Preparation method of polyether hydrotalcite mixed solution

A mixed solution and hydrotalcite technology, which is applied in lubricating compositions, petroleum industry, additives, etc., can solve problems such as surface corrosion and pH value reduction, and achieve the effect of avoiding corrosion, shortening the process of super slipperiness, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings.

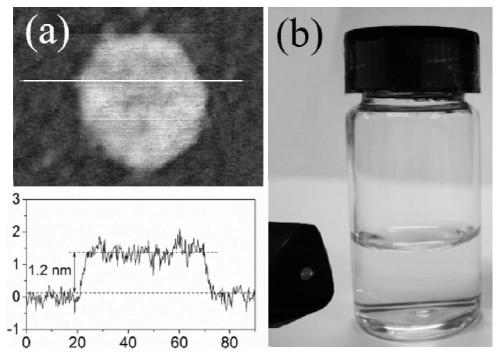

[0025] figure 1 These are the microscopic pictures of the ultra-thin nano-hydrotalcite sheets in the mixed solution prepared by the present invention and their dispersion in water, where (a) is the atomic force microscope picture of the synthesized ultra-thin nano-hydrotalcite sheets; (b) is the dispersion in water.

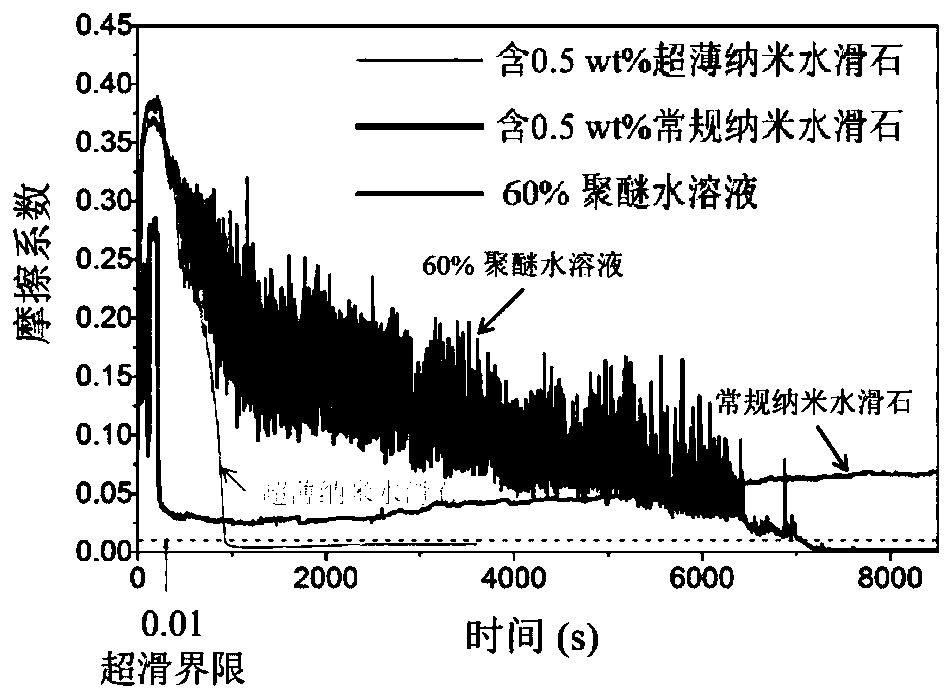

[0026] figure 2 This is a graph of the friction coefficient of the polyether aqueous solution containing different types of hydrotalcite additives of the present invention.

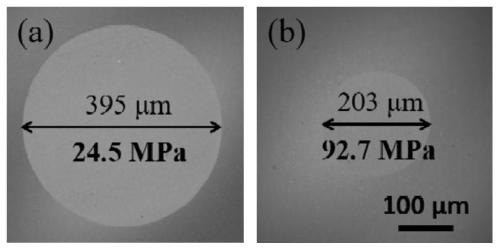

[0027] image 3 Wherein (a) is the polyether aqueous solution and (b) is the wear scar diameter diagram after the friction test of the sample containing 0.5wt% ultra-thin nano-hydrotalcite sheet.

[0028] The present invention provides a preparation and application method of a polyether hydrotalcite mixed solution that can achieve an ultra-low friction coefficient. The present invention will b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com