Combined trench cable support

A cable support and combined technology, which is applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of easy breakage and damage, weak structural strength, and inconvenient installation at the connection between the pallet and the column, and achieve Improve anti-theft performance, long service life, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

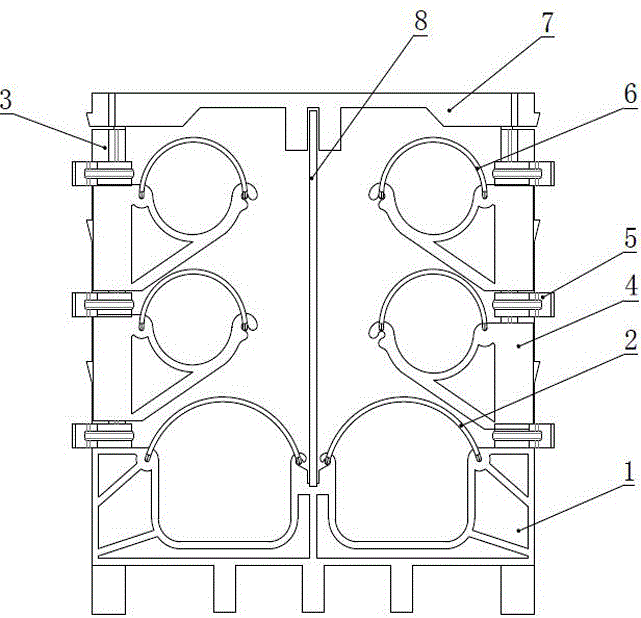

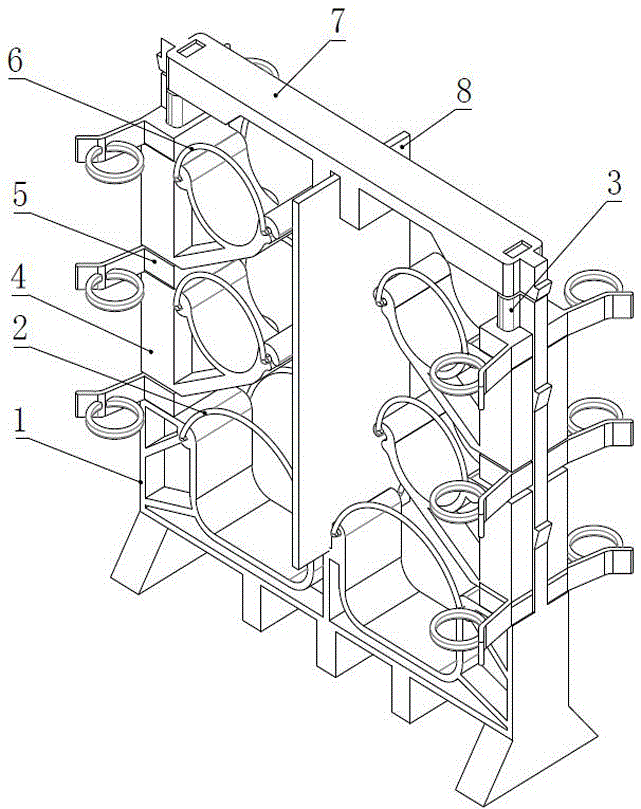

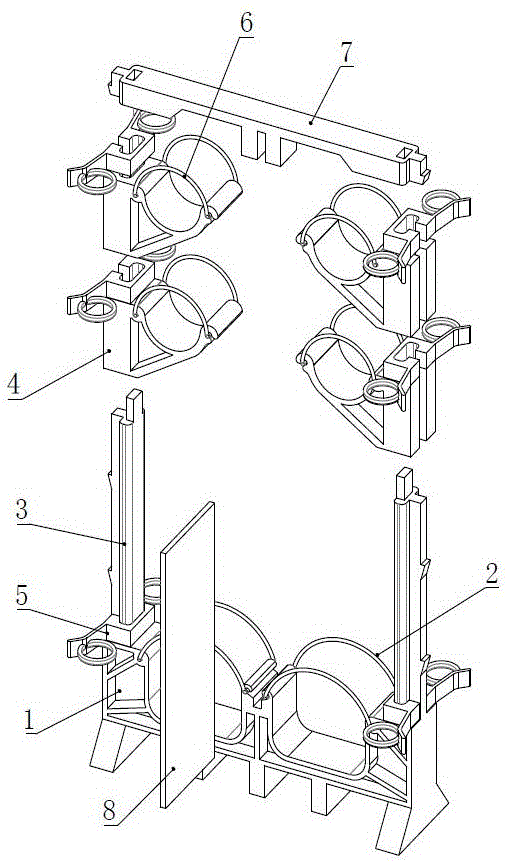

[0030] Such as figure 1 , 2 , 3, the combined trench cable bracket of the present invention includes a bracket main body 1, an arc-shaped circlip A2, a hook guide rail 3, a cable hook module 4, an anti-fall block 5, an arc-shaped circlip B6, a top block 7, Fire barrier 8.

[0031] Such as Figure 4 , 5 As shown, the main body of the bracket 1 is in the shape of "Ш" formed by integrally forming three vertical vertical plates 12 on the base 11, and its material can be selected from metal alloy, plastic, glass, fiberglass, etc. according to the needs of the construction site, and the adjacent vertical plates 12 cooperates with the base 11 respectively to form a bottom cable groove 13 that can accommodate cables, and there is a snap ring mounting hole 14 at the top of a vertical plate among the adjacent vertical plates 12, and a spring mounting hole 14 is provided at the top of the other vertical plate among the adjacent vertical plates. Buckle A15 with card slot. The circlip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com