Non-standard wear-resistant stop block feeding and stopping device

A kind of stopper, non-standard technology, applied in the direction of ships, etc., can solve the problem of easy wear and tear of the contact surface between the stopper and the anchor chain, and achieve the effect of shortening the production cycle, reducing the weight and reducing the weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

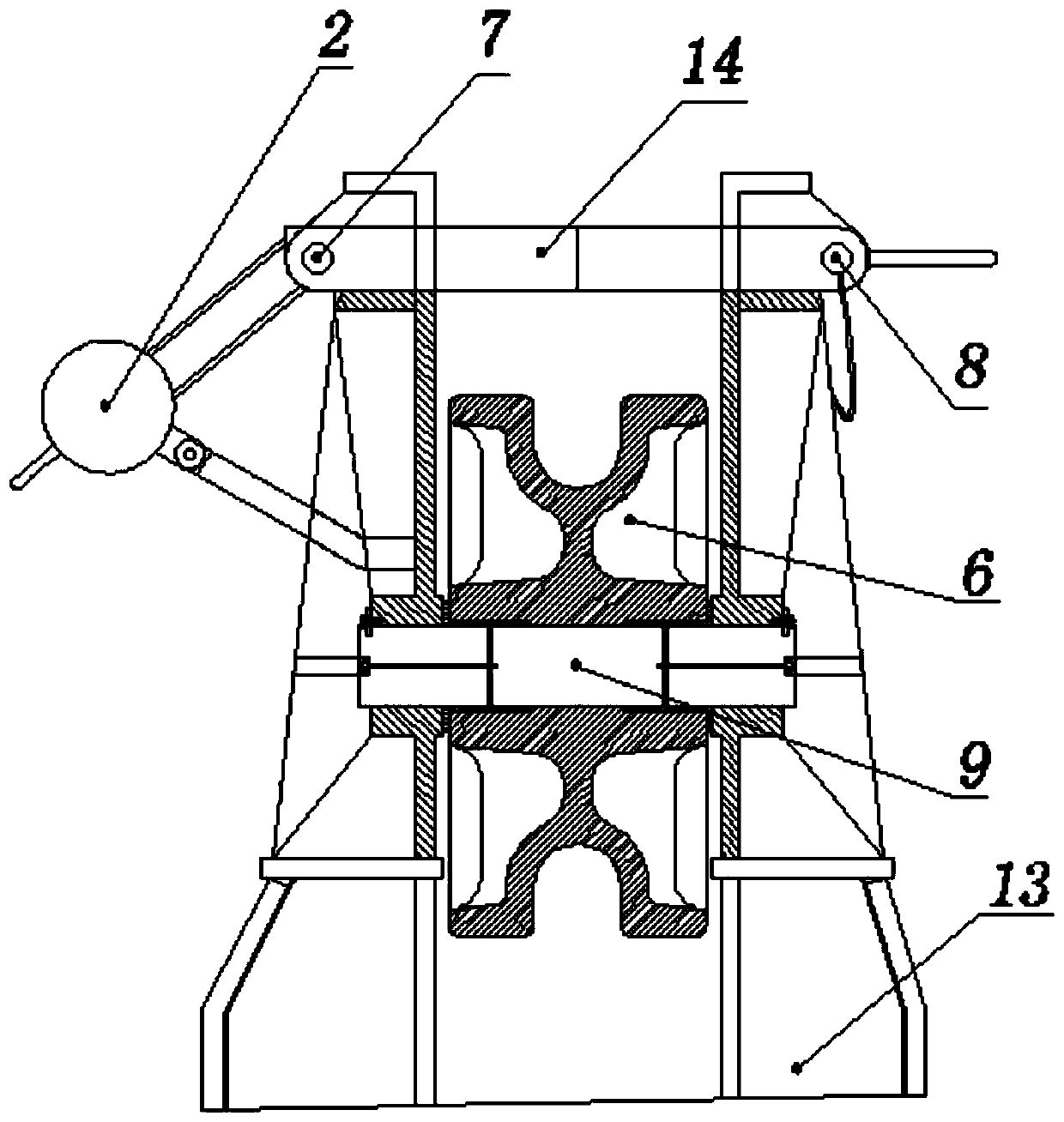

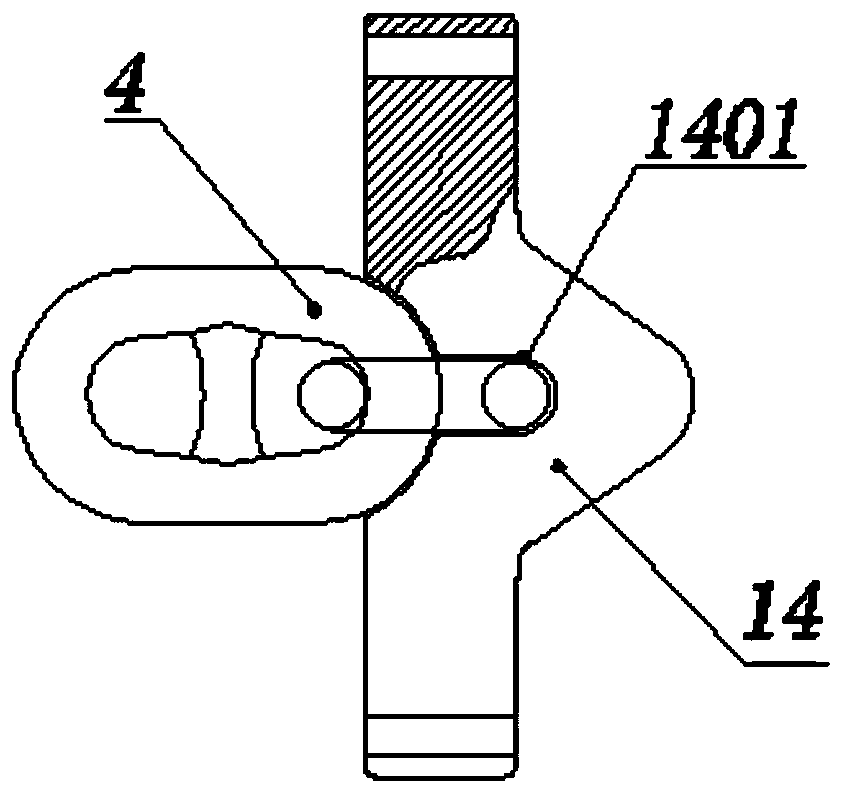

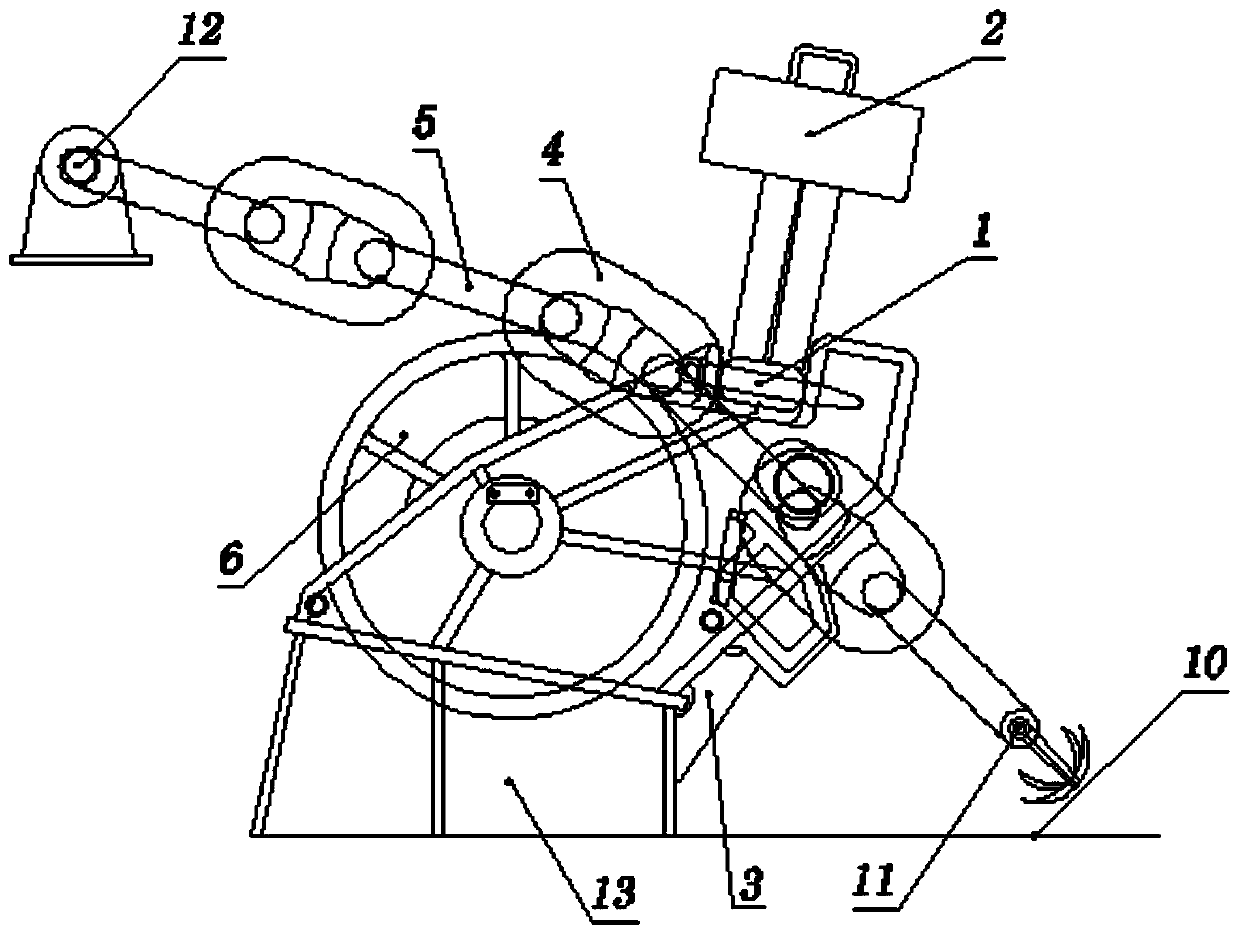

[0026] Such as Figure 1-4 As shown in the figure, a non-standard wear-resistant stop block is provided for a chain catch device, including a chain catcher 13, and a roller shaft 9 is connected to the top of the chain catcher 13 through a support, and a roller 6 is mounted on the roller shaft 9. , one side of the roller shaft 9 is connected with a balance weight 2 through a support, and the balance weight 2 is connected with the new stop block 14 through a rotating pin shaft 7, and the other end of the new stop block 14 is equipped with a positioning pin Axis 8.

[0027] The material of the new stop block 14 is wear-resistant high-alloy structural steel, and the casting is changed to steel plate flame cutting, which can effectively slow down the wear of the stop block; at the contact position of the anchor chain and the new stop block 14, drill a small hole and then The polymer wear-resistant material is injected, and the polymer wear-resistant material has the advantage of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com