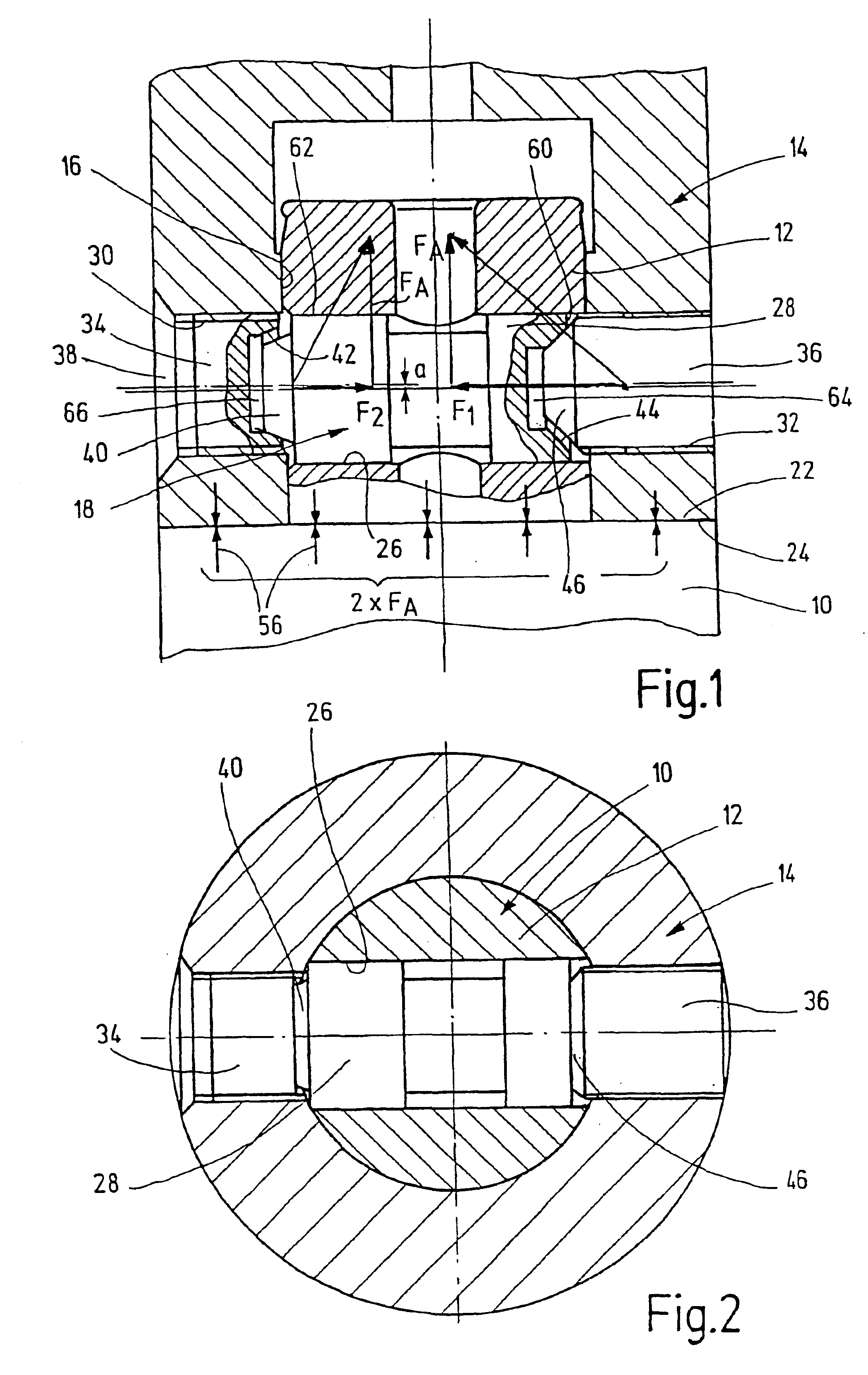

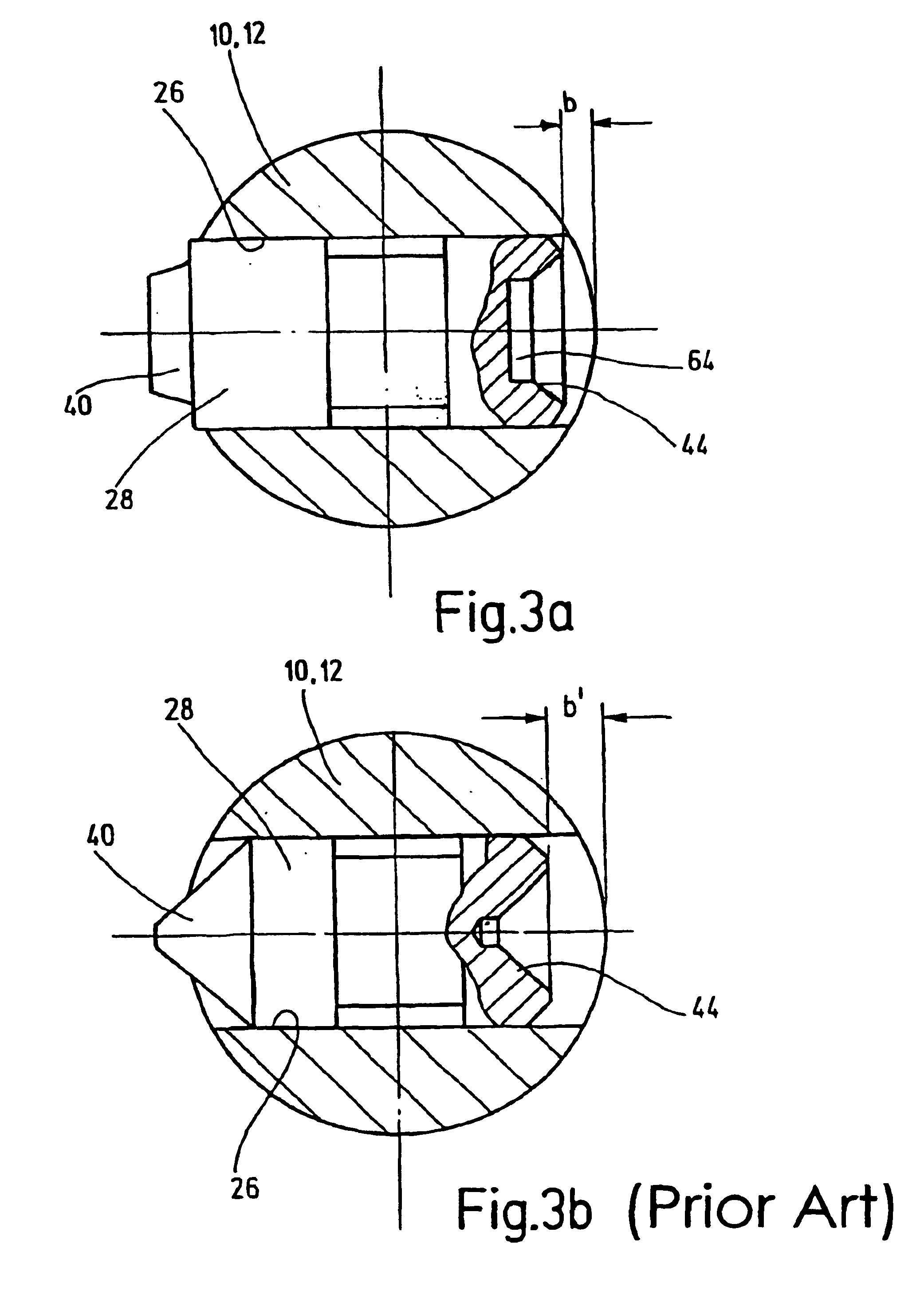

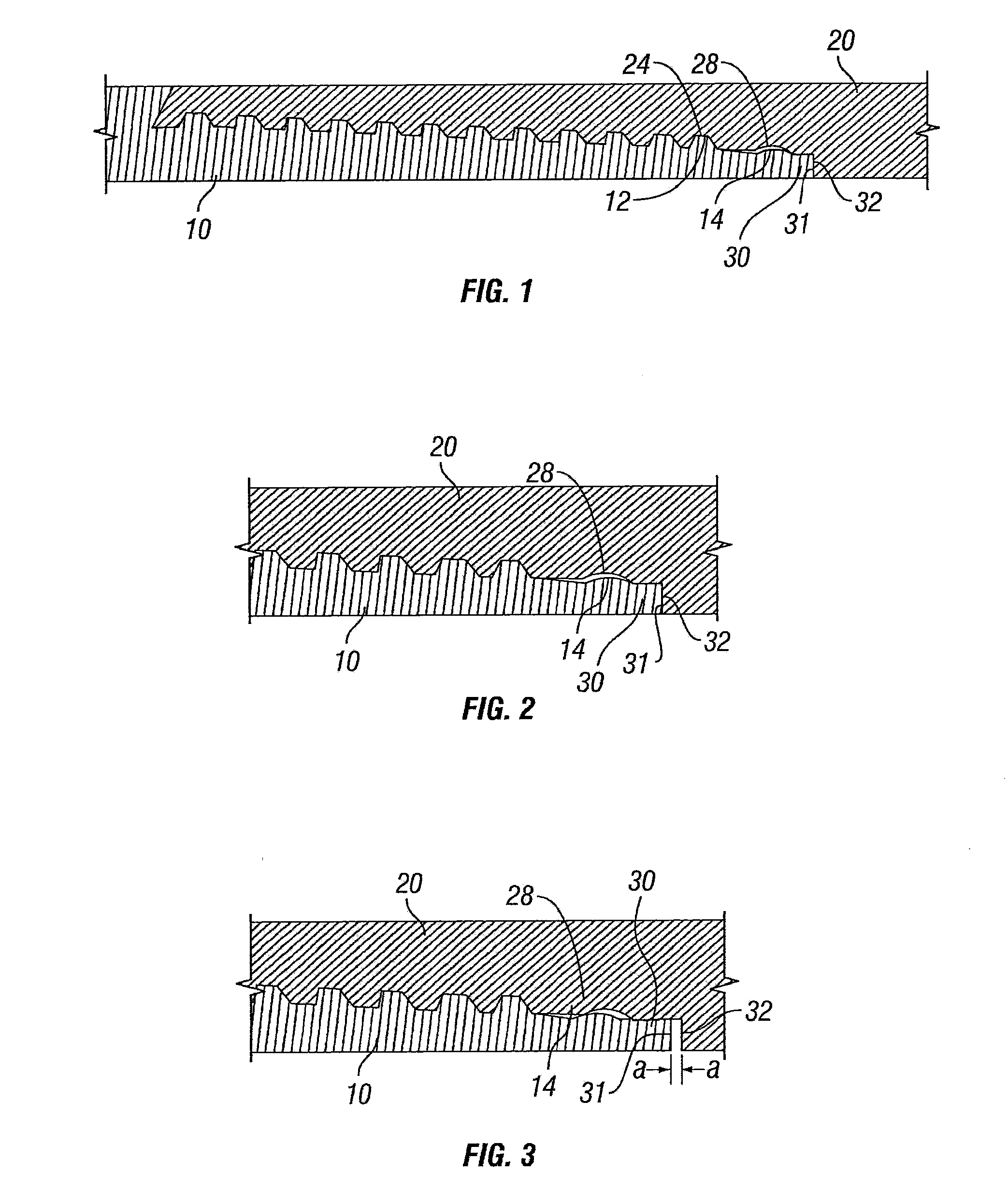

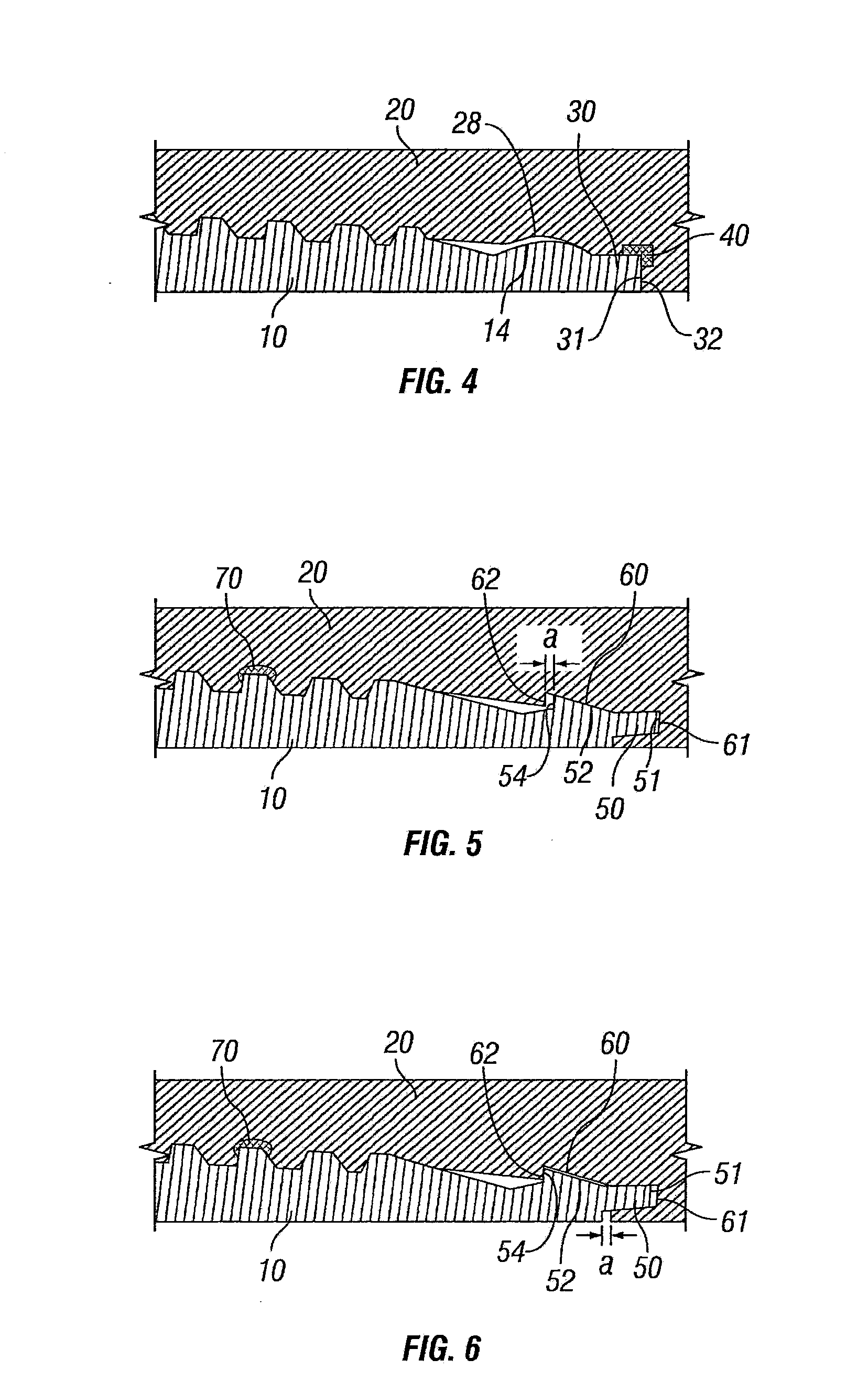

An expandable threaded connection between segments of expandable tubulars that provides a high bearing pressure seal at a specific area along the pin and box members is disclosed. The invention utilizes a “groove” in a surface of the box member and a corresponding “rib” on the pin nose. The radial expansion of the tubulars causes the pin to become shorter in length, thereby causing the pin nose to retract from the back of the box member. As the pin nose retracts, the rib on the pin nose moves backward until a portion of the rib contacts a portion of the groove in the box member. The point of contact between the rib and the groove creates a metal-to-metal seal between the pin and box members. Because the point of contact between the rib and the groove is a relatively small area, the force acting on the point of contact generates a high bearing pressure that is equal to or greater than the internal pressure within the expandable tubulars and, thus, generates a high pressure seal.

Owner:WEATHERFORD TECH HLDG LLC

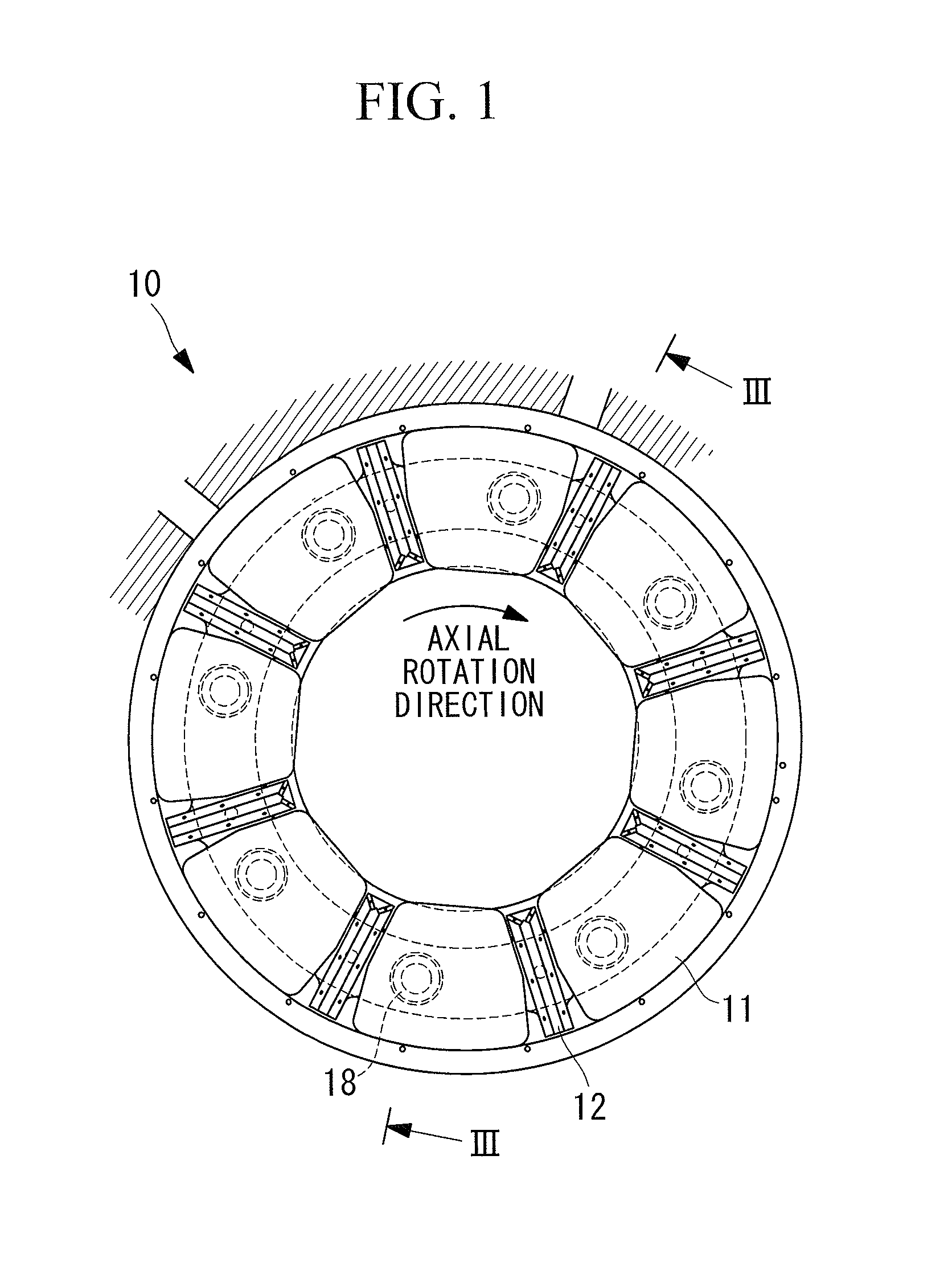

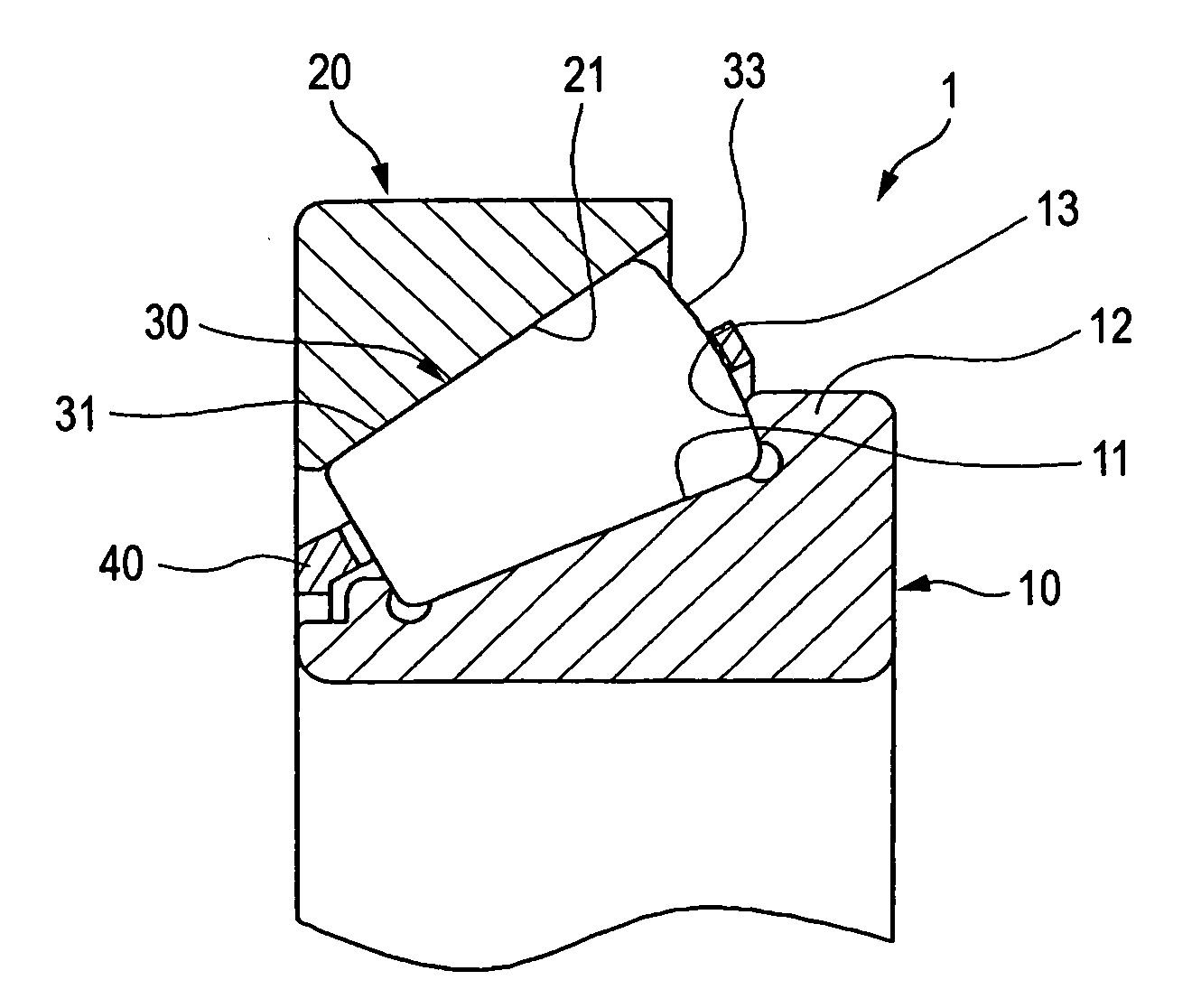

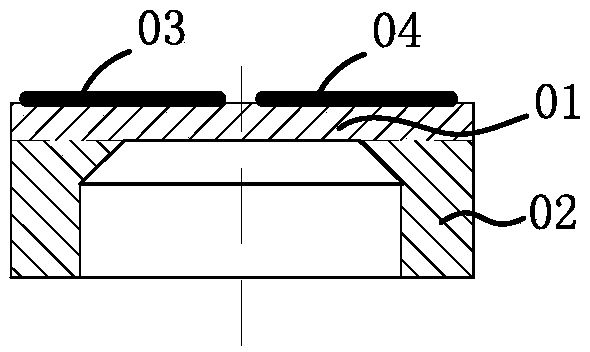

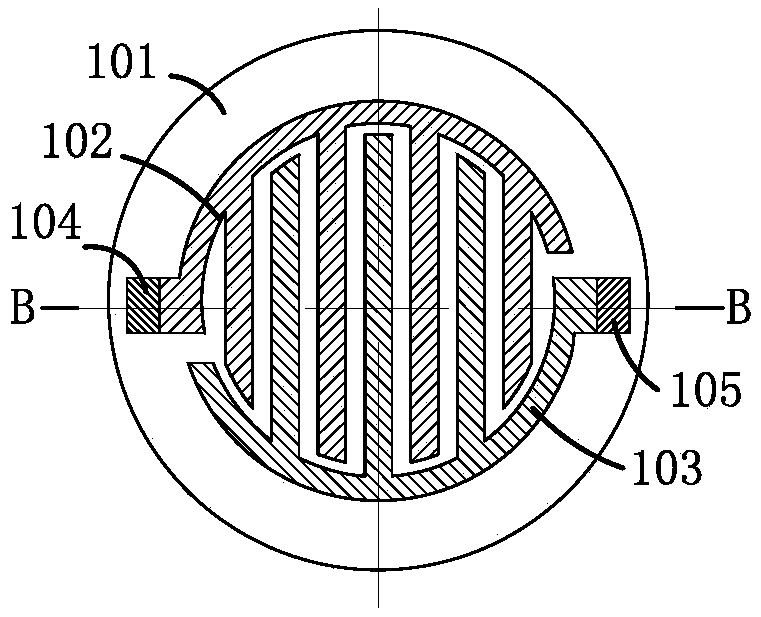

Oiling nozzle for thrust bearing

ActiveUS20100215299A1Efficiently supplySuppress increase in metal temperatureEngine manufactureBearing assemblyNozzleGasket

