Pipeline welding robot integrating functions of TIG welding and MIG welding

A technology for welding robots and pipes, which is applied in the direction of welding equipment, welding accessories, welding rod characteristics, etc., can solve the problems of reducing welding accuracy, large height and volume of crawling units, and affecting welding quality, and achieve height and volume reduction, which is conducive to welding Accuracy, overall small form factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

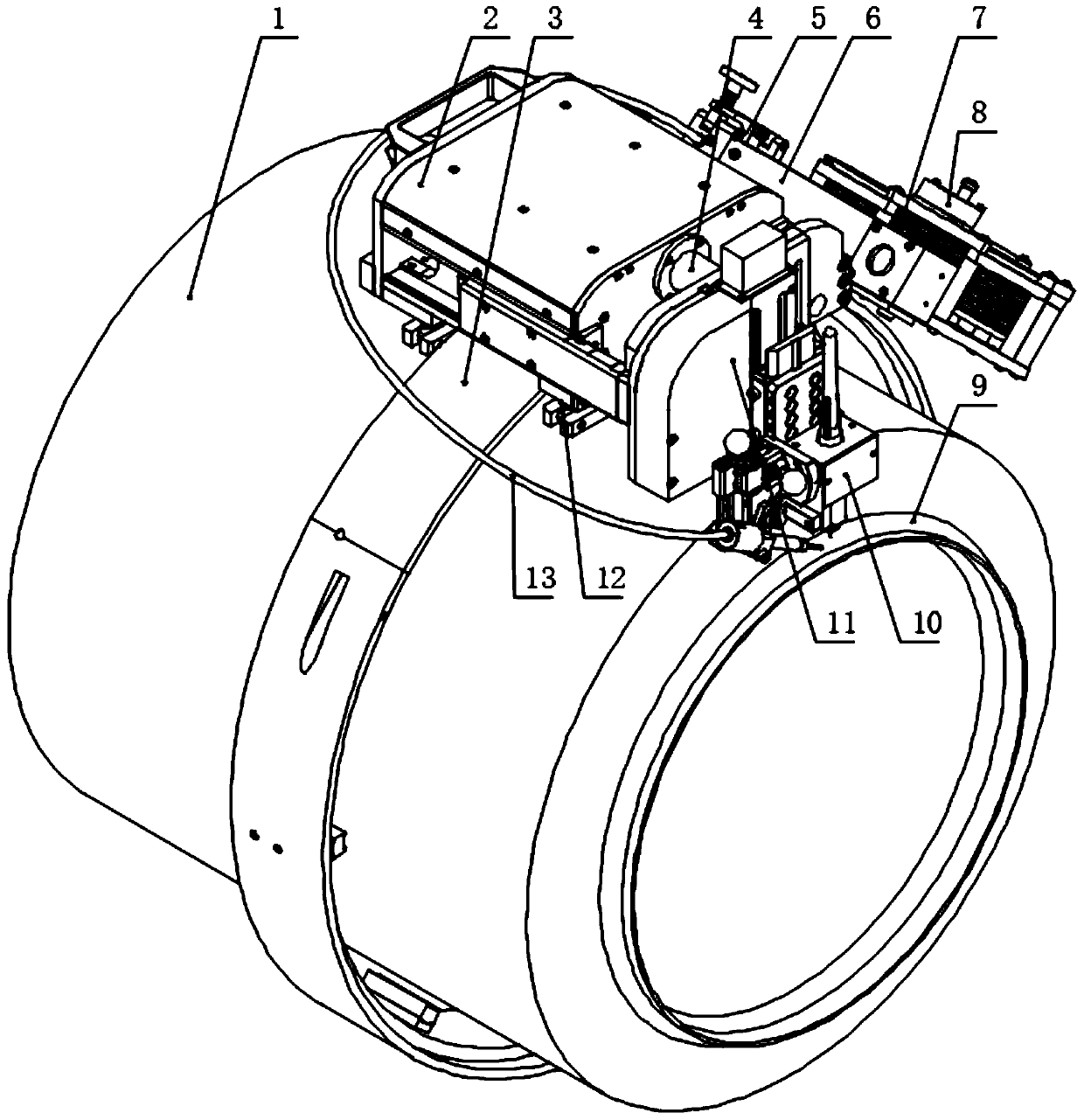

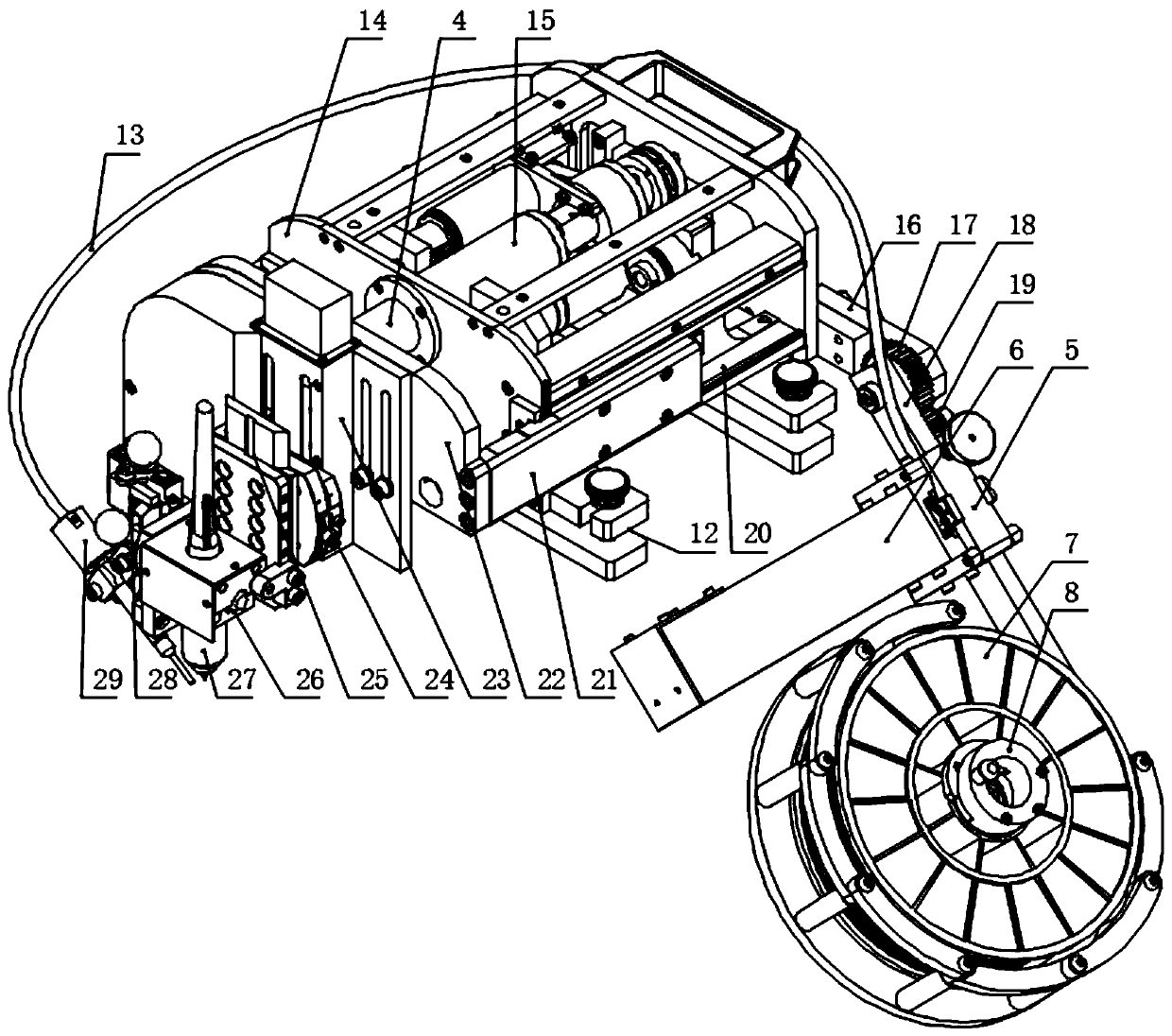

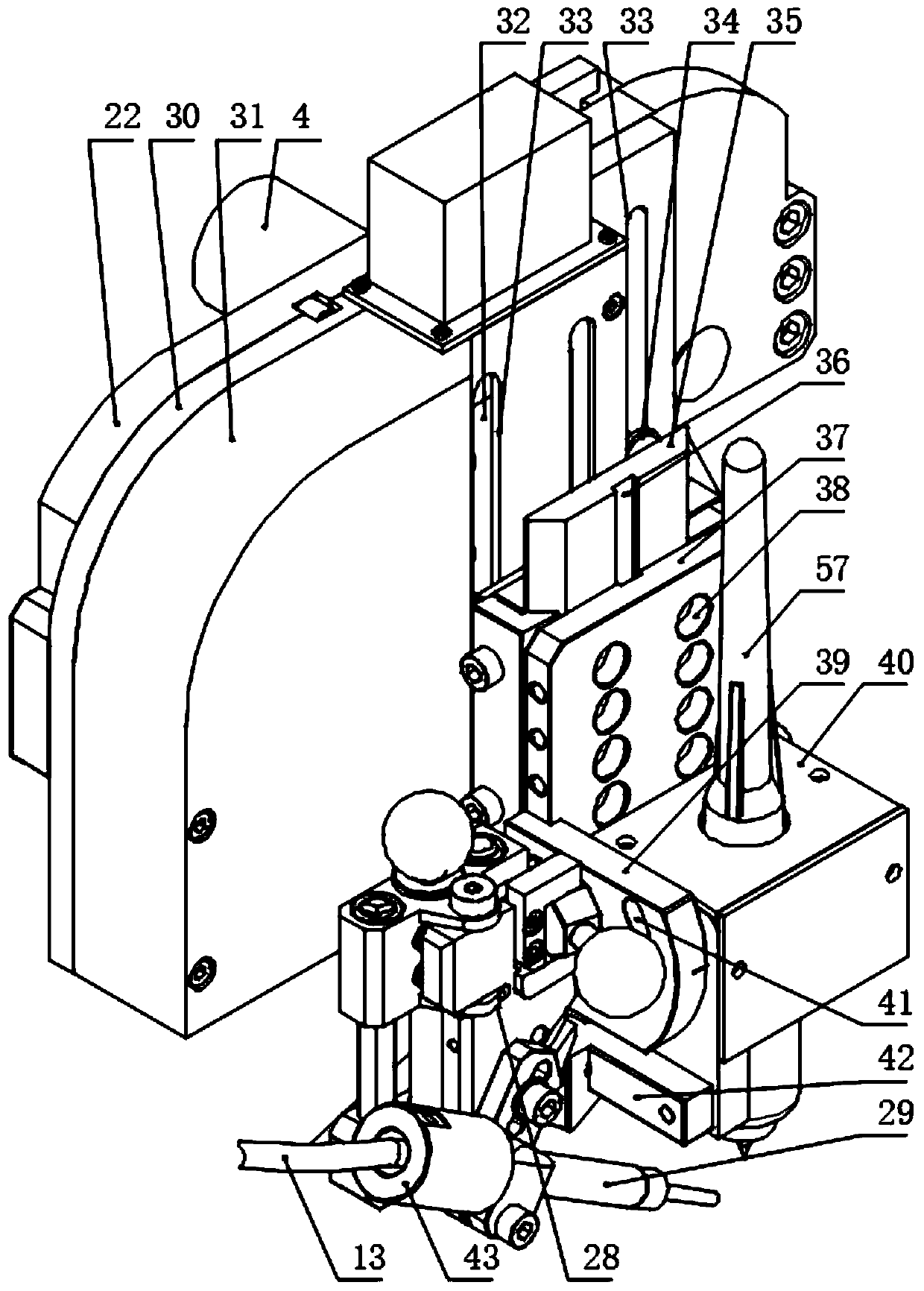

[0051] A pipeline welding robot integrating TIG welding and MIG welding functions, such as Figure 1-7 As shown, it includes a crawling unit 2, a wire reel unit, a position adjustment unit 11 and a welding unit 10. The wire reel unit is arranged on the crawler unit and is used to transport welding wire 46. The crawler unit drives the welding unit along the axial direction of the pipeline 1 through the position adjustment unit. The direction reciprocates at the welding seam 9. The innovation of the present invention is that the welding unit includes a base, a nozzle 27 and a welding wire. Weld and spray inert gas.

[0052] When the base is in the Figure 1~6 Tungsten pole 57 is set as shown and welding wire ( Figure 4 When the end of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com