Hanger articulated bridge inspection vehicle

A bridge maintenance vehicle, articulated technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of large volume and weight, complex structure, etc., achieve large anti-overturning ability, light structure, and improve the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

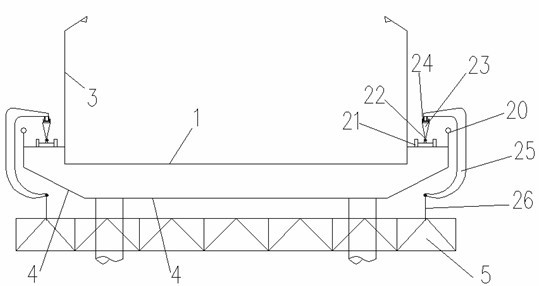

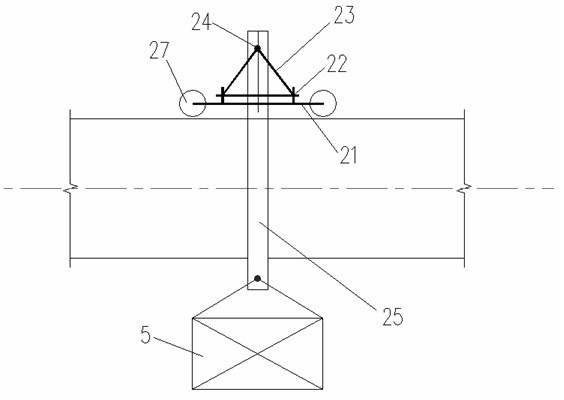

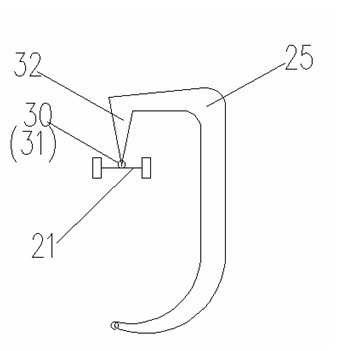

[0026] see figure 1 , figure 2 , the first structure of a hanger articulated bridge maintenance vehicle in the present invention includes a frame vehicle and a boom that can extend to the outside of the bridge, the frame vehicle includes a frame chassis 21 and a pillar 23, and the boom arm It is a C-shaped hanger 25, the frame chassis 21 is hinged to the lower end of the pillar 23 through the longitudinal axis hinge 22 and the longitudinal axis, and the upper end of the pillar 23 is connected to the C-shaped hanger through the transverse axis hinge 24 and the transverse axis. 25 The extended ends of the upper crossbeam are hinged, and the extended end of the lower crossbeam of the C-shaped hanger 25 is at least provided with a fixed point of a suspension rope 26 or a suspension rope retractable device.

[0027] When the maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com