Expansion packer rubber barrel

A packer and expansion technology, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of small expansion and low pressure bearing, achieve small residual deformation and prolong service life , High tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

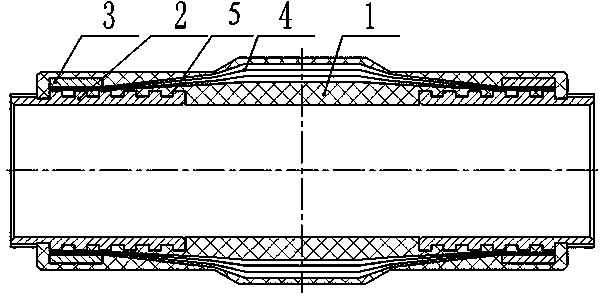

[0012] figure 1 It is a schematic structural diagram of the present invention. As shown in the figure, the expansion packer rubber sleeve includes a rubber sleeve 1, a metal connecting pipe 2 and an annular ring 3. The glue is fixed together, and the two ends of the rubber tube 1 are fastened with annular rings 3 to prevent the rubber tube 1 from sliding. In order to fix the annular ring 3 , the outer wall of the metal connecting pipe 2 is provided with an annular groove 5 , and the annular ring 3 is stuck in the annular groove 5 . The rubber tube 1 is embedded with carbon fiber cord fabric 4, and the tensile strength of the selected carbon fiber cord fabric 4 is 380N / mm 2 , The carbon fiber diameter is 0.5mm. The carbon fiber cord fabric is used to replace the traditional steel wire. Carbon fiber cord fabric is favored and concerned for its soft texture, corrosion resistance, hydrogen sulfide gas resistance, high tensile strength, small residual deformation and many fatigue...

Embodiment 2

[0015] figure 1 It is a schematic structural diagram of the present invention. As shown in the figure, the expansion packer rubber sleeve includes a rubber sleeve 1, a metal connecting pipe 2 and an annular ring 3. The glue is fixed together, and the two ends of the rubber tube 1 are fastened with annular rings 3 to prevent the rubber tube 1 from sliding. In order to fix the annular ring 3 , the outer wall of the metal connecting pipe 2 is provided with an annular groove 5 , and the annular ring 3 is stuck in the annular groove 5 . The rubber tube 1 is embedded with carbon fiber cord fabric 4, and the tensile strength of the selected carbon fiber cord fabric 4 is 450N / mm 2 , The carbon fiber diameter is 0.65mm. The carbon fiber cord fabric is used to replace the traditional steel wire. Carbon fiber cord fabric is favored and concerned for its soft texture, corrosion resistance, hydrogen sulfide gas resistance, high tensile strength, small residual deformation and many fatigu...

Embodiment 3

[0018] figure 1 It is a schematic structural diagram of the present invention. As shown in the figure, the expansion packer rubber sleeve includes a rubber sleeve 1, a metal connecting pipe 2 and an annular ring 3. The glue is fixed together, and the two ends of the rubber tube 1 are fastened with annular rings 3 to prevent the rubber tube 1 from sliding. In order to fix the annular ring 3 , the outer wall of the metal connecting pipe 2 is provided with an annular groove 5 , and the annular ring 3 is stuck in the annular groove 5 . The rubber tube 1 is embedded with carbon fiber cord fabric 4, and the tensile strength of the selected carbon fiber cord fabric 4 is 650N / mm 2 , the carbon fiber diameter is 1mm. The carbon fiber cord fabric is used to replace the traditional steel wire. Carbon fiber cord fabric is favored and concerned for its soft texture, corrosion resistance, hydrogen sulfide gas resistance, high tensile strength, small residual deformation and many fatigue t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com