Pressure-bearing lost circulation additive for drilling fluid and for stably bearing pressure on smooth fracture leakage wall surface

A technology of drilling fluid and plugging agent, which is applied in the field of oil exploration, can solve the problems of low plugging success rate, fracture pressure plugging failure, low bearing pressure, etc. The effect of high pressure and sliding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

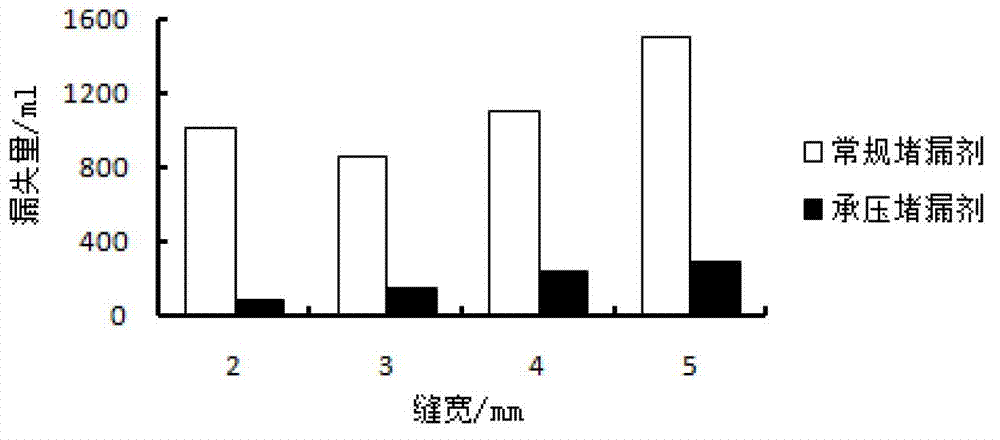

[0025] A fracture module with a width of 2 mm was selected, and 3.5 L of plugging base slurry was prepared. The base slurry formula was: 6% bentonite + 1% CMC-HV. The dosage of the plugging agent is 6% of the plugging slurry (mass volume percentage g / ml). The size of the material is 14-20 mesh of the standard mesh of the sample sieve, and the size of the friction material is 1.0×1.0-1.6×1.6mm. The amount of plugging agent added is 21g of friction material; 105g of bridging material; 84g of filling material, of which the first level: 42g of calcium carbonate powder with a standard mesh size of 20-40 mesh in the sampling sieve, and the second level: standard mesh size in the sampling sieve 16.8g of calcium carbonate powder of 40-80 mesh, the third stage: 16.8g of calcium carbonate powder with a standard mesh size of 80-150 mesh in the sampling sieve, and 16.8g of calcium carbonate powder with a standard mesh number of 80-150 mesh in the sampling sieve, and 8.4g of flexible graph...

Embodiment 2

[0027] A fracture module with a width of 3 mm was selected, and 3.5 L of plugging base slurry was prepared. The base slurry formula was: 6% bentonite + 1% CMC-HV. The dosage of the plugging agent is 8% of the plugging slurry (mass volume percentage g / ml). The material is a sampling sieve with a standard mesh number of 10-20 mesh, and the size of the friction material is 1.0×1.0-2.0×2.0mm. The amount of plugging agent added is 33.6g of friction material; 140g of bridging material; 106.4g of filling material, of which the first stage: 53.2g of calcium carbonate powder with a standard mesh size of 20-40 mesh in the sampling sieve, and the second stage: sampling sieve 21.3g of calcium carbonate powder with a standard mesh number of 40-80 mesh, the third level: 21.3g of calcium carbonate powder with a standard mesh number of 80-150 mesh in the sampling sieve, 21.3g of calcium carbonate powder with a standard mesh number of 80-150 mesh in the sampling sieve, and 10.6 grams of flexib...

Embodiment 3

[0029] A fracture module with a width of 4 mm was selected, and 3.5 L of plugging base slurry was prepared. The base slurry formula was: 6% bentonite + 1% CMC-HV. The dosage of the plugging agent is 9% of the plugging slurry (mass volume percentage g / ml). The material is a sampling sieve with a standard mesh of 8-20 mesh, and the size of the friction material is 1.0×1.0-2.5×2.5mm. The amount of plugging agent added is 47.2g of friction material; 151.2g of bridging material; 116.6g of filling material, of which the first stage: 58.3g of calcium carbonate powder with a standard mesh size of 20-40 mesh in the sampling sieve, and the second stage: sampling 23.3g of calcium carbonate powder with a standard mesh of 40-80 mesh, the third stage: 23.3g of calcium carbonate powder with a standard mesh of 80-150 mesh in the sampling sieve, fourth stage: flexible graphite powder with a standard mesh of more than 150 mesh in the sampling sieve 11.7g. The cracks were successfully sealed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com