Three-branch single-cylinder hydraulic bidirectional expansion-extrusion device

A three-chamber single-cylinder, hydraulic technology, applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the complex structure of the double-cylinder two-way hydraulic expansion device, increase the difficulty and power supply, and the deviation of the longitudinal bearing shape. and other problems, to achieve the effect of good promotion and use value, simple structure and good cavity forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the accompanying drawings of the description, the three-fork single-cylinder hydraulic two-way expansion device of the present invention will be further described in detail as follows:

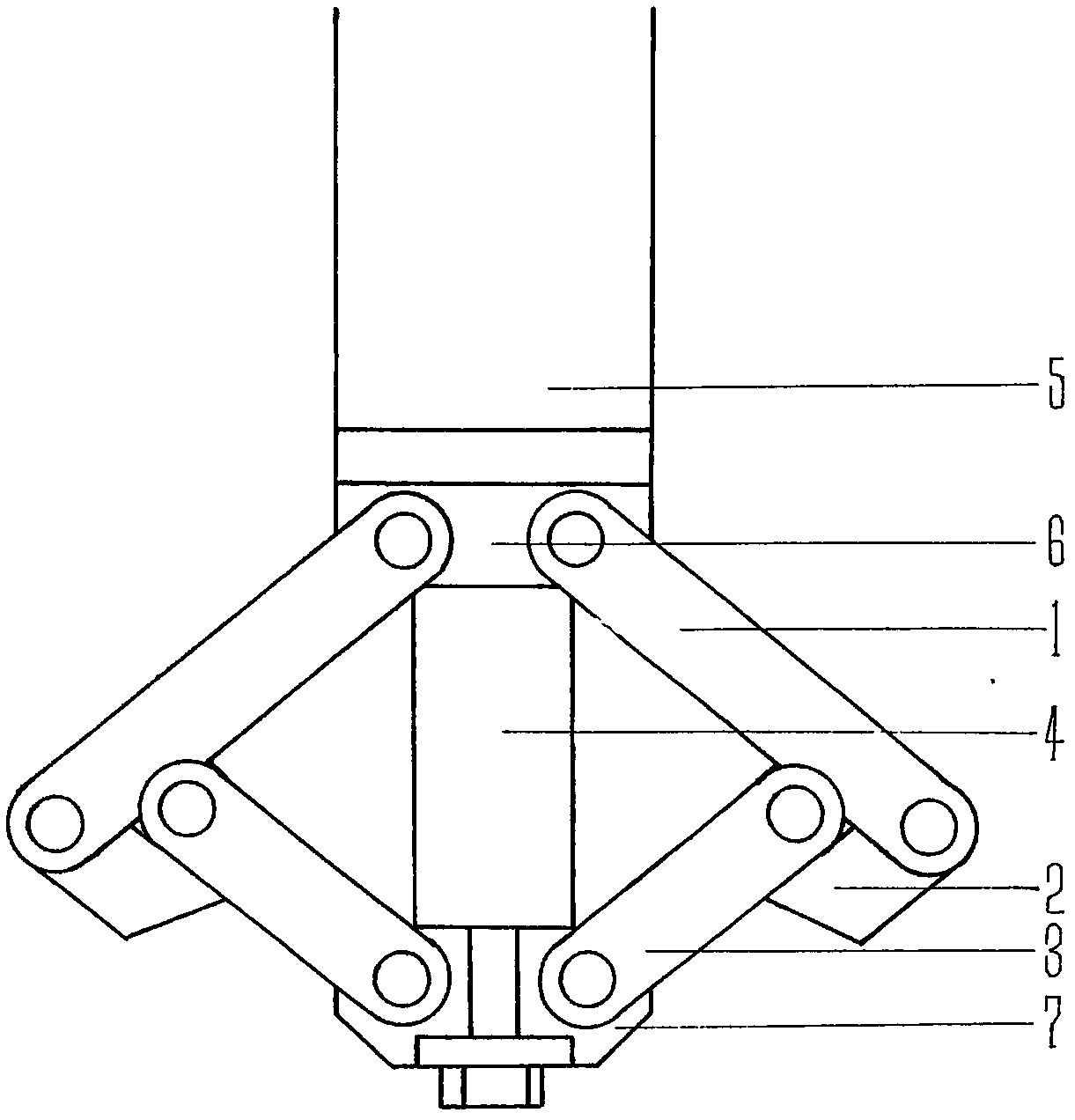

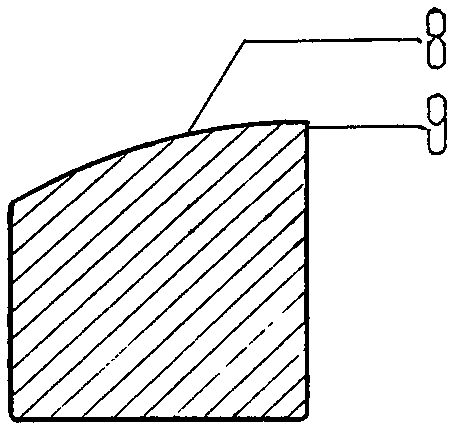

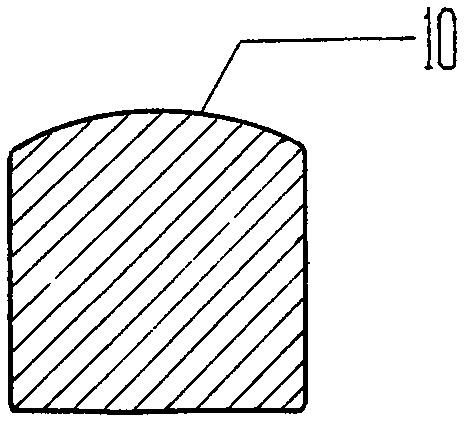

[0019] Such as figure 2 As shown, the functional part of the three-fork single-cylinder hydraulic two-way separate expansion device is composed of the expansion upper arm 1, the support arm 3 as two fixed sides, the piston rod 4 as a variable side, and is composed of a fixed disc 6 and a movable disc 7. Three congruent triangles with equal angles. The extended lower end of the extended extruded upper arm 1 is shaft-connected and extruded the severed lower arm 2 . The lower end of the extruded lower arm 2 is an oblique broken end, which is parallel to the support arm 3, and one side of the cross section of the extruded upper arm 1 is an oblique arc surface 8, and the angle between the oblique arc surface 8 and the bottom is the cutting edge 9. One side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com