General operation method for reaching given pre-tightening torque of high-strength bolt for tower crane

A technology of high-strength bolts and operating methods, applied to cranes, wrenches, wrenches, etc., can solve problems such as large volume, unsatisfactory use requirements, and unsatisfactory structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

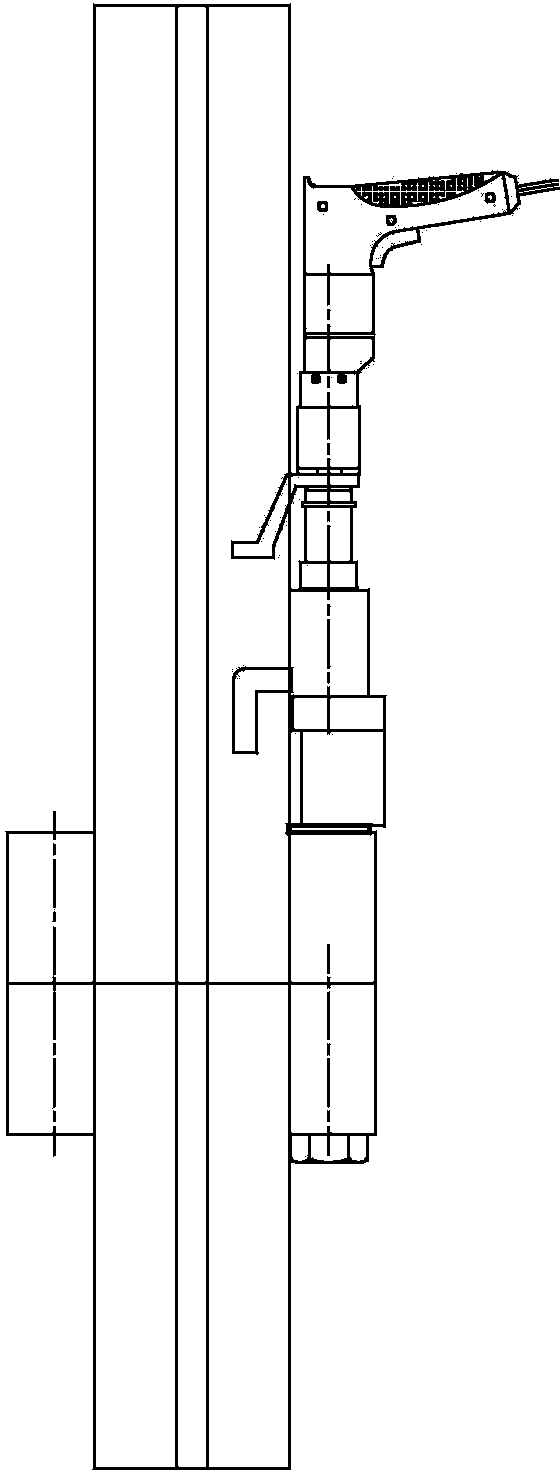

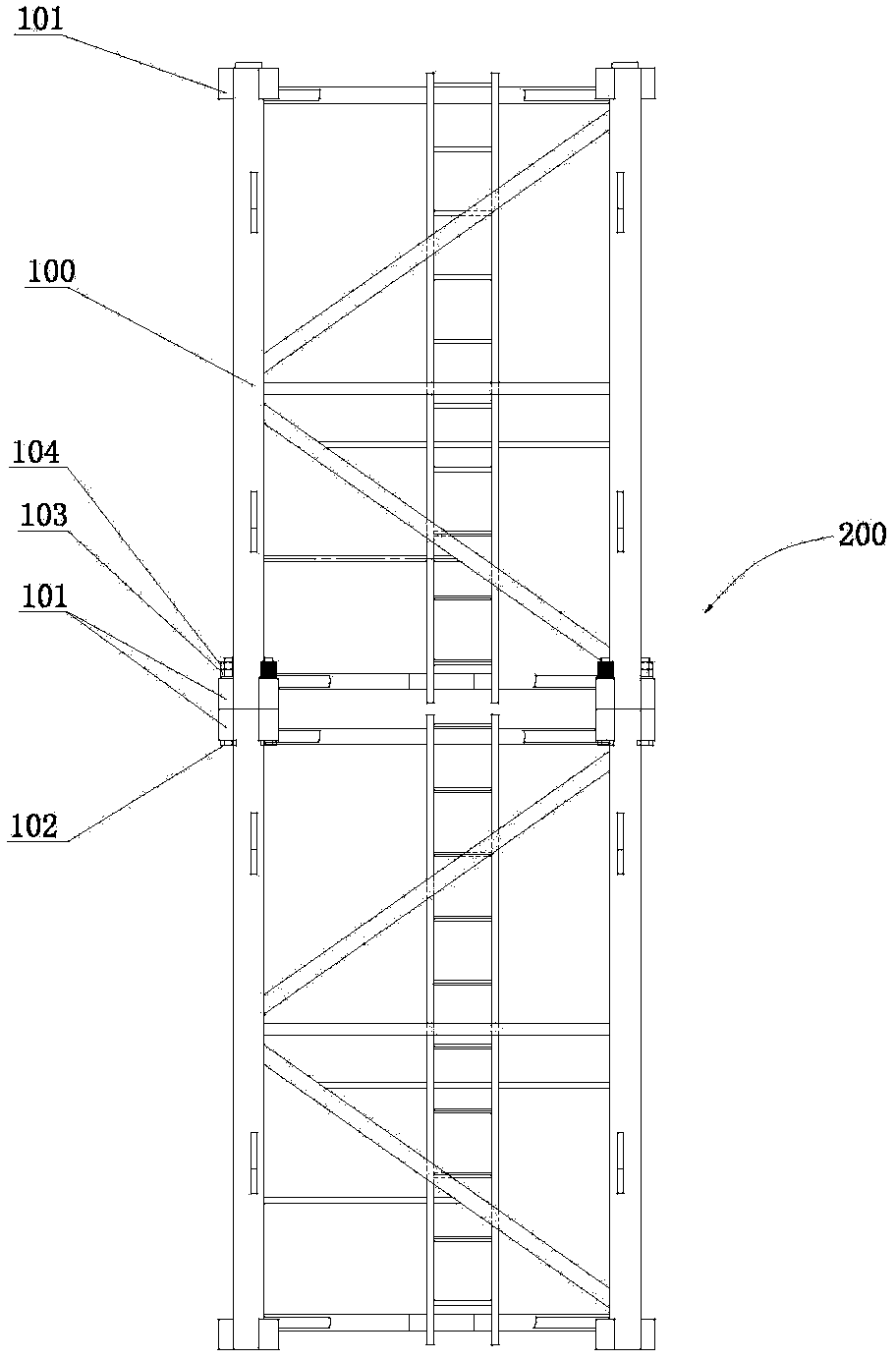

[0048] Such as figure 1 As shown, the tower body 200 is connected by standard sections 100, and the connection between the standard sections is realized by high-strength bolts 102 passing through the connecting ears 101 at both ends of the main chord, and locked with lower nuts 103 and upper nuts 104 .