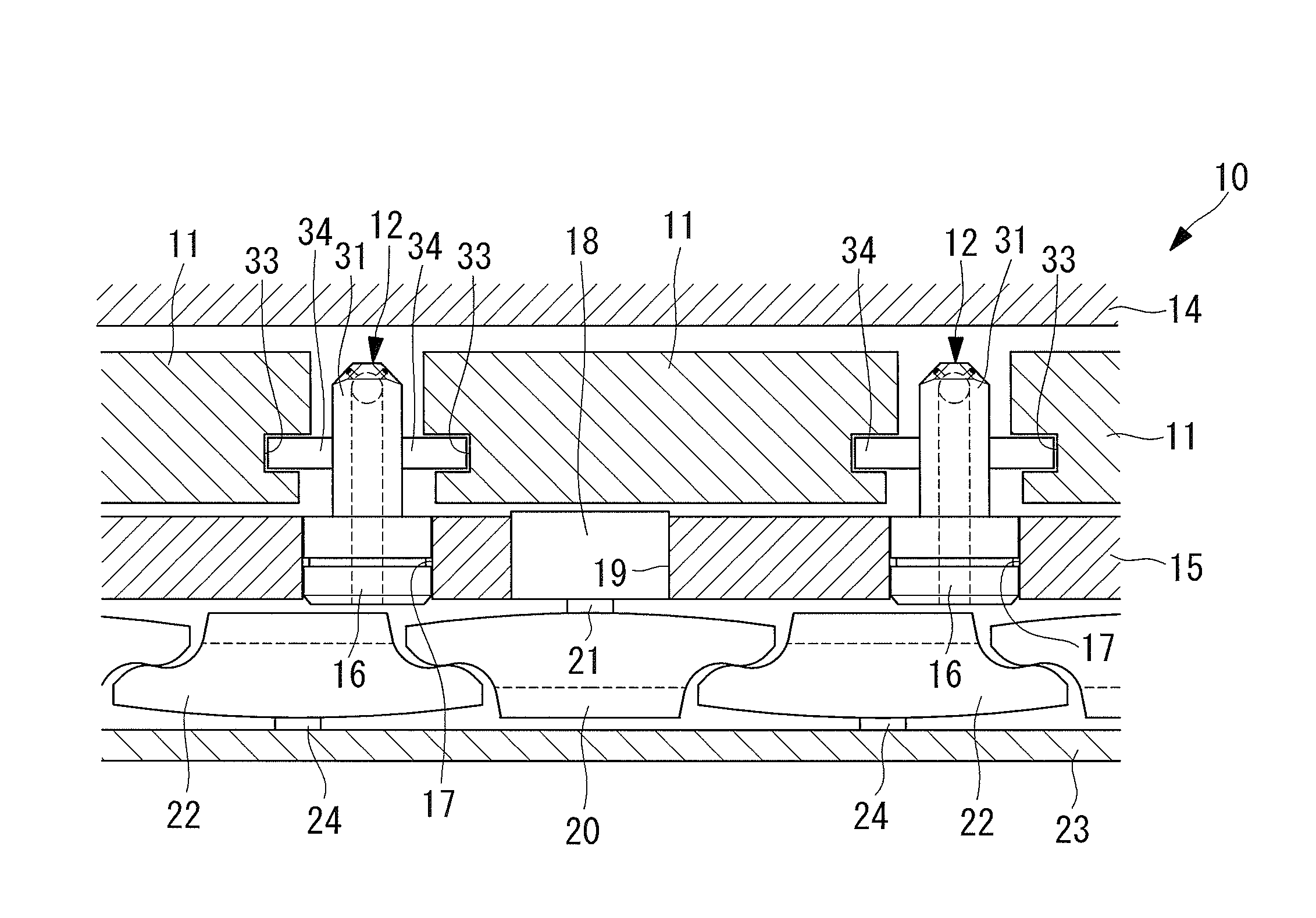

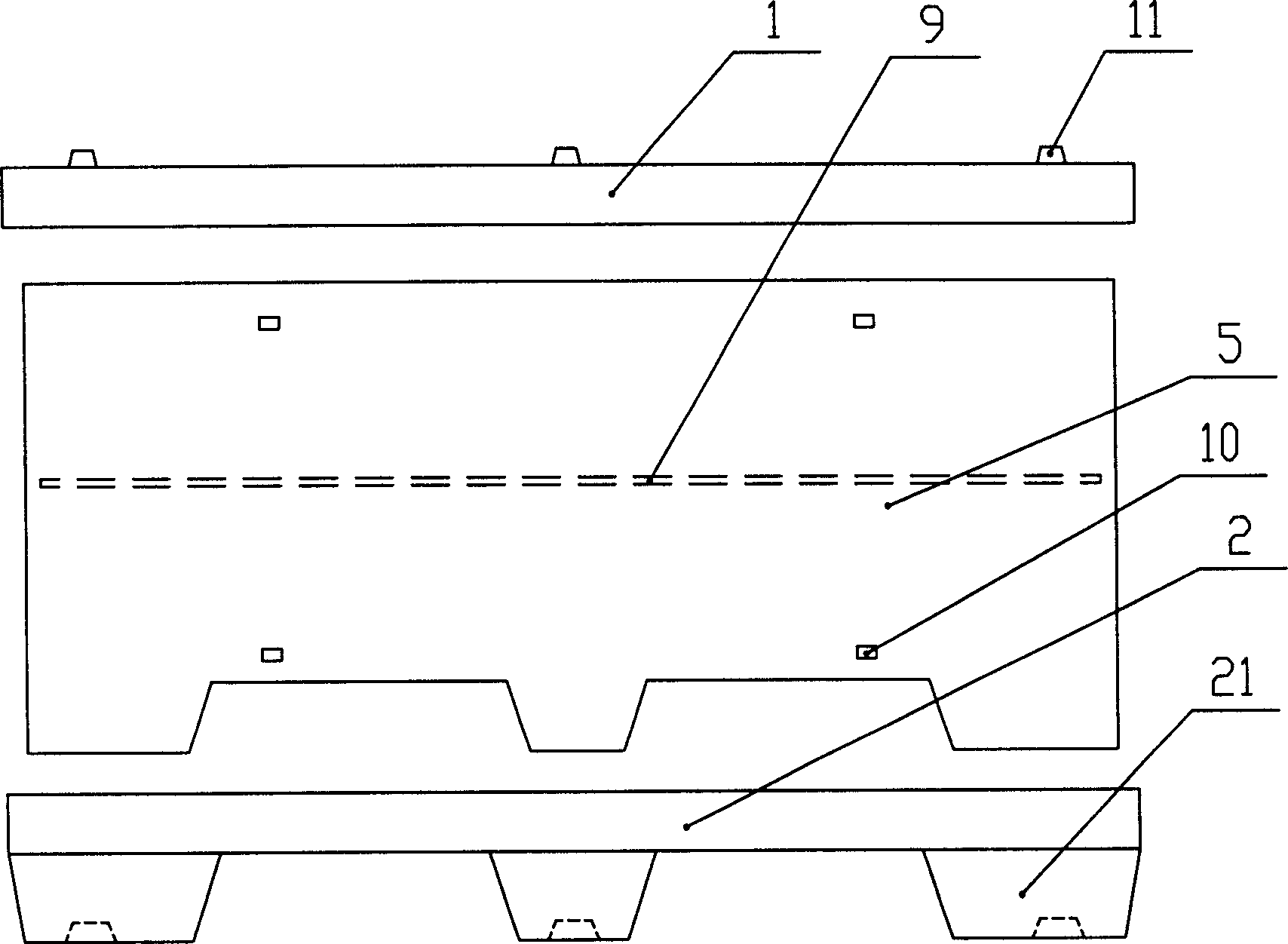

Provided is an oiling nozzle for a thrust bearing, capable of improving the following capability of pads, and achieving a higher bearing pressure of the thrust bearing. An oiling nozzle which is for use in a thrust bearing and is respectively arranged between pads disposed in positions facing the thrust surface of a thrust collar that protrudes radially outward from a rotor shaft, along the circumferential direction, wherein the oiling nozzle comprises: a cylindrical stem; and a rectangular-shaped mainframe whose heightwise middle portions of opposite lateral sides are provided with convex parts each presenting a semicircular disk shape in a plane view, to be fitted into concave parts that are formed in lateral sides of the pads, and whose top portion located on the side opposite to the stem is formed with a plurality of nozzle holes for ejecting lubricating oil that has been supplied from the bottom of the stem toward a space between the thrust collar and the pads.

Owner:MITSUBISHI HEAVY IND LTD

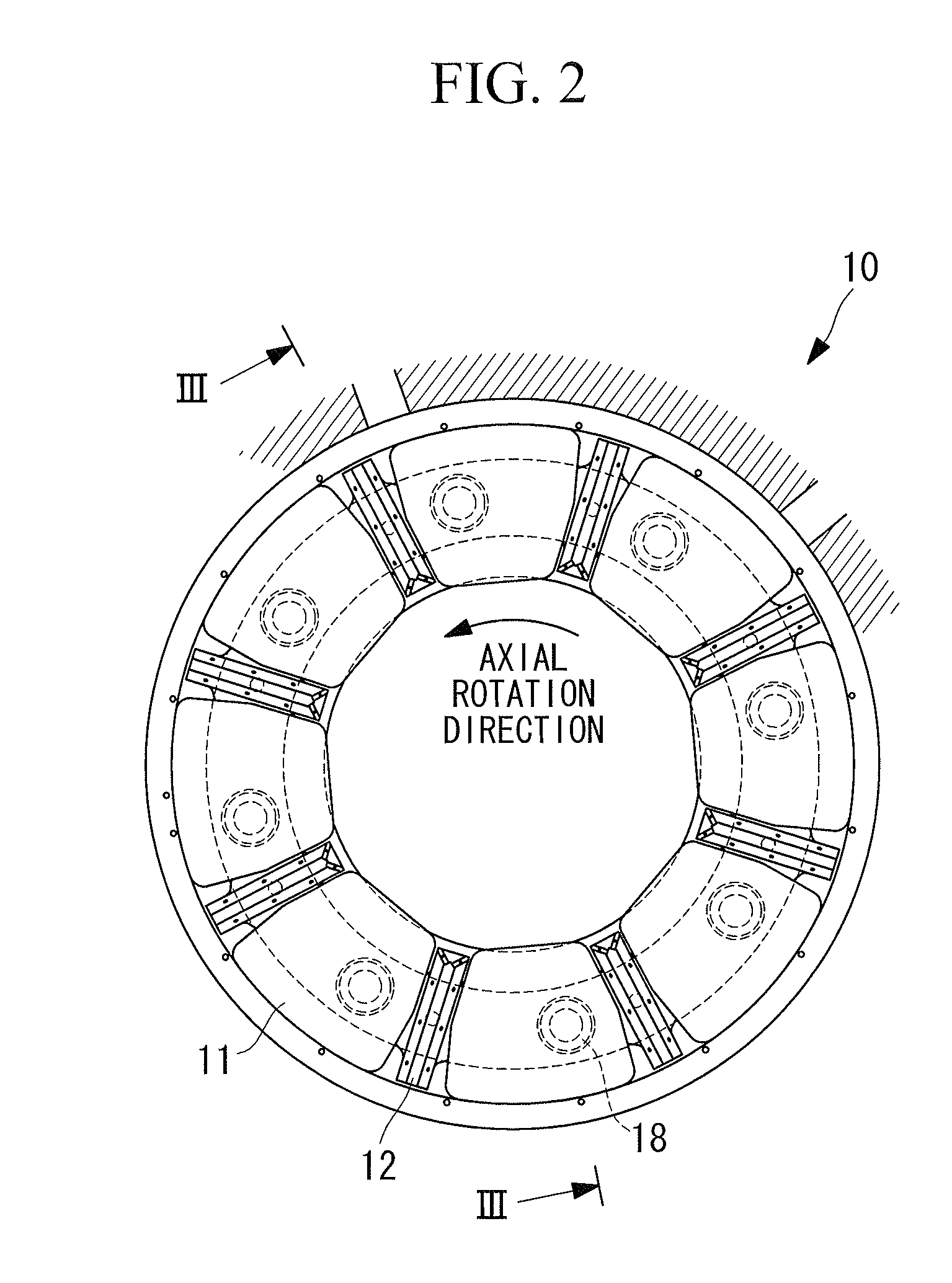

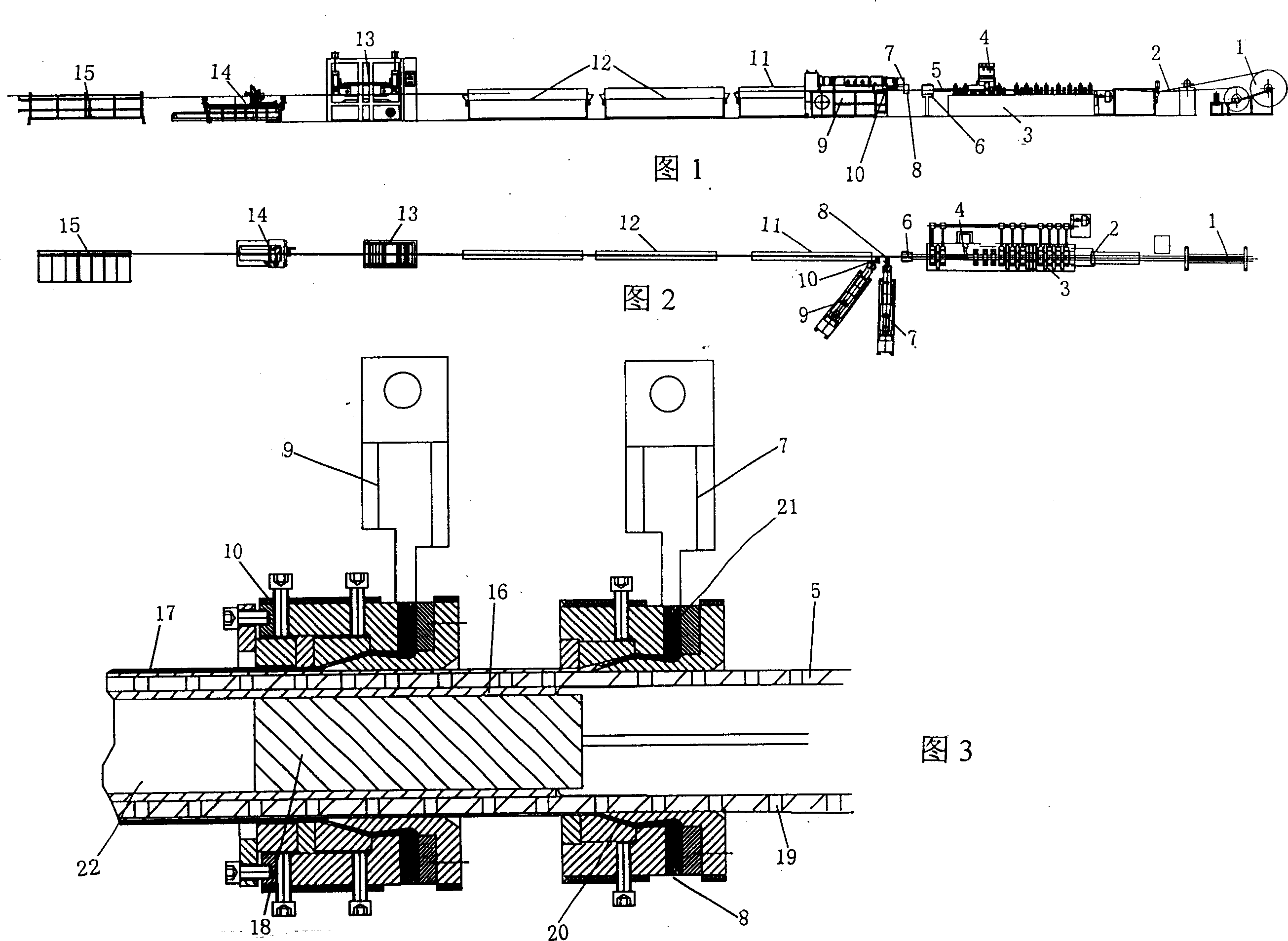

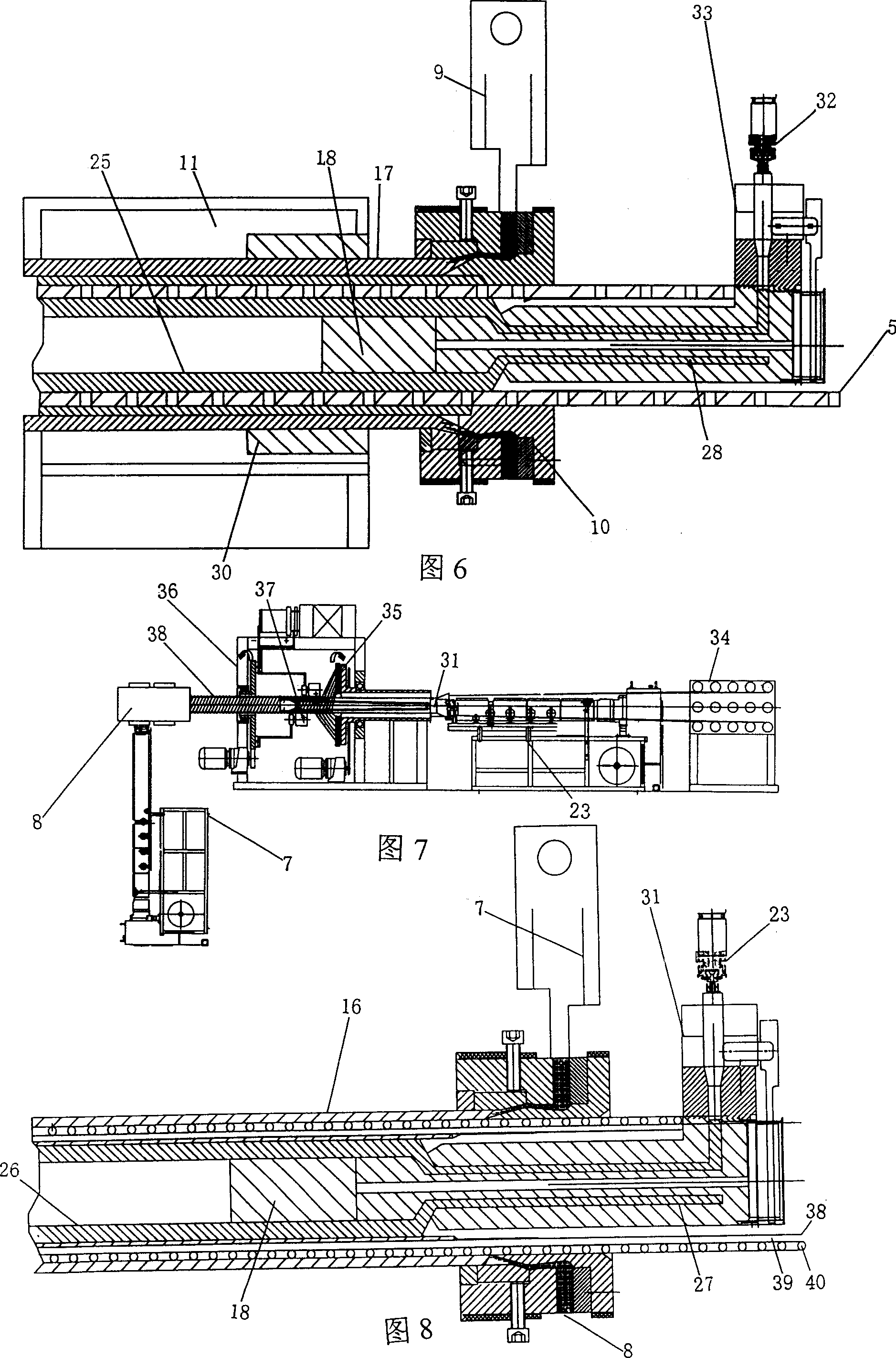

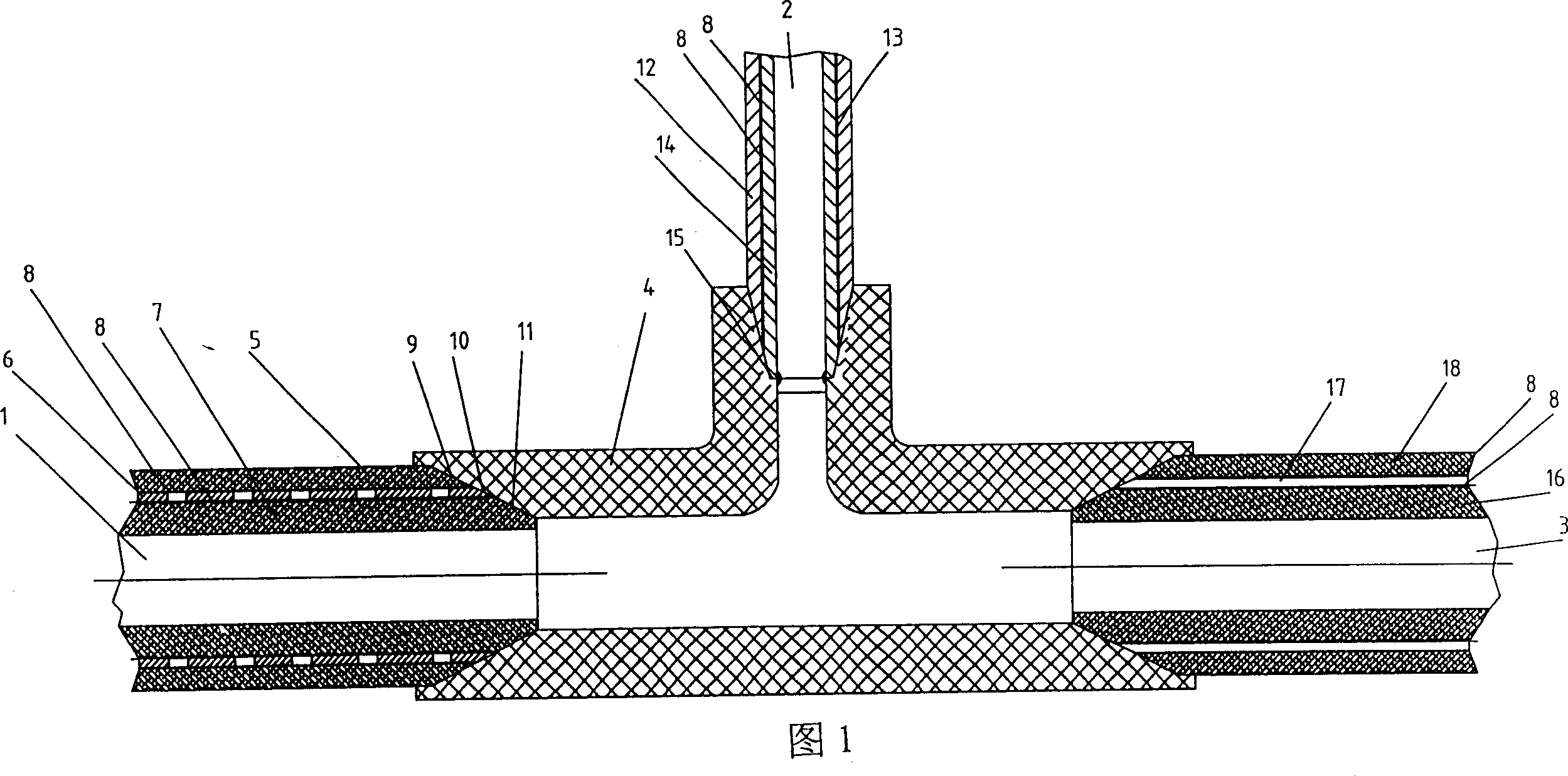

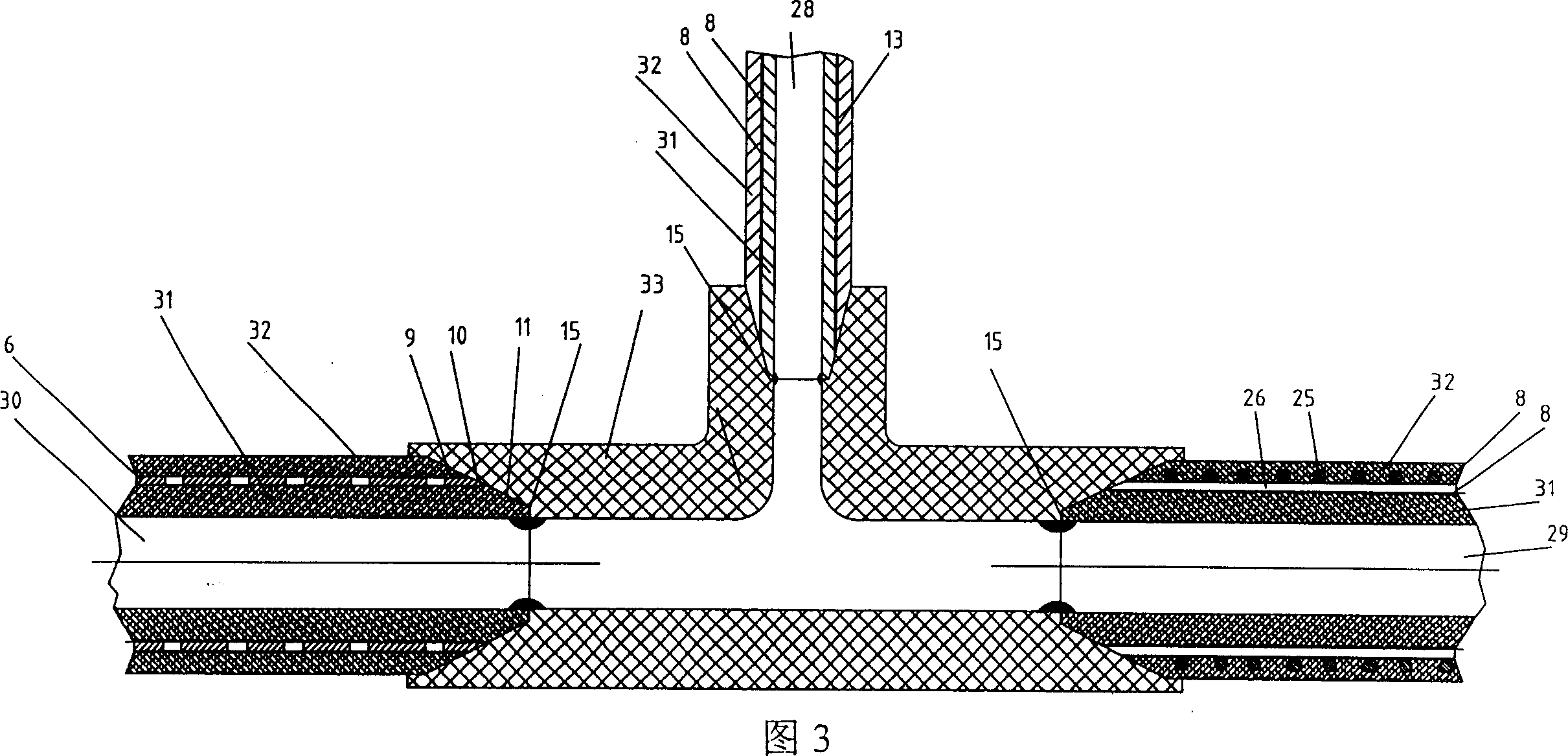

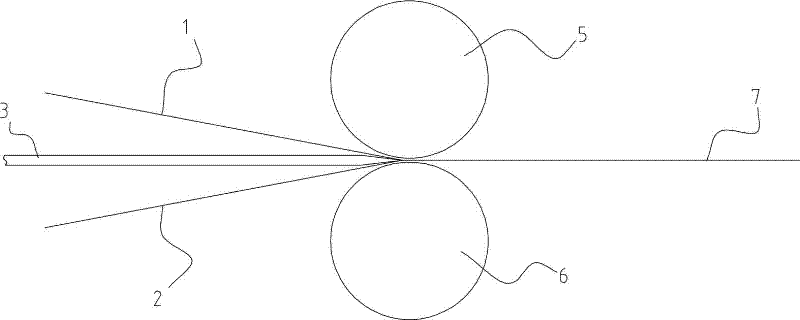

Method and equipment for producing steel-plastics composite tube with two layers of polymer layer

InactiveCN101003173AIncrease bearing pressureSolving Interface Affinity IssuesTubular articlesSheet steelSteel belt

A method for preparing the composite steel-plastics pipe with two polymer layers includes such steps as providing steel plate or steel band with holes, longitudinal curving or spiral rolling, welding to become a cylindrical metal skeleton, using an extruder to extrude out the fused polymer and make it to pass through the holes for wrapping the metal skeleton to form pipe wall, using another extruder to extrude out the fused polymer but make it not to pass through holes to form a polymer layer on formed pipe wall, and cooling. Its apparatus is also disclosed.

