Rubber tapping machine and rubber tapping method

A rubber tapping machine and rubber tapping technology, applied in forestry, application, agriculture, etc., can solve problems such as instability, influence of glue, vibration and deformation of guide rails, etc., and achieve the effects of improving stability, ensuring continuity, and reducing the force arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

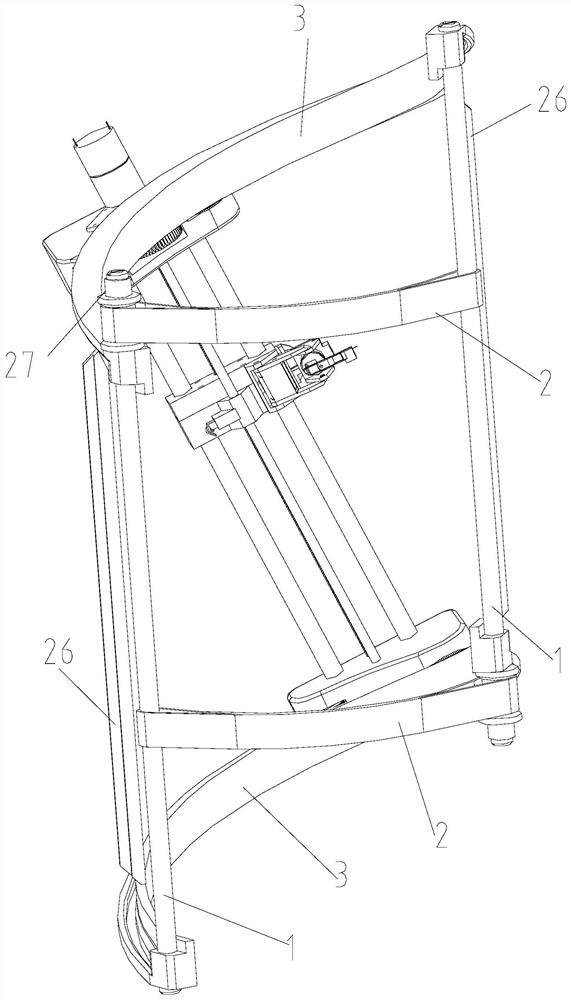

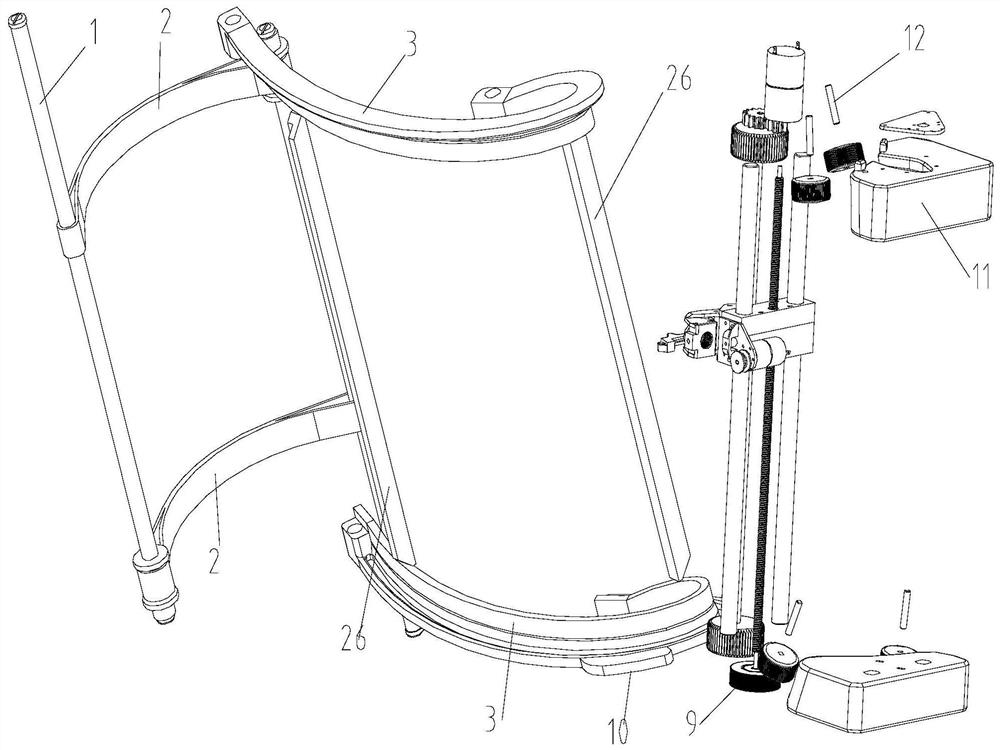

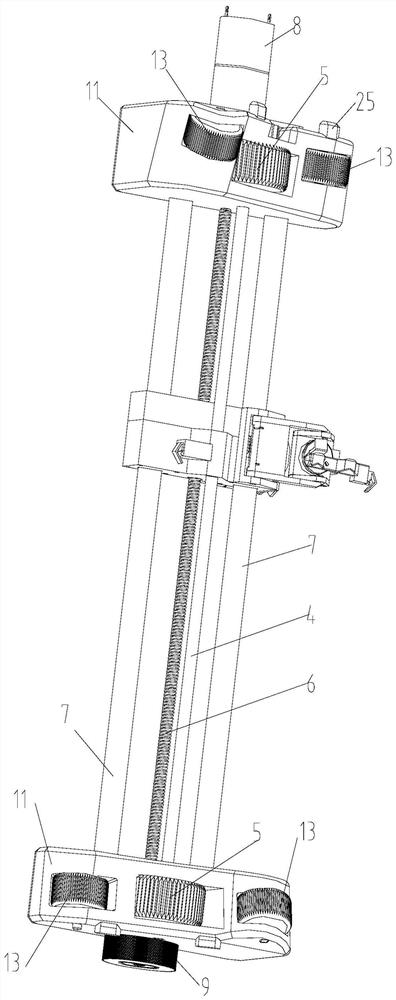

[0052] Example 1, such as Figure 1-5 As shown, this embodiment discloses a rubber tapping machine, the rubber tapping machine includes two supporting steel pipes 1, one side of the two supporting steel pipes 1 is connected by a strap 2, and the other side is connected by two upper and lower spiral guide rails. 3 are connected, and the spiral guide rail is opposite to the strap position on the opposite side, the spiral guide rail 3 can be made of rubber and the cross section is nearly L-shaped; the rubber tapping machine in this embodiment also includes a knife rest assembly with a motor 8 , the upper and lower ends of the power steel shaft 4 of the tool rest assembly are respectively equipped with a power wheel 5 that can roll along the spiral guide rail. The fixed rod 7, the above-mentioned power wheel 5 is driven to rotate by the motor 8 installed on the tool holder assembly, the lower end of the screw 6 is installed with the lowering roller 9 through a one-way bearing, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com