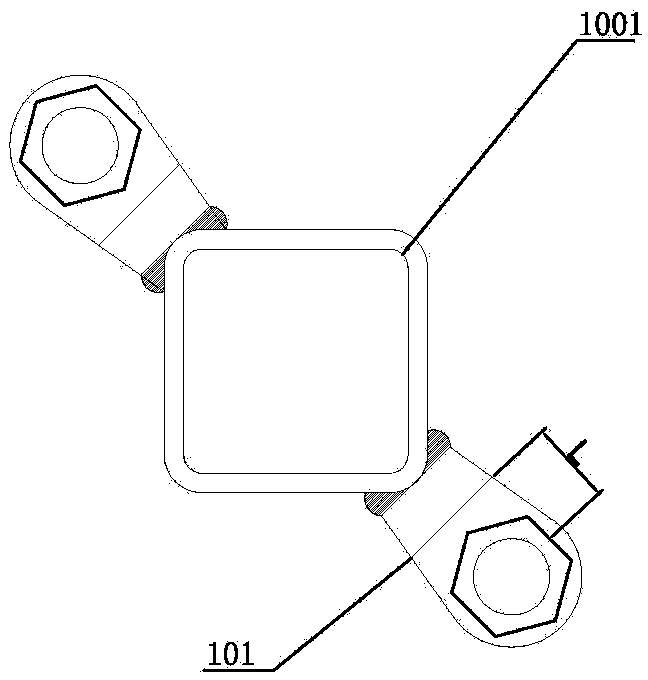

[0049] Such as Figure 2 to Figure 5 As shown, it is a connection structure diagram between several connection lugs 101 and the main chord 1001 of the standard section. Among them, such as Figure 2 to Figure 4 As shown, the connecting ear 101 is connected at the corner of the main chord 1001 of the standard section, and the distance from the center of the connecting ear 101 to the side of the main chord 1001 is L, as Figure 5 As shown, the connecting lug 101 is connected to the side of the main chord 1001 of the standard section,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com