Owner:甘国工

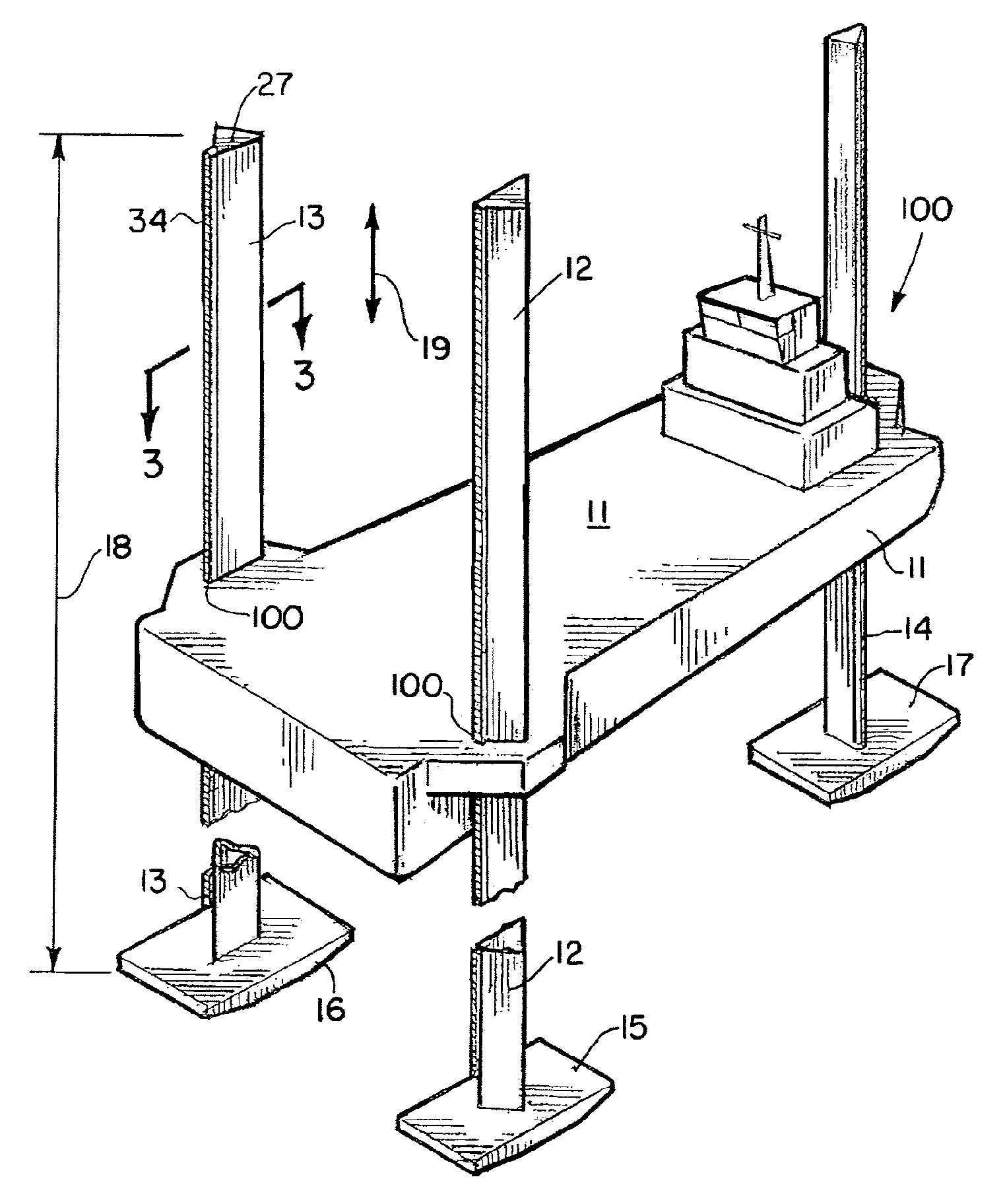

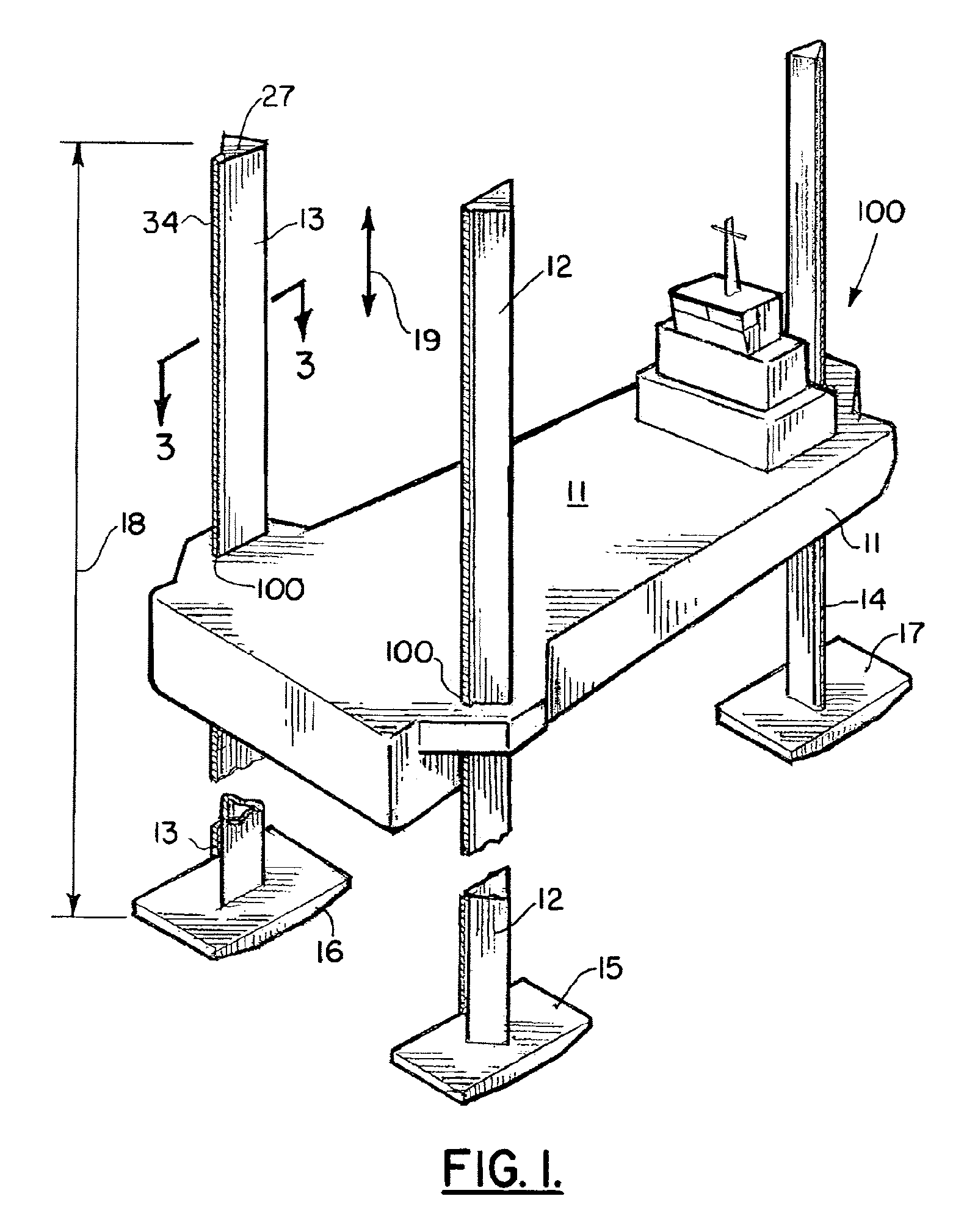

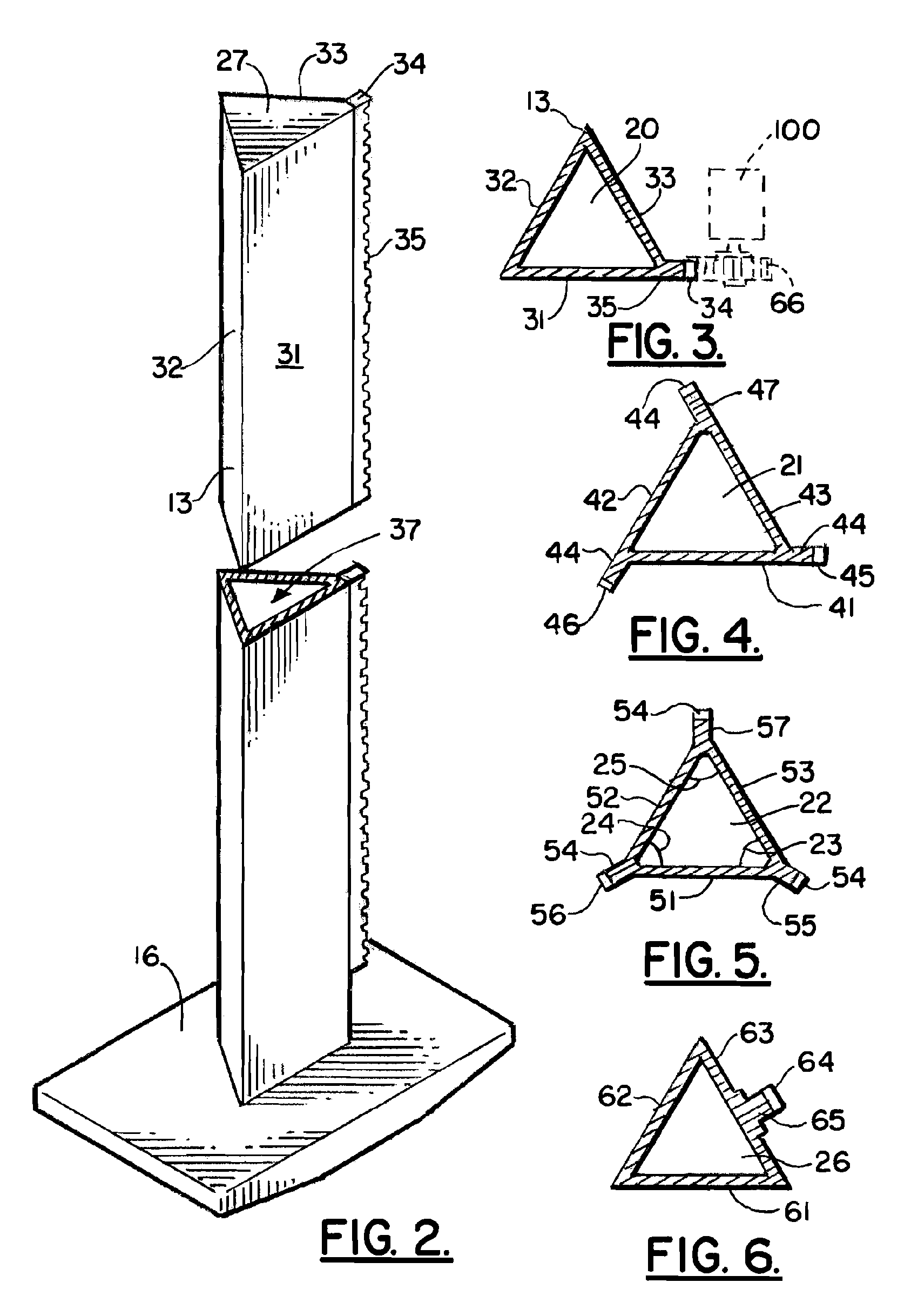

Lift boat leg

InactiveUS7594781B1Vortex shedding is eliminated or minimizedMovement is minimized and eliminatedArtificial islandsUnderwater structuresEngineeringMechanical engineering

Owner:SANDERS RONALD

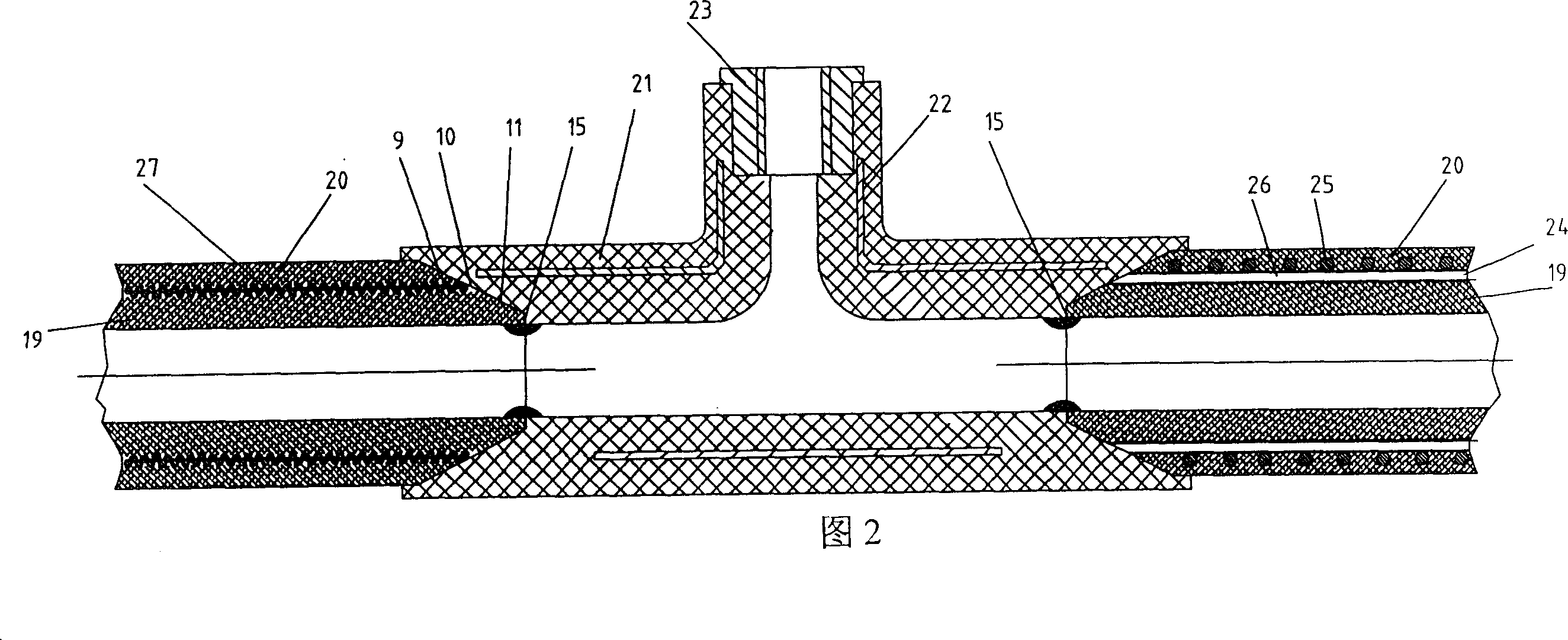

Pipe network for connecting metal composite plastic pipe and plastic pipe

InactiveCN1987188AImprove performanceImprove reliabilityPipe connection arrangementsRigid pipesHot meltMechanical engineering

A tube network is composed of the plastic tubers whose end has a conic receipting recess and the composite metal-plastics tubes consisting of a central metallic skeleton layer, an internal plastic layer and an external plastic layer and with conic ends matched with the conic recess at the end of plastic tube. Both tubes are joined through insertion and thermal fusion.

Owner:DONGTAI NEW MATERIAL SCI ANG TECH SICHUAN

Tapered roller bearing and automotive pinion shaft supporting apparatus utilizing same tapered roller bearing

ActiveUS20070098317A1Reduce rotation lossReduce gear noiseRolling contact bearingsShaftsSurface roughnessEngineering

A tapered roller bearing according to the invention is such that when an arithmetical mean roughness as a surface roughness of a large end face of a tapered roller is σ1 and an arithmetical mean roughness as a surface roughness of a large rib surface of an inner ring is σ2, σ1 is 0.04 μm or larger, and a composite roughness that is expressed by a square root of a sum of a squared value of σ1 and a squared value of σ2 is 0.17 μm or smaller. Raceway surfaces of an outer ring and the inner ring and a rolling contact surface of the tapered roller are crowned, and a total crowning amount is set to 50 μm or larger, an outer ring crowning rate is set to 40% or larger, and a roller crowning rate is set to 20% or smaller.

Owner:JTEKT CORP

Reverse sliding seal for expandable tubular connections

InactiveUS7798536B2High bearing pressure sealPrevent retractionDrilling rodsJoints with sealing surfacesInternal pressureEngineering

An expandable threaded connection between segments of expandable tubulars that provides a high bearing pressure seal at a specific area along the pin and box members is disclosed. The invention utilizes a “groove” in a surface of the box member and a corresponding “rib” on the pin nose. The radial expansion of the tubulars causes the pin to become shorter in length, thereby causing the pin nose to retract from the back of the box member. As the pin nose retracts, the rib on the pin nose moves backward until a portion of the rib contacts a portion of the groove in the box member. The point of contact between the rib and the groove creates a metal-to-metal seal between the pin and box members. Because the point of contact between the rib and the groove is a relatively small area, the force acting on the point of contact generates a high bearing pressure that is equal to or greater than the internal pressure within the expandable tubulars and, thus, generates a high pressure seal.

Owner:WEATHERFORD TECH HLDG LLC

Pressure-bearing lost circulation additive for drilling fluid and for stably bearing pressure on smooth fracture leakage wall surface

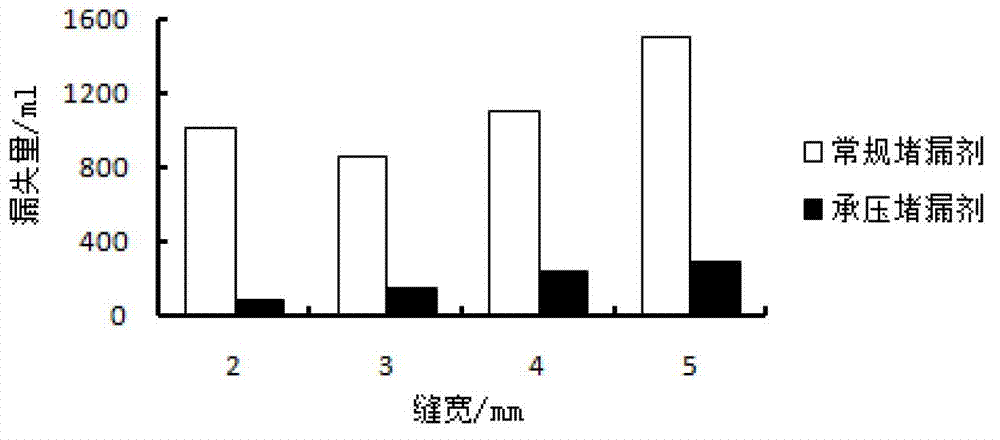

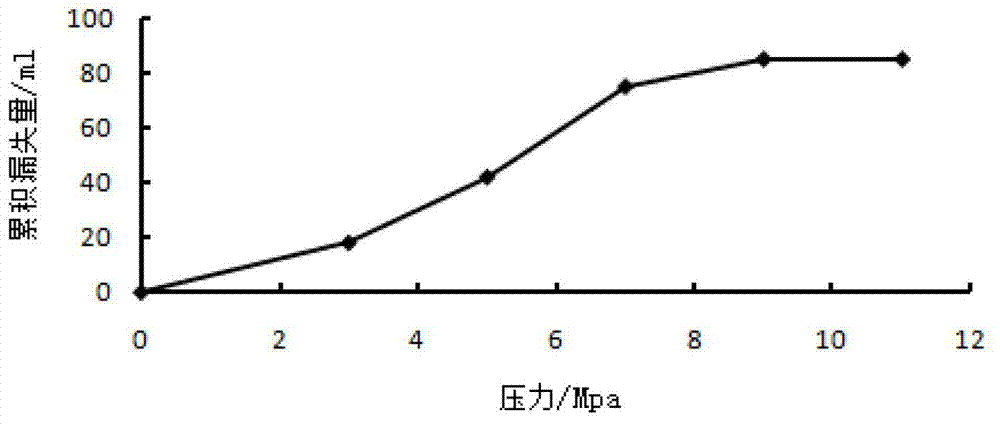

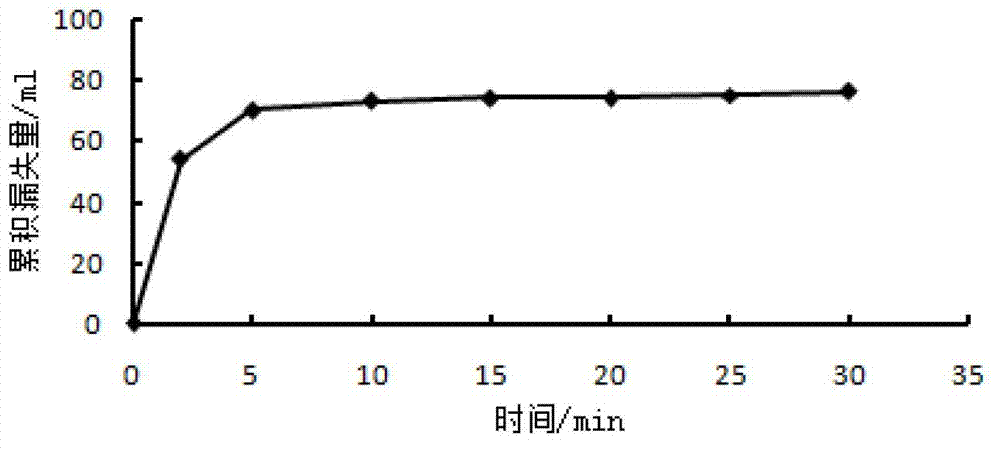

InactiveCN102876303AIncrease bearing pressureIncrease internal frictionDrilling compositionBridge materialFilling materials

The invention relates to a pressure-bearing lost circulation additive for a drilling fluid and for stably bearing pressure on a smooth fracture leakage wall surface. The lost circulation additive is composed of 10%-20% of damping material, 45%-50% of bridging material and 35%-40% of filling material by weight, wherein the damping material is an industrial metal screen, having the size of the damping material is 1.0*1.0mm to 3.0*3.0 mm and the thickness of the damping material is about 0.5 mm; the bridging material is calcium carbonate particles, and the standard mesh number of the screening mesh product of the bridging material is lower than 20 meshes; the filling material is a mixture composed of calcium carbonate powder and flexible graphite powder; the calcium carbonate powder is further divided into three grades to realize multi-grade filling and to form a compact shielding layer; and the mesh number of the flexible graphite is greater than 150, and the anti-pressure ability of a bridge plug section is improved. With the pressure-bearing lost circulation additive for the drilling fluid and for stably bearing pressure on the smooth fracture leakage wall surface disclosed by the invention, leak stoppage success rate and bearing pressure for smooth fracture leakage can be improved, leakage stoppage failure due to complexity is reduced, the benefits of exploring and developing a bored well are improved; and the preparation process of the lost circulation additive is simple and convenient, the source of the materials of the lost circulation additive is broad, and the lost circulation additive is easy to spread and apply.

Owner:SOUTHWEST PETROLEUM UNIV

Tapered roller bearing and automotive pinion shaft supporting apparatus utilizing same tapered roller bearing

ActiveUS7874737B2Reduce operating torqueRolling viscous resistanceRolling contact bearingsShaftsSurface roughnessEngineering

A tapered roller bearing according to the invention is such that when an arithmetical mean roughness as a surface roughness of a large end face of a tapered roller is σ1 and an arithmetical mean roughness as a surface roughness of a large rib surface of an inner ring is σ2, σ1 is 0.04 μm or larger, anda composite roughness that is expressed by a square root of a sum of a squared value of σ1 and a squared value of σ2 is 0.17 μm or smaller. Raceway surfaces of an outer ring and the inner ring and a rolling contact surface of the tapered roller are crowned, and a total crowning amount is set to 50 μm or larger, an outer ring crowning rate is set to 40% or larger, and a roller crowning rate is set to 20% or smaller.

Owner:JTEKT CORP

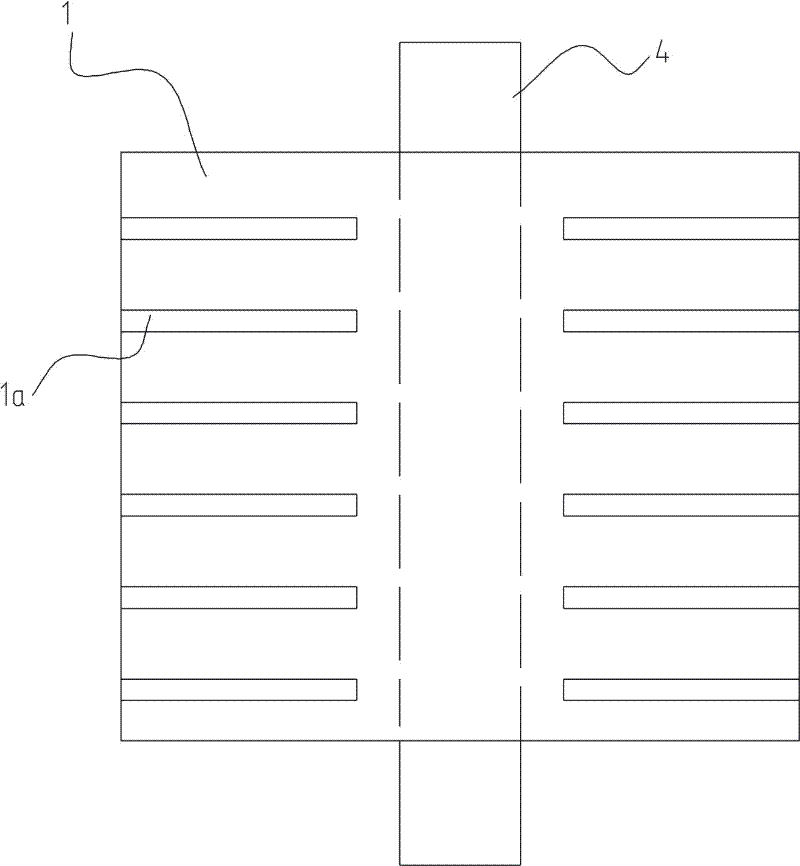

Double layer hollow large sucking plastic tray

InactiveCN1821022AIncrease bearing pressureImprove impact resistanceRigid containersEngineeringHigh pressure

The present invention relates to plastic tray, and is especially one kind of large double layer hollow plastic tray. The large double layer hollow plastic tray has plastic top cover with buckles, plastic pedestal with buckles, and connecting columns and enclosing plates between the top cover and the pedestal for connecting. The large double layer hollow plastic tray has high pressure bearing capacity and impact resistance, simple assembling and disassembling, and small recovering volume, and may be used for transporting un-packed products to raise logistic speed and lower transport cost.

Owner:朱富来

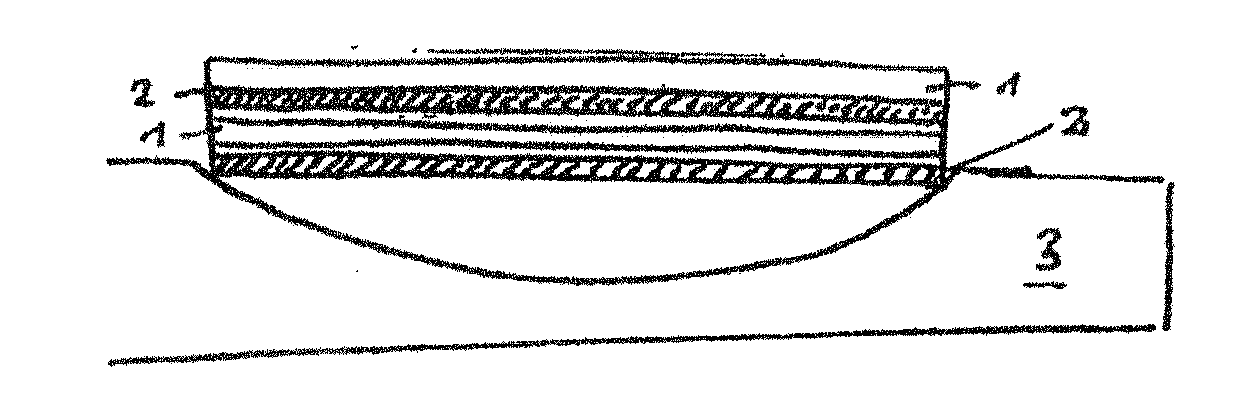

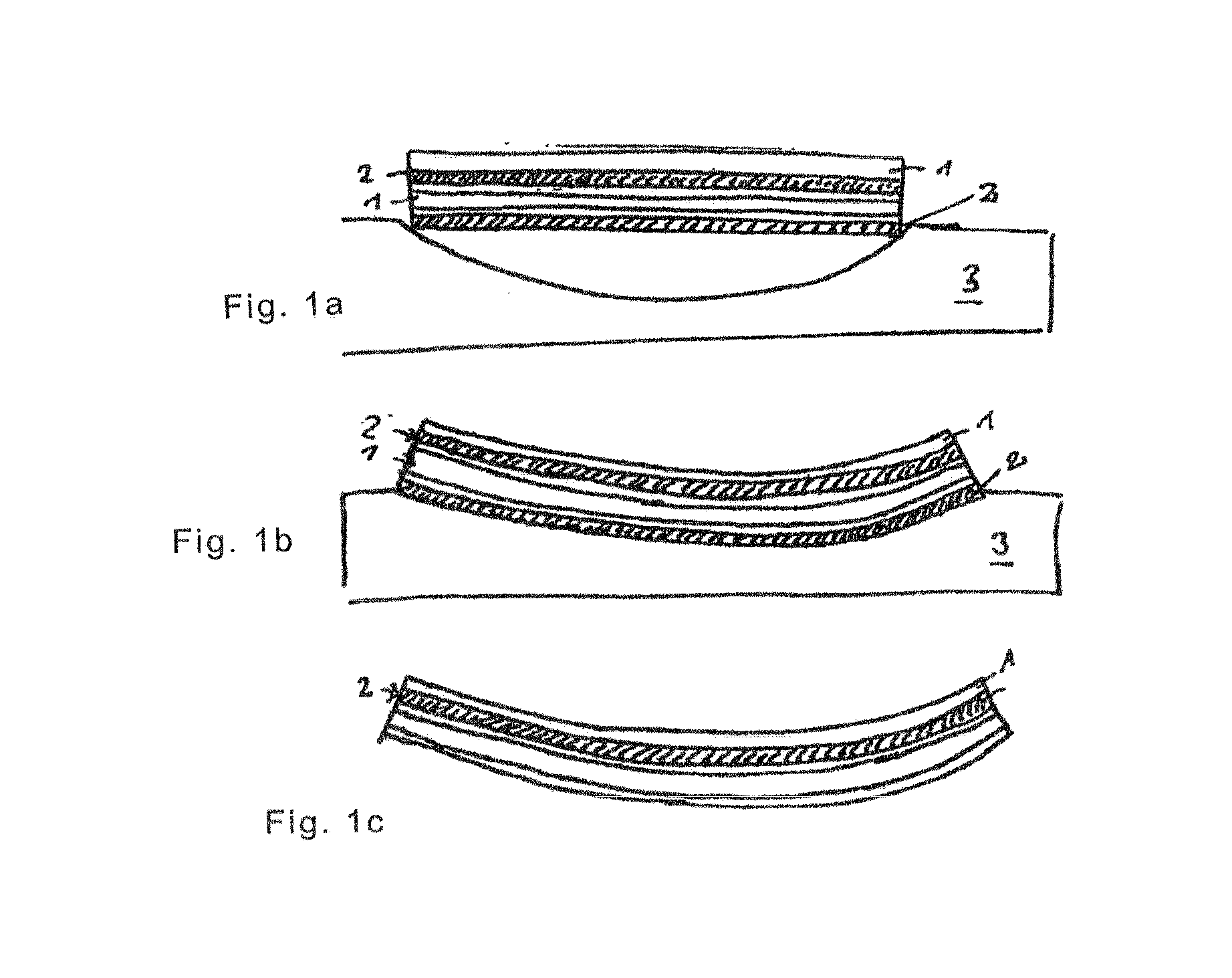

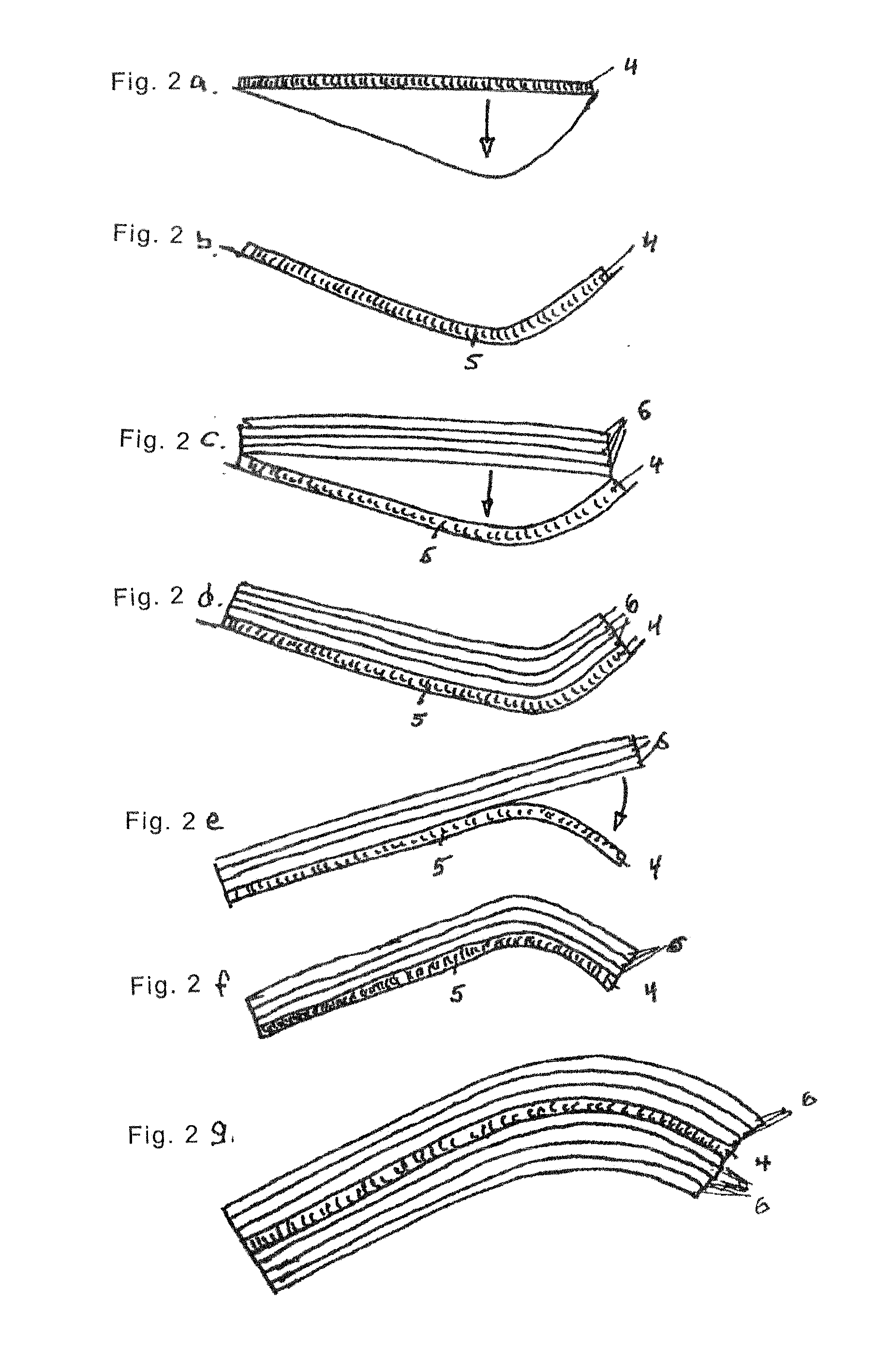

Laminated, transparent set of panes, process for producing and bending same, and use thereof

InactiveUS20120028015A1Improve fitHigh viscosityArmourSynthetic resin layered productsCrystalline materialsGlass-ceramic

Laminated, transparent set of panes made of brittle materials and interleaved laminated films, wherein the brittle materials are various glasses, special glasses, glass-ceramics, transparent ceramics and crystalline materials, process for producing and bending the set of panes and films, and its use thereof, as a bulletproof, unbreakable and shockproof glazing with a low weight per unit area.

Owner:SCHOTT AG

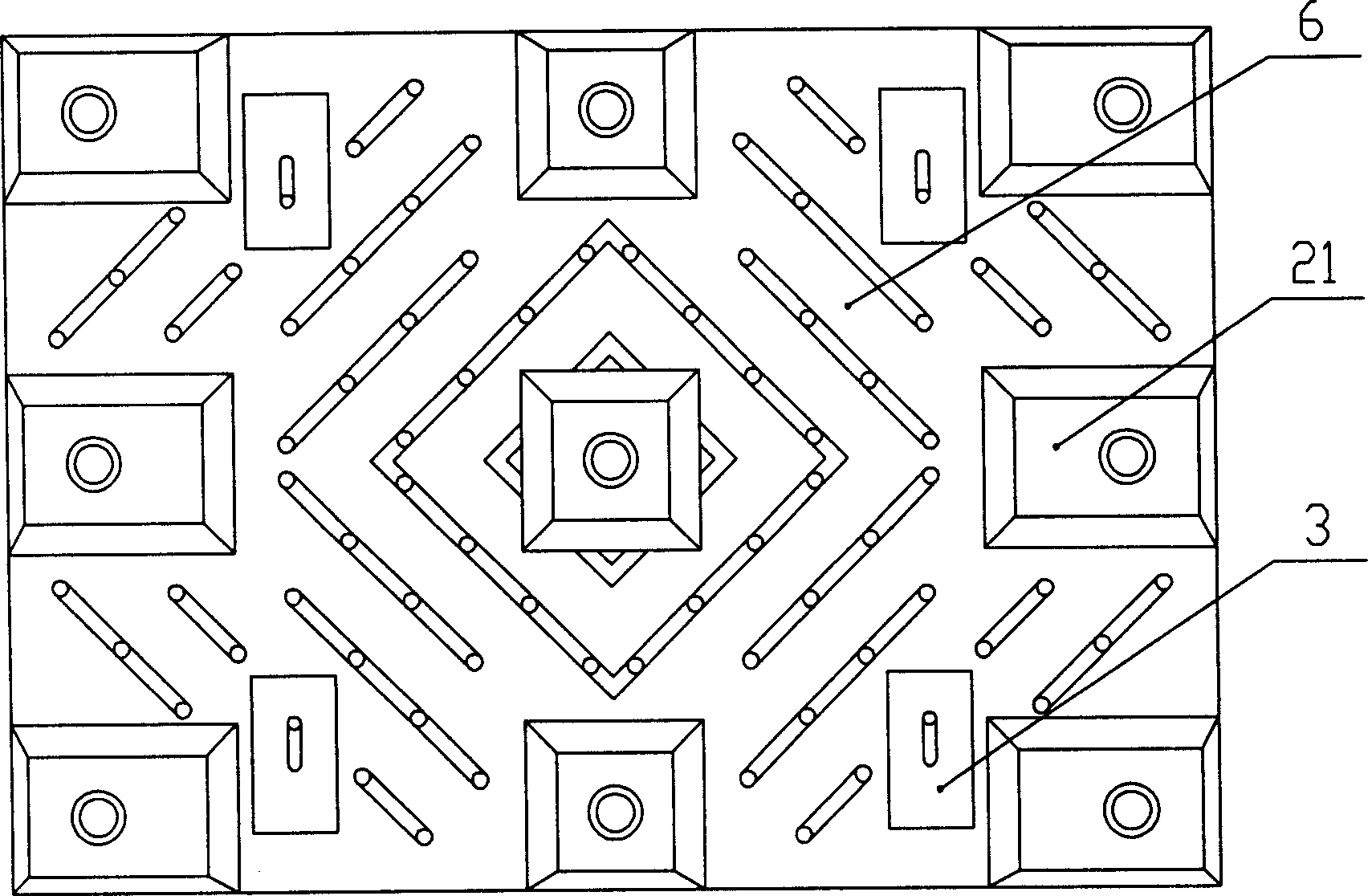

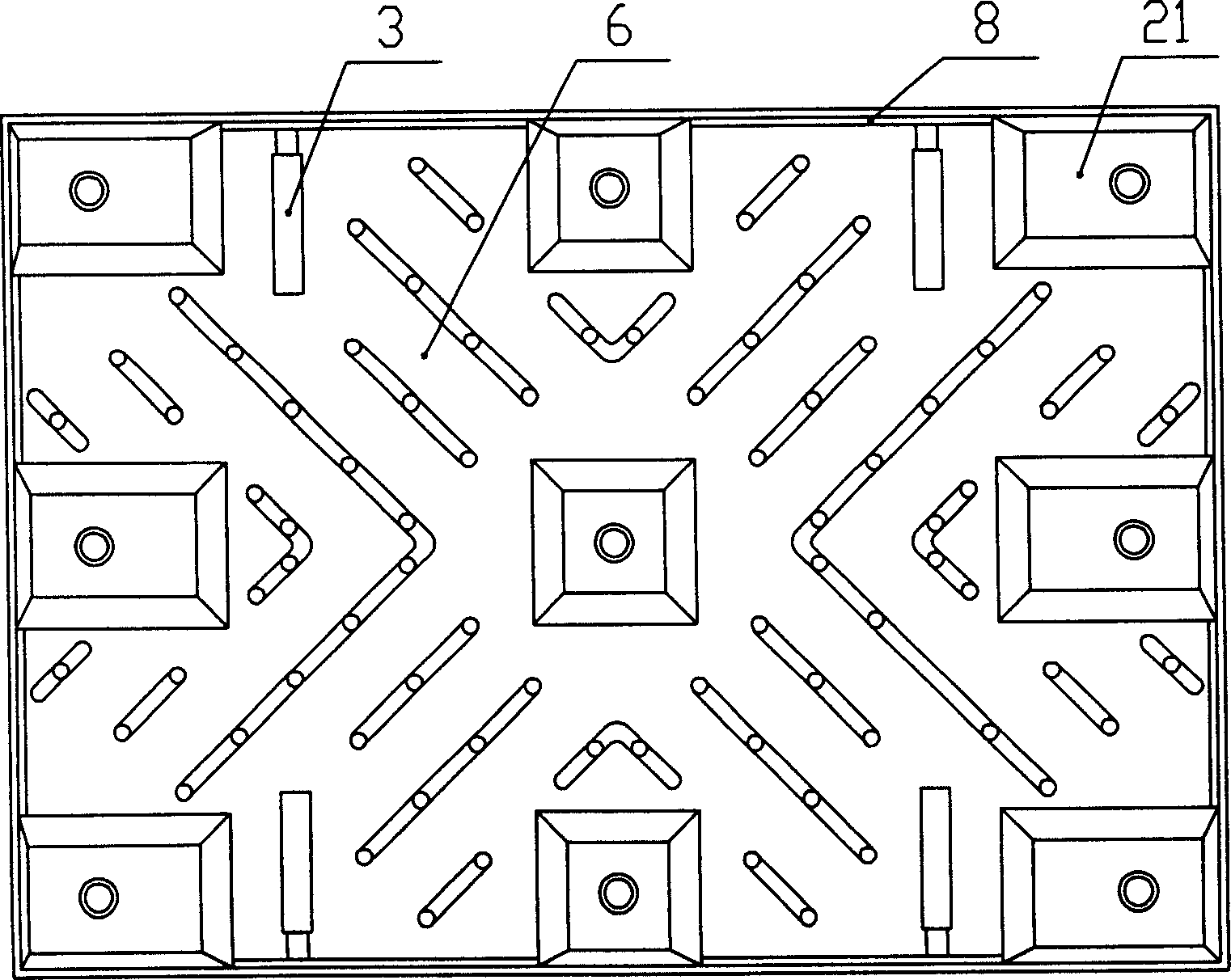

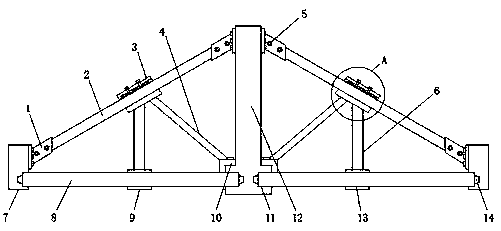

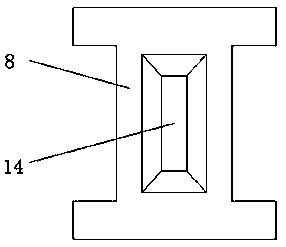

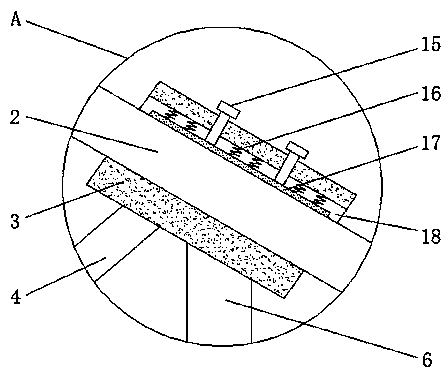

Steel structure roof frame with pressure resistance function

PendingCN109322434AImprove structural rigidityIncrease bearing pressureBuilding roofsShock proofingEngineeringSteel structures

The invention discloses a steel structure roof frame with pressure resistance function. The steel structure roof frame comprises pressure-bearing rods, cross rods and a main frame body, wherein the cross rods are arranged at the two ends of the bottom of the main frame body, one ends of the cross rods extend to the bottom of the main frame body and clamped and fixed with the main frame body, and fixing seats are fixedly arranged at the other ends of the cross rods; fixing plates are installed on the two sides of the main frame body, and first connecting rods are installed at the tops of the fixing plates; clamping connecting seats are fixedly arranged at one ends of the first connecting rods and second connecting rods, and fixing cavities are formed in the center of the clamping connectingseat; the pressure-bearing rods penetrate through the center of the fixing cavities; and connecting seats are fixedly arranged at the two ends of the pressure-bearing rods, and the fixing seats and the main frame body are correspondingly fixed to one ends of the connecting seats. According to the steel structure roof frame with the pressure resistance function, the connecting seats, the pressure-bearing rods, the fixing seats, the cross rods and the main frame body are installed, so that a triangular structure is formed through the fixing seats, the cross rods and the main frame body conveniently, the structure rigidity of the device is increased conveniently, and the bearing pressure of the device is increased conveniently.

Owner:辰信重工(江苏)有限公司

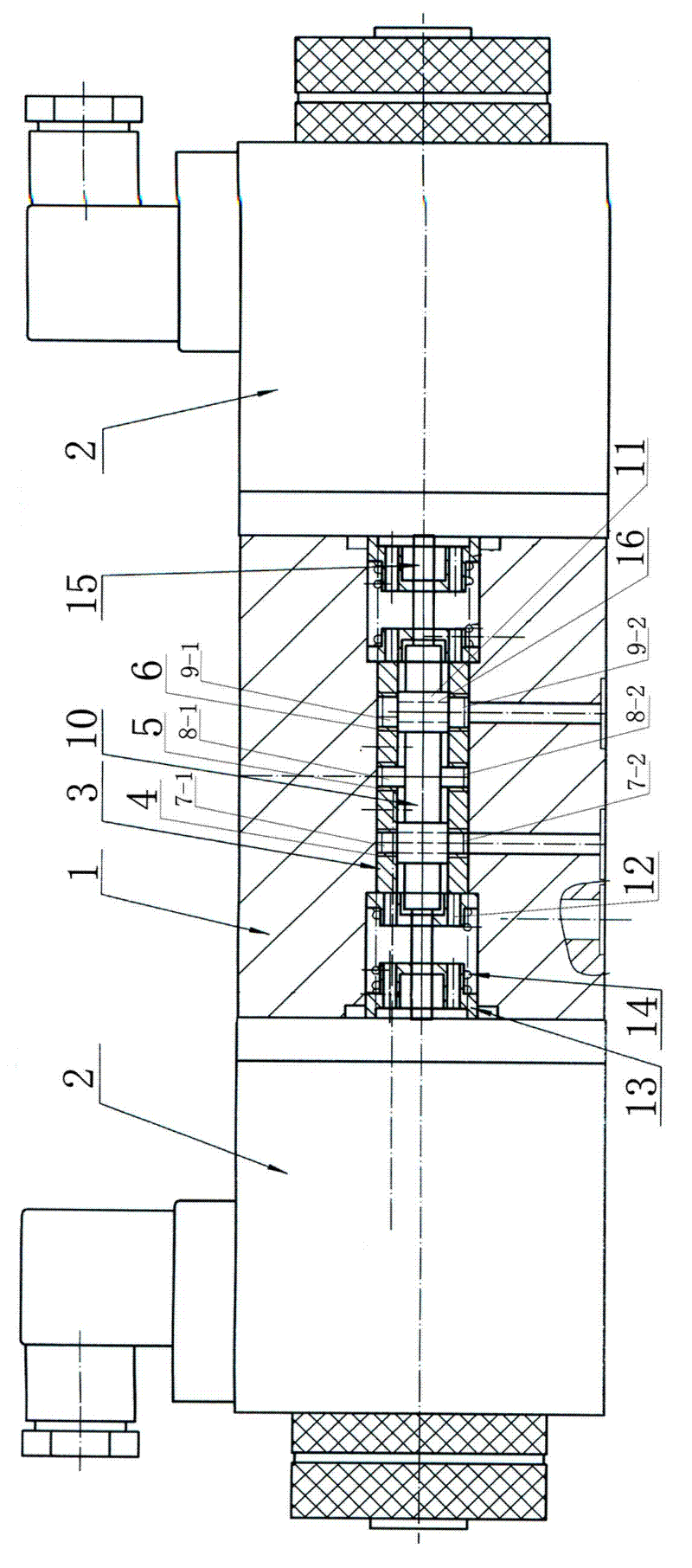

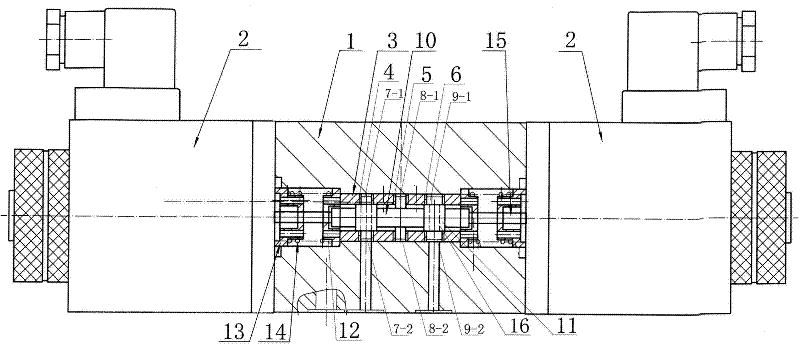

Ultrahigh-pressure three-position four-way electromagnetic reversing valve

InactiveCN102364179ARestore mutual closureIncrease bearing pressureOperating means/releasing devices for valvesMultiple way valvesEngineeringHigh pressure

The invention discloses an ultrahigh-pressure three-position four-way electromagnetic reversing valve and relates to the technical field of fluid pressure executing mechanisms. The ultrahigh-pressure three-position four-way electromagnetic reversing valve comprises a valve body, wherein a through hole is formed in the valve body; electromagnets are connected at two ends of the through hole; an oil distributing sliding sleeve is sleeved in the through hole; a first annular undercut groove, a second annular undercut groove and a third annular undercut groove are formed on the outer periphery of the oil distributing sliding sleeve; an oil inlet is formed on the second annular undercut groove; a first oil outlet is formed on the first annular undercut groove; a second oil outlet is formed on the third annular undercut groove; a valve core is arranged in the oil distributing sliding sleeve; annular blocks matched with the first oil outlet and the second oil outlet are arranged in the length direction of the valve core; spring bases are arranged in the through hole and between the two ends of the oil distributing sliding sleeve and the two electromagnets; each spring base is provided with an inner base body and an outer base body; and a spring is connected and a push rod is arranged between each group of the inner base body and the outer base body. A slide valve structure is easy to reverse under high pressure.

Owner:张家庆

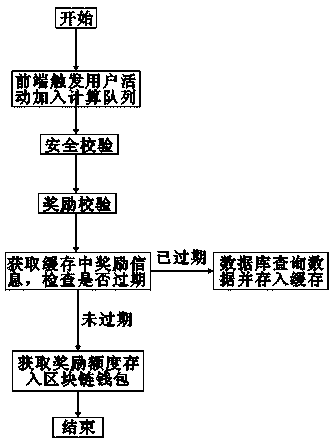

Live video platform reward data processing method

InactiveCN109547823ANot affected by weak network environmentAvoid attackSelective content distributionMarketingUser verificationLive video

The invention relates to a live video platform reward data processing method. A live broadcast platform is pre-connected with a blockchain network. The data processing method comprises the following steps: receiving a live broadcast room identifier of a currently located live broadcast room, a user verification identifier and reward information sent by a user node in the blockchain network. According to the live video platform reward data processing method provided by the invention, better user experience is provided for users, and the situation of wrong collection can be avoided; when an administrator opens the reward, a customer enters for viewing and must start the normal playing before starting the timing, when the timing starts to meet relevant reward conditions, a page pops up a pop-up window of obtaining a related reward, the user only needs to click to collect the reward, when the user does not collect the rewards overtime, the pop-up window is automatically closed until the next reward pops up; the audience can watch the video content alone, especially the advertising contents can only be inserted in the video contents or placed in front of the video contents, and the usermust view the advertising contents; and by setting the revenue for the viewing time of the audience, the passive viewing of the video contents of the audience is changed into active viewing.

Owner:四川链窗区块链科技有限公司

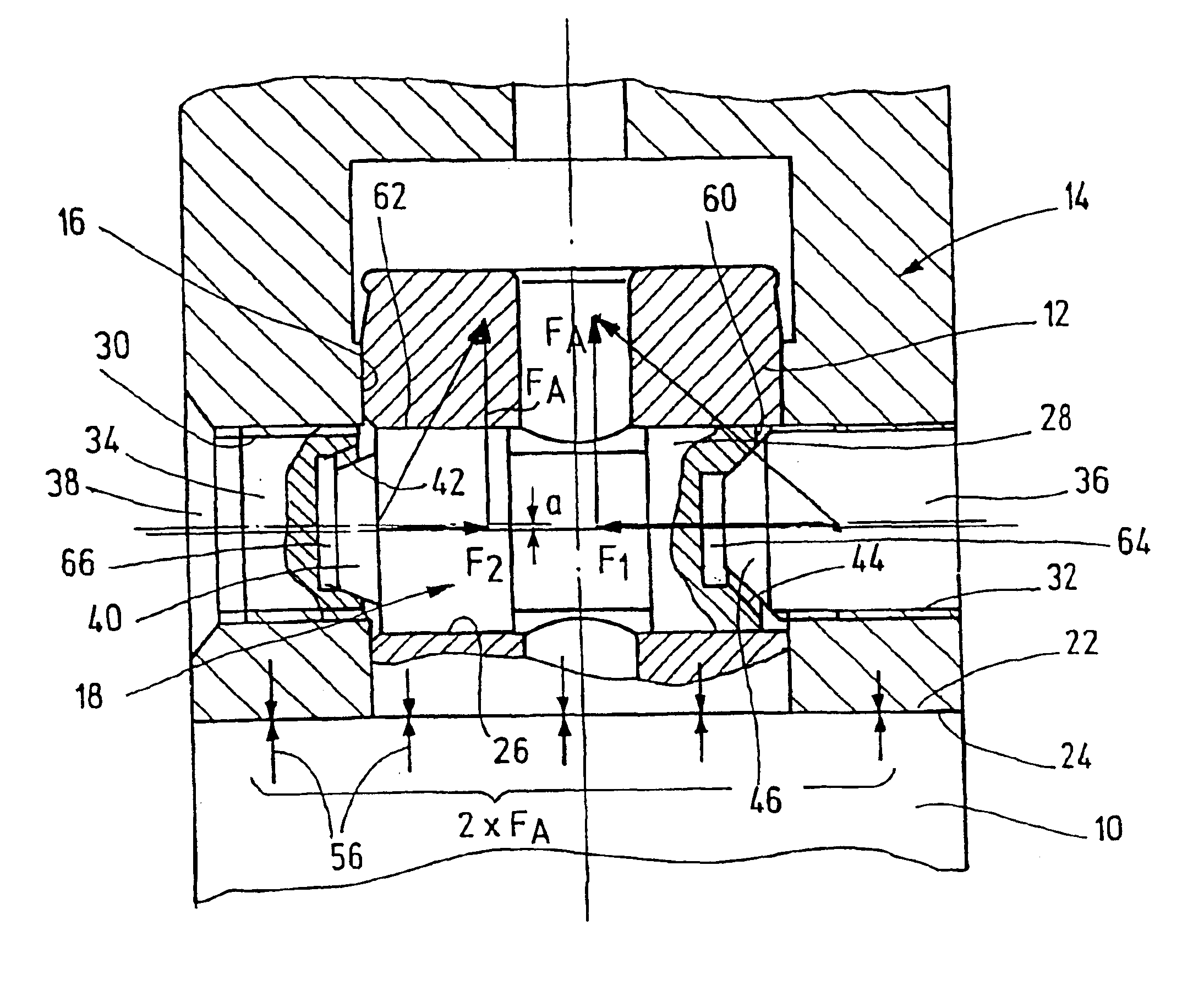

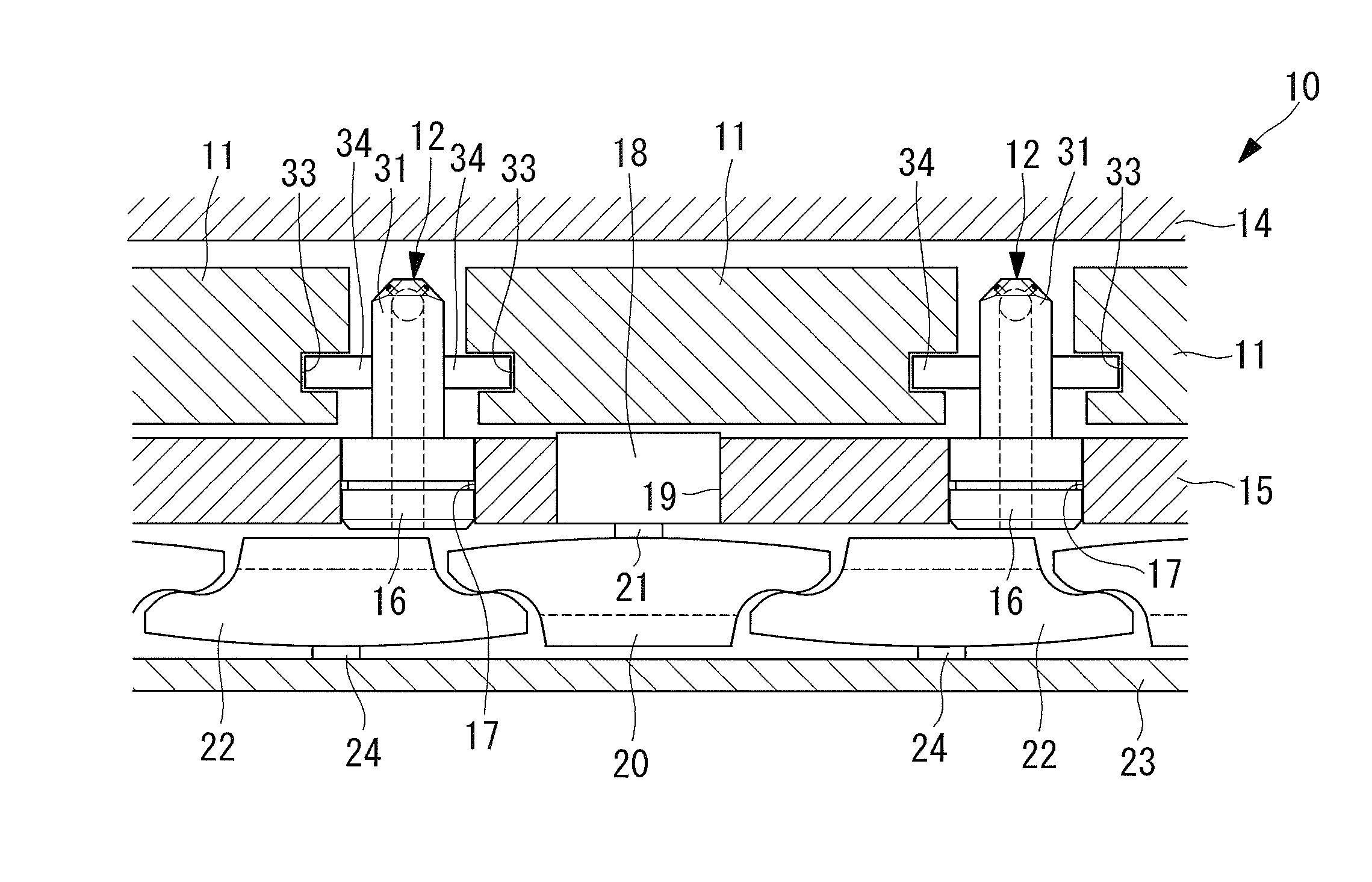

Device for connecting two components

InactiveUS6902347B2Improve friction relationshipAccurate guideThread cutting machinesTransportation and packagingFrustumEngineering

The tensioning mechanism (18) comprises a clamp bolt (28), arranged in a displaceable manner in a transverse bore (26) in the fitting plug (12) and two diametrically opposed retainers (34, 36) in the second component (14) which engage with an axially facing internal or external cone against a complementary internal or external cone on the clamp bolt (28) and, during tensioning, are tensioned with the same in a wedge fashion. According to the invention, the clamp bolt (28) comprises a frustum-shaped external cone (40), the base diameter of which is smaller than the diameter of the guide surface (62) thereof in the transverse bore (26).

Owner:KOMET GROUP GMBH

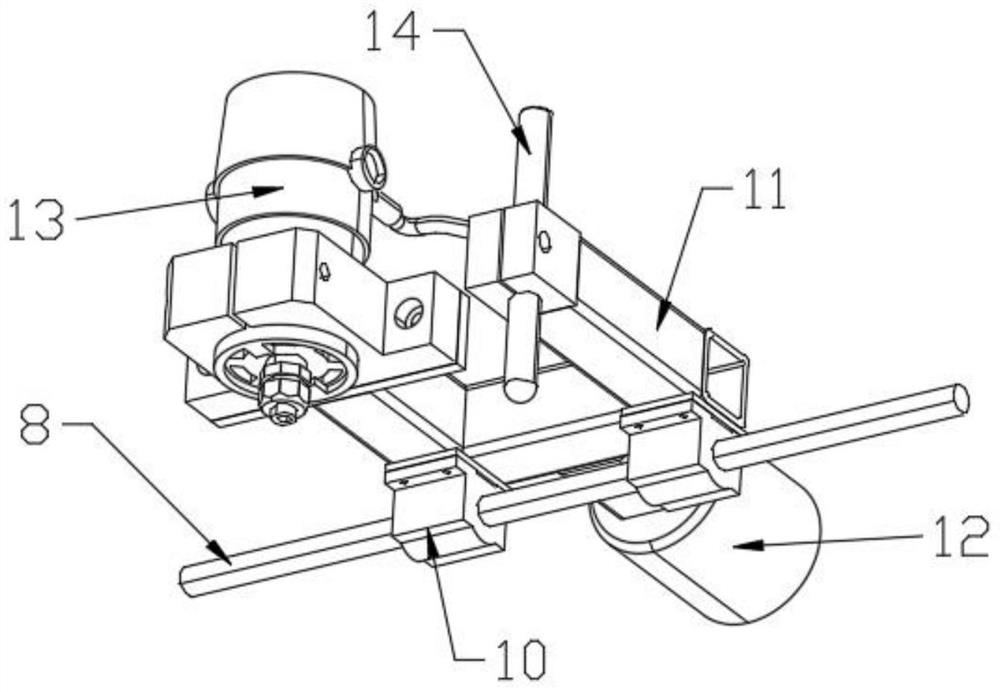

Multi-channel jet vacuum pump

ActiveCN104121236AIncrease bearing pressureEasy to cleanJet pumpsMachines/enginesVacuum pumpInjection pump

The invention relates to a multi-channel jet vacuum pump, and belongs to the technical field of injection pumps pumping fluid through the inertia of the fluid to be pumped. The multi-channel jet vacuum pump comprises a submersible pump, a jet device and a vacuum tank. The jet device comprises a jet box with an outlet. A left clamping plate and a right clamping plate attached to the left clamping plate are arranged in the jet box. A jet liquid inlet pipe which penetrates through the left clamping plate and is perpendicular to the left clamping plate is arranged in the center of the left clamping plate, and the inlet end of the jet liquid inlet pipe is communicated with the outlet of the submersible pump. A plurality of jet nozzles communicated with the jet liquid inlet pipe are arranged between the left clamping plate and the right clamping plate and uniformly distributed in the circumferential direction of the center of the jet liquid inlet pipe. The diameter of each jet nozzle is 8-20 mm. The outlet end of each jet nozzle is opposite to the outlet of the jet box. An air inlet pipe communicated with each jet nozzle is arranged on the edge of the right clamping plate and communicated with the outlet of the vacuum tank. The multi-channel jet vacuum pump has the advantages that the bearing pressure is large and the cleaning performance is good.

Owner:GP ENTERPRISES CO LTD

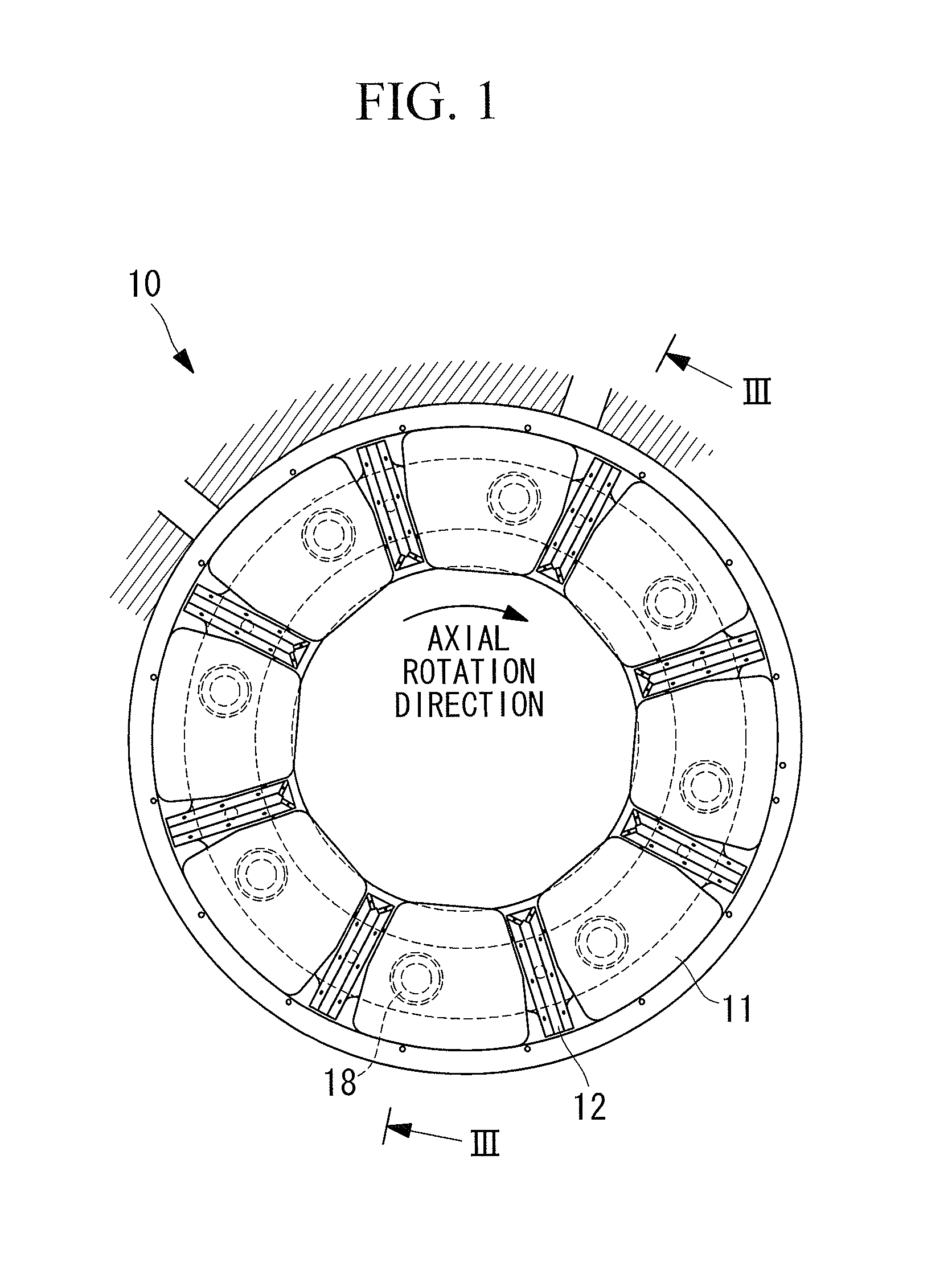

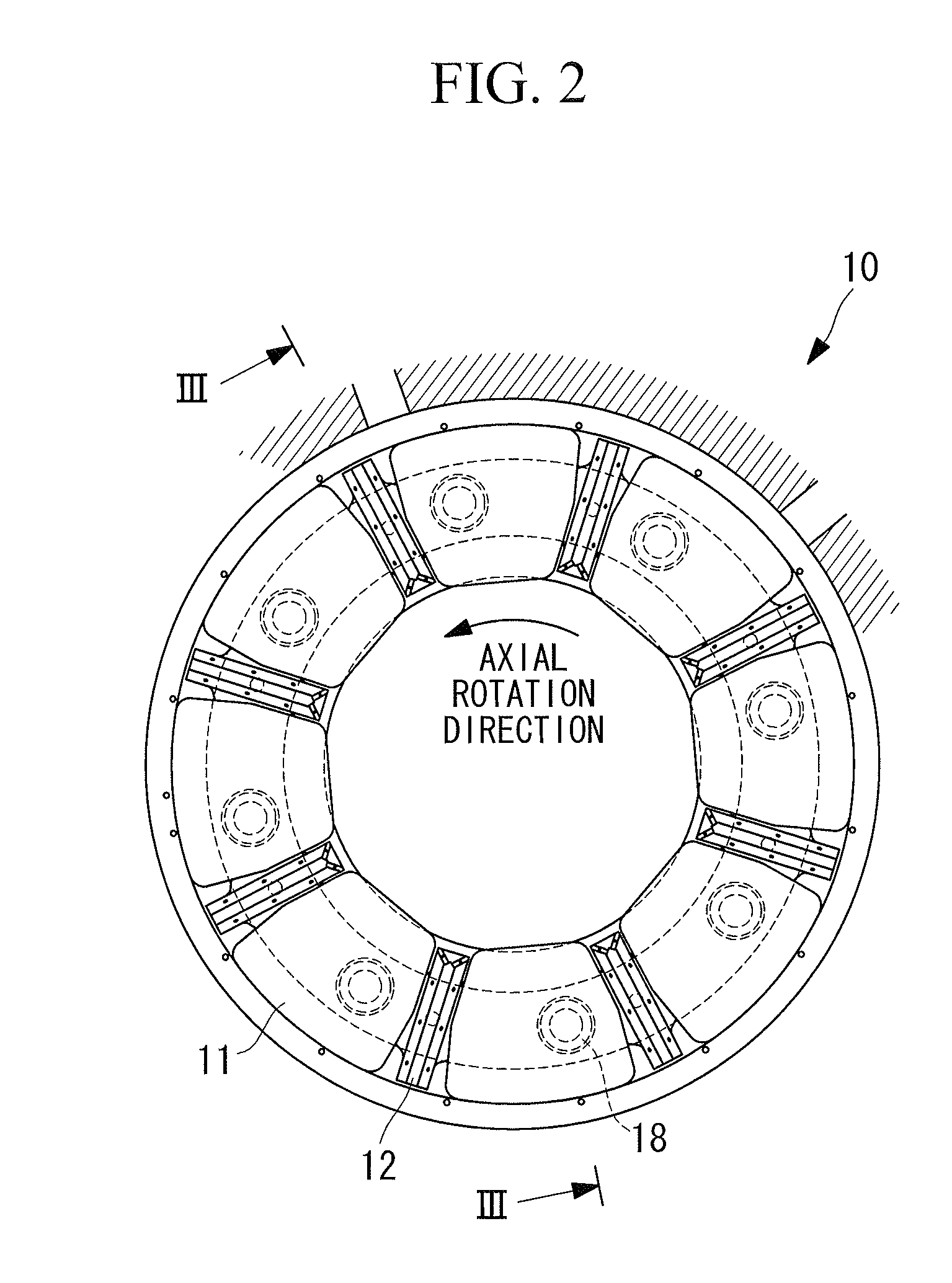

Oiling nozzle for thrust bearing

ActiveUS8408801B2Good followabilityIncrease bearing pressureEngine manufactureBearing assemblyThrust bearingNozzle

An oiling nozzle for a thrust bearing improves the following capability of pads and achieves a higher bearing pressure of the thrust bearing. The oiling nozzles are arranged between respective pads disposed in positions facing the thrust surface of a thrust collar that protrudes radially outward from a rotor shaft, along the circumferential direction. Each oiling nozzle has a cylindrical stem and a rectangular-shaped mainframe whose heightwise middle portions of opposite lateral sides are provided with convex parts. Each convex part presents a semicircular disk shape in a plane view to be fitted into concave parts that are formed in lateral sides of the pads. A top portion located on a side opposite to the stem is formed with a plurality of nozzle holes for ejecting lubricating oil that has been supplied from the bottom of the stem toward a space between the thrust collar and the pads.

Owner:MITSUBISHI HEAVY IND LTD

Reverse sliding seal for expandable tubular connections

InactiveUS20100320754A1High bearing pressure sealPrevent retractionDrilling rodsFluid removalInternal pressureHigh pressure

An expandable threaded connection between segments of expandable tubulars that provides a high bearing pressure seal at a specific area along the pin and box members is disclosed. The invention utilizes a “groove” in a surface of the box member and a corresponding “rib” on the pin nose. The radial expansion of the tubulars causes the pin to become shorter in length, thereby causing the pin nose to retract from the back of the box member. As the pin nose retracts, the rib on the pin nose moves backward until a portion of the rib contacts a portion of the groove in the box member. The point of contact between the rib and the groove creates a metal-to-metal seal between the pin and box members. Because the point of contact between the rib and the groove is a relatively small area, the force acting on the point of contact generates a high bearing pressure that is equal to or greater than the internal pressure within the expandable tubulars and, thus, generates a high pressure seal.

Owner:WEATHERFORD TECH HLDG LLC

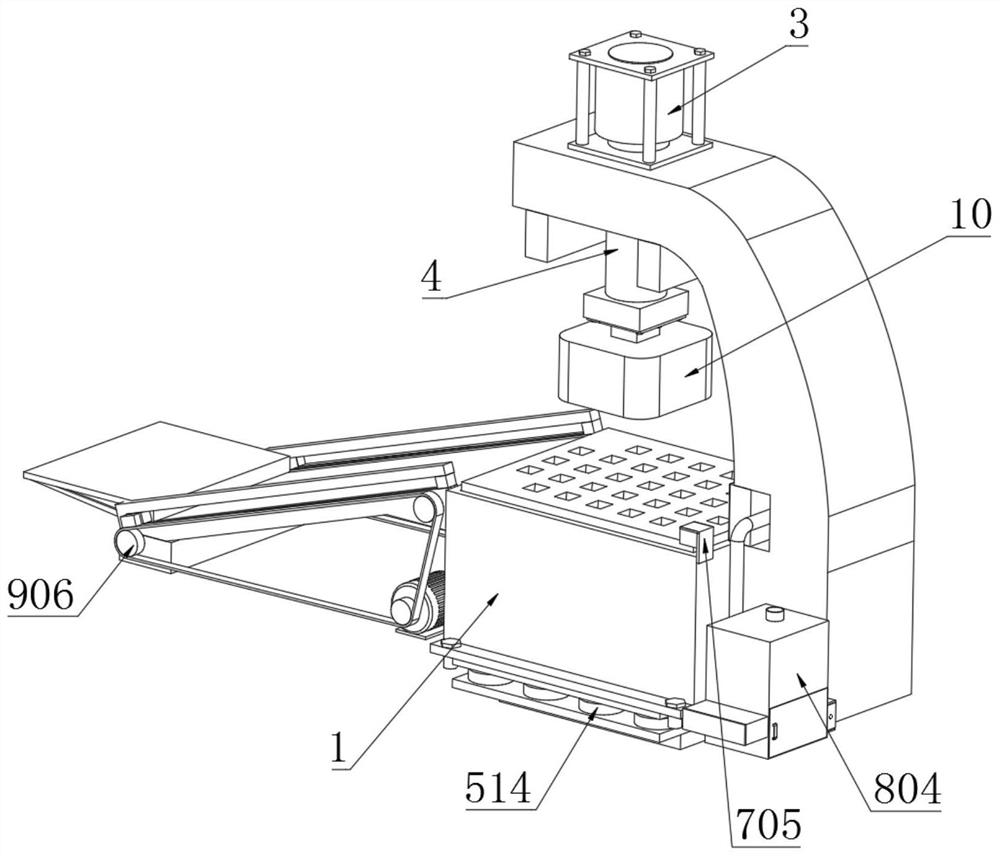

Forging method capable of realizing multi-surface forging forming

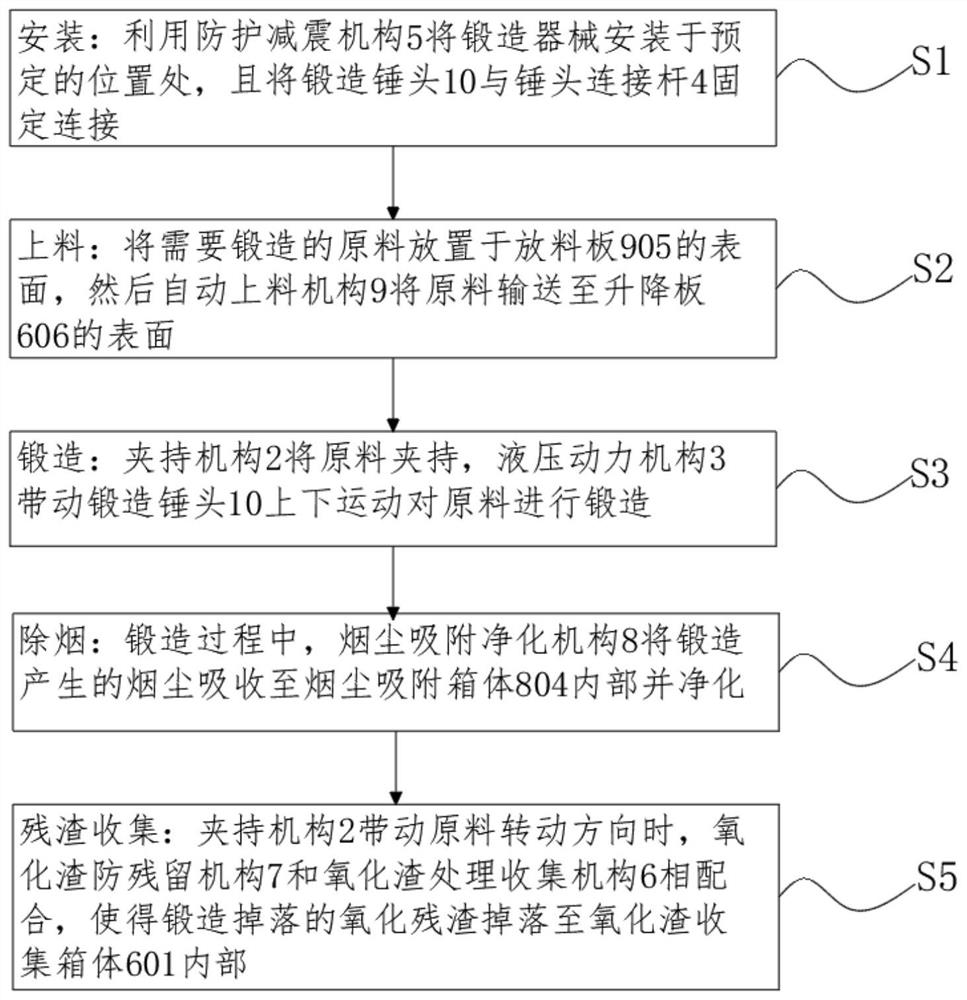

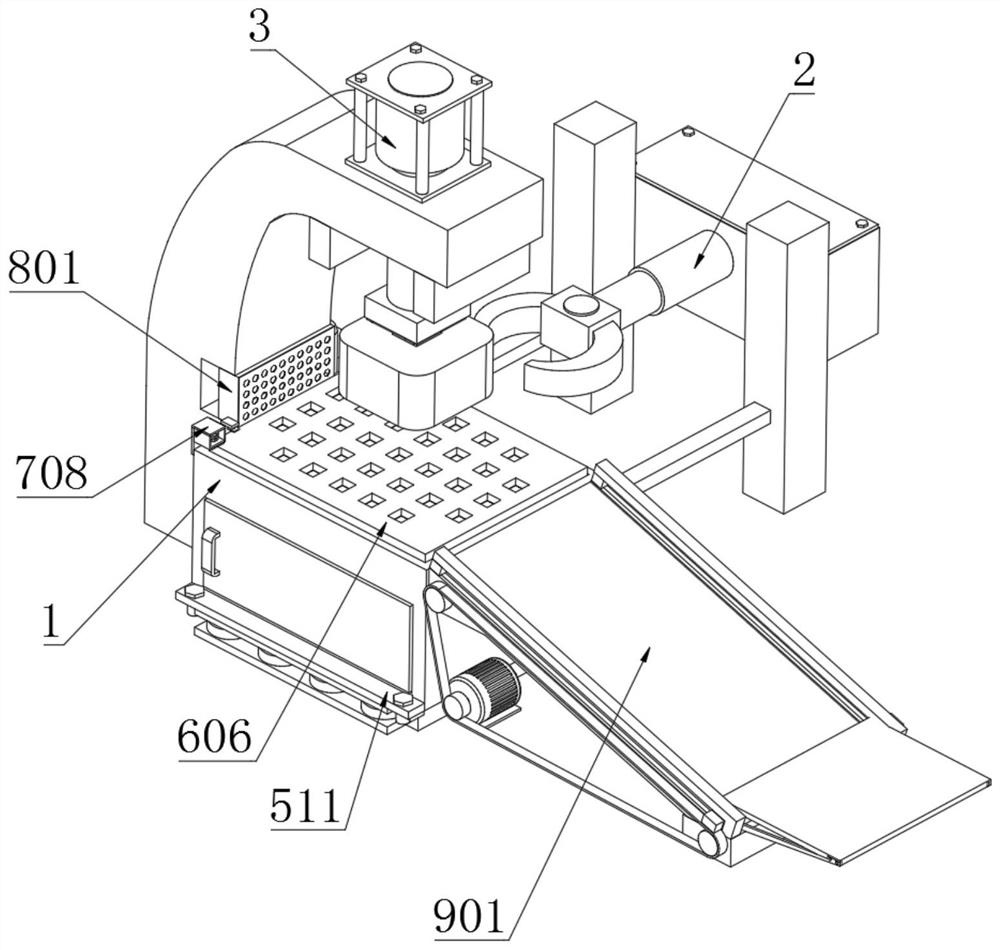

InactiveCN111822636AScientific and reasonable structureEasy to useCombination devicesNon-rotating vibration suppressionSlagStructural engineering

The invention discloses a forging method capable of realizing multi-surface forging forming. According to the forging method, a fixed sleeve is fixedly installed in a circular groove, the surface of the fixed sleeve is sleeved with a reset spring, the top end of the reset spring is fixedly connected with a lifting plate, and movable columns are fixedly connected to the four corners of the bottom end of the lifting plate correspondingly; and conical discharging holes are formed in the middle of the lifting plate at equal intervals, cross beams are symmetrically and fixedly installed at the topend of an oxidation slag collecting box body, and conical clamping blocks are fixedly connected to the top ends of the cross beams at equal intervals. Through cooperative use of the reset spring and the conical discharging holes, oxidation residues generated by forging can fall down when the lifting plate is jacked up, the situation that oxidation residues are accumulated on the surface of the lifting plate to affect the normal forging process, a raw material is forged on the accumulated residues, pits are formed in the surface of the raw material, and the surface of the raw material is uneven, so that the forging quality of a subsequent raw material is reduced is avoided, the surface of a machining platform can be kept clean without manual cleaning, and the qualified rate of forging is increased.

Owner:林璋

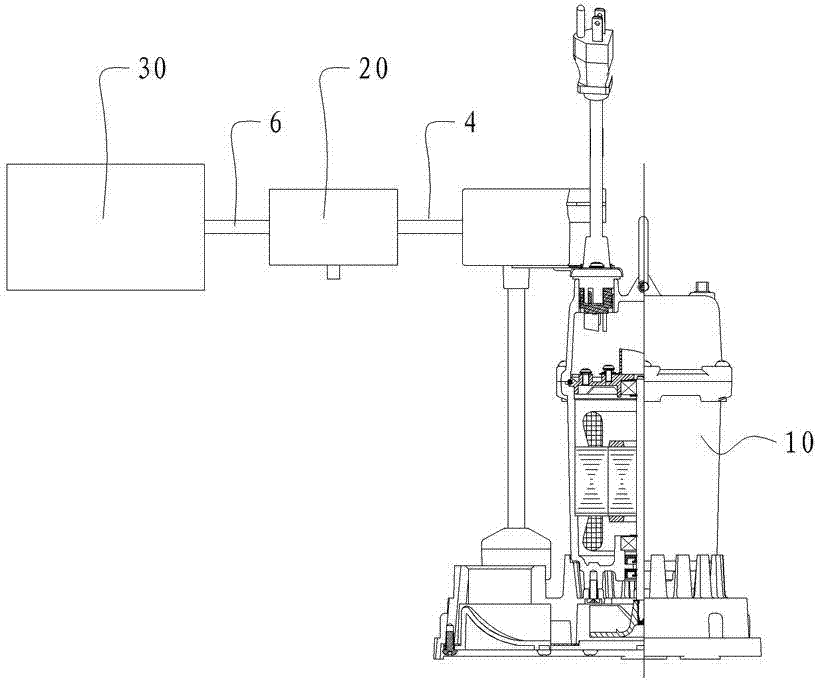

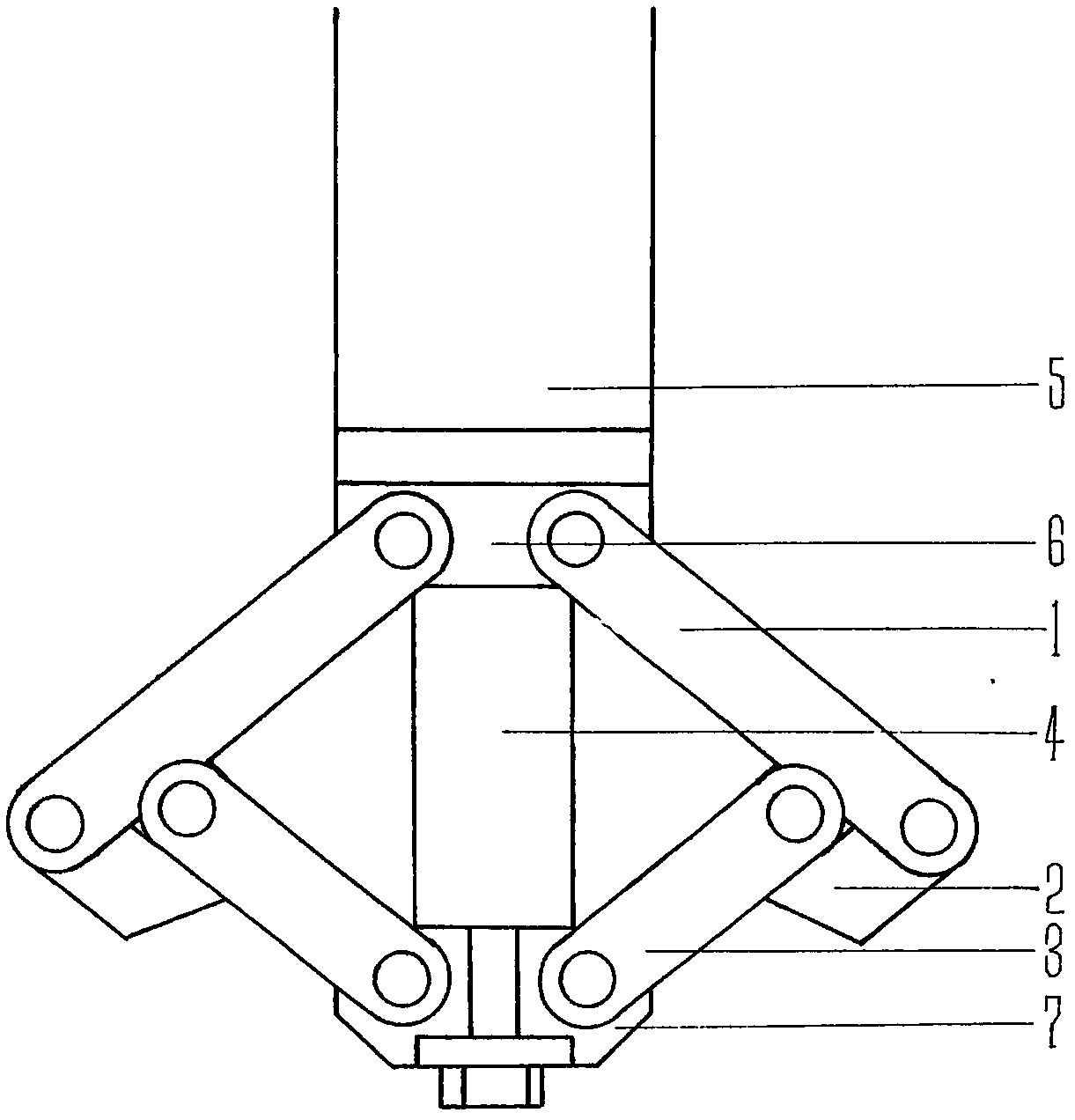

Three-branch single-cylinder hydraulic bidirectional expansion-extrusion device

The invention provide a three-branch single-cylinder hydraulic bidirectional expanding-extrusion device, which comprises upper expanding-extrusion arms, lower broken-end expanding-extrusion arms, support arms, a piston rod, a fixed disk, a moving disk and a cylinder block. The three-branch single-cylinder hydraulic bidirectional expanding-extrusion device is characterized in that in rotation of the three-branch single-cylinder hydraulic bidirectional expanding-extrusion device, a soil layer is cut by cutting edges of the upper expanding-extrusion arms to form a cavity, and the lower wall of a bearing disk cavity is rolled by the lower broken-end expanding-extrusion arms to compact the soil layer; when the cavity is formed, the three-branch single-cylinder hydraulic bidirectional expanding-extrusion device rotates reversely; and the upper wall of the bearing disk cavity is squeezed by arc slants of the upper expanding-extrusion arms to compact the soil layer, and the lower broken-end expanding-extrusion arms scrape fallen residue and rotate reversely to roll the lower wall of the bearing disk cavity for the second time so as to compact the soil layer. Compared with the prior art, the three-branch single-cylinder hydraulic bidirectional expanding-extrusion device has the evident advantages that expanding-extrusion is separately performed, quick, laborsaving and reliably effective, the shape of the formed cavity more meets the load bearing requirement, and the like, and accordingly is well worthy of popularization and application.

Owner:董兰田

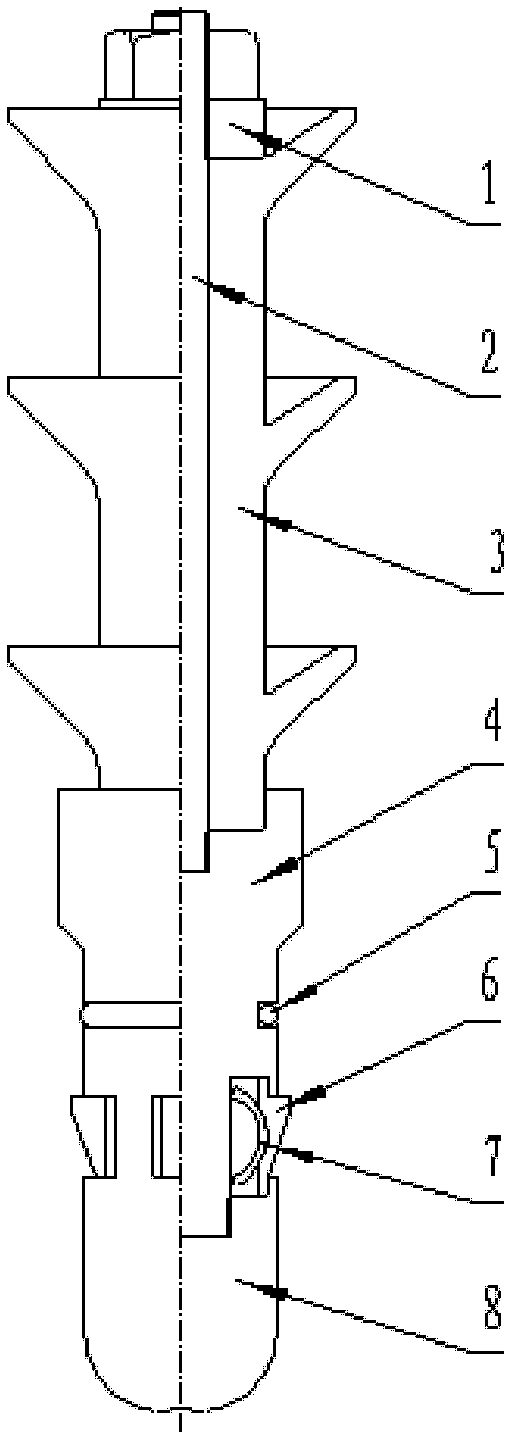

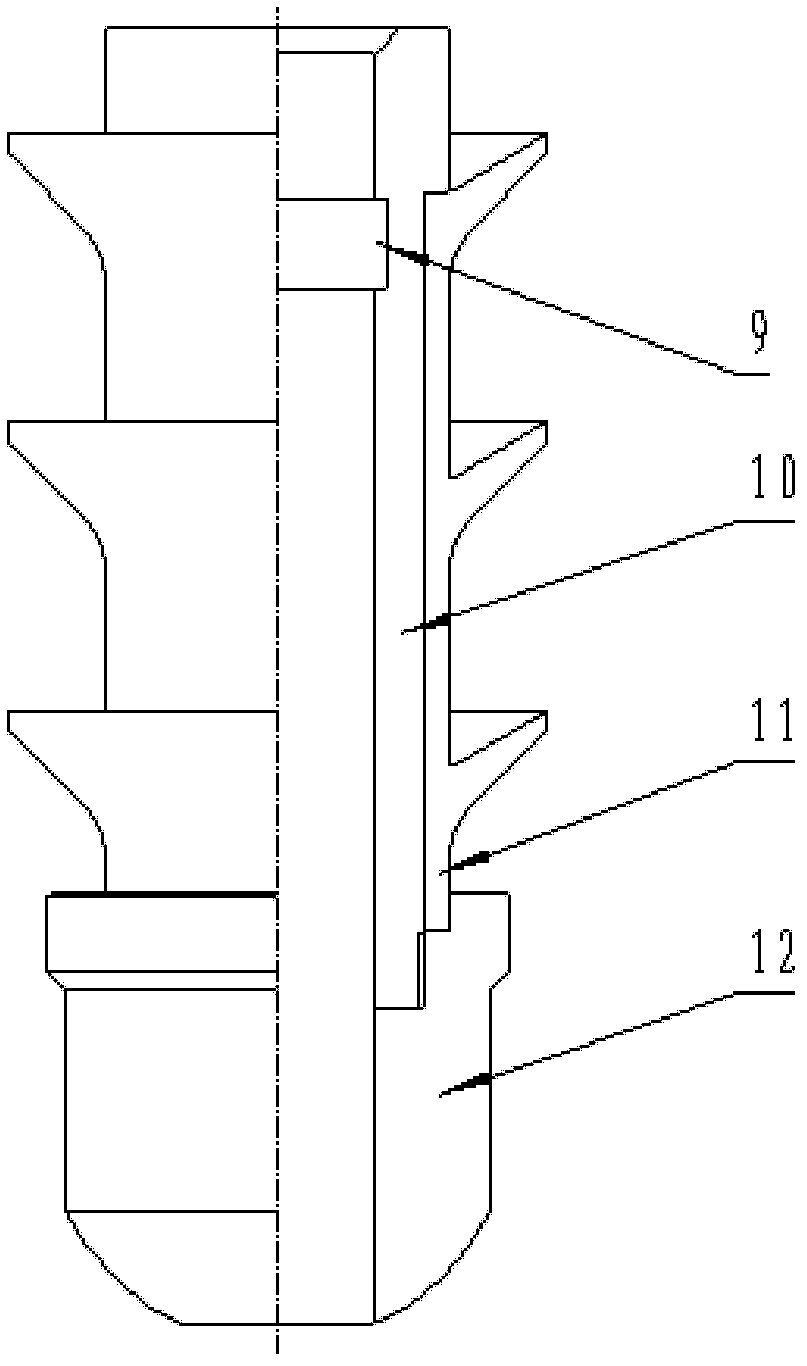

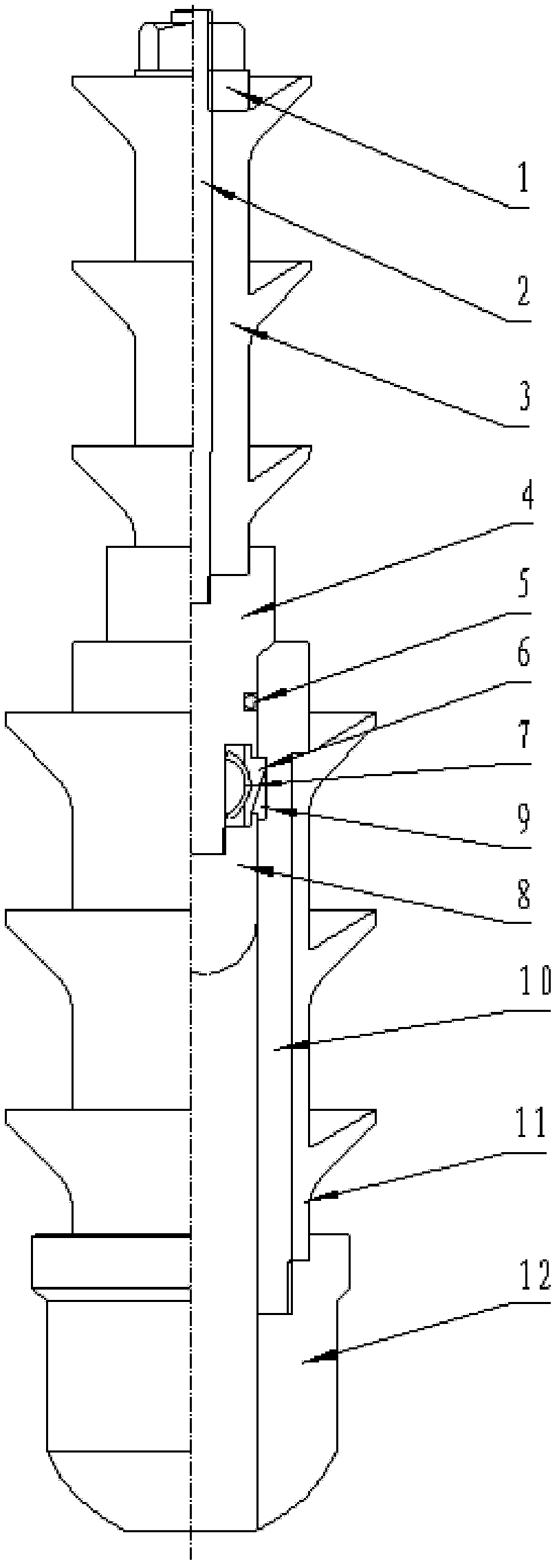

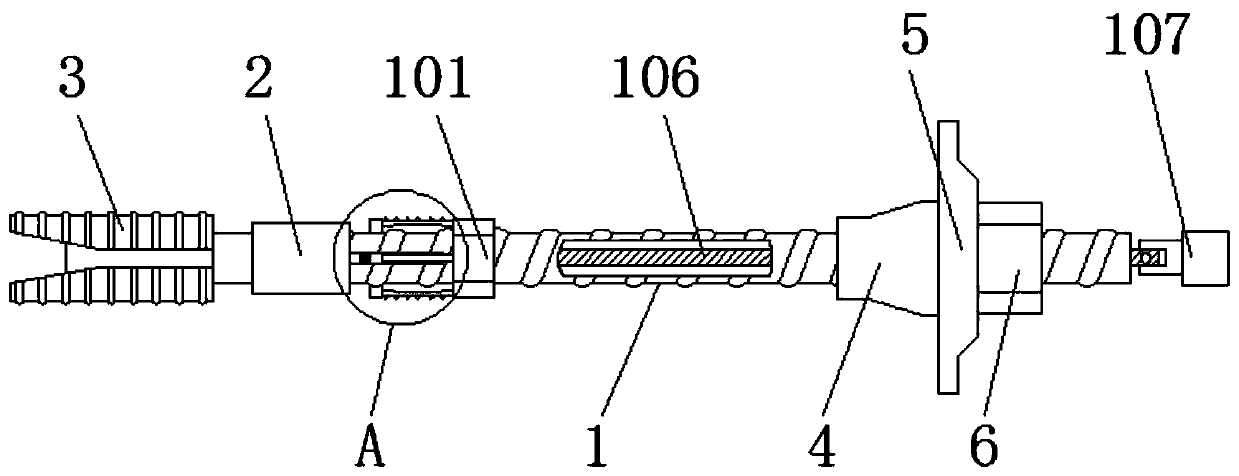

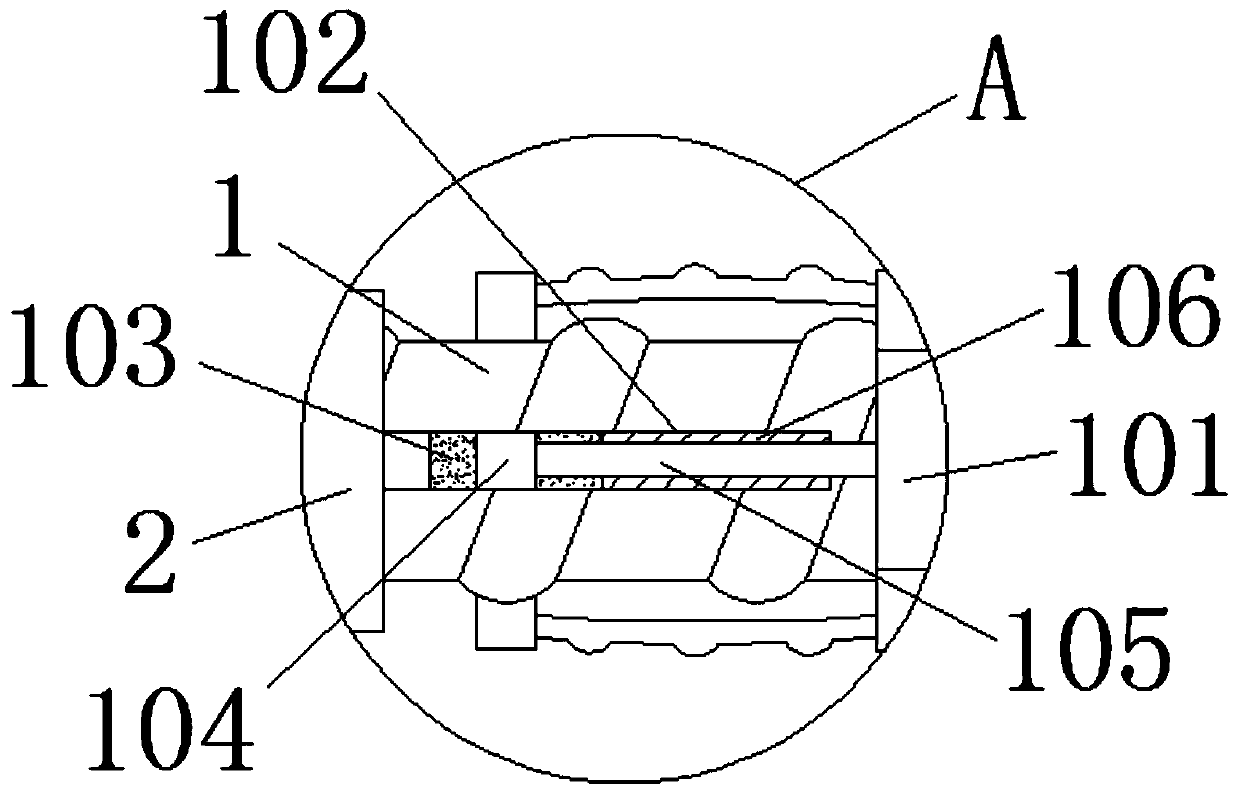

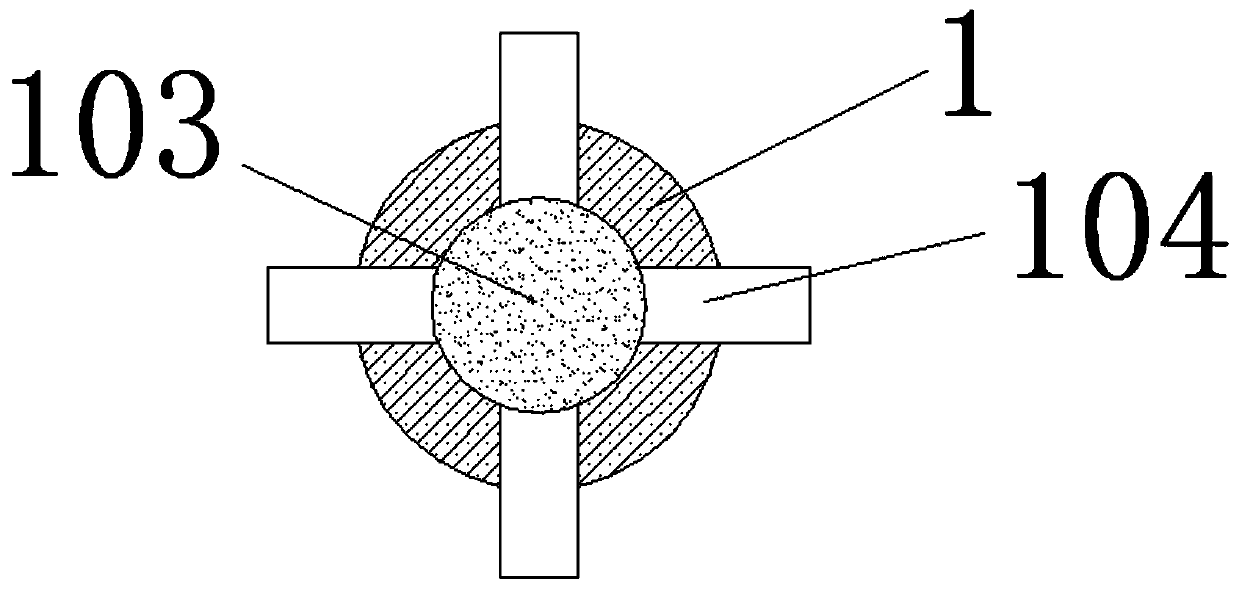

Drilling liner cementing rubber plug composite colliding device

InactiveCN102628347APrevent fallbackAvoid plug and low return problems outside the tubeSealing/packingEngineeringScrew thread

The invention relates to a petroleum drilling and cementing tool, in particular to a drilling liner cementing rubber plug composite colliding device. A drilling rod rubber plug of the device comprises a fixed nut, a connecting rod, a small rubber bowl and a bowl seat, the fixed nut, the connecting rod, the bowl seat and a guiding head are sequentially in threaded connection from top to bottom, the small rubber bowl is sleeved outside the connecting rod, a clamping block is installed on the outside of the bowl seat, and a back-moving spring is installed on the inside of the clamping block. A tail pipe tubular rubber plug comprises a tubular connector, a big rubber bowl and a tubular guiding bowl seat, the tubular connector is designed to be hollow, a clamping block groove matched with the clamping block is designed on the inner wall of the tubular connector, the lower end of the tubular connector is in threaded connection with the tubular guiding bowl seat, and the big rubber bowl is sleeved outside the tubular connector. The drilling liner cementing rubber plug composite colliding device is high in carrying power, reliable in fixation, simple in structure and convenient to use, and solves the problem that the existing well cementation rubber plug is low in carrying power, not safe in use and apt to cause cement inverse returning, low returning outside a pipe, and cement plug leaving in the pipe and the like.

Owner:CNPC GREATWALL DRILLING ENG

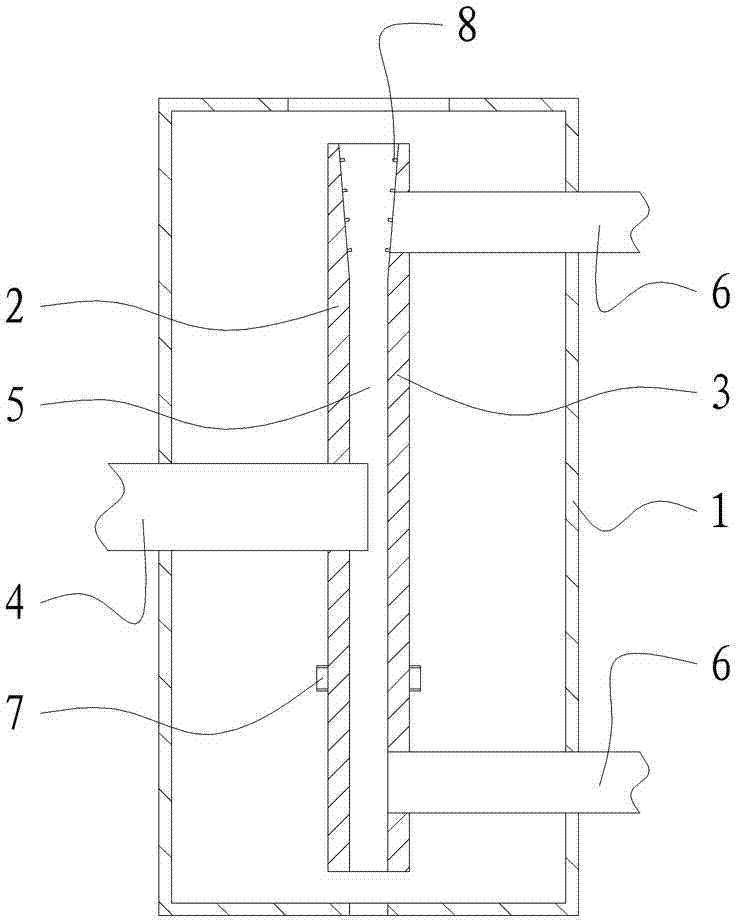

Sensor device

PendingCN109387304AGuaranteed accuracyIncrease bearing pressureForce measurementFluid pressure measurementKey pressingElastic component

The invention relates to a load-enhancing micromechanical sensor device in the detection fields of mass, weight, pressure, touch force, pulse, blood pressure, object resistance displacement, magnetostrictive displacement and the like and in the control fields of precision control, keys, switches and the like. The sensor device comprises a pressure sensor component and a force transmission component, wherein an external input force is decomposed or transferred to a base body or a shell and the force transmission component by an elastic component, so that an elastic diaphragm portion thereof only receives part of the input force. The technical solution has the advantages that a pressure sensor chip or a thin-film pressure sensor with low loading pressure and low range can also be used to manufacture a high-performance, high-loading pressure or high range sensor device.

Owner:许建平

Wood plastic composite board formula used for wardrobe

The invention discloses a wood plastic composite board formula used for wardrobe. The wood plastic composite board comprises the following raw materials with percentage in total mass percentage: 45-52% of polyvinyl chloride powder, 21-28% of wood powder, 6-8% of glass fiber, 2-4% of carbon fiber, 2.5% of an antistatic agent, 2% of a fire retardant, 2.5% of an anti-aging agent, 1.5% of a sign printing adhesion agent, 4% of a foaming agent, 1% of a lubricant, 0.5% of a foaming conditioning agent, and 3% of light calcium carbonate. The wood plastic composite board overcomes difficulty of fusion of timber and plastic, the wood plastic composite board solves the disadvantages of steel, timber and plastic, has the advantage of low cost, and is benefit to environment protection, and the prepared wardrobe has the advantages of light weight, high intensity, and strong bearing force.

Owner:彭绍宾

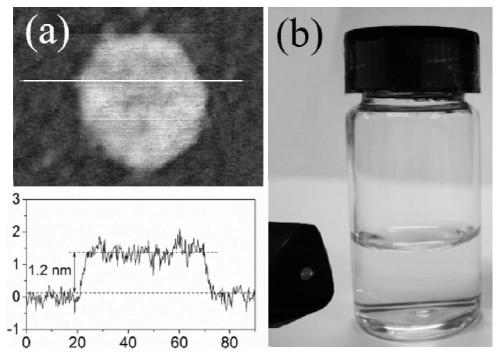

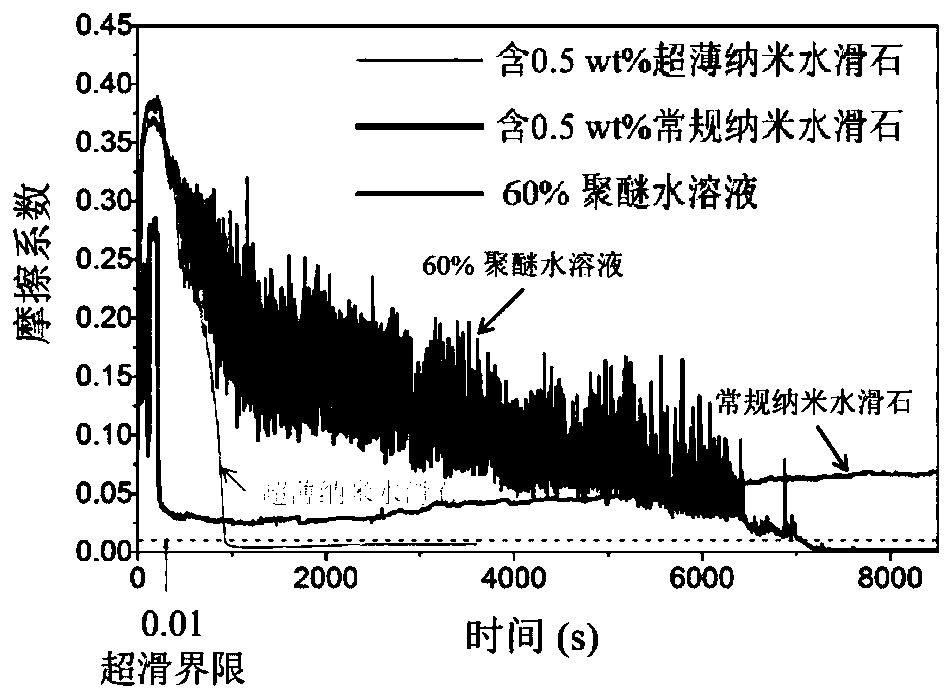

Preparation method of polyether hydrotalcite mixed solution

ActiveCN109722323AImprove the lubrication effectIncrease roughnessAdditivesHydrotalciteAqueous solution

The invention discloses a preparation method of a polyether hydrotalcite mixed solution with an ultra-low friction coefficient (less than 0.01), and belongs to the field of lubricating materials. Thesurface of an ultrathin nano hydrotalcite sheet prepared by adopting a hydrothermal method is provided with hydrophilic groups, and the ultrathin nano hydrotalcite sheet is uniformly dispersed in water according to the ratio of 0.5-2%, so that an uniform and translucent colloidal solution can be prepared, and then the uniform and translucent colloidal solution is mixed with a polyether lubricatingfluid at a ratio of 20-50%. The longitudinal dimension of the ultrathin nano hydrotalcite sheet in the polyether hydrotalcite mixed solution is very small compared with the thickness of a lubricatingfilm, and the surface of a friction pair can be flattened and polished in the running-in stage by addition of the hydrotalcite sample, so that the running-in process can be quickly completed, and bycombined with a polyether water solution, the ultralow friction coefficient is realized, and the final bearing capacity is improved.

Owner:TSINGHUA UNIV

Extremely-soft rock anchor rod structure and construction method

ActiveCN110043301AImprove the support effectIncrease bearing pressureAnchoring boltsMechanical engineeringGrout

The invention relates to the technical field of tunnel anchor rods and discloses an extremely-soft rock anchor rod structure. The extremely-soft rock anchor rod structure comprises a hollow anchor rodbody, a connecting sleeve, an expanding shell anchor head, a grout-stopping plug, a backing plate and a fixing nut, a limiting nut is mounted on the side, close to the connecting sleeve, of the hollow anchor rod body in threaded and sleeving modes, through grooves located between the limiting nut and the connecting sleeve are formed in the front surface, the rear surface, the upper surface and the lower surface of the hollow anchor rod body correspondingly, the hollow anchor rod body is internally provided with a movable block located in the through grooves, the movable block can move in thelimiting nut, and the front surface, the rear surface, the upper surface and the lower surface of the movable block are fixedly connected with linkage blocks correspondingly. A supporting rib is additionally arranged inside the hollow anchor rod body, the supporting rib is matched with the hollow anchor rod body and an anchoring agent inside the hollow anchor rod body, the bearing pressure of an anchor rod can be increased, the supporting effect of the hollow anchor rod body is improved, and the stability of tunnel supporting is improved.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

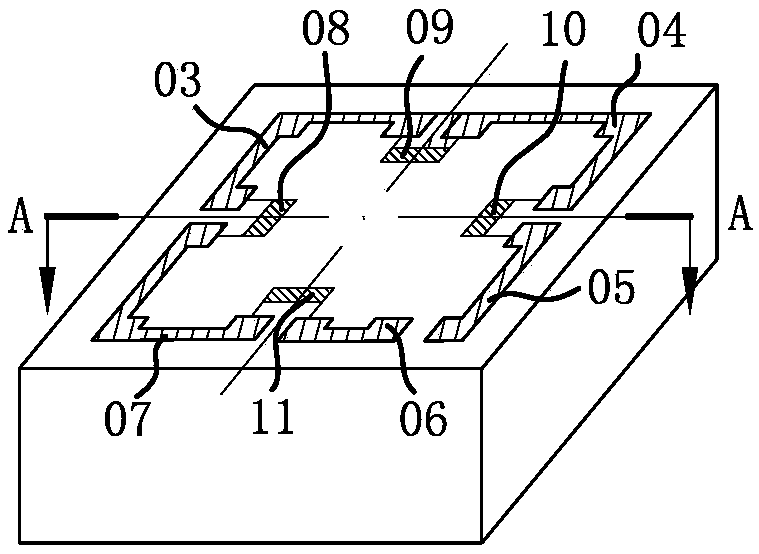

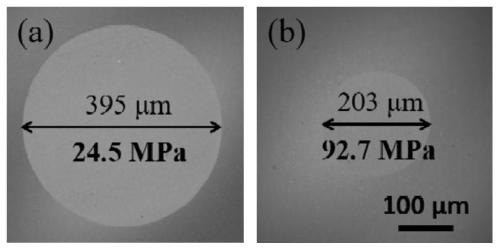

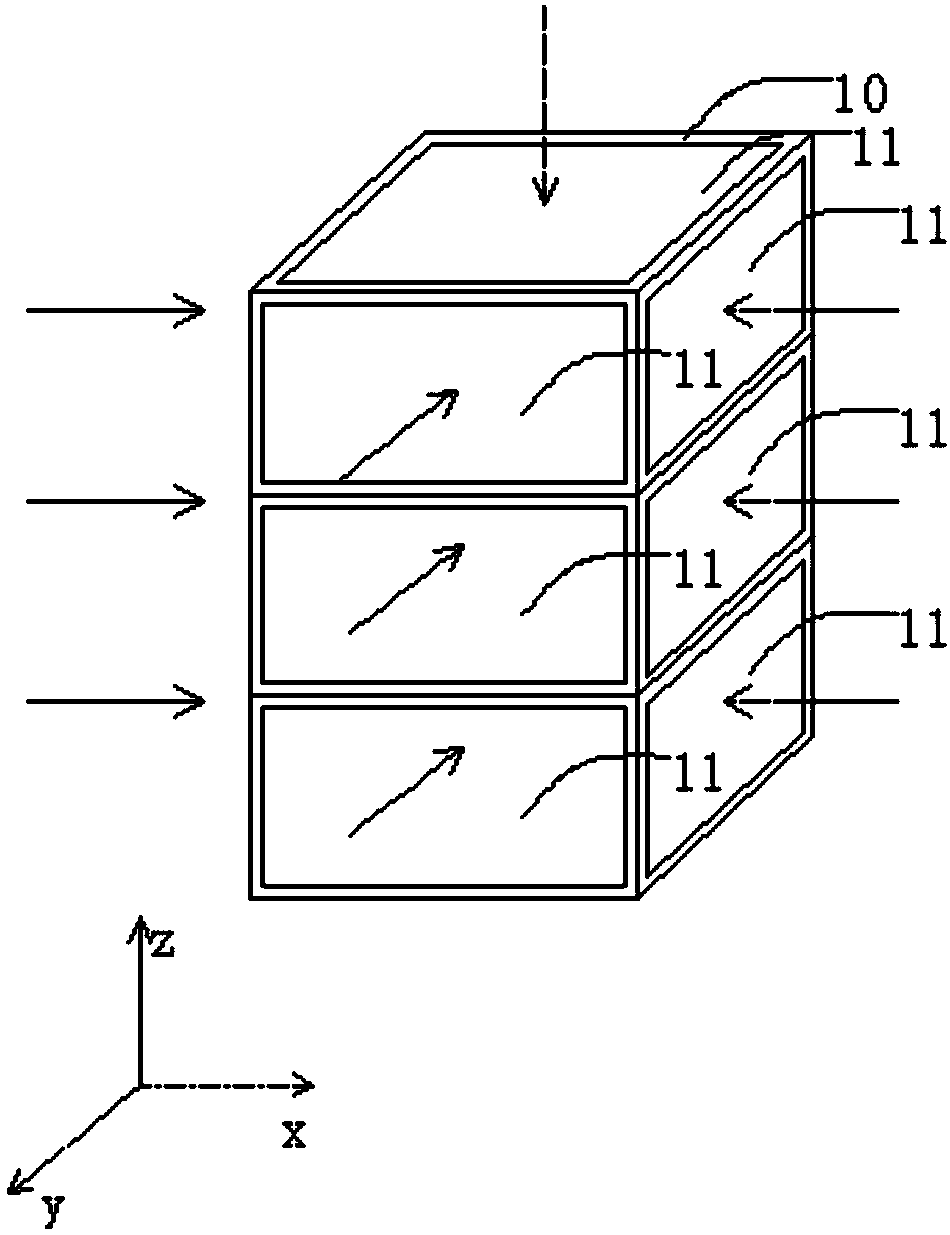

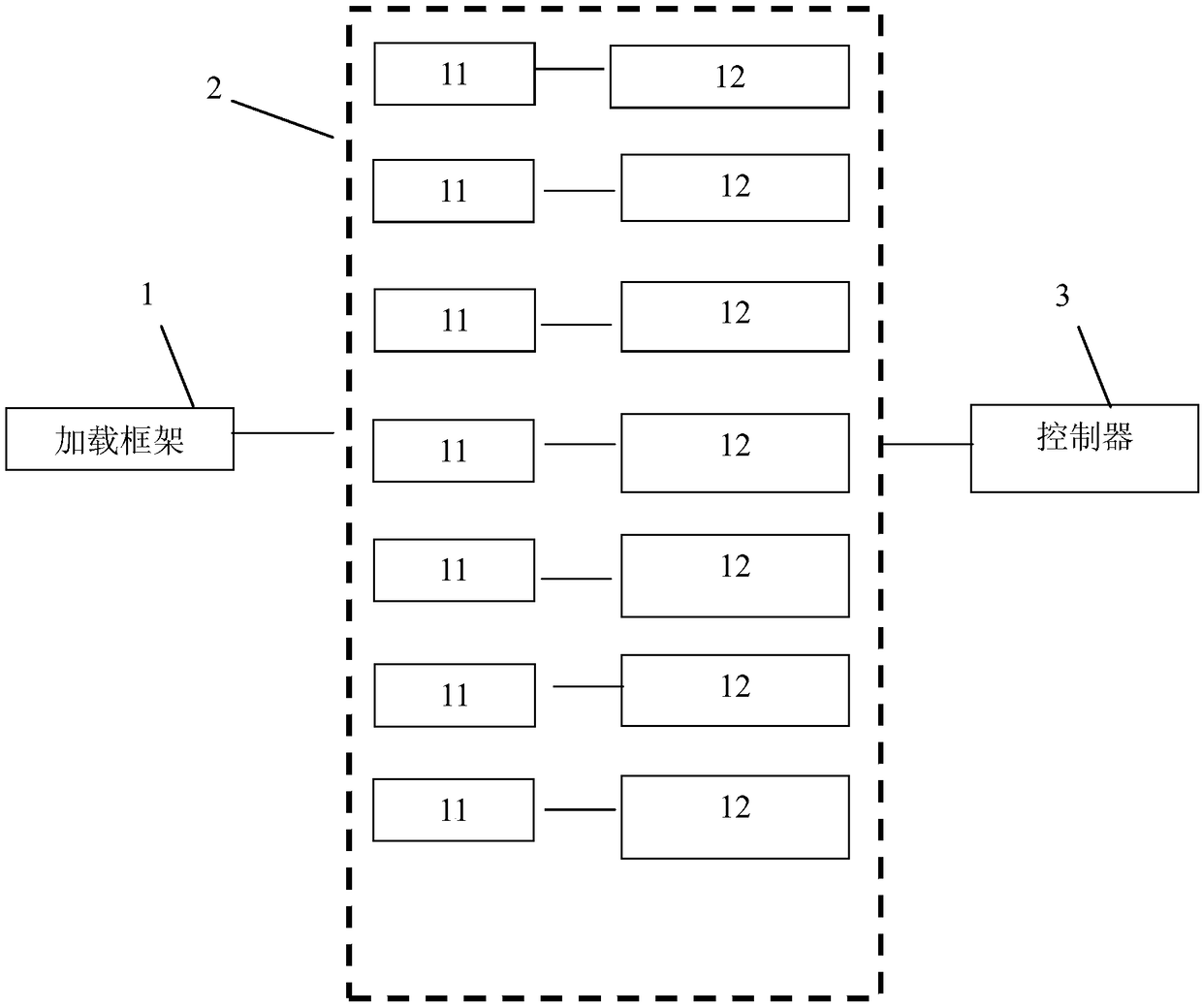

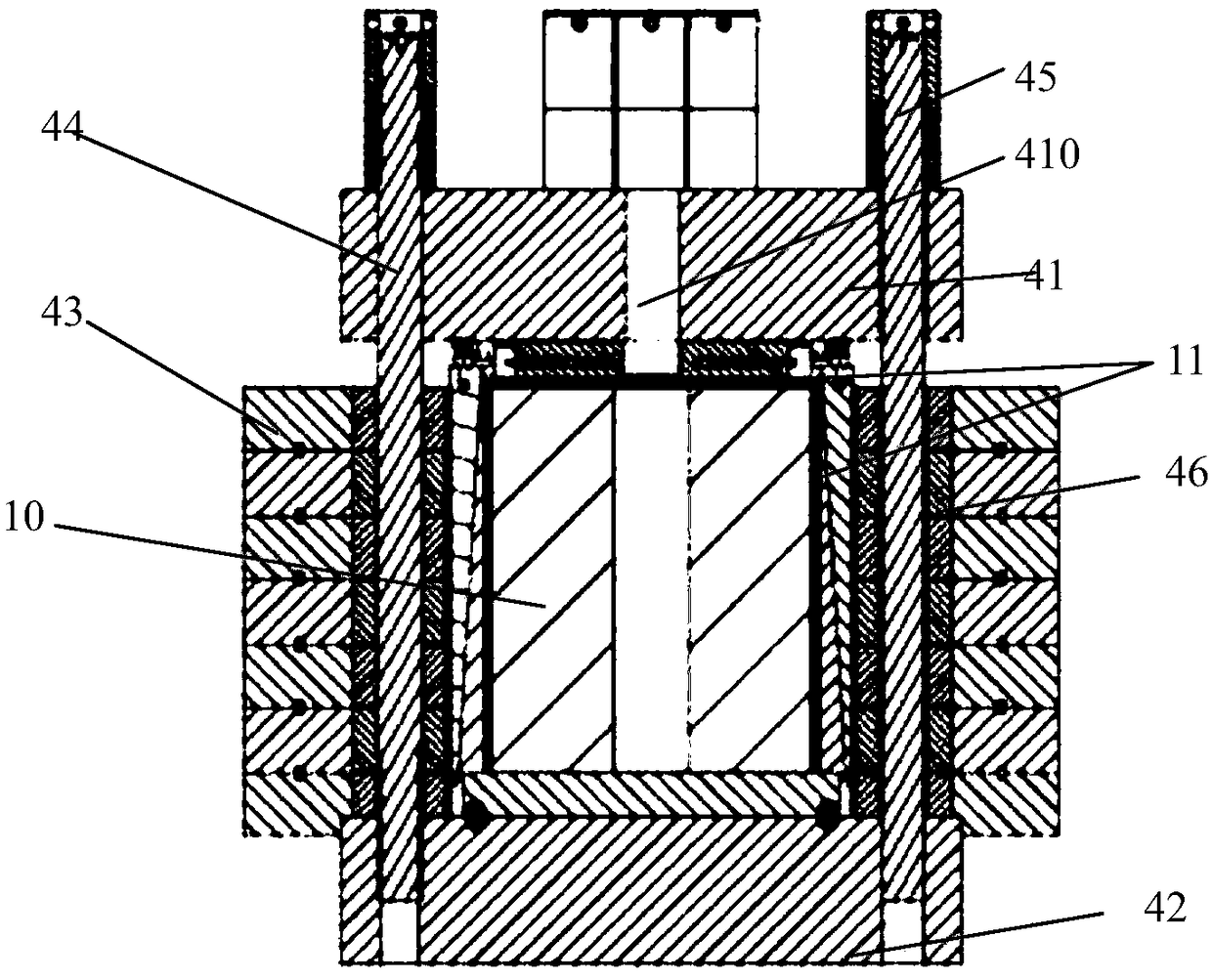

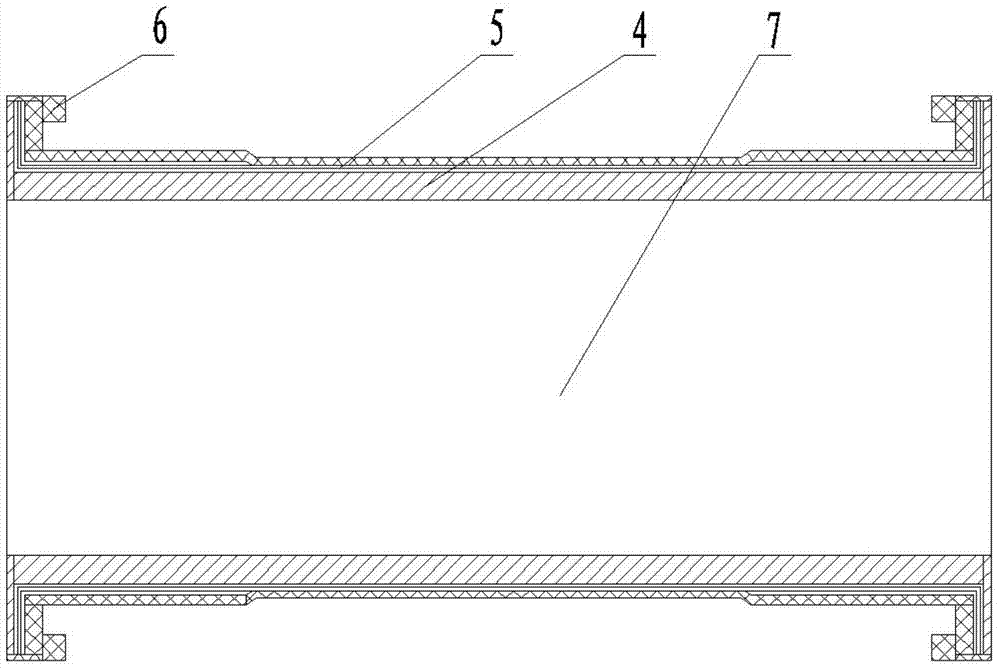

Experimental system and method for loading height extension of cracks in stress test

ActiveCN108760515AImplement independent loadingDeepen understandingMaterial strength using tensile/compressive forcesHorizontal stressTest sample

The invention discloses experimental system and method for loading height extension of cracks in stress test. The experimental system includes: a loading framework which is used for loading a test sample, a loading chamber which is formed in interior of the loading framework and is square in shape, and a true-triaxial ground stress loading unit which loads a pressure to the test sample and includes: an expandable loading plate which has a hollow structure, and a pressure pump, which is communicated with the expandable loading plate and supplies pressure thereto. The expandable loading plate includes: first loading plates between the loading chamber and the test sample and a second loading plate located on one end of the test sample, wherein the first loading plates include at least two groups in the depth direction of the loading chamber; a pressure sensor which is connected to the pressure pump; and a controller electrically connected to the pressure pump and the pressure sensor. Thesystem can achieve independent application of a load of multi-layer horizontal stress field in the vertical direction of the test sample and supplies beneficial technical support to optimization design on height growth controlled fracture technology.

Owner:PETROCHINA CO LTD

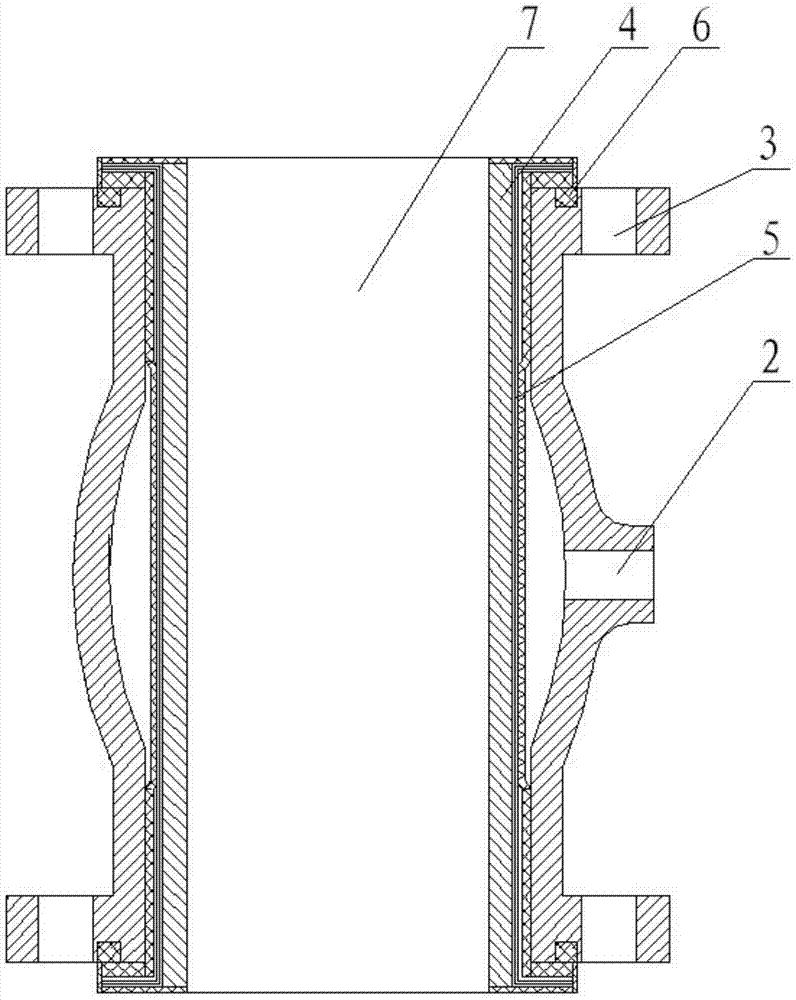

Pneumatic control valve

InactiveCN103615566AImprove sealingExtended service lifeDiaphragm valvesEngine diaphragmsEngineeringControl valves

The invention relates to a pneumatic control valve which comprises a valve body and a valve element arranged in the inner cavity of the valve body. The valve body comprises a shell body, an upper tubular inner cavity, an elliptic inner cavity, a lower tubular inner cavity and an air inlet, the upper tubular inner cavity, the elliptic inner cavity and the lower tubular inner cavity are arranged in sequence and are communicated in sequence, the air inlet is formed in the shell body, the air inlet is formed in the cavity wall of the elliptic inner cavity, and the valve element is provided with a middle through hole, a wear-resisting rubber layer and a tyre fabric reinforcement layer from inside to outside in sequence. The pneumatic control valve is good in sealing effect, the wear resistance of the valve element is good, the service life is long, and bearing pressure is high. The problem that the pneumatic control valve is poor in sealing or the valve element is easy to pull out is solved, the structure is simplified, and processing difficulty is lowered. The problems that an existing pneumatic control valve element is not resistant to wear and bearing pressure is low are solved.

Owner:烟台宜陶矿业有限公司

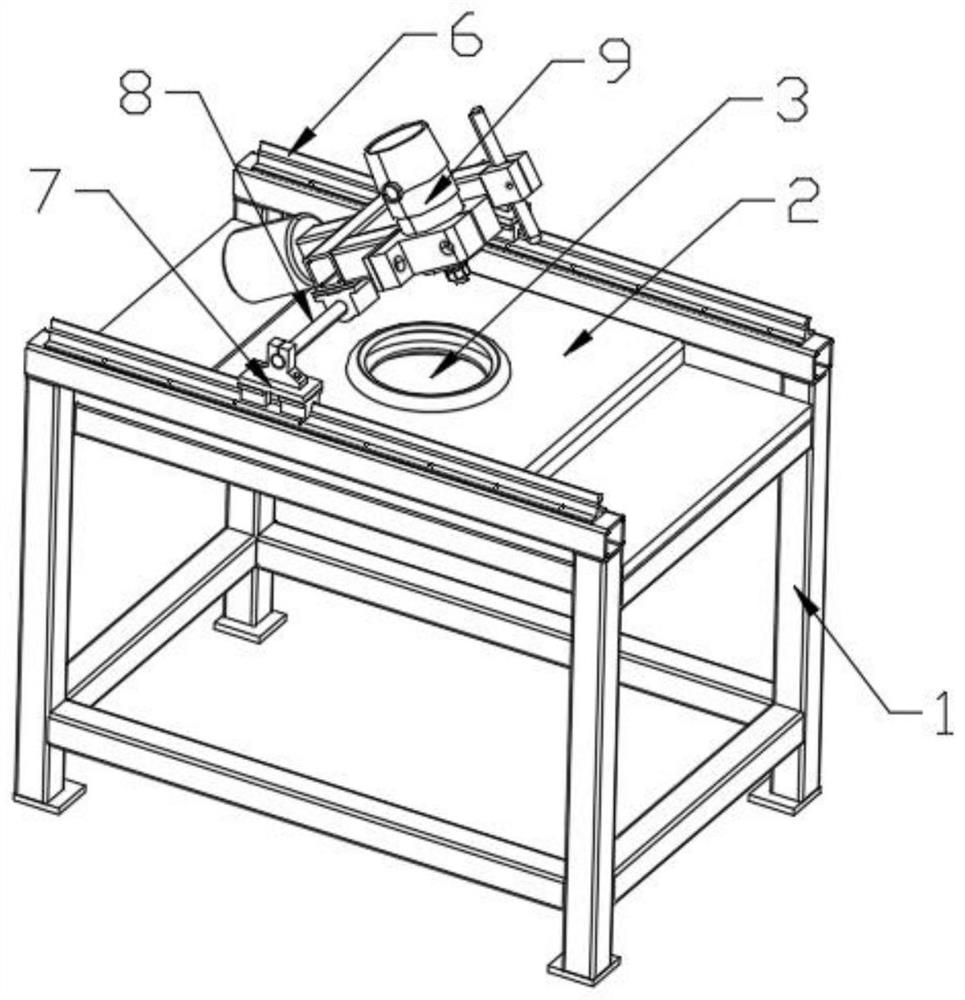

Machining device for high-precision servo motor brake disc

PendingCN113618114AAvoid overlappingImprove processing efficiencyProgramme controlComputer controlData informationControl engineering

The invention discloses a machining device for a high-precision servo motor brake disc. The device comprises a support frame and a data management module, wherein the data management module comprises a data detection module and a data processing module; the data detection module is used for detecting the real-time state of the device during operation, and transmitting data information to the data processing module; the data processing module is used for processing the received data information and controlling the device according to the processing result; a fixing plate is fixedly installed on the support frame; a limiting groove is formed in the center of the fixing plate, an elastic limiting piece is fixedly installed at the top of the limiting groove, and a fixed baffle is arranged at the bottom of the limiting groove; sliding rails are arranged at the two sides of the support frame; sliding blocks are connected to the tops of the sliding rails in a sliding manner; and rotary connecting rods are connected to the tops of the sliding blocks through bearings. The machining device has the characteristics that the brake disc is protected and the machining efficiency is improved.

Owner:QINGDAO FENGGUANG PRECISION MACHINERY

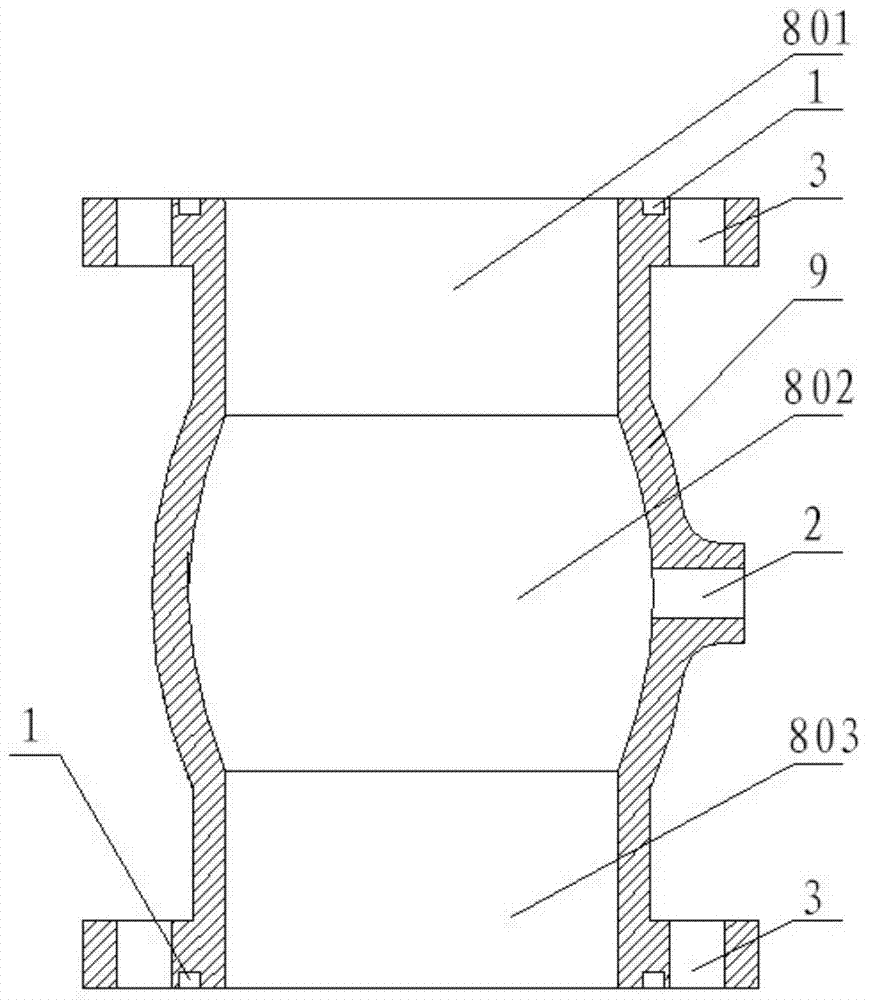

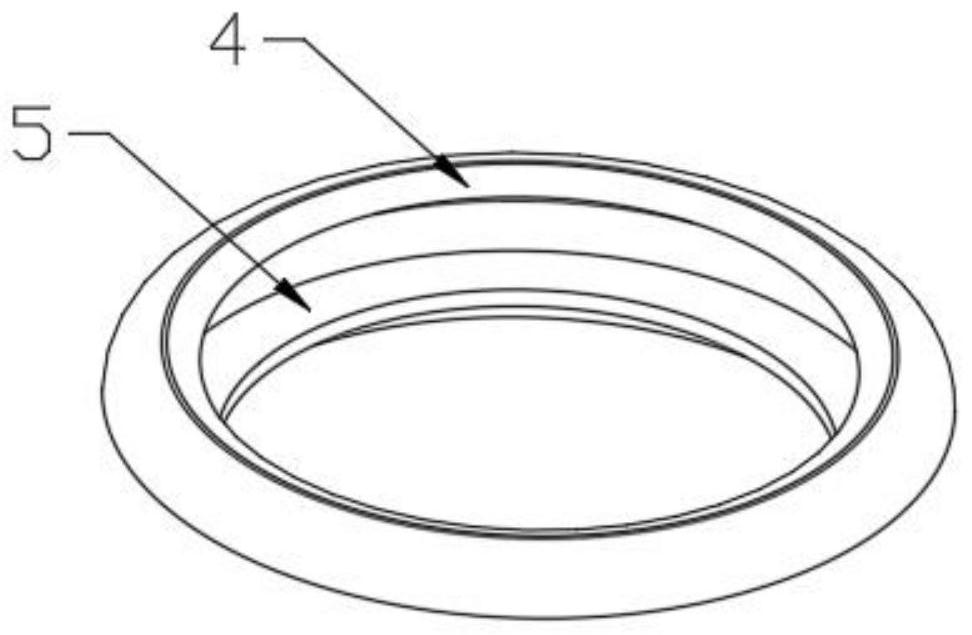

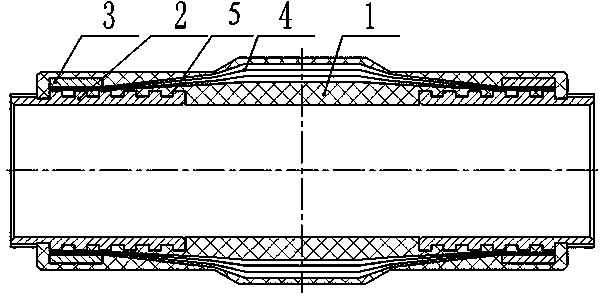

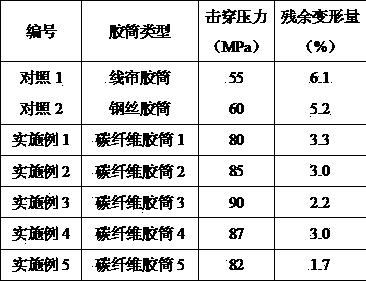

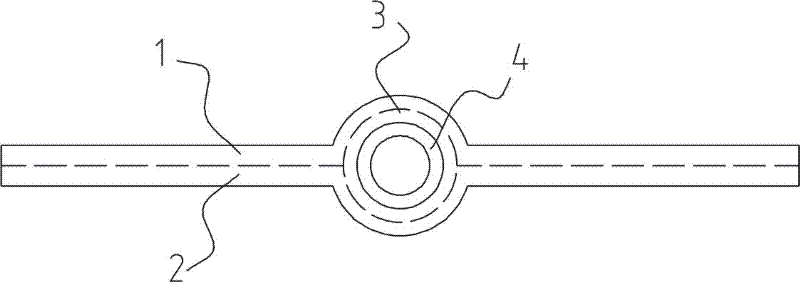

Expansion packer rubber barrel

InactiveCN103670325ASoft textureHigh tensile strengthSealing/packingCorrosion resistantPolymer chemistry

The invention relates to an expansion packer rubber barrel. The expansion packer rubber barrel comprises a rubber barrel body (1), metal connecting pipes (2) and annular rings (3), wherein the two ends of the rubber barrel body (1) are fixed to the metal connecting pipes (2) through heat vulcanization technology glue, the two ends of the rubber barrel body (1) are fastened through the annular rings (3), and carbon fiber cord fabric (4) is buried in the rubber barrel body (1). The carbon fiber cord fabric high in tensile strength is buried in the rubber barrel body and is very popular and catches close attention because of having the advantages of being soft in texture, resistant to corrosion, very thin in sheet material, high in tensile strength and the like. Compared with an existing method that steel wires are buried in the rubber barrel body, the bearing capacity and expansion amount of the rubber barrel are greatly improved, the service life of the rubber barrel at high temperature is greatly prolonged, the phenomenon that because the steel wires are high in to rigidity, the components are damaged easily is avoided, and the expansion packer rubber barrel is simple in machining technology and easy to popularize and apply.

Owner:DAQING HAOYUN RUBBER PROD

Solar energy heat collecting tube and production method thereof

InactiveCN102338492AIncrease bearing pressureImprove antifreeze effectSolar heat devicesHeat exchange apparatusSolderingMaterials science

The invention discloses a solar energy heat collecting tube comprising two aluminum strips an aluminum tube and a copper tube, wherein the aluminum tube is arranged between the two aluminum strips and compounded with the two aluminum strips into a whole, the copper tube is penetrated in the aluminum tube, and the outer wall of the copper tube is in contact with the inner wall of the aluminum tube. A runner of the solar energy heat collecting tube provided by the invention has three layers of walls, and copper is not stretched by a roller, therefore, the heat collecting tube has high bearing capacity and good freezing prevention performance and can be used under a low-temperature environment; and the copper tube is not stretched by the roller, therefore, the thickness of the copper tube is not reduced, and the service life of a product is greatly prolonged; in addition, two ends of the copper tube extend out of the aluminum tube, and during use, the copper tube is directly connected with the heat collecting tube, therefore, fewer soldering points exist, and less influence to the bearing capacity of the heat collecting tube is caused. Meanwhile, the invention discloses a production method of the solar energy heat collecting tube.

Owner:GUANGZHOU HOPESUN SOLAR EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com