Solar energy heat collecting tube and production method thereof

A technology for solar heat collecting tubes and production methods, which is applied in the production of solar heat collecting tubes and in the field of solar heat collecting tubes, and can solve the problems of reduced pressure, short service life, and bursting of heat collecting tubes, and achieve extended service life, long service life, and bearing capacity stressful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

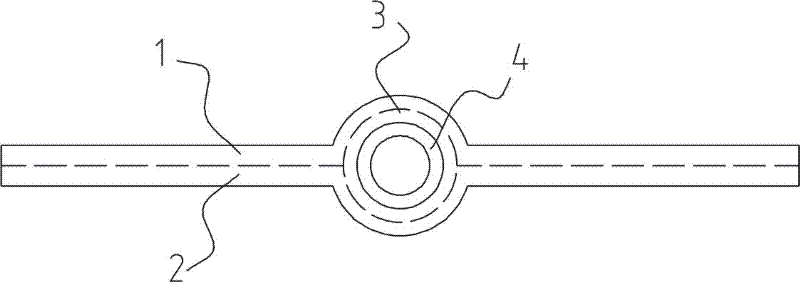

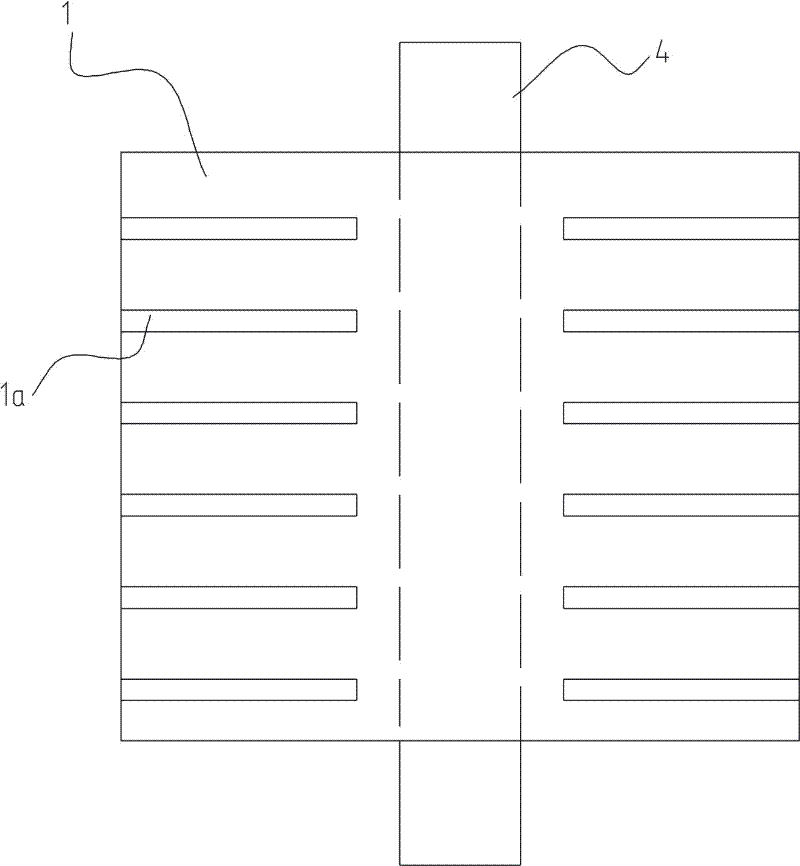

[0030] Such as figure 1 , 2 As shown, the solar collector tube of the present embodiment is made up of two aluminum strips 1,2, an aluminum tube 3 and a copper tube 4, and the aluminum tube 3 is arranged between the two aluminum strips 1,2, and is connected with the two aluminum strips 1,2. The aluminum strips 1 and 2 are combined into one body, and the copper tube 4 is penetrated in the aluminum tube 3 and is in contact with the aluminum tube 3 . The aluminum strips on both sides of the aluminum tube 3 are pressed with convex ribs 1a. A heat absorbing coating is provided on the outer surfaces of the two aluminum strips 1 and 2 . Both ends of the copper tube 4 protrude from the aluminum tube 3 .

Embodiment 2

[0032] One of the production methods of the solar collector tube of embodiment 1 is as follows:

[0033] (1) Aluminum tube 3 is combined with aluminum strips 1 and 2

[0034] Aluminum strip compounding refers to crushing the oxide film on the composite surface of aluminum strips 1, 2, and aluminum tube 3 through plastic deformation, exposing the metal atoms to reach the distance of interatomic attraction, and making the two aluminum strips 1, 2, The aluminum tubes 3 are connected into one body. Before compounding, the compound surfaces of the two aluminum strips 1 and 2 are polished. Moreover, in order to facilitate the separation of the composite surface and insert the blowing nozzle during inflation, lubricating oil (preferably heat-conducting oil lubricating oil) is applied to the inner wall of the aluminum tube 3 .

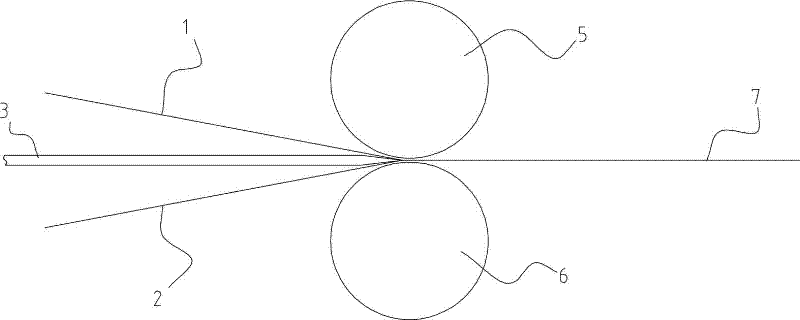

[0035] Such as image 3 As shown, the aluminum tube 3 is sandwiched between two aluminum strips 1 and 2, and is composited into one body by two rolls 5 and...

Embodiment 3

[0044] Different from Example 2, the method of contacting the aluminum tube 3 and the copper tube 4 is: after the copper tube 4 is inserted into the aluminum tube 3, it is placed between the second upper inflation mold and the second lower inflation mold with a pipeline cavity. During this period, the pressure fluid is passed into the copper tube 4 to inflate the copper tube 4 so as to be in close contact with the aluminum tube 3 . With this method, damage to the heat-absorbing coating on the surface of the aluminum sheet can be avoided during pressing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com