Double layer hollow large sucking plastic tray

A double-layer hollow, large-scale technology, applied in the direction of rigid containers, containers, packaging, etc., can solve the problems of limited logistics speed, high transportation cost, consumption of auxiliary materials, etc., and achieve the effect of improving logistics speed, reducing transportation cost and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

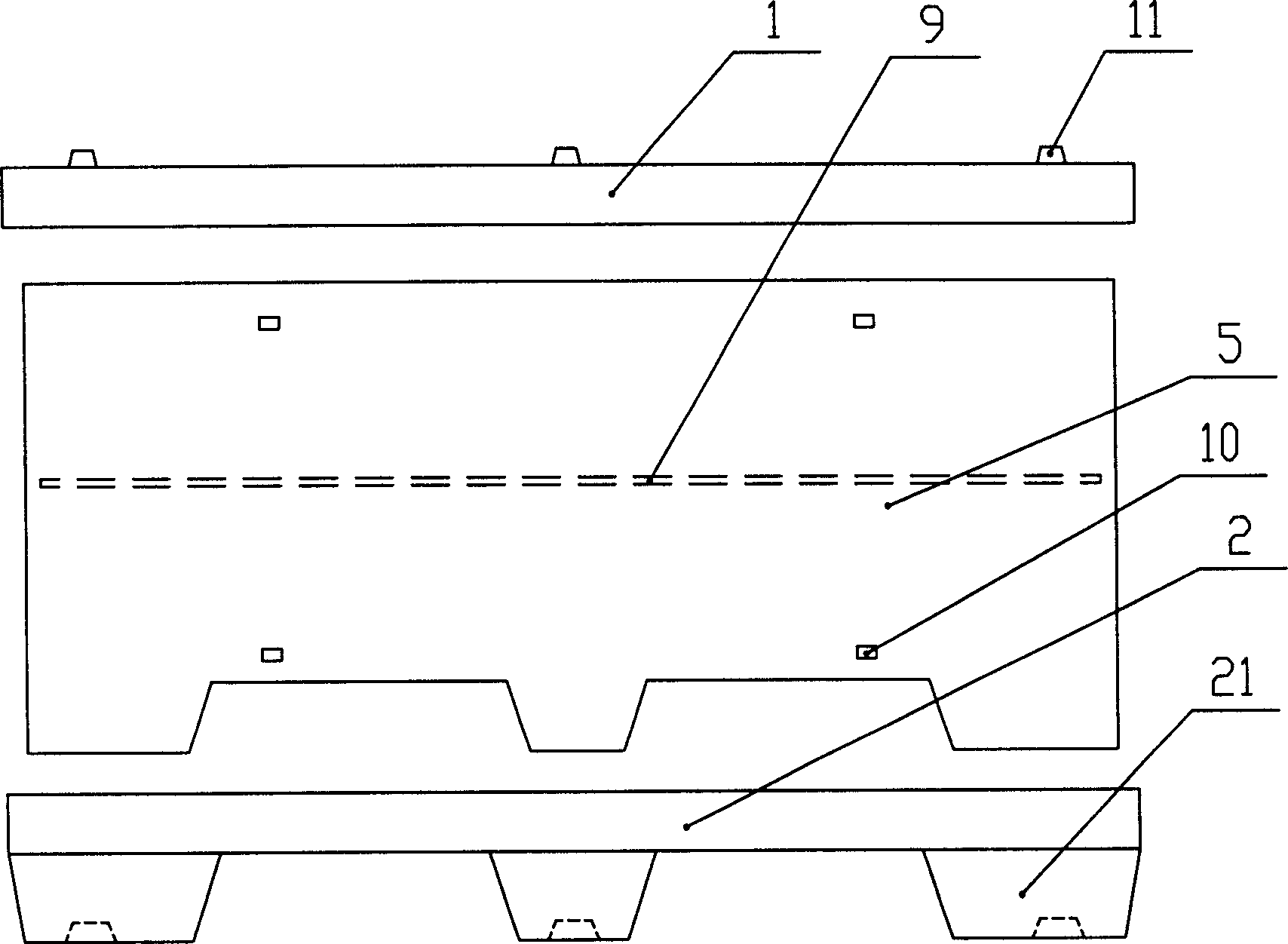

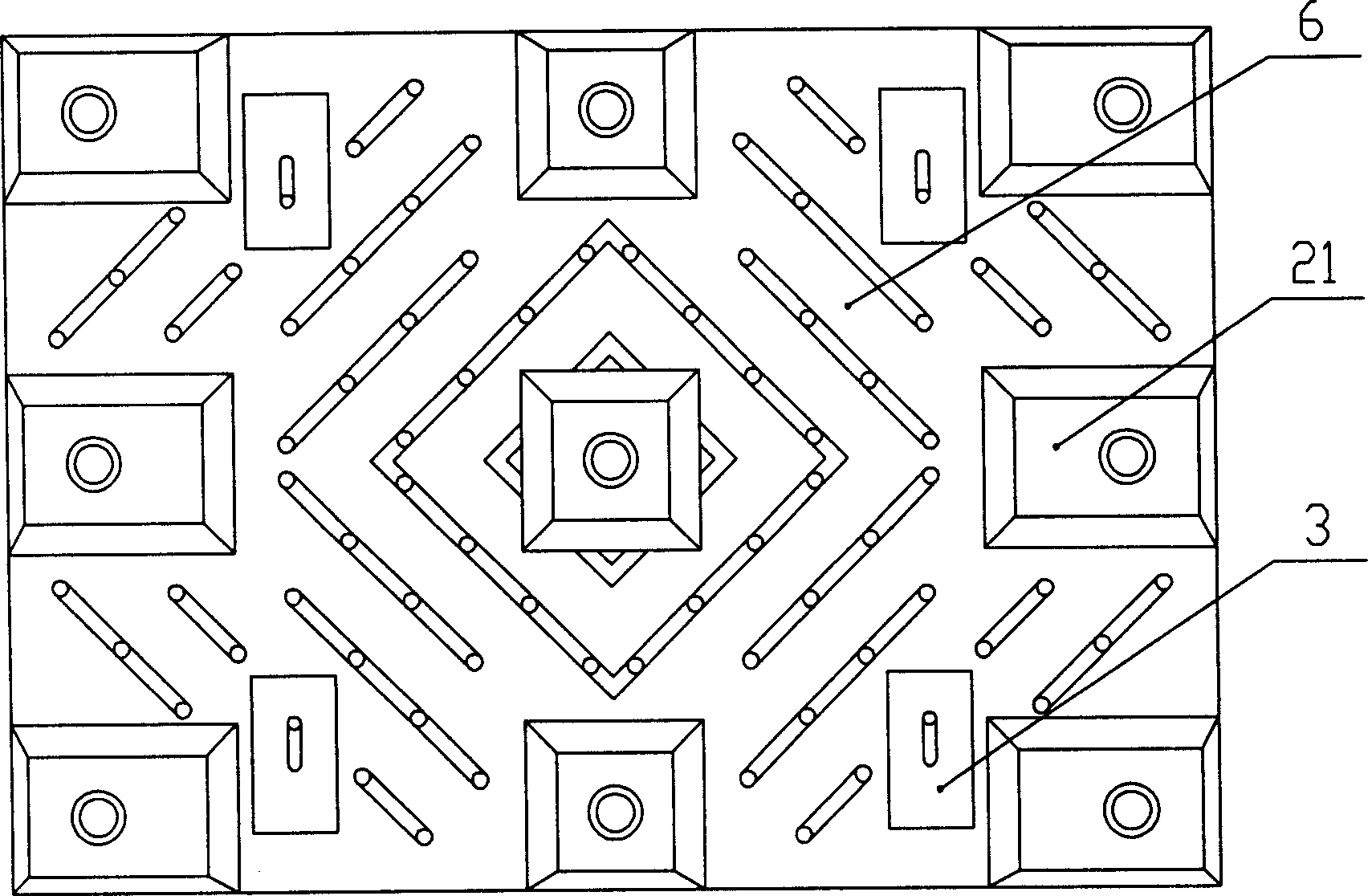

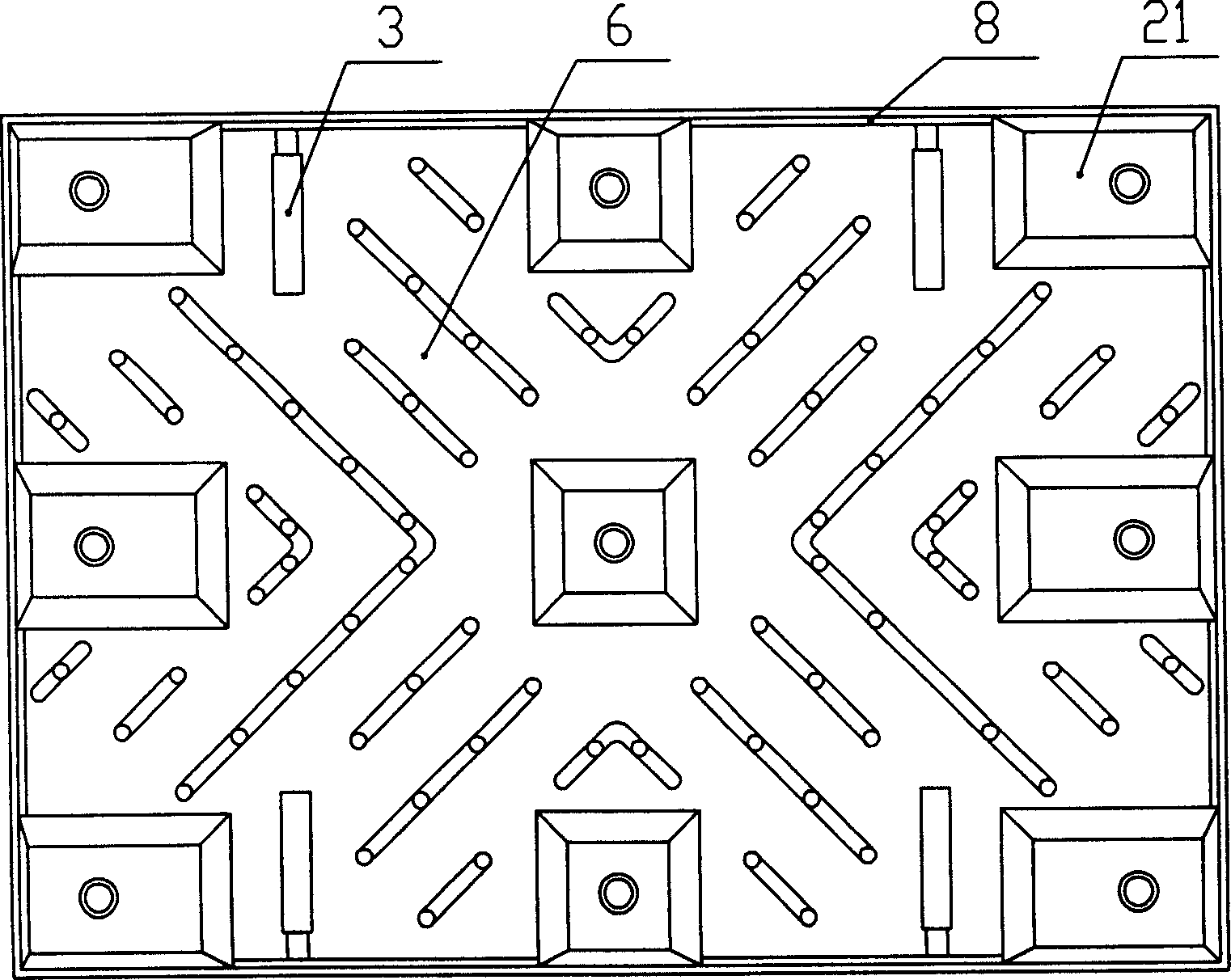

[0022] Such as Figure 1~3 The first embodiment of the shown double-layer hollow large blister tray of the present invention has a plastic top cover 1 and a plastic base 2, and both the plastic top cover 1 and the plastic base 2 are made of two pieces of high-density polyethylene (HDPE) Hollow structure made of single-piece thermal bonding, plastic top cover 1 and plastic base 2 are provided with reinforcing ribs 6, plastic top cover 1 and plastic base 2 are respectively provided with locks 3, and locks 3 are bolt-type locks buckle, the plastic top cover 1 and the plastic base 2 are provided with a coaming plate 5, the coaming plate 5 can be made of various materials, such as plastic board or cardboard, etc., the plastic top cover 1 and the plastic base 2 are respectively provided with a coaming plate groove 8 , both ends of the coaming plate 5 are respectively embedded in the coaming plate groove 8, a pin hole 10 is provided on the coaming plate 5 corresponding to the latch o